Self-Compacting Concrete Market Summary

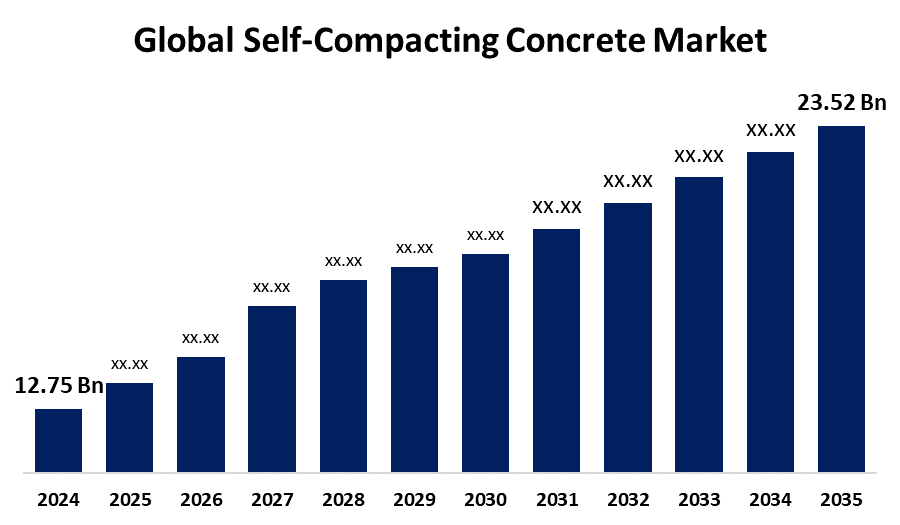

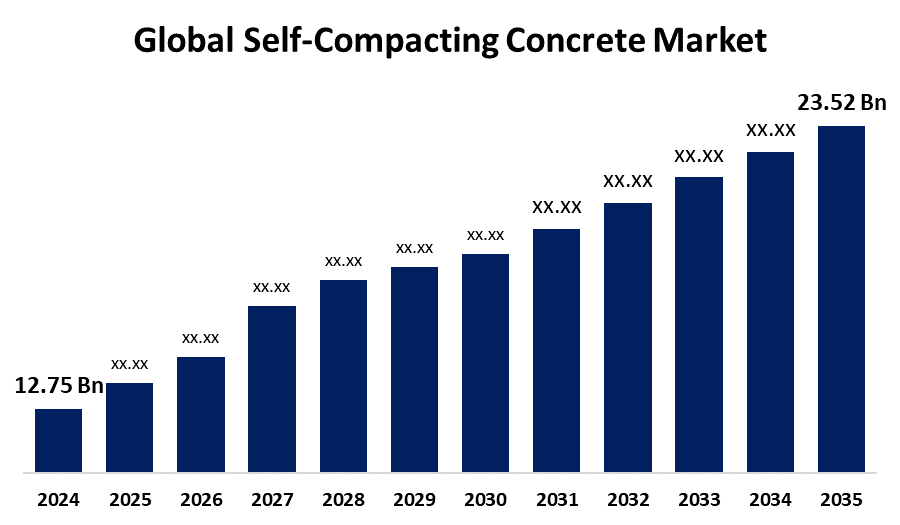

The Self-Compacting Concrete Market Size was valued at USD 12.75 Billion in 2024 and is projected to reach USD 23.52 Billion by 2035, Growing at a CAGR of 5.72% from 2025 to 2035. A number of factors, such as its excellent qualities, an increase in construction activity, and a growing emphasis on sustainable construction, are driving the expansion of the self-compacting concrete (SCC) industry.

Key Regional and Segment-Wise Insights

- In 2024, Asia Pacific held the biggest revenue share of 44.5%, dominating the global market for self-compacting concrete.

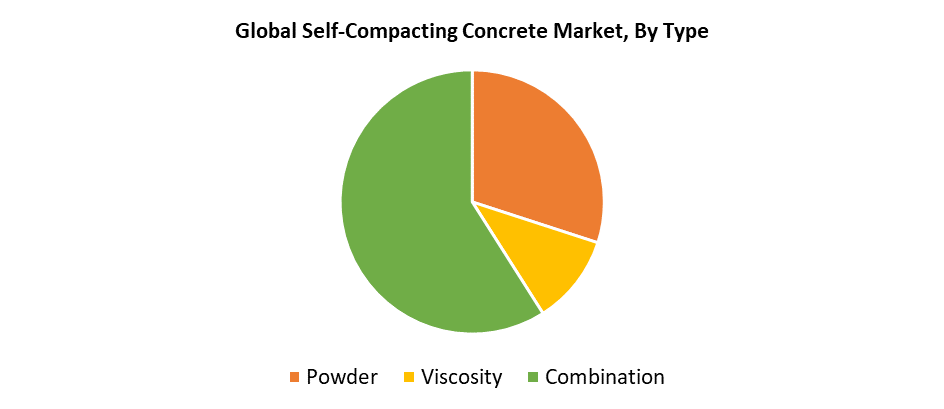

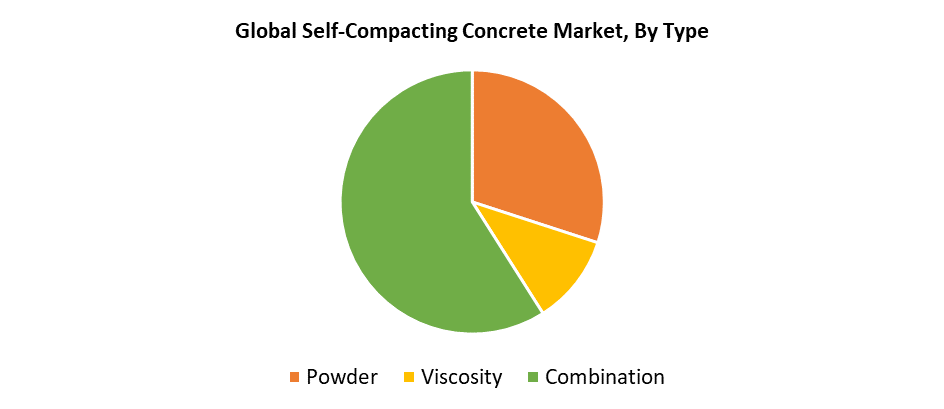

- In 2024, the combination type held the biggest share, accounting for 59.3% by type.

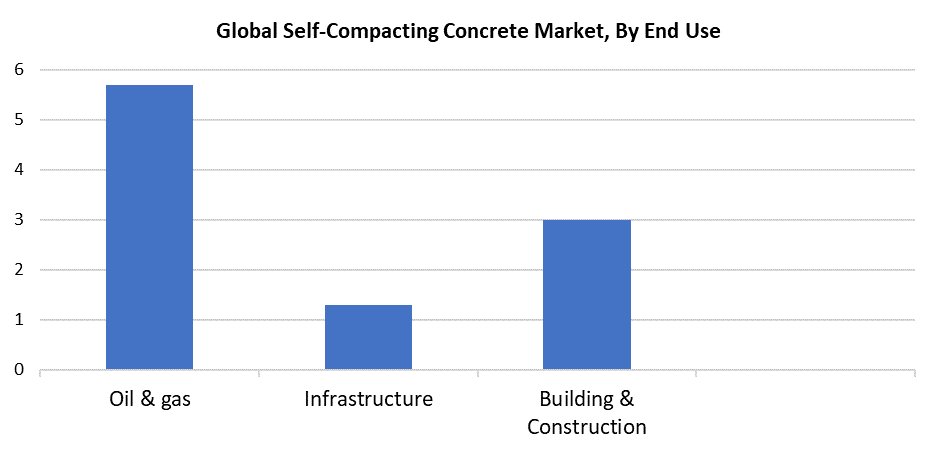

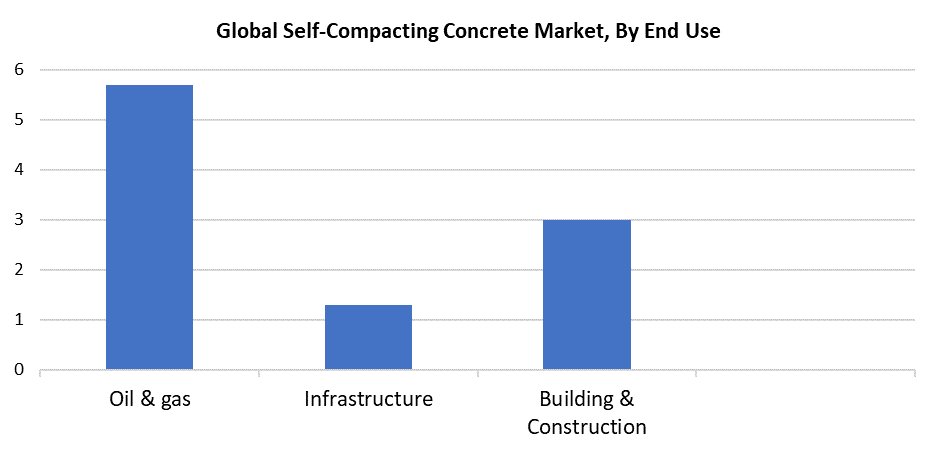

- The oil and gas end-use segment had the biggest market share in 2024 by end-use.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 12.75 Billion

- 2035 Projected Market Size: USD 23.52 Billion

- CAGR (2025-2035): 5.72%

- Asia Pacific: Largest market in 2024

The market for self-compacting concrete (SCC) represents the business environment, which covers the manufacturing, marketing, and usage of SCC. The self-compacting concrete (SCC) market shows rapid growth due to its superior performance characteristics and increasing demand for advanced building materials. The ability of SCC to self-flow and fill complicated formworks while requiring no vibration allows for faster construction times and decreased personnel requirements. SCC provides multiple advantages for infrastructure, commercial, and residential projects through its ability to enhance productivity while cutting project duration and lowering labor expenses. The use of SCC has grown substantially for complex architectural designs and highly reinforced structures. Modern construction projects have driven the rising adoption of SCC because of their need for strong, durable concrete that maintains uniformity throughout the structure. The consistent surface finish and reduced void risk of SCC provide both structural and aesthetic advantages, which developers and contractors now demand.

The rising interest in sustainable construction techniques serves as a fundamental driver of the SCC market growth. Self-compacting concrete delivers multiple advantages for construction businesses that shift to environmentally sustainable operations by decreasing waste generation, enhancing energy performance, and reducing noise through its vibration-free application. These benefits align with worldwide sustainable construction campaigns. The recommendation for contractors to implement SCC in their projects stems from both new construction and retrofitting requirements, which stem from sustainable material regulations. The safety and environmental benefits, along with quality improvements of SCC, are gaining increasing recognition from governmental organizations and industry associations. The self-compacting concrete market will continue to rise because of material technology advancements, together with global infrastructure investment, even though certain regions experience awareness issues and cost challenges.

Type Insights

The combination type category dominated the market with a 59.3% share in 2024. The improved performance and versatile applications across different construction projects have driven its increasing popularity. This type of SCC integrates fine particle benefits with VMA properties to create high flowability, cohesive, and segregation-resistant concrete. The traits become essential when working with complex structural elements containing extensive reinforcement because traditional concrete often falls short. The balanced formulation of this material suits high-specification architectural and infrastructure projects by delivering smooth placement along with reduced defect risks and outstanding surface quality. The combination type remains the preferred choice for modern construction projects since it addresses multiple building needs and delivers structural integrity alongside efficiency and visual appeal.

Powder type demonstrates the fastest growth in the forecasted period, because these solutions enhance both sustainability and performance features of self-compacting concrete. The section includes Portland cement together with fly ash, slag, and other supplemental cementitious materials (SCMs). The components play a significant role in determining the concrete's workability, together with its strength and durability. The application of fly ash or slag reduces both the heat of hydration and thermal cracking risks while boosting long-term strength and weather resistance of concrete. The powder-type SCC shows exceptional performance for wide infrastructure projects because of these beneficial properties. The use of industrial waste delivers environmental advantages that assist the ongoing sustainability development within the construction industry.

End-use Insights

The oil and gas industry leads the self-compacting concrete market because it requires reliable building materials that endure tough conditions. Facilities such as storage tanks and refineries, together with offshore platforms, face severe environments that combine corrosive chemicals with temperature changes and elevated pressure levels. Self-compacting concrete (SCC) delivers a dense, homogeneous mixture that forms minimal voids to achieve outstanding strength and durability in demanding applications. The concrete's excellent flow properties allow easy placement in complex restricted spaces, thus reducing construction time and labor costs while enhancing structural strength. The oil and gas sector's infrastructure improvement plan and sector growth will drive substantial growth in SCC demand because it delivers durable and safe solutions for harsh operational conditions.

The building & construction industry relies heavily on Self-compacting concrete (SCC) because of its excellent workability features and its straightforward application in complicated building projects. Self-compacting concrete moves freely to fill complex formworks and areas with heavy reinforcement because it does not need mechanical vibration during placement. The flow characteristics of SCC reduce labor requirements, which reduces construction expenses and accelerates project completion times. The use of SCC guarantees reliable, high-quality finishes with minimal defects, which enhances both structural durability and aesthetic outcomes. Modern construction projects find SCC highly attractive because it delivers cost savings alongside precise results and operational efficiency. Modern infrastructure, together with commercial properties and residential construction projects, drives the ongoing expansion of the market because SCC is increasingly adopted.

Regional Insights

The North American self-compacting concrete (SCC) industry experiences significant growth because infrastructure restoration projects continue to expand. Modernized highways, bridges, tunnels, and other public works require SCC because this concrete delivers superior durability and speedier construction times. The self-leveling qualities of SCC lower the requirement for workers and equipment, increasing project efficiency and lowering costs. The region's growing focus on sustainability helps drive SCC adoption because its manufacturing process demands less power and water while generating less construction waste compared to traditional concrete production. The environmental standards and green building targets align with SCC properties. Multiple factors combine to create a rapidly expanding demand for self-compacting concrete throughout North American public and private construction projects.

U.S. Self-Compacting Concrete Market Insights

Self-compacting concrete (SCC) is experiencing significant growth in the United States in 2024, because of growing environmental concerns, along with the construction industry's innovation. Concrete technology has advanced to enhance SCC's workability and strength, along with durability, which enables its application across different construction projects in this region. The growing demand for advanced concrete solutions primarily stems from the need to use high-performance concrete for infrastructure projects such as roads, bridges, and tunnels. The widespread adoption of SCC receives a significant boost from substantial government funding directed at infrastructure expansion and modernization projects. SCC's ability to minimize both construction costs and time frames matches the US construction industry's current drive toward operational efficiency. The United States construction industry favors SCC because its sustainable characteristics match both the nation's changing construction trends and rising environmental awareness.

Asia Pacific Self-Compacting Concrete Market Trends

The Asia-Pacific region generated the highest revenue share, accounting for 44.5% and led the self-compacting concrete market globally. The market expansion stems from quick urban development, together with rising populations and substantial infrastructure projects. Infrastructure, alongside business and residential projects, receives substantial funding from China, India, and Japan. The demand for superior construction methods that reduce work expenses and enhance construction quality in crowded metropolitan zones drives the SCC market. The market continues to grow because of fast economic development, together with government efforts to develop housing, transportation, and industrial infrastructure. The region's rising interest in sustainable construction methods leads to increased SCC usage because this concrete type provides environmental benefits. The combination of factors makes Asia Pacific the leading region for continuous strong growth in the SCC industry.

Key Self-Compacting Concrete Companies:

The following are the leading companies in the self-compacting concrete market. These companies collectively hold the largest market share and dictate industry trends.

- BASF SE

- Unibeton Ready Mix

- ACC Limited

- HEIDELBERGCEMENT AG

- SIKA AG

- Tarmac

- LafargeHolcim

- Ultratech Concrete

- Kilsaran

- CEMEX S.A.B. de C.V

- Ambuja Cements Ltd.

- Others

Recent Developments

- In August 2024, the Competition and Consumer Protection Commission (CCPC) granted permission to Kilsaran to purchase Kilmurray Precast Concrete Limited, which operates from Derryarkin in County Offaly. The acquisition includes all assets of Kilmurray, including Kilmurray's chip-processing facility, sand and gravel quarry, stock, vehicles, plant, supply and sale contracts, interest in leased assets, goodwill, and two small freehold properties.

- In April 2024, Kilsaran unveiled two Volvo FM electric concrete trucks, which were the first in the UK and Ireland. These zero-emission cars, which are located in Ringsend, Dublin, have five batteries apiece and, depending on the load, may go up to 300 kilometers between charges. The initiative's goal is to lower carbon emissions and noise pollution in metropolitan areas.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the self-compacting concrete market based on the below-mentioned segments:

Global Self-Compacting Concrete Market, By Type

- Powder

- Viscosity

- Combination

Global Self-Compacting Concrete Market, By End Use

- Oil & gas

- Infrastructure

- Building & Construction

Global Self-Compacting Concrete Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa