Discover Top 40 Companies in Permanent Magnet Concentrator Market: Global Share, Market Size, Revenue Report (2024–2035)

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

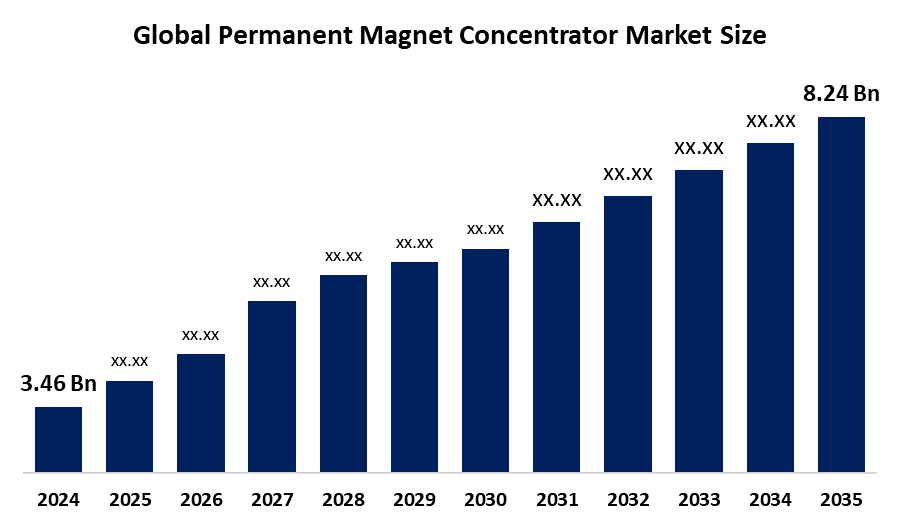

According to a research report published by Spherical Insights & Consulting, The Global Permanent Magnet Concentrator Market Size is projected To Grow from USD 3.46 Billion in 2024 to USD 8.24 Billion by 2035, at a CAGR of 8.21% during the forecast period 2025–2035. This expansion is fueled by rising demand in diverse industrial applications and technological innovations that improve the effectiveness and functionalities of magnetic systems. A key driver of expansion in the permanent magnet concentrator market is the swift industrialisation and urban development taking place worldwide.

Introduction

The Global Permanent Magnet Concentrator Market Size pertains to the industrial field that centres on equipment utilising permanent magnets to concentrate or segregate magnetic materials from non-magnetic ones. Permanent magnetic concentrators play a crucial role in mining, recycling, and material processing industries by effectively extracting valuable magnetic minerals such as iron ore and eliminating tramp metals from product streams. These concentrators contrast with electromagnetic separators because they utilise permanent magnets, offering energy-efficient, low-maintenance, and long-lasting solutions for magnetic separation tasks. The market for permanent magnet concentrators is projected to grow significantly because of rising demand in industries like mining, renewable energy, and electronics, fueled by the growing utilisation of rare earth permanent magnets in electric vehicles, wind turbines, and high-tech industrial uses. A key factor contributing to market growth is the rising demand for clean and sustainable energy alternatives. Permanent magnet concentrators are essential in generating renewable energy, especially in wind turbines and electric vehicles (EVS). The increasing focus on lowering carbon emissions and the worldwide movement towards sustainable technologies are driving the need for innovative magnetic materials and systems, thus enhancing market growth.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Permanent Magnet Concentrator Market.

Permanent Magnet Concentrator Market Size & Statistics

- The Market Size for Permanent Magnet Concentrator Was Estimated to be worth USD 3.46 Billion in 2024.

- The Market size is Going to Expand at a CAGR of 8.21% between 2025 and 2035.

- The Global Permanent Magnet Concentrator Market Size is anticipated to reach USD 8.24 Billion by 2035.

- Asia Pacific is projected to generate the highest share during the forecast period in the permanent magnet concentrator market.

- North America is estimated to grow at the fastest CAGR during the forecast period in the permanent magnet concentrator market.

Regional growth and demand

North America is anticipated to grow at the fastest CAGR over the forecast period in the permanent magnet concentrator market. North America is set for significant expansion in the permanent magnet concentrator market due to the robust industrial foundation and widespread adoption of cutting-edge technologies in this region. The growing investments in renewable energy initiatives and the heightened focus on sustainable methods are boosting the need for advanced magnetic separation technologies in these regions. The existence of established market participants and ongoing innovations in magnetic materials and technologies is anticipated to further enhance market expansion.

Asia Pacific is expected to grow at the highest share during the forecast period in the permanent magnet concentrator market. The permanent magnet concentrator market is anticipated to be led by the Asia Pacific region throughout the forecast period, driven by the swift industrialisation and urban development in nations like China and India. The region's thriving industrial sector, especially in mining, recycling, and chemical processing, is driving the substantial need for magnetic separation technologies. The growing funding in renewable energy initiatives and the expanding use of electric vehicles (EVs) are predicted to significantly boost the demand for advanced magnetic materials in the region.

Top 10 Trends in the Permanent Magnet Concentrator Market

- Surge in Mining and Recycling Applications

- Rise of Neodymium and Samarium-Cobalt Magnets

- Shift Toward Drum and Roller Magnetic Separators

- Sustainability and Energy Efficiency Focus

- Expansion in Steel and Chemical Processing

- Integration with Smart Sorting Systems

- Modular and Compact Designs

- Diversification into Food and Pharma Sectors

- Growing Demand for Custom Configurations

- AI-driven automation and robotics

- Asia-Pacific Leads Market Growth

1. Surge in Mining and Recycling Applications

The increasing need for effective magnetic separation in mining, coal, and recycling industries is fueling the use of permanent magnet concentrators.

2. Rise of Neodymium and Samarium-Cobalt Magnets

NdFeB and SmCo magnets are becoming popular because of their strong magnetic properties and thermal stability, particularly in industrial settings and elevated temperature conditions.

3. Shift Toward Drum and Roller Magnetic Separators

Drum and roller setups prevail because of their ongoing functionality and elevated productivity, especially in bulk material management.

4. Sustainability and Energy Efficiency Focus

Permanent magnet systems are preferred over electromagnets due to their lower energy usage and decreased maintenance, which supports global sustainability objectives.

5. Expansion in Steel and Chemical Processing

Steel mills and chemical facilities are incorporating magnetic concentrators to enhance purity and minimise contamination in manufacturing processes.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the permanent magnet concentrator market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the Permanent Magnet Concentrator Market

- Hitachi Metals Ltd.

- Shin-Etsu Chemical Co., Ltd.

- TDK Corporation

- VACUUMSCHMELZE GmbH & Co. KG

- Arnold Magnetic Technologies

- Electron Energy Corporation

- Lynas Corporation Ltd.

- Adams Magnetic Products Co.

- Bunting Magnetics Co.

- Yantai Shougang Magnetic Materials Inc.

- Daido Steel Co., Ltd.

- Ningbo Yunsheng Co., Ltd.

- Jiangmen Magsource New Material Co., Ltd.

- Zhong Ke San Huan Hi-Tech Co., Ltd.

- Hangzhou Permanent Magnet Group

- Ningbo Ketian Magnet Co., Ltd.

- OM Group, Inc.

- Goudsmit Magnetics Group

- Magnetics, a division of Spang & Company

- Advanced Technology & Materials Co., Ltd.

1. Hitachi Metals Ltd.

Headquarters: Tokyo, Japan

Hitachi Metals Ltd. is a worldwide frontrunner in advanced magnetic materials, featuring neodymium-iron-boron (NDFEB) permanent magnets that serve as crucial elements in permanent magnet concentrators. The firm prioritises the creation of high-efficiency magnets that minimise the use of rare earth elements such as dysprosium, enhancing coercivity and magnetic strength to meet the needs of electric vehicles, industrial motors, renewable energy, and electronics. Hitachi Metals additionally offers magnet assemblies for the automotive, aerospace, medical, and energy industries, utilising advanced materials and manufacturing techniques to boost motor efficiency, minimise size, and enhance reliability. Their advancements greatly impact the permanent magnet concentrator market by providing superior magnets that facilitate effective magnetic separation and concentration in mining, recycling, and industrial processing.

2. Shin-Etsu Chemical Co., Ltd.

Headquarters: Chiyoda-ku, Tokyo, Japan

Shin-Etsu Chemical Co., Ltd. is a prominent producer of high-performance rare earth magnets, featuring neodymium magnets that are essential in the market for permanent magnet concentrators. The firm has created top-tier large permanent magnet-type magnetic circuits utilised in manufacturing processes like heat treatment for MRAM semiconductors, showcasing exceptional magnetic field stability, energy efficiency, and maintenance-free functioning. Shin-Etsu's proficiency in producing rare earth magnets aids various applications such as electric vehicles, renewable energy, electronics, and industrial automation. The advanced magnetic materials produced by the company help improve the efficiency and performance of permanent magnet concentrators utilised in mining, recycling, and industrial separation methods.

3. TDK Corporation

Headquarters: Chuo-ku, Tokyo, Japan

TDK Corporation is a global leader in magnetic materials and components, with a long history dating back to 1935 as the first company to commercialise ferrite magnet material. Today, TDK produces a broad portfolio of permanent magnets, including high-performance neodymium magnets and ferrite magnets, which are widely used in electric motors, sensors, actuators, and industrial equipment. The company emphasises technological innovation, offering magnets that reduce or eliminate the use of heavy rare earth elements like dysprosium and terbium, improving sustainability and cost efficiency. TDK’s advanced magnetic materials play a critical role in industries such as automotive, consumer electronics, renewable energy, and industrial automation, supporting demand in markets like permanent magnet concentrators by providing strong, heat-resistant, and compact magnet solutions.

4. VACUUMSCHMELZE GmbH & Co. KG

Headquarters: Hessen, Germany

VACUUMSCHMELZE GmbH & Co. KG (VAC) is a prominent German producer focused on advanced magnetic materials, such as permanent magnets, crucial for the permanent magnet concentrator sector. The company manufactures high-performance rare earth magnets, including sintered neodymium iron boron (NDFEB) magnets marketed under the VACODYM brand, and samarium-cobalt magnets branded as VACOMAX, recognised for their high energy density, coercivity, and thermal stability. VAC’s magnets find extensive application in high-efficiency electric motors, industrial automation, aerospace, and renewable energy sectors, improving performance and enabling compact designs of permanent magnet concentrators for magnetic separation and concentration methods. Through vertically integrated manufacturing and aerospace-grade certifications, VAC delivers precision-engineered magnets and assemblies designed to meet rigorous industry requirements.

5. Arnold Magnetic Technologies

Headquarters: New York, USA

Arnold Magnetic Technologies is a top global producer of high-performance permanent magnets, magnetic assemblies, electromagnetics, and precision thin metals. Samarium cobalt, neodymium-iron-boron (NdFeB), and Alnico magnets are extensively employed in high-efficiency electric motors, generators, sensors, and magnetic separation tools such as permanent magnet concentrators. Arnold emphasises sophisticated magnetic field technologies, including shaped field magnets and laminated magnets, which provide improved performance, greater magnetic fields, and minimised energy losses. The custom magnet solutions from the company serve various sectors such as aerospace, automotive, industrial automation, and defence, making a notable impact on the permanent magnet concentrator market by delivering precisely engineered magnets and assemblies tailored for challenging environments and high-efficiency uses.

Are you ready to discover more about the permanent magnet concentrator market?

The report provides an in-depth analysis of the leading companies operating in the global permanent magnet concentrator market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Hitachi Metals Ltd.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Shin-Etsu Chemical Co., Ltd.

- TDK Corporation

- VACUUMSCHMELZE GmbH & Co. KG

- Arnold Magnetic Technologies

- Electron Energy Corporation

- Lynas Corporation Ltd.

- Adams Magnetic Products Co.

- Bunting Magnetics Co.

- Yantai Shougang Magnetic Materials Inc.

- Daido Steel Co., Ltd.

- Ningbo Yunsheng Co., Ltd.

- Jiangmen Magsource New Material Co., Ltd.

- Zhong Ke San Huan Hi-Tech Co., Ltd.

- Hangzhou Permanent Magnet Group

- Ningbo Ketian Magnet Co., Ltd.

- OM Group, Inc.

- Goudsmit Magnetics Group

- Magnetics, a division of Spang & Company

- Advanced Technology & Materials Co., Ltd

- Others

Conclusion

The Global Permanent Magnet Concentrator Market Size is set for robust growth, with its size projected to more than double from USD 3.46 billion in 2024 to USD 8.24 billion by 2035, achieving a strong CAGR of 8.21%. This expansion is fundamentally driven by the rising global focus on sustainability and energy efficiency, favouring permanent magnet systems over electromagnets in high-volume industrial applications. Key demand areas include mining, recycling, and clean energy (electric vehicles and wind turbines), where high-performance Neodymium (NDFEB) and Samarium-Cobalt (SMCO) magnets are crucial for effective separation and concentration. While the Asia-Pacific region is expected to command the highest market share due to rapid industrialisation, North America is projected to grow the fastest, fueled by advanced technology adoption. The market is competitive, led by major global magnet and material technology firms like Hitachi Metals, Shin-Etsu Chemical, TDK Corporation, and Arnold Magnetic Technologies, all focused on developing superior, energy-efficient magnetic solutions.

Browse Related Reports

Global Emission Control Catalyst Market Size Exceed to USD 65.8 Million by 2035| CAGR of 3.45% : Market Size Report

Global Fluid Catalytic Cracking Market Size Exceed to USD 34.78 Billion by 2035| CAGR of 3.88% : Forecast Analysis Report

Global Beauty And Personal Care Surfactants Market Size Exceed to USD 20.05 Billion by 2035| CAGR of 5.6% : Market Statistics Report

Global Release Agents Market Size Exceed to USD 2.22 Billion by 2035| CAGR of 5.83% : Market Insight Report

Global Flame Retardant Market Size Exceed to USD 20.88 Billion by 2035| CAGR of 7.02% : Industry Report

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?