Japan 3D Printing Materials Market Size, Share, and COVID-19 Impact Analysis, By Type (Plastics, Polymers, Metals, Ceramic, and Others), By End User (Consumer Products, Aerospace and Defense, Automotive, Healthcare, Education and Research, and Others), and Japan 3D Printing Materials Market Insights, Industry Trend, Forecasts to 2035

Industry: Chemicals & MaterialsJapan 3D Printing Materials Market Insights Forecasts to 2035

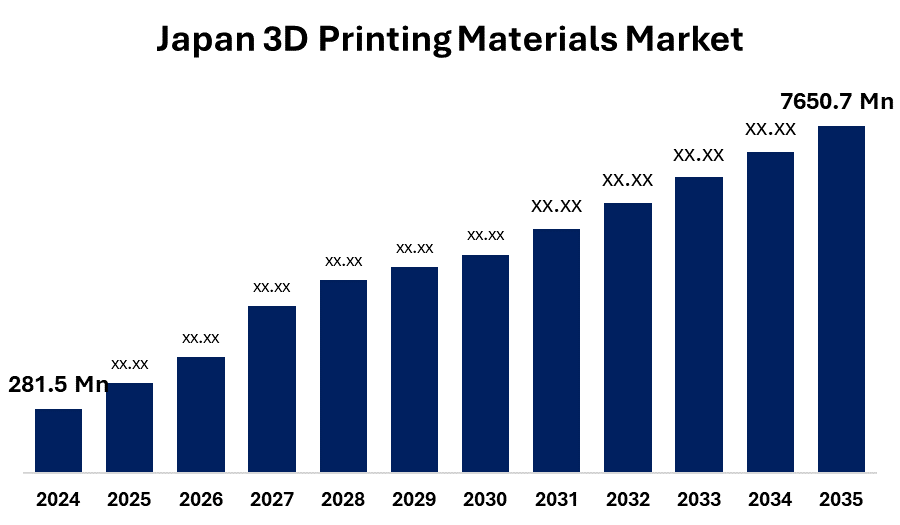

- The Japan 3D Printing Materials Market Size Was Estimated at USD 281.5 Million in 2024

- The Japan 3D Printing Materials Market Size is Expected to Grow at a CAGR of Around 31.68% from 2025 to 2035

- The Japan 3D Printing Materials Market Size is Expected to Reach USD 7650.7 Million by 2035

Get more details on this report -

According to a research report published by Spherical Insights & Consulting, The Japan 3D Printing Materials Market Size is anticipated to reach USD 7650.7 Million by 2035, Growing at a CAGR of 31.68% from 2025 to 2035. The 3D printing materials market in Japan is driven by the main factors, including the growing need for 3D printing materials in the industrial sector, the development of materials that are sterile and safe for medical usage, and encouraging government regulations.

Market Overview

3D printing material refers to a variety of materials made for especially adaptable manufacturing techniques, which use digital models to create products layer by layer. Depending on the use, these materials are designed to provide accuracy, flexibility, durability, and mechanical strength. The materials used in 3D printing in the US include metal, polymer, ceramic, composite, and biometals. These materials serve various types of industries, including consumer goods, healthcare, motor vehicles, aerospace, and construction. Polymers, such as PLA, ABS, and Nylon, are most commonly used due to their thermoplastic properties, processing, cost-effectiveness, and simplicity of adaptability. High-performing polymers, because they can provide mild, highly durable components, metal-related materials, such as titanium, stainless steel, aluminum, and nickel alloys, are increasingly used in aerospace, defense, and medical industries. Because they are resistant to heat and wear, ceramics and composites are used in state-of-the-art applications such as electronics, dental transplants, and structural elements. Meanwhile, durable and bio-based materials are becoming more popular according to environmental laws and the increasing requirement for environmentally friendly production. The basic manufacturing ecosystem is made up of 3D printing materials, which help companies achieve flexibility, reduce production waste, and speed up development cycles, while also assisting digital changes in manufacturing.

Report Coverage

This research report categorizes the market for the Japan 3D printing materials market based on various segments and regions, and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Japan 3D printing materials market. Recent market developments and competitive strategies, such as expansion, product launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Japan 3D printing materials market.

Japan 3D Printing Materials Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Forecast Period: | 2025-2035 |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 210 |

| Tables, Charts & Figures: | 126 |

| Segments covered: | By Type, By End User |

| Companies covered:: | FASOTEC, Altera Japan, DMM.make 3DPRINT, Roland DG, BENA Co .Ltd, Polyuse, Others |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis. |

Get more details on this report -

Driving Factors

Expanding additive manufacturing in industries including healthcare, automotive, and aerospace, where special and mild solutions are important. Application areas are increasing as a result of growth in metals, polymers, and biocompatible materials. Strong R&D and government activities support permanent materials, cost-effective production, and increasing demand for rapid prototypes, which further enhances market expansion.

Restraining Factors

The 3D Printing Materials market is mostly constrained by the high cost, lack of standardization, and difficulties with mass production. Widely adopting advanced 3D printing materials in Japan is also slowed down by technical obstacles such as uneven mechanical properties, experienced labor deficiency, and regulatory obstacles in the fields of medical and aerospace.

Market Segmentation

The Japan 3D printing materials market share is classified into type and end user.

- The plastic segment dominated the market in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Japan 3D printing materials market is segmented by type into plastics, polymers, metals, ceramics, and others. Among these, the plastic segment dominated the market in 2024 and is expected to grow at a significant CAGR during the forecast period. The growing requirement of automotive, aerospace, and military areas for high-performing materials will promote market expansion for the plastic segment. The need for plastic will also be increased by the production of complex designs without simple prototyping, low costs, low weight, and loss of materials.

- The automotive segment is anticipated to grow at a substantial CAGR during the forecast period.

The Japan 3D printing materials market is segmented by end user into consumer products, aerospace and defense, automotive, healthcare, education and research, and others. Among these, the automotive segment is anticipated to grow at a substantial CAGR during the forecast period. The automobile industry has seen an increase in demand for 3D printed metals and polymers due to their dimensional accuracy and mild nature. The market expansion is expected to be driven by increasing demand for these materials from the automotive sector and automotive applications.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Japan 3D printing materials market, along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- FASOTEC

- Altera Japan

- DMM.make 3DPRINT

- Roland DG

- BENA Co .Ltd

- Polyuse

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at the Japan, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the Japan 3D printing materials market based on the below-mentioned segments:

Japan 3D Printing Materials Market, By Type

- Plastics

- Polymers

- Metals

- Ceramic

- Others

Japan 3D Printing Materials Market, By End User

- Consumer Products

- Aerospace And Defense

- Automotive

- Healthcare

- Education and Research

- Others

Frequently Asked Questions (FAQ)

-

Q: What is the market size of the Japan 3D Printing Materials Market in 2024?A: The Japan 3D Printing Materials Market was valued at USD 281.5 million in 2024.

-

Q: What is the forecasted market size by 2035?A: The market is expected to reach USD 7,650.7 million by 2035.

-

Q: What is the growth rate (CAGR) of the market?A: The market is projected to grow at a CAGR of 31.68% from 2025 to 2035.

-

Q: What are the key types of 3D printing materials analyzed in this report?A: The market is segmented into Plastics, Polymers, Metals, Ceramics, and Others.

-

Q: Which material type dominated the market in 2024?A: The plastic segment dominated the market in 2024 due to its versatility, cost-effectiveness, and adaptability.

-

Q: What are the major end-user industries for 3D printing materials in Japan?A: Key industries include Consumer Products, Aerospace & Defense, Automotive, Healthcare, Education & Research, and Others.

-

Q: Which end-user industry is expected to grow the fastest?A: The automotive industry is anticipated to grow at a substantial CAGR, driven by demand for 3D printed polymers and metals.

-

Q: Who are the key players in the Japan market?A: Notable companies include FASOTEC, Altera Japan, DMM.make 3DPRINT, Roland DG, BENA Co. Ltd, Polyuse, and others.

Need help to buy this report?