Top 10 Global Companies in Aluminum 3D Printing Materials Market 2025: Strategic Overview and Future Trends (2024–2035)

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

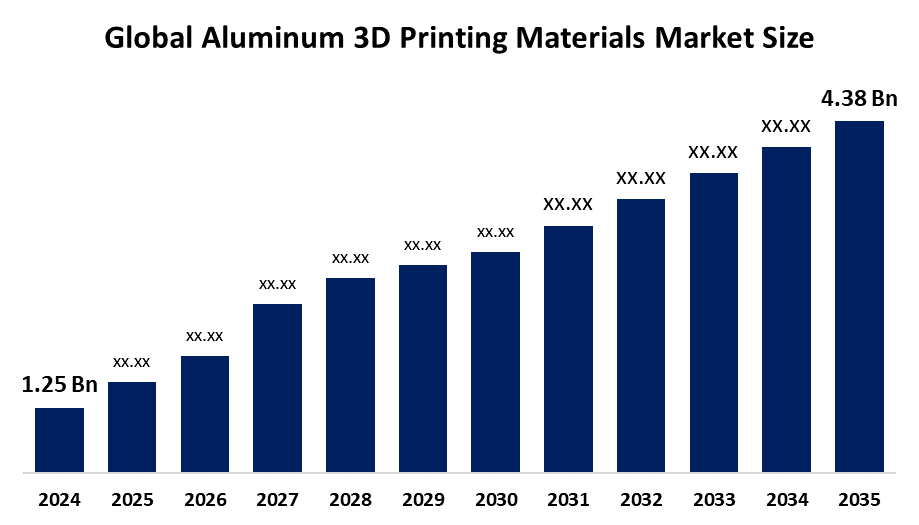

According to a research report published by Spherical Insights & Consulting, The Global Aluminum 3D Printing Materials Market Size is projected to Grow from USD 1.25 Billion in 2024 to USD 4.38 Billion by 2035, at a CAGR of 12.07% during the forecast period 2025–2035. The growing need for strong, lightweight parts in the automotive and aerospace sectors is one of the main drivers of the market for aluminum 3D printing materials.

Introduction

The Global Aluminum 3D Printing Materials Market Size is related to the development and supply of aluminum-based powders and filaments for additive manufacturing. These materials provide a good balance of strength-to-weight, thermal conductivity and corrosion resistance for aerospace, automotive and industrial applications. Additionally, the ongoing developments in 3D printing and material science present an opportunity. New applications in a variety of industries are made possible by the creation of aluminum alloys and composites with improved qualities, such as greater strength, flexibility, and heat resistance. Additionally, the ongoing developments in 3D printing and material science present an opportunity. New applications in a variety of industries are made possible by the creation of aluminum alloys and composites with improved qualities, such as greater strength, flexibility, and heat resistance. Additionally, the creation of intricate and personalized parts with enhanced performance is made possible by advancements in 3D printing techniques like hybrid manufacturing and multi-material printing. Manufacturers of aluminum 3D printing materials are well-positioned to satisfy changing industry demands and propel market expansion due to their capacity to provide high-performance and application-specific materials.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Aluminum 3D Printing Materials Market.

Aluminum 3D Printing Materials Market Size & Statistics

- The Market Size for Aluminum 3D Printing Materials Was Estimated to be Worth USD 1.25 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 12.07% Between 2025 and 2035.

- The Global Aluminum 3D Printing Materials Market Size is Anticipated to Reach USD 4.38 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Aluminum 3D Printing Materials Market.

- North America is expected to grow the fastest during the forecast period in the Aluminum 3D Printing Materials Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the aluminum 3D printing materials market. This is due to the early adoption of advanced manufacturing technologies and the presence of significant auto and aerospace manufacturers. With significant investments in R&D and a strong emphasis on innovation and sustainability, the U.S. is a major contributor to the market. The use of aluminum 3D printing materials in North America is also being driven by the expanding need for high-performance, lightweight parts in the automotive and aerospace industries.

Asia Pacific is expected to generate the highest demand during the forecast period in the aluminum 3D printing materials market. This is due to accelerated industrialization, growing 3D printing technology adoption, and encouraging government programs. To improve their production capacities, nations like China, Japan, and South Korea are making large investments in R&D and 3D printing infrastructure. The region's adoption of aluminum 3D printing materials is driven by the growing need for high-performance, lightweight components in the electronics, automotive, and aerospace industries.

Top 10 Aluminum 3D Printing Materials Trends

1.Strong Aluminum Alloys

2.Sustainability and Recyclability of Powder

3.Compatibility of Binder Jetting

4.Optimization of Heat Treatment

5.Initiatives for Automobile Lightweighting

6.Integration of Multi-Material Printing

7.Improvement of Surface Finish

8.Applications of Medical Devices

9.Design Driven by Simulations

10.Localization and Regional Growth

1.Strong Aluminum Alloys

Mechanical performance in additive manufacturing is being improved by the creation of sophisticated aluminum alloys such as AlSi10Mg and Scalmalloy. These materials have better strength-to-weight ratios, which makes them perfect for defense, automotive, and aerospace parts that need to be lightweight and durable.

2.Sustainability and Recyclability of Powder

To cut waste and production costs, manufacturers are concentrating on making aluminum powders more recyclable. Closed-loop recycling procedures and improved powder handling systems promote sustainable production and are in line with ESG objectives.

3.Compatibility of Binder Jetting

Aluminum's scalability and affordability make it a popular choice for binder jetting technology. Advanced sintering and powder chemistry methods are making it possible to create high-density components with intricate geometries for use in industrial settings.

4.Optimization of Heat Treatment

To enhance the mechanical characteristics and microstructure of 3D-printed aluminum components, post-processing methods such as heat treatment are being improved. Critical components' fatigue resistance is being improved and residual stress is being decreased with the use of controlled thermal cycles.

5.Initiatives for Automobile Lightweighting

Aluminum 3D printing is being used more and more by automakers to create lightweight structural and thermal control components. This trend facilitates rapid prototyping and design flexibility while supporting fuel efficiency and electric vehicle range goals

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the aluminum 3D printing materials market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Aluminum 3D Printing Materials Market

1.3D Systems Corporation

2.EOS GmbH Electro Optical Systems

3.Renishaw plc

4.Materialise NV

5.SLM Solutions Group AG

6.GE Additive

7.Hoganas AB

8.Sandvik AB

9.Carpenter Technology Corporation

10.GKN Additive

11.Heraeus Holding GmbH

12.Arcam AB (a GE Additive company)

13.ExOne Company

14.Voxeljet AG

15.Additive Industries

16.Sciaky Inc.

17.Others

1.3D Systems Corporation

Headquarters - Rock Hill, South Carolina, the US.

The specialty of 3D Systems Corp (3D Systems) is offering complete 3D printing solutions. Design, development, production, and marketing of 3D printers, software, materials, metals and plastics, and digital design tools are among its main operations. A wide range of 3D printers, 3D scanners, related materials, digitizers, software licenses, and haptic devices are among the company's offerings. It caters to the automotive, aerospace, government, defense, consumer goods, education, technology, electronics, healthcare, and energy industries. 3D Systems uses distributors, channel partners, and direct sales agents to market its goods.

2.EOS GmbH Electro Optical Systems

Headquarters - Krailling, Bavaria, Germany.

A leader in industrial 3D printing, EOS GmbH Electro Optical Systems focuses on metal and polymer additive manufacturing solutions. The company is well known for its proficiency with laser sintering technologies and dedication to the advancement of digital manufacturing. Lightweight, high-performing components are made possible by EOS's extensive portfolio of aluminum-based materials, which are tailored for use in automotive, aerospace, and medical applications.

3.Renishaw plc

Headquarters - Wotton Under Edge, Gloucestershire, United Kingdom

Renishaw plc (Renishaw) is an engineering technology company that focuses on developing high-precision medical and metrological equipment. The business creates and develops solutions and systems. Healthcare solutions, machine calibration and optimization tools, and precision measurement and process control products are all part of its product line. Assistance and support, upgrades, online supply, customer support, and training are all included in Renishaw's services. Numerous industries, including transportation, agriculture, electronics, aerospace, energy, and healthcare, use the company's products.

4.Materialise NV

Headquarters - Leuven, Brabant Flamand, Belgium.

The medical technology business Materialise NV (Materialise) focuses on 3D printing services, medical software tools, and additive manufacturing. Among its products are patient-specific implants and surgical guides, customized anatomical models, related bone models, and proprietary software for 3D printers and 3D printing operations. Its products are used in consumer goods, healthcare, automotive, aerospace, and art and design. To improve its distribution network, the company partners with CAD, CAM, and PLM firms as well as manufacturers of 3D printing machines. Orthopedic, cranio-maxillofacial, eyewear, footwear, and measurement fixtures are the main areas of application for additive manufacturing.

5.SLM Solutions Group AG

Headquarters - Lübeck, Schleswig-Holstein, Germany.

SLM Solutions Group AG is a prominent supplier of metal additive manufacturing technology, with a focus on industrial selective laser melting systems. The business offers high-performance solutions designed for the energy, medical, automotive, and aerospace industries, facilitating the manufacturing of intricate, robust, and lightweight parts. Multi-laser systems, open architecture platforms, and advanced process control-all of which facilitate scalability and customization—are among SLM Solutions' well-known innovations.

Are you ready to discover more about the aluminum 3D printing materials market?

The report provides an in-depth analysis of the leading companies operating in the global aluminum 3D printing materials market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

1.3D Systems Corporation

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

2.EOS GmbH Electro Optical Systems

3.Renishaw plc

4.Materialise NV

5.SLM Solutions Group AG

6.GE Additive

7.Hoganas AB

8.Sandvik AB

9.Carpenter Technology Corporation

10.GKN Additive

11.Heraeus Holding GmbH

12.Arcam AB (a GE Additive company)

13.ExOne Company

14.Voxeljet AG

15.Additive Industries

16.Sciaky Inc.

17.Others

Conclusion

The Worldwide Market Size for Aluminum 3D Printing Materials is expected to grow strongly, driven by the increasing need for lightweight, strong components in aerospace, automotive, industrial sectors and more. Innovation in alloy development, binder jetting, and post-processing are broadening the application space and improved performance. Regionally, Asia Pacific commands the largest demand, while North America leads the innovation. The emphasis on sustainability, recyclability, and the ability to design through simulations are also reshaping the production methods. In response to the evolving needs of industry, leading firms are using research and development (R&D) and strategic partnerships to stay in a strong position.

Browse Related Reports

Global Truffle Market Size To Exceed USD 1339.7 Million by 2035 | CAGR of 7.15% : Market Insight Report

Global Date Syrup Market Size To Exceed USD 760.8 Million by 2035 | CAGR of 6.04% : Market Study Report

Global Contrast Agents Market Size Exceed to USD 15.69 Billion by 2035| CAGR of 8.57%: Market Study Report

Global Cloud FinOps Market Size Exceed to USD 41.66 Billion by 2035| CAGR of 10.88% : Industry Analysis Report

Global Airborne Radars Market Size Exceed to USD 31.23 Billion by 2035| CAGR of 9.46% : Industry Report

France cricket Protein powders Market Size Insights Forecasts to 2035

France croissant Market Size Insights Forecasts to 2035

France Crop Micronutrient Market Size Insights Forecasts to 2035

France Crop breeding Technology Market Size Insights Forecasts to 2035

France Crop Oil Concentrates Market Size Insights Forecasts to 2035

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?