Global Magnesium Alloy Ingot Market Size, Share, and COVID-19 Impact Analysis, By Type (Wrought Alloys, Cast Alloys, and Other Types), By Application (Aerospace and Defense, Consumer Electronics, Automotive and Transportation, and Other Applications), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Industry: Chemicals & MaterialsGlobal Magnesium Alloy Ingot Market Size Insights Forecasts to 2035

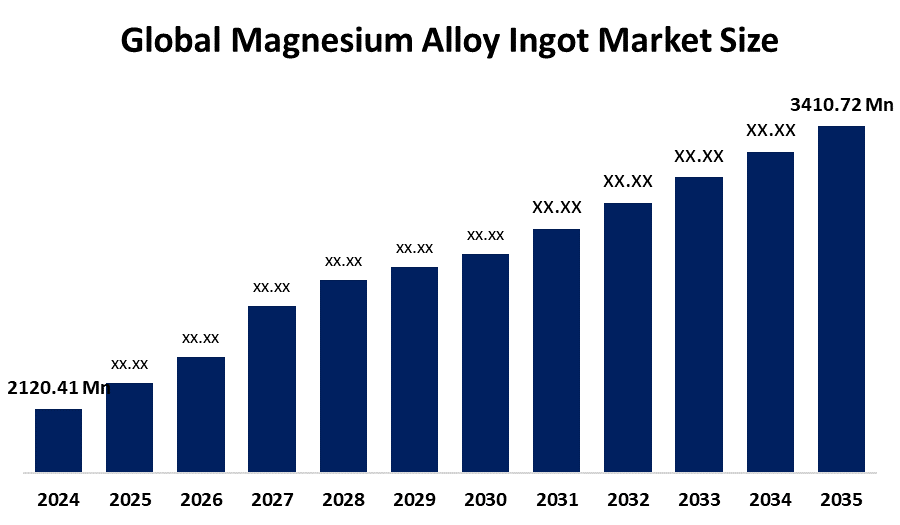

- The Global Magnesium Alloy Ingot Market Size Was Estimated at USD 2120.41 Million in 2024

- The Market Size is Expected to Grow at a CAGR of around 4.42% from 2025 to 2035

- The Worldwide Magnesium Alloy Ingot Market Size is Expected to Reach USD 3410.72 Million by 2035

- North America is expected to Grow the fastest during the forecast period.

Get more details on this report -

According to a Research Report Published by Spherical Insights and Consulting, The Global Magnesium Alloy Ingot Market Size was worth around USD 2120.41 Million in 2024 and is predicted to Grow to around USD 3410.72 Million by 2035 with a compound annual growth rate (CAGR) of 4.42% from 2025 to 2035. The international magnesium alloy ingot market is expanding owing to the rising demand for light metal materials in electric vehicles (EVs) and the aerospace industry to enhance fuel efficiency. The rising demand in the electronics industry, high-performance die casting, and the increasing adoption of sustainable and recyclable materials are the major drivers of the market.

Market Overview

The global magnesium alloy ingot market refers to the manufacturing of solid, light, and strong metal blocks, mainly made up of magnesium with the addition of other alloying materials such as aluminium, zinc, and rare earth metals. These metal ingots are the main raw materials used extensively in die-casting, aluminium alloying, steel desulfurization, and the manufacturing of aerospace, automotive, and 3C electronic components because of their exceptional strength-to-weight ratio. The major drivers of the market include the increasing regulations for enhanced fuel efficiency and carbon emissions in the transportation industry, along with the rapidly growing electric vehicle (EV) market that demands light metal structural components.

In April 2025, the Magnesium Industry Chain and Magnesium Market Forum came to an end in Jinhua, Zhejiang Province. This forum was organised by Shangmei Network and SMM Information & Technology. It was sponsored by the National Engineering Research Center for Magnesium Alloys and the Magnesium Alloy Branch of the Chinese Materials Research Society. The forum covered the trends in the industry. Opportunities exist in the production of biodegradable medical implants (for example, the WE43 alloy) and in the development of high-performance wrought alloys. In 2024, global primary magnesium production reached 1.12 million mt, up 12% YoY. China produced 1.0258 million mt of primary magnesium and 396,800 mt of magnesium alloys, increasing 24.73% and 14.95% YoY, respectively. Exports rose 13.62%, totalling 459,800 mt, according to China Customs.

Report Coverage

This research report categorizes the magnesium alloy ingot market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the magnesium alloy ingot market. Recent market developments and competitive strategies, such as expansion, type launch, development, partnership, merger, and acquisition, have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the magnesium alloy ingot market.

Global Magnesium Alloy Ingot Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 2120.41 Million |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | 4.42% |

| 2035 Value Projection: | USD 3410.72 Million |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 165 |

| Tables, Charts & Figures: | 101 |

| Segments covered: | By Type, By Application and COVID-19 Impact Analysis |

| Companies covered:: | Nanjing Yunhai Special Metals Co., Ltd., Magontec Limited, US Magnesium LLC, Luxfer MEL Technologies, Dead Sea Magnesium Ltd., Baowu Magnesium Technology Co., Ltd., Meridian Lightweight Technologies Inc., RIMA Group, POSCO Magnesium, Luxfer MEL Technologies, Nippon Kinzoku Co., Ltd., Shanxi Qizhen Magnesium Co. Ltd, and Others |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The key driving factor in the global magnesium alloy ingot market is the burning need for weight reduction in the automotive and aerospace industries to improve fuel efficiency and lower carbon emissions. The growing popularity of electric vehicles (EVs), in which magnesium assists in reducing the weight of batteries and improving their range, is a major driving factor. The demand from consumer electronics (laptops and smartphones) for enhanced heat dissipation and electromagnetic shielding is another driving factor. The growing demand for eco-friendly materials with more stringent global environmental regulations and the focus on sustainable, 99% recyclable materials further drives this market. Finally, new growth opportunities emerge in the biomedical implants and defense industries.

Restraining Factors

The major factors inhibiting the global magnesium alloy ingot market are the high price variability, the concentration of the supply chain in China, and the stringent environmental laws. The technical limitations of low corrosion resistance, poor weldability, and high flammability, together with intense competition from aluminium materials and composites, are also major inhibiting factors.

Market Segmentation

The magnesium alloy ingot market share is classified into type and application.

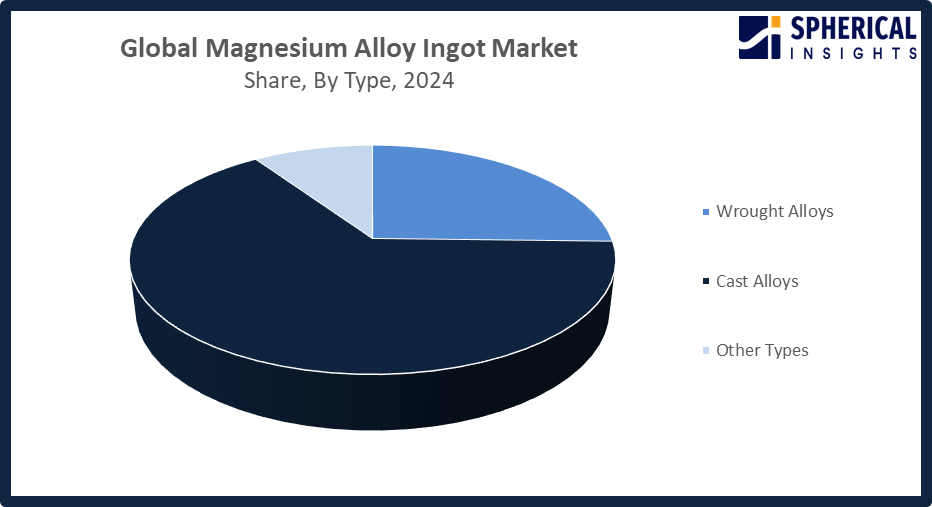

- The cast alloys segment dominated the market in 2024, approximately 65% and is projected to grow at a substantial CAGR during the forecast period.

Based on the type, the magnesium alloy ingot market is divided into wrought alloys, cast alloys, and other types. Among these, the cast alloys segment dominated the market in 2024 and is projected to grow at a substantial CAGR during the forecast period. Cast magnesium alloys are preferred extensively for their excellent dimensional stability and ability to form complex shapes, making them suitable for the manufacture of lightweight engine, transmission, and structural components. The strength-weight ratio and ease of mass production at a relatively low cost support demand, while the increasing use of lightweight materials and developments in die-casting processes enhance market dominance.

Get more details on this report -

- The automotive and transportation segment accounted for the highest market revenue in 2024, approximately 45% and is anticipated to grow at a significant CAGR during the forecast period.

Based on the application, the magnesium alloy ingot market is divided into aerospace and defense, consumer electronics, automotive and transportation, and other applications. Among these, the automotive and transportation segment accounted for the highest market revenue in 2024 and is anticipated to grow at a significant CAGR during the forecast period. The automotive and transport sector accounted for a major market share owing to the increasing use of lightweight materials to enhance fuel efficiency and reduce emissions. Magnesium alloys are used extensively in engine blocks, transmission bodies, steering wheels, and seat frames. The rising production of electric vehicles also enhanced demand, as the use of lightweight materials increases the range of batteries and improves vehicle performance.

Regional Segment Analysis of the Magnesium Alloy Ingot Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Asia Pacific is anticipated to hold the largest share of the magnesium alloy ingot market over the predicted timeframe.

Get more details on this report -

Asia Pacific is anticipated to hold the largest share of the magnesium alloy ingot market over the predicted timeframe. The Asia Pacific region is expected to account for the 54% market share of the magnesium alloy ingot market, due to the region’s robust automotive and electronics sectors, availability of magnesium resources, and government encouragement for the development of advanced materials. China leads the world in production and encourages the use of high-performance alloys through its policies and initiatives, while India and Japan follow suit through the growing production of electric vehicles and the demand for lightweight components. In July 2025, Hebi City, Henan Province, issued the Implementation Plan for Accelerating the Breakthrough of Six New Industries in Manufacturing, to change the magnesium-based materials industry by establishing a magnesium ecosystem, improving R&D, commercializing innovations, developing standards, and expanding applications.

North America is expected to grow at a rapid CAGR in the magnesium alloy ingot market during the forecast period. The North American region is expected to have a 18% market share of the magnesium alloy ingot market, owing to the rising demand for lightweight materials in the automotive, aerospace, and defense industries. The United States, the largest national market in North America, fuels the market with the adoption of magnesium alloys in electric vehicles, aircraft parts, and industrial applications. Effective R&D programs, technological developments in the production of alloys, and government support for fuel-efficient and sustainable production methods also encourage the region’s rapidly growing market.

The European region is experiencing a steady growth in the magnesium alloy ingot market due to the increasing demand for lightweight materials in the automotive and aerospace industries. Germany, being the largest contributor to the region, is leading the growth with its robust automotive production and adoption of electric vehicles. Emission regulations, a focus on energy-efficient transportation, and developments in magnesium alloy technology are fueling the growth of the region in the global market.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the magnesium alloy ingot market, along with a comparative evaluation primarily based on their type of offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes type development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Nanjing Yunhai Special Metals Co., Ltd.

- Magontec Limited

- US Magnesium LLC

- Luxfer MEL Technologies

- Dead Sea Magnesium Ltd.

- Baowu Magnesium Technology Co., Ltd.

- Meridian Lightweight Technologies Inc.

- RIMA Group

- POSCO Magnesium

- Luxfer MEL Technologies

- Nippon Kinzoku Co., Ltd.

- Shanxi Qizhen Magnesium Co. Ltd

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In March 2025, Baowu Magnesium announced collaborations with industrial robot manufacturers. The company highlighted magnesium alloys’ advantages: lightness, speed, stability, and cost-effectiveness, to enhance robotics performance, offering lightweight, high-efficiency, and fast-response solutions for industrial automation, aiming to boost competitiveness and innovation in the robotics sector.

- In September 2025, US Magnesium filed for bankruptcy, raising US reliance on imports and supply chain concerns. China’s Yimeitai exported high-end magnesium alloy equipment to South Korea, while the EU launched the HighMag project for magnesium battery R&D. The developments highlight global competition in magnesium resources, technology, and strategic supply chains.

- In December 2024, the World Intelligent Manufacturing Conference opened in Nanjing. Baowu Magnesium and Nanjing Estun Automation signed a Global New Quality Productivity strategic cooperation agreement and launched new magnesium alloy robot products, marking a milestone in intelligent manufacturing and setting industry development trends.

- In November 2022, Yunhai Special Metals surged 3.4% after Baowu Steel Group announced a CNY4.7 billion (USD656 million) investment to expand magnesium alloy production. The plan includes four new plants in Nanjing, Tianjin, Chongqing, and Shanxi, boosting processing capacity, automotive market share, and high-performance magnesium alloy output.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the magnesium alloy ingot market based on the below-mentioned segments:

Global Magnesium Alloy Ingot Market, By Type

- Wrought Alloys

- Cast Alloys

- Other Types

Global Magnesium Alloy Ingot Market, By Application

- Aerospace and Defense

- Consumer Electronics

- Automotive and Transportation

- Other Applications

Global Magnesium Alloy Ingot Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the magnesium alloy ingot market over the forecast period?The global magnesium alloy ingot market is projected to expand at a CAGR of 4.42% during the forecast period.

-

2. What is the market size of the magnesium alloy ingot market?The global magnesium alloy ingot market size is expected to grow from USD 2120.41 million in 2024 to USD 3410.72 million by 2035, at a CAGR of 4.42% during the forecast period 2025-2035.

-

3. What is the magnesium alloy ingot market?The magnesium alloy ingot market involves producing and selling lightweight, durable magnesium mixtures for automotive, aerospace, and electronics industries, driving demand.

-

4. Which region holds the largest share of the magnesium alloy ingot market?Asia Pacific is anticipated to hold the largest share of the magnesium alloy ingot market over the predicted timeframe.

-

5. Who are the top 10 companies operating in the global magnesium alloy ingot market?Nanjing Yunhai Special Metals Co., Ltd., Magontec Limited, US Magnesium LLC, Luxfer MEL Technologies, Dead Sea Magnesium Ltd., Baowu Magnesium Technology Co., Ltd., Meridian Lightweight Technologies Inc., RIMA Group, POSCO Magnesium, Luxfer MEL Technologies, and Others.

-

6. What factors are driving the growth of the magnesium alloy ingot market?Key drivers include rising demand for lightweight electric vehicles and aerospace components to boost fuel efficiency, strict emission regulations, and the need for superior material strength-to-weight ratios in high-performance structural applications.

-

7. What are the market trends in the magnesium alloy ingot market?Key trends include rising demand for electric vehicle lightweighting, growth in aerospace, increased eco-friendly semi-solid casting, and high, volatile raw material prices.

-

8. What are the main challenges restricting wider adoption of the magnesium alloy ingot market?Key challenges limiting wider magnesium alloy adoption include high production costs, significant price volatility (due to reliance on Chinese supply), poor corrosion resistance, and high flammability risks during processing.

Need help to buy this report?