Global Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market Size, Share, and COVID-19 Impact Analysis, By Form (Liquid PMDI and Solid / Semi-Solid PMDI), By Product Type(Standard/Industrial-Grade PMDI, Modified PMDI, Low-Viscosity PMDI, High-Functionality PMDI, and Custom-Formulated / Specialty PMDI), By Application (Rigid Polyurethane Foam, Flexible Polyurethane Foam, Binders for Wood Panels, Coatings, Adhesives, Sealants & Elastomers (CASE), and Specialty & High-Performance Applications), By End-Use (Construction & Building, Furniture & Bedding, Automotive & Transportation, Electrical Appliances, and Industrial & Infrastructure), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Industry: Advanced MaterialsGlobal Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market Size Insights Forecasts to 2035

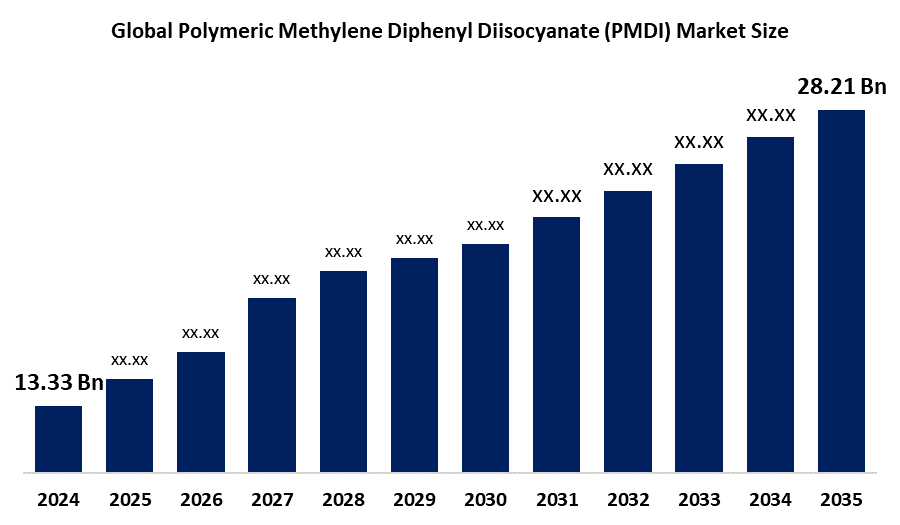

- The Global Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market Size Was Estimated at USD 13.33 Billion in 2024

- The Market Size is Expected to Grow at a CAGR of around 7.05% from 2025 to 2035

- The Worldwide Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market Size is Expected to Reach USD 28.21 Billion by 2035

- North America is expected to Grow the fastest during the forecast period.

Get more details on this report -

According to a Research Report Published by Spherical Insights and Consulting, The Global Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market Size was worth around USD 13.33 Billion in 2024 and is predicted to Grow to around USD 28.21 Billion by 2035 with a compound annual growth rate (CAGR) of 7.05% from 2025 to 2035. The global polymeric MDI market is growing because construction projects need energy-efficient insulation materials, automotive manufacturers require lightweight materials, urban areas continue to expand, and industrial sectors grow, which leads to more people using rigid polyurethane foams for furniture and refrigeration products.

Market Overview

Polymeric methylene diphenyl diisocyanate (PMDI) is a brown liquid aromatic isocyanate that contains monomeric MDI and higher oligomers and serves as an essential raw material in the production of polyurethane products. The material is primarily used to create rigid and semi-rigid polyurethane foams, which deliver exceptional thermal insulation for construction panels and spray foam and refrigeration and transportation systems. The global PMDI market is growing as the need for energy-efficient insulation increases, along with the rapid urbanisation of emerging markets and the automotive industry's shift towards lightweight materials.

The polyurethane industry in December 2025 showed no signs of recovery after European, Japanese, and South Korean asset sales. China's growing raw material production facilities helped to secure supply routes while pushing forward environmentally friendly polyurethane manufacturing processes. The US government established a 511.75% preliminary anti-dumping duty on Chinese MDI, which created international trade barriers, while India investigated Chinese TPU paint protection films. The development of sustainable, low-emission bio-based MDI products offers manufacturers a substantial opportunity to create products that fulfil green building certifications. The market operates with high consolidation because major companies control it, while Wanhua Chemical, BASF SE, Covestro AG, Huntsman Corporation and The Dow Chemical Company expand their production facilities to satisfy increasing market requirements.

Report Coverage

This research report categorizes the polymeric methylene diphenyl diisocyanate (PMDI) market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the polymeric methylene diphenyl diisocyanate (PMDI) market. Recent market developments and competitive strategies, such as expansion, type launch, development, partnership, merger, and acquisition, have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the polymeric methylene diphenyl diisocyanate (PMDI) market.

Global Polymeric Methylene Diphenyl Diisocyanate Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 13.33 Billion |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | 7.05% |

| 2035 Value Projection: | USD 28.21 Billion |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 157 |

| Tables, Charts & Figures: | 111 |

| Segments covered: | By Form, By Product Type and COVID-19 Impact Analysis |

| Companies covered:: | Wanhua Chemical Group, Covestro AG, Huntsman Corporation, BASF SE, Dow Chemical Company, Tosoh Corporation, Kumho Mitsui Chemicals, Lanxess AG, Chevron Phillips Chemical, Gujarat Narmada Valley Fertilizers Limited (GNFC), Tokyo Chemical Industry Co., Ltd., Anhui Huayi Chemical Co., Ltd., Shandong Yisheng Chemical Co., Ltd., and Others |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The global polymeric methylene diphenyl diisocyanate (PMDI) market experiences its main growth because construction projects need energy-saving insulation materials, which are driven by urbanization trends and green building standards. The automotive industry needs lightweight parts to improve fuel efficiency, which drives up demand for PMDI used in making long-lasting insulation foams. The demand for rigid foams in cold-chain systems, together with the rising furniture and bedding market, creates new opportunities for business development. The industry is developing sustainable methods, which include bio-based MDI production, because of mandatory environmental standards.

Restraining Factors

The global PMDI market experiences major restrictions because of two factors, which include stringent environmental and safety regulations that control chemical emissions and toxicity, together with rising raw material costs that fluctuate due to petrochemical market dependence and existing transportation difficulties. The market growth faces obstacles because competitors offer environmentally friendly alternatives, while businesses need to invest significant funds to build new sustainable production facilities.

Market Segmentation

The polymeric methylene diphenyl diisocyanate (PMDI) market share is classified into form, product type, application, and end-use.

- The liquid PMDI segment dominated the market in 2024, approximately 80% and is projected to grow at a substantial CAGR during the forecast period.

Based on the form, the polymeric methylene diphenyl diisocyanate (PMDI) market is divided into liquid PMDI and solid / semi-solid PMDI. Among these, the liquid PMDI segment dominated the market in 2024 and is projected to grow at a substantial CAGR during the forecast period. The market leader liquid PMDI offers easy handling, uniform reactivity and automated production compatibility. The material enables rapid production processes and reduces material waste while improving quality assessment, which makes it the optimal selection for industrial operations and construction projects that need to achieve high efficiency and maintain product uniformity.

- The standard/industrial-grade PMDI segment accounted for the largest share in 2024, approximately 46% and is anticipated to grow at a significant CAGR during the forecast period.

Based on the product type, the polymeric methylene diphenyl diisocyanate (PMDI) market is divided into standard/industrial-grade PMDI, modified PMDI, low-viscosity PMDI, high-functionality PMDI, and custom-formulated / specialty PMDI. Among these, the standard/industrial-grade PMDI segment accounted for the largest share in 2024 and is anticipated to grow at a significant CAGR during the forecast period. Standard or industrial-grade PMDI is widely used in high-volume applications like rigid foams and insulation. The product achieves strong market demand because it combines cost-effectiveness and dependable operation with processing flexibility, which makes it suitable for use in construction materials and industrial-grade insulation products that emerge in developing markets that experience high-demand consumption patterns.

- The rigid polyurethane foam segment accounted for the largest share in 2024, approximately 48% and is anticipated to grow at a significant CAGR during the forecast period.

Based on the application, the polymeric methylene diphenyl diisocyanate (PMDI) market is divided into rigid polyurethane foam, flexible polyurethane foam, binders for wood panels, coatings, adhesives, sealants & elastomers (CASE), and specialty & high-performance applications. Among these, the rigid polyurethane foam segment accounted for the largest share in 2024 and is anticipated to grow at a significant CAGR during the forecast period. The largest application of PMDI involves rigid polyurethane foam, which serves as thermal insulation for building projects and refrigeration systems, cold storage facilities and household appliances. The rising adoption of green building practices, together with more rigorous energy efficiency regulations and increased need for insulated panels and appliances, will drive ongoing market expansion for PMDI products within this specific market sector.

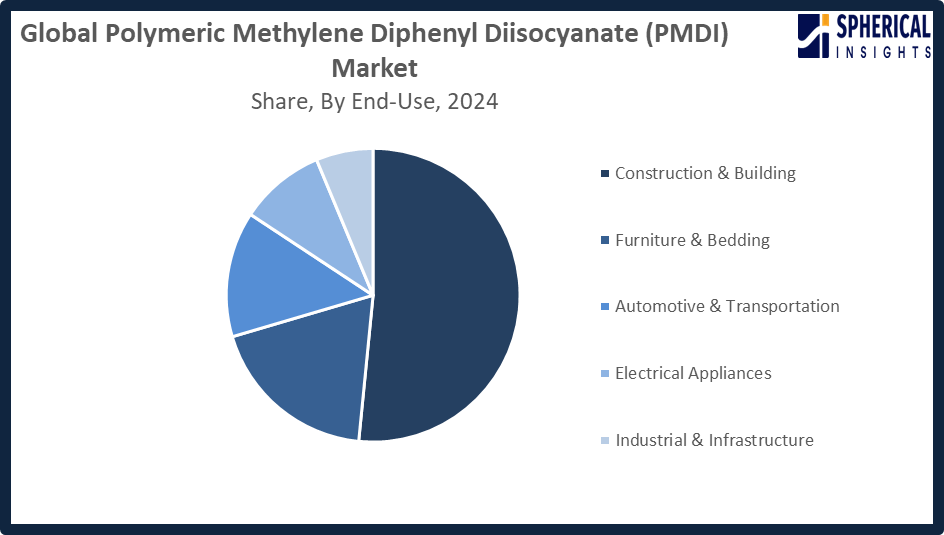

- The construction & building segment accounted for the highest market revenue in 2024, approximately 52% and is anticipated to grow at a significant CAGR during the forecast period.

Based on the end-use, the polymeric methylene diphenyl diisocyanate (PMDI) market is divided into construction & building, furniture & bedding, automotive & transportation, electrical appliances, and industrial & infrastructure. Among these, the construction & building segment accounted for the highest market revenue in 2024 and is anticipated to grow at a significant CAGR during the forecast period. The building and construction industry represents the primary market segment for PMDI because it uses the material for insulation purposes, structural applications and sandwich panel production. The demand for PMDI-based insulation solutions in residential and commercial construction projects increases because of the growing interest in environmentally friendly building practices and the need to decrease carbon emissions.

Get more details on this report -

Regional Segment Analysis of the Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Asia Pacific is anticipated to hold the largest share of the polymeric methylene diphenyl diisocyanate (PMDI) market over the predicted timeframe.

Get more details on this report -

Asia Pacific is anticipated to hold the largest share of the polymeric methylene diphenyl diisocyanate (PMDI) market over the predicted timeframe. The polymeric methylene diphenyl diisocyanate (PMDI) market will experience its 44% market share in Asia-Pacific due to the fast urban development, infrastructure growth and industrial development happening in China, India and Japan. The increasing need for energy-saving insulation materials in building construction, appliance operation and cold-storage facilities, together with the expanding automotive industry and furniture market, results in higher PMDI usage. The world’s leading PMDI producer, China, establishes reliable supply networks while India develops its construction and industrial sectors, which create major business expansion possibilities. China established a new standard in April 2024, which combined GB 31828-2015 and GB 31830-2015, and this new standard will take effect on May 1, 2025, to improve energy efficiency in TDI and MDI manufacturing processes.

North America is expected to grow at a rapid CAGR in the polymeric methylene diphenyl diisocyanate (PMDI) market during the forecast period. The North American polymeric methylene diphenyl diisocyanate PMDI market will experience a 20% share of rapid growth through its compound annual growth rate, which the United States and Canada will drive. The market expands because of high demand for rigid polyurethane foam, which the construction, refrigeration and appliance sectors require, together with the implementation of energy-efficient standards and environmentally friendly construction practices. The development of new technologies, together with better manufacturing processes and increased interest in environmental insulation solutions, leads to higher PMDI usage. The US ITC announced its first antidumping investigation into Chinese MDI imports in February 2025 after BASF and Dow filed a petition, which reported 2024 imports of 229000 tonnes.

The European PMDI market experiences growth because Germany, France and the UK drive market expansion through their implementation of strict energy efficiency regulations and green building programs, and their increased demand for insulated panels and refrigeration systems. The sustainable polyurethane investments, together with the growing use of PMDI in construction, automotive and appliance sectors, create pathways for business expansion. The EU implemented environmental regulations in March 2025, which restrict specific chemicals while regulating emissions and advancing sustainable PU foam alternatives to support circular economy practices and environmentally friendly manufacturing throughout the industry.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the polymeric methylene diphenyl diisocyanate (PMDI) market, along with a comparative evaluation primarily based on their type of offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes type development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Wanhua Chemical Group

- Covestro AG

- Huntsman Corporation

- BASF SE

- Dow Chemical Company

- Tosoh Corporation

- Kumho Mitsui Chemicals

- Lanxess AG

- Chevron Phillips Chemical

- Gujarat Narmada Valley Fertilizers Limited (GNFC)

- Tokyo Chemical Industry Co., Ltd.

- Anhui Huayi Chemical Co., Ltd.

- Shandong Yisheng Chemical Co., Ltd.

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In December 2025, Dow Chemical announced a $200/ton price increase for polymer MDI in Southeast Asia, effective immediately or per contract terms. The adjustment addresses rising polyurethane raw material costs and ensures service continuity amid strong demand from refrigeration, construction insulation, automotive, and cold-chain sectors in the region.

- In December 2025, BASF, Wanhua Chemical, and Hungary’s BorsodChem raised TDI and MDI prices by $200–$325/ton across Asia and Europe. Following earlier increases by Covestro and Huntsman, this coordinated move by the top isocyanate producers triggered a rare global price surge, impacting the polyurethane supply chain.

- In December 2025, Kumho Mitsui Chemicals announced a 140 billion KRW investment to increase MDI production by 100,000 tons, raising annual capacity from 610,000 to 710,000 tons. The expansion, starting in February 2026, is expected to be completed by May 2027, enhancing supply for growing industrial and construction demand.

- In November 2025, BASF announced a $200/ton price increase for its Lupranate MDI products in South Asia, effective immediately or per contract terms. The adjustment responds to rising transportation, energy, and regulatory costs, ensuring continued supply and maintaining product quality for regional customers.

- In January 2024, Wanhua Chemical restarted its 400,000 t/yr MDI unit at Ningbo after a 50-day maintenance, while an 800,000 t/yr unit remains offline. The company confirmed January list prices: polymeric MDI at 18,000 yuan/t and monomeric MDI at 24,500 yuan/t, unchanged from December.

- In September 2023, Dow launched a new MDI distillation and prepolymers facility at its Freeport, Texas site, replacing La Porte operations. The world-scale facility boosts supply by 30%, enhances Dow’s presence in automotive, construction, consumer, and industrial markets, while La Porte polyurethane assets were simultaneously shut down.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the polymeric methylene diphenyl diisocyanate (PMDI) market based on the below-mentioned segments:

Global Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market, By Form

- Liquid PMDI

- Solid / Semi-Solid PMDI

Global Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market, By Product Type

- Standard/Industrial-Grade PMDI

- Modified PMDI

- Low-Viscosity PMDI

- High-Functionality PMDI

- Custom-Formulated / Specialty PMDI

Global Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market, By Application

- Rigid Polyurethane Foam

- Flexible Polyurethane Foam

- Binders for Wood Panels

- Coatings, Adhesives, Sealants & Elastomers (CASE)

- Specialty & High-Performance Applications

Global Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market, By End-Use

- Construction & Building

- Furniture & Bedding

- Automotive & Transportation

- Electrical Appliances

- Industrial & Infrastructure

Global Polymeric Methylene Diphenyl Diisocyanate (PMDI) Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the polymeric methylene diphenyl diisocyanate (PMDI) market over the forecast period?The global polymeric methylene diphenyl diisocyanate (PMDI) market is projected to expand at a CAGR of 7.05% during the forecast period.

-

2. What is the polymeric methylene diphenyl diisocyanate (PMDI) market?The polymeric methylene diphenyl diisocyanate (PMDI) market involves the production, distribution, and use of PMDI for polyurethane applications.

-

3. What is the market size of the polymeric methylene diphenyl diisocyanate (PMDI) market?The global polymeric methylene diphenyl diisocyanate (PMDI) market size is expected to grow from USD 13.33 billion in 2024 to USD 28.21 billion by 2035, at a CAGR of 7.05% during the forecast period 2025-2035.

-

4. Which region holds the largest share of the polymeric methylene diphenyl diisocyanate (PMDI) market?Asia Pacific is anticipated to hold the largest share of the polymeric methylene diphenyl diisocyanate (PMDI) market over the predicted timeframe.

-

5. Who are the top 10 companies operating in the global polymeric methylene diphenyl diisocyanate (PMDI) market?Wanhua Chemical Group, Covestro AG, Huntsman Corporation, BASF SE, Dow Chemical Company, Tosoh Corporation, Kumho Mitsui Chemicals, Lanxess AG, Chevron Phillips Chemical, Gujarat Narmada Valley Fertilizers Limited (GNFC), and Others.

-

6. What factors are driving the growth of the polymeric methylene diphenyl diisocyanate (PMDI) market?Key drivers include soaring demand for rigid insulation in construction, automotive lightweighting, increased furniture production, and a shift toward eco-friendly/bio-based polyurethane products, particularly in the Asia-Pacific and North American markets.

-

7. What are the market trends in the polymeric methylene diphenyl diisocyanate (PMDI) market?PMDI market trends include surging demand for rigid insulation in construction, lightweighting in automotive, sustainability, eco-friendly products, and high growth in the Asia-Pacific.

-

8. What are the main challenges restricting wider adoption of the polymeric methylene diphenyl diisocyanate (PMDI) market?Key challenges restricting PMDI market adoption include stringent health and safety regulations, high toxicity causing respiratory sensitization, raw material price volatility, complex transportation protocols, and stiff competition from eco-friendly alternatives.

Need help to buy this report?