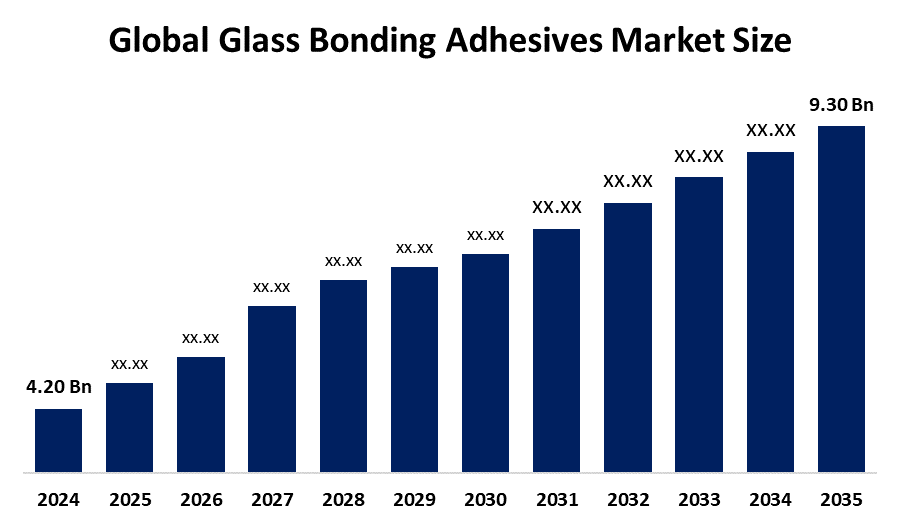

Global Glass Bonding Adhesives Market Insights Forecasts to 2035

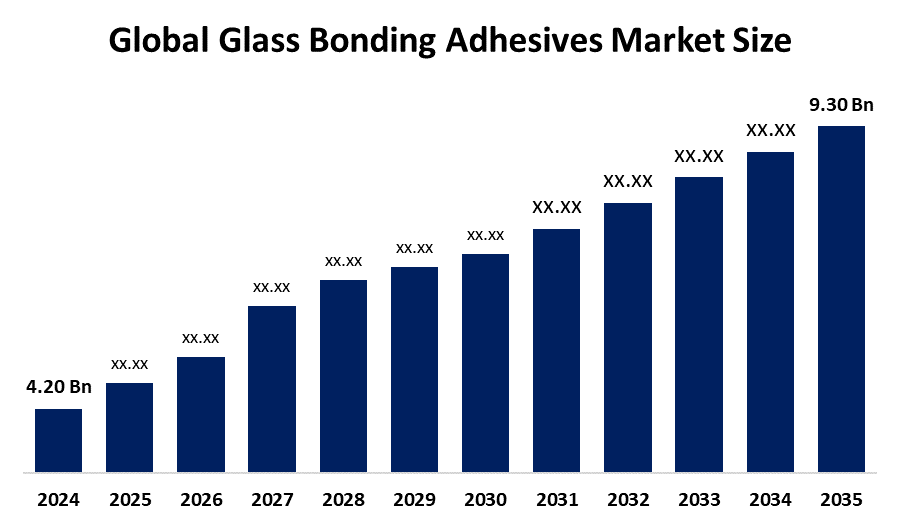

- The Global Glass Bonding Adhesives Market Size Was Estimated at USD 4.20 Billion in 2024

- The Market Size is Expected to Grow at a CAGR of around 7.49% from 2025 to 2035

- The Worldwide Glass Bonding Adhesives Market Size is Expected to Reach USD 9.30 Billion by 2035

- North America is expected to grow the fastest during the forecast period.

Glass Bonding Adhesives Market

The glass bonding adhesives market encompasses adhesives specially formulated to bond glass with materials such as metals, plastics, and other glass types. These adhesives are crucial in applications where transparency, strength, and durability are required, including automotive windshields, architectural glazing, electronics, and solar panels. The market features a variety of adhesive types such as silicone, polyurethane, and epoxy, each offering distinct properties like flexibility, chemical resistance, or high bonding strength. These adhesives ensure a strong, clear bond that maintains the integrity and aesthetics of glass components while withstanding environmental stresses like temperature fluctuations and UV exposure. Advances in adhesive technology focus on enhancing performance characteristics such as faster curing times, improved weather resistance, and compatibility with diverse substrates. Glass bonding adhesives enable manufacturers to create lightweight, durable, and visually appealing products by securely joining glass to other materials. This market continues to evolve with innovations that support more efficient, reliable, and high-quality bonding solutions.

Attractive Opportunities in the Glass Bonding Adhesives Market

- Development of adhesives with self-healing properties and stress/damage sensing capabilities opens up new advanced application areas, especially in automotive and electronics sectors.

- EVs require adhesives that can withstand higher temperatures and provide electrical insulation, creating a specialized market for high-performance glass bonding adhesives.

- Increasing investments in energy-efficient and eco-friendly buildings promote the use of sustainable, low-VOC adhesives bonded with glass, expanding the demand for environmentally friendly products.

- The growing wearable technology and flexible screen markets need adhesives that combine flexibility with strong bonding, offering niche growth potential in electronics applications.

Global Glass Bonding Adhesives Market Dynamics

DRIVER: Rising use of glass for aesthetic and energy-efficient building designs further propels the market

In the automotive sector, the need for strong yet flexible bonds to enhance vehicle safety and fuel efficiency fuels adoption. The construction industry’s rising use of glass for aesthetic and energy-efficient building designs further propels the market. Additionally, the expanding electronics industry, particularly in display technologies and touchscreens, requires reliable adhesive solutions for glass components. Advances in adhesive formulations, such as improved bonding strength, faster curing times, and enhanced environmental resistance, also stimulate market growth. Furthermore, growing emphasis on sustainable and low-VOC (volatile organic compound) adhesives aligns with stricter environmental regulations, encouraging manufacturers to develop eco-friendly products. The increasing integration of glass in renewable energy applications, like solar panels, adds another growth dimension. Together, these factors create a robust demand for high-performance glass bonding adhesives across multiple sectors.

RESTRAINT: High cost associated with advanced adhesive formulations

One significant challenge is the high cost associated with advanced adhesive formulations, which can deter smaller manufacturers from adopting these specialized products. Additionally, the complexity of bonding different substrates, such as glass to metals or plastics, requires precise surface preparation and application techniques, increasing manufacturing time and costs. The sensitivity of glass to stress and thermal expansion differences can lead to bonding failures if adhesives are not properly selected or applied. Furthermore, stringent regulatory standards related to chemical safety and environmental impact restrict the use of certain adhesive components, complicating product development. Limited awareness and technical expertise among end-users about optimal adhesive selection and application can also hinder widespread adoption. Finally, competition from alternative joining methods, such as mechanical fasteners or welding in some industries, may reduce reliance on adhesives, posing a challenge to market expansion.

OPPORTUNITY: Innovations in smart adhesive technologies

Innovations in smart adhesive technologies, such as adhesives with self-healing properties or those capable of sensing stress and damage, open new avenues for advanced applications. The rise of electric vehicles (EVs) creates demand for adhesives that can withstand higher temperatures and electrical insulation requirements. Increasing investments in green building initiatives promote the use of energy-efficient glass bonded with eco-friendly adhesives, expanding market potential. Growth in wearable electronics and flexible displays also offers opportunities for adhesives that combine flexibility with strong bonding. Additionally, expanding use of glass in medical devices, where biocompatibility and sterilization resistance are critical, creates niche markets. Collaborations between adhesive manufacturers and end-user industries to develop customized solutions further enhance growth prospects. Lastly, digitalization and automation in manufacturing processes increase demand for adhesives that enable faster assembly and improved product reliability, supporting market expansion.

CHALLENGES: Difficulty in achieving consistent adhesive performance across diverse glass types

One key challenge is the difficulty in achieving consistent adhesive performance across diverse glass types and surface conditions, which can lead to variability in bond quality. The long-term durability of bonds under harsh environmental conditions such as extreme temperatures, humidity, and mechanical stress remains a concern, especially for outdoor and automotive applications. Additionally, the need for specialized equipment and skilled labor for precise adhesive application limits adoption in smaller manufacturing units. Supply chain disruptions affecting raw materials for adhesives can also impact production timelines and costs. Moreover, evolving customer expectations for thinner, lighter, and more complex glass structures require continuous innovation, putting pressure on manufacturers to rapidly develop and validate new adhesive solutions. Lastly, compatibility issues with emerging glass coatings and treatments may pose technical challenges in ensuring strong and lasting bonds. These challenges require ongoing research and collaboration across industries.

Global Glass Bonding Adhesives Market Ecosystem Analysis

The global glass bonding adhesives market ecosystem includes adhesive manufacturers producing silicone, epoxy, and polyurethane adhesives, supported by raw material suppliers. Distributors ensure efficient delivery to key end-users in automotive, construction, electronics, and solar industries. Equipment manufacturers provide application and curing technologies, while regulatory bodies set safety and environmental standards that drive product innovation. Research institutions contribute by developing advanced adhesive chemistries and techniques. Together, these stakeholders create a dynamic ecosystem fostering continuous innovation and market growth.

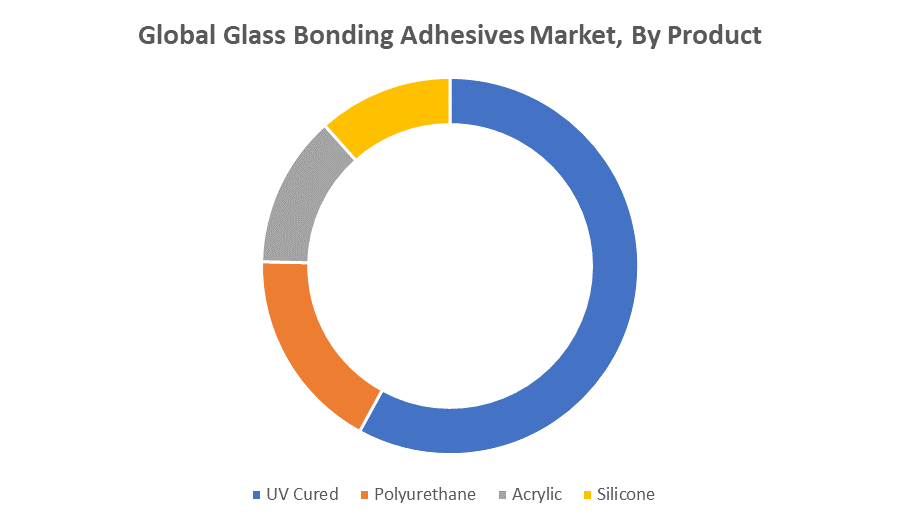

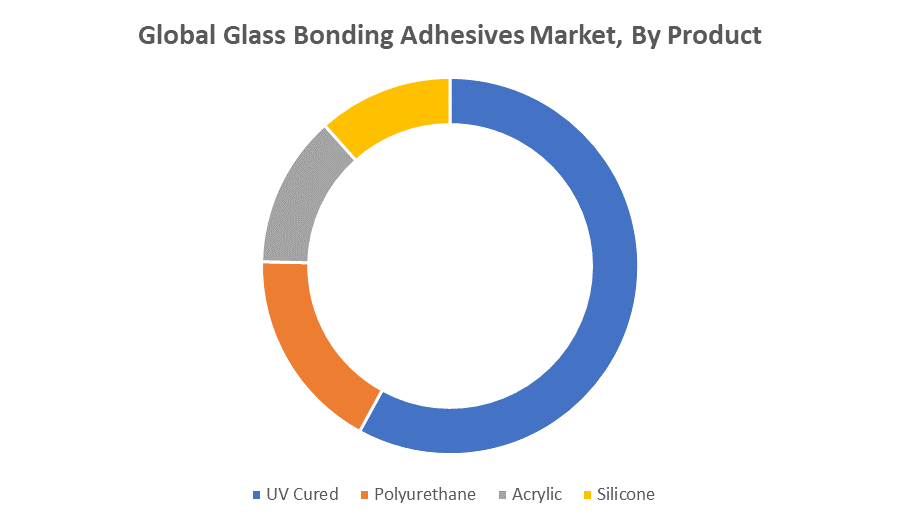

Based on the product, the UV cured adhesives accounted for the largest revenue share over the forecast period

UV-cured adhesives accounted for the largest revenue share over the forecast period. This is due to their fast curing times, excellent bonding strength, and high clarity, making them ideal for applications requiring precise and durable glass bonding. Their ability to cure quickly under ultraviolet light enables efficient manufacturing processes, especially in electronics and automotive sectors. Additionally, UV-cured adhesives offer superior resistance to environmental factors, contributing to their growing preference and significant market share in glass bonding applications.

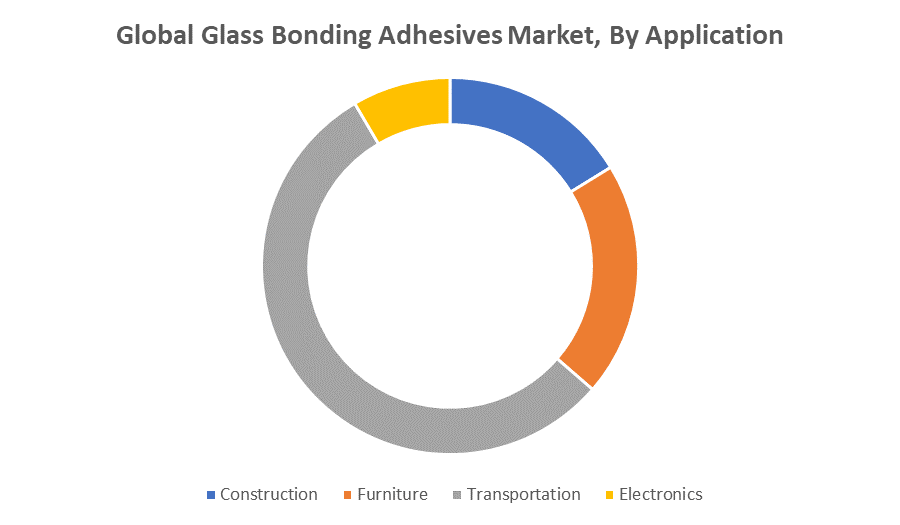

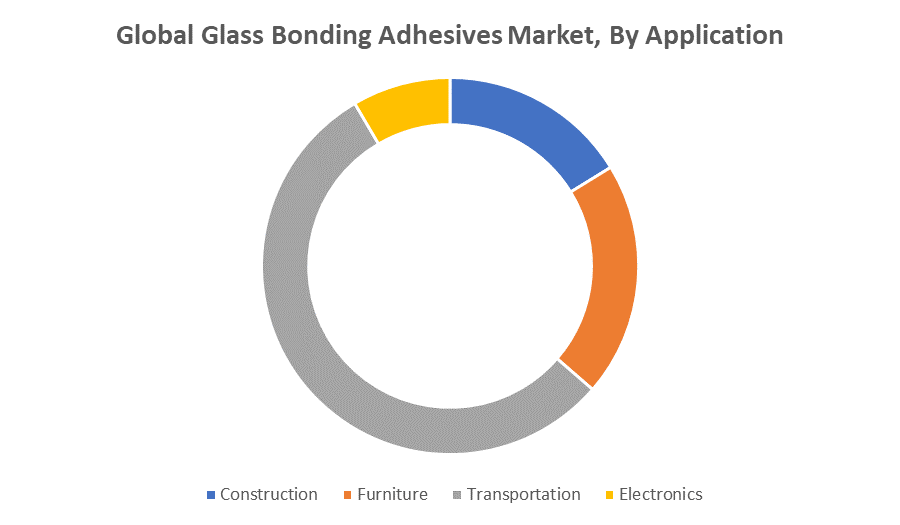

Based on the application, the transportation sector and constituted glass bonding adhesives industry share during the forecast period

The transportation sector held a significant share of the glass bonding adhesives market during the forecast period. This is driven by the extensive use of glass bonding adhesives in automotive manufacturing for windshields, windows, and structural components, where strong, durable, and lightweight bonds are essential. The transportation industry's demand for enhanced safety, improved fuel efficiency, and aesthetic designs further supports the widespread adoption of these adhesives, contributing substantially to the overall market share in glass bonding applications.

Asia Pacific is anticipated to hold the largest market share of the glass bonding adhesives market during the forecast period

Asia Pacific is anticipated to hold the largest market share in the glass bonding adhesives market during the forecast period. This is attributed to rapid industrialization, growing automotive production, expanding construction activities, and increasing electronics manufacturing in the region. The presence of major adhesive manufacturers and a strong supply chain infrastructure further support market growth. Additionally, rising investments in renewable energy projects, such as solar panel installations, boost the demand for advanced glass bonding adhesives, making Asia Pacific a key driver of the global market.

North America is expected to grow at the fastest CAGR in the glass bonding adhesives market during the forecast period

North America is expected to grow at the fastest CAGR in the glass bonding adhesives market during the forecast period. This growth is driven by strong demand from the automotive and electronics sectors, increasing adoption of advanced adhesive technologies, and stringent regulatory standards promoting high-performance and eco-friendly adhesives. Additionally, ongoing investments in smart building construction and renewable energy projects, such as solar panels, further accelerate market expansion in the region. The presence of key industry players and continuous innovation also contributes to North America’s rapid market growth.

Recent Development

- In January 2023, Henkel AG & Co. KGaA introduced Loctite 3296, a dual-cure adhesive combining UV and thermal curing, tailored for lens bonding in ADAS sensors. This innovation ensures precision and durability in sensor assembly.

Key Market Players

KEY PLAYERS IN THE GLASS BONDING ADHESIVES MARKET INCLUDE

- Henkel AG & Co. KGaA

- Dow Inc.

- Huntsman Corporation

- 3M Company

- Sika AG

- Permabond LLC

- H.B. Fuller Company

- Ashland Global Holdings Inc.

- Lord Corporation

- Arkema Group

- Others

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the glass bonding adhesives market based on the below-mentioned segments:

Global Glass Bonding Adhesives Market, By Product

- UV Cured

- Polyurethane

- Acrylic

- Silicone

Global Glass Bonding Adhesives Market, By Application

- Construction

- Furniture

- Transportation

- Electronics

Global Glass Bonding Adhesives Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa