Discover Top 20 Companies in Brazing Filler Metals Market: Global Share, Market Size, Revenue Report (2024-2035).

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

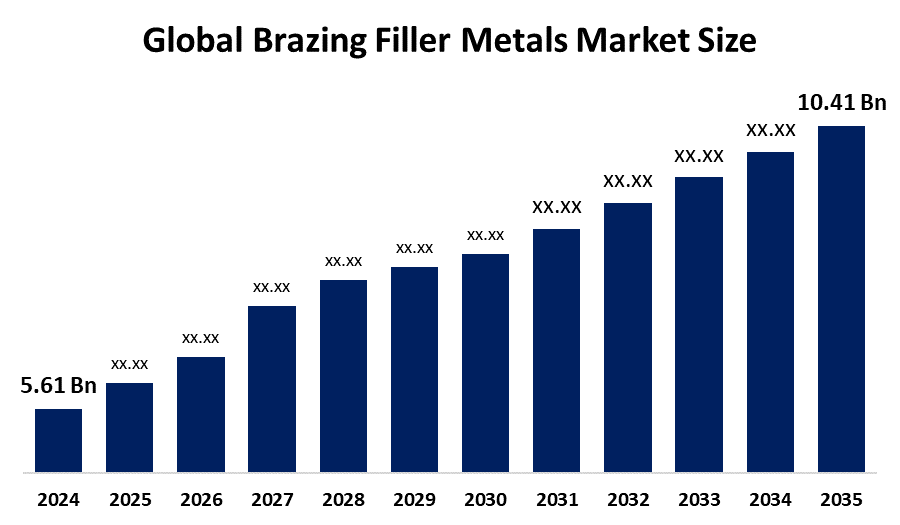

According to a research report published by Spherical Insights & Consulting, The Global Brazing Filler Metals Market Size is projected To Grow from USD 5.61 Billion in 2024 to USD 10.41 Billion by 2035, at a CAGR of 5.78 % during the forecast period 2025–2035. Future opportunities in the Brazing Filler Metals market include rising demand for lightweight automotive components, aerospace applications, renewable energy systems, advanced alloys, and increased adoption in HVAC, electronics, and industrial manufacturing sectors globally.

Introduction

The Brazing Filler Metals Market Size is experiencing significant growth due to the increasing demand for high-performance joining solutions across multiple industries. Brazing filler metals, including alloys of copper, silver, nickel, and aluminum, are widely used to create strong, leak-proof joints in automotive, aerospace, electronics, HVAC, and industrial applications. These metals enable precise, durable connections with minimal thermal distortion, making them essential for lightweight and high-strength assemblies. Rising adoption of advanced materials, focus on energy efficiency, and growing investments in manufacturing technologies are driving market expansion. Continuous innovations in alloy compositions and flux technologies further enhance performance, reliability, and application versatility.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Brazing Filler Metals market.

Brazing Filler Metals Market Size & Statistics

- The Market Size for Brazing Filler Metals Was Estimated to be Worth USD 5.61 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 5.78 % Between 2025 and 2035.

- The Global Brazing Filler Metals Market Size is Anticipated to Reach USD 10.41 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in The Brazing Filler Metals Market.

- North America is expected to grow the fastest during the forecast period in The Brazing Filler Metals Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Brazing Filler Metals market. North America is expected to grow fastest due to advanced manufacturing technologies, high adoption in aerospace and automotive sectors, strong R&D investments, stringent quality standards, and increasing demand for lightweight, durable, and corrosion-resistant brazing solutions in critical applications.

Asia Pacific is expected to generate the highest demand during the forecast period in the Brazing Filler Metals market. The region's growth is driven by rapid industrialization, urbanization, and infrastructure development in countries such as China, India, and Southeast Asian nations. The expanding automotive, aerospace, and electronics industries in these countries are key contributors to the demand for brazing filler metals.

Top 5 Trends in the Brazing Filler Metals Market

1. Rising Demand in Automotive and Aerospace Applications

Brazing filler metals are increasingly adopted in automotive and aerospace sectors due to their ability to create strong, lightweight, and corrosion-resistant joints. The growth of electric vehicles (EVs), fuel-efficient engines, and lightweight aircraft components drives demand for high-performance brazing alloys. Manufacturers are focusing on silver, copper, and nickel-based fillers to meet stringent strength, thermal, and conductivity requirements. Brazing enables complex geometries, reduces mechanical fasteners, and improves assembly efficiency. Additionally, regulatory pressures for fuel efficiency and emissions reduction are encouraging the use of brazed components. This trend is expected to sustain strong market growth.

2. Advancements in Alloy Compositions

Technological innovations in alloy compositions are transforming the brazing filler metals market. Companies are developing alloys with improved melting ranges, corrosion resistance, and thermal conductivity, tailored for specialized applications in electronics, HVAC, and industrial machinery. Low-temperature brazing alloys reduce thermal stress, prevent substrate damage, and enable joining of dissimilar metals. High-performance nickel, silver, and copper-based alloys are being designed for aerospace and automotive applications requiring strength and durability under extreme conditions. These advancements enhance process efficiency, reliability, and product lifespan, allowing manufacturers to meet evolving industry standards and expanding opportunities in high-demand, precision-engineered sectors.

3. Focus on Energy Efficiency and Lightweighting

Lightweighting initiatives in automotive, aerospace, and industrial equipment are driving the adoption of brazing filler metals. Brazed joints enable the use of lightweight metals like aluminum and copper, reducing overall component weight and improving fuel efficiency. In EVs and aircraft, lightweight assemblies help optimize energy consumption and extend operational performance. Brazing also minimizes mechanical fasteners and welding requirements, lowering material usage and production costs. Increasing emphasis on energy-efficient systems and sustainable manufacturing is fueling demand for advanced brazing solutions. This trend aligns with global environmental regulations and corporate sustainability goals, creating long-term opportunities for market expansion.

4. Integration of Automated Brazing Technologies

Automation is transforming brazing processes by enhancing precision, repeatability, and production efficiency. Robotic and furnace-based automated systems allow consistent heating, controlled flux application, and precise joint formation, reducing human error and increasing throughput. Integration with Industry 4.0 technologies, including sensors and real-time process monitoring, optimizes brazing cycles, reduces defects, and ensures uniform quality. Automated brazing is particularly beneficial for high-volume automotive, electronics, and industrial applications. As manufacturers strive for scalable, cost-effective production, the adoption of automated brazing equipment and process innovations is accelerating, driving demand for compatible high-performance filler metals.

5. Growth in Electronics and Industrial Machinery Applications

Brazing filler metals are increasingly used in electronics, semiconductor, and industrial machinery sectors due to their thermal and electrical conductivity, corrosion resistance, and ability to join complex assemblies. Applications include heat exchangers, power modules, transformers, and precision electronic components. Rising demand for compact, high-performance devices, along with the expansion of renewable energy systems and industrial automation, is fueling the adoption of brazed joints. Manufacturers are seeking specialized filler metals that provide reliability under extreme temperatures and mechanical stress. This trend underscores the importance of brazing solutions in enabling durable, high-performance assemblies across critical industrial and electronic applications.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Brazing Filler Metals market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the Brazing Filler Metals Market

- Lucas-Milhaupt, Inc.

- Harris Products Group

- Morgan Advanced Materials

- Umicore N.V.

- Oerlikon Metco

- Bellman-Melcor LLC

- Aimtek, Inc.

- Prince & Izant Company

- Saru Silver Alloy Private Limited

- Indian Solder and Braze Alloys

- VBC Group

- Stella Welding Alloys

- Wieland Edelmetalle GmbH

- Linbraze S.r.l.

- Tokyo Braze Co., Ltd.

- Wall Colmonoy Corporation

- Johnson Matthey Plc

- Sentes-BIR A.S.

- Hangzhou Huaguang Advanced Welding Materials Co., Ltd.

- Zhejiang Seleno Science and Technology Co., Ltd.

1. Lucas-Milhaupt, Inc.

Headquarters: Cudahy, Wisconsin, USA

Founded in 1942, Lucas-Milhaupt is a global leader in brazing technologies. The company offers over 400 custom alloys, including silver, copper, and nickel-based filler metals, along with fluxes and solder pastes. Serving industries such as aerospace, automotive, medical devices, and HVAC, Lucas-Milhaupt emphasizes innovation and quality in metal joining solutions. Their vertically integrated operations—from alloy casting to final fabrication—ensure precise and reliable products. Since 2018, Lucas-Milhaupt has been a part of Steel Partners Holdings, expanding its global reach and technological capabilities.

2. Harris Products Group

Headquarters: Mason, Ohio, USA

Established in 2006 through the merger of Harris Calorific and J.W. Harris, Harris Products Group is a subsidiary of Lincoln Electric. The company specializes in metalworking products for brazing, soldering, welding, cutting, heating, and gas control. With a global presence, Harris provides a comprehensive range of consumables and equipment to meet the needs of industries including manufacturing, construction, and maintenance. Their commitment to quality and innovation has positioned them as a trusted partner in the metalworking sector.

3. Morgan Advanced Materials

Headquarters: Windsor, Berkshire, United Kingdom

Morgan Advanced Materials is a leading manufacturer of advanced ceramic, carbon, and composite products. With a history dating back to 1856, the company operates in over 50 countries and serves markets including aerospace, automotive, electronics, and energy. Morgan’s expertise in materials science enables them to develop innovative solutions that enhance performance and efficiency across various applications. Their commitment to sustainability and technological advancement drives ongoing success in the global market.

4. Umicore N.V.

Headquarters: Brussels, Belgium

Umicore is a global materials technology and recycling company, focusing on clean technologies and sustainable materials. Their operations span automotive catalysts, energy materials, and recycling services. Umicore's commitment to innovation and sustainability has positioned them as a leader in the materials sector. The company continues to evolve its operations to meet changing market demands and emerging trends in electric mobility and clean energy.

5. Oerlikon Metco

Headquarters: Pfäffikon, Switzerland

Oerlikon Metco is a leading provider of surface solutions, offering a broad portfolio of materials for surface technology and advanced processes. Their services include thermal spray, laser cladding, and metal and ceramic injection molding. Serving industries such as aerospace, automotive, and energy, Oerlikon Metco focuses on enhancing the performance and longevity of components through innovative surface treatments. Their global presence and technological expertise make them a key player in the surface solutions market.

Are you ready to discover more about the Brazing Filler Metals market?

The report provides an in-depth analysis of the leading companies operating in the global Brazing Filler Metals market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Lucas-Milhaupt, Inc.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- Harris Products Group

- Morgan Advanced Materials

- Umicore N.V.

- Oerlikon Metco

- Bellman-Melcor LLC

- Aimtek, Inc.

- Prince & Izant Company

- Saru Silver Alloy Private Limited

- Indian Solder and Braze Alloys

Conclusion

The Brazing Filler Metals Market Size is poised for sustained growth driven by increasing demand across automotive, aerospace, electronics, HVAC, and industrial sectors. Rising adoption of lightweight materials, energy-efficient assemblies, and high-performance alloys is fueling market expansion. Technological advancements in alloy compositions, automated brazing, and precision joining processes are enhancing efficiency, reliability, and product performance. Growing infrastructure development, industrialization, and government initiatives further support market opportunities. As industries focus on sustainability, durability, and high-quality manufacturing, brazing filler metals continue to play a critical role in creating robust, corrosion-resistant, and energy-efficient assemblies, ensuring long-term market growth and innovation.

Browse Related Reports:

Global Gum Rosin Market Size Exceed To USD 4.10 Billion by 2035| CAGR of 5.19% : Industry Report

Global Emission Control Catalyst Market Size Exceed to USD 65.8 Million by 2035| CAGR of 3.45% : Market Size Report

Global Fluid Catalytic Cracking Market Size Exceed to USD 34.78 Billion by 2035| CAGR of 3.88% : Forecast Analysis Report

Global Beauty And Personal Care Surfactants Market Size Exceed to USD 20.05 Billion by 2035| CAGR of 5.6% : Market Statistics Report

Global Release Agents Market Size Exceed to USD 2.22 Billion by 2035| CAGR of 5.83% : Market Insight Report

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?