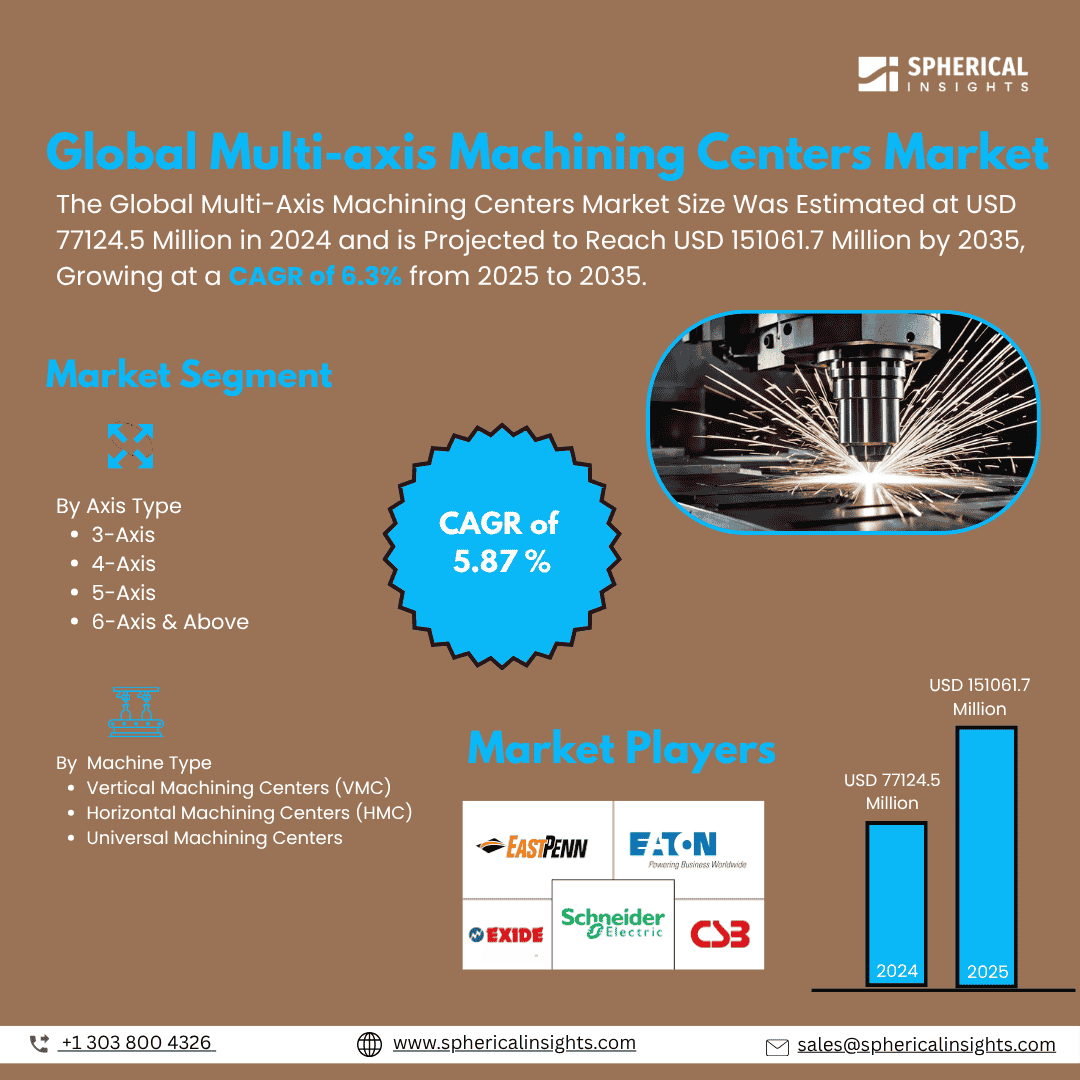

Multi-axis Machining Centers Market Summary

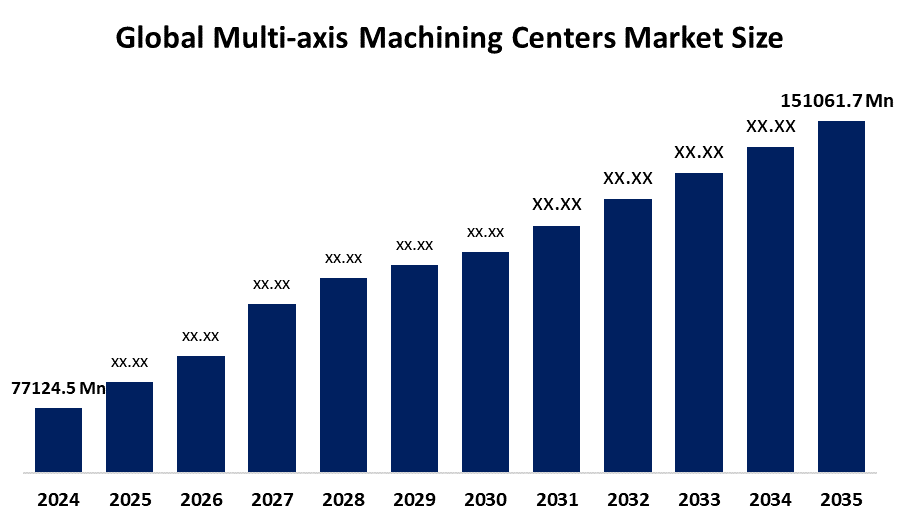

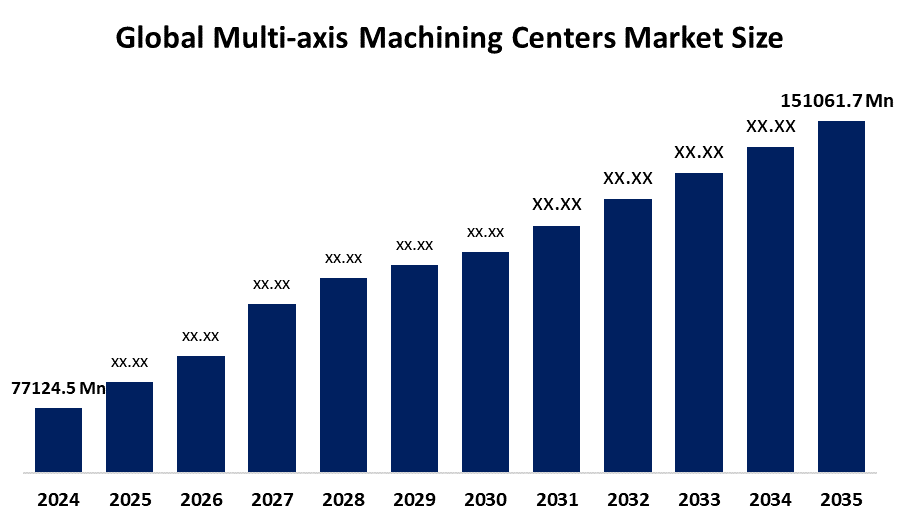

The Global Multi-Axis Machining Centers Market Size Was Estimated at USD 77124.5 Million in 2024 and is Projected to Reach USD 151061.7 Million by 2035, Growing at a CAGR of 6.3% from 2025 to 2035. The market for multi-axis machining centers is expanding because of the growing need for precision manufacturing, wider use in the automotive, aerospace, and medical sectors, automation integration, CNC system advancements, and the requirement for complex, high-efficiency part production with shorter setup times.

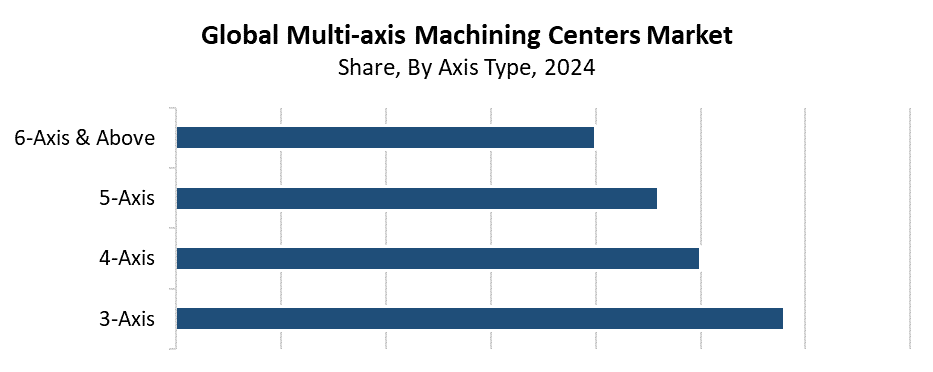

Key Regional and Segment-Wise Insights

- In 2024, the Asia Pacific multi-axis machining centers market size held the largest revenue share of 53.7% and dominated the global market.

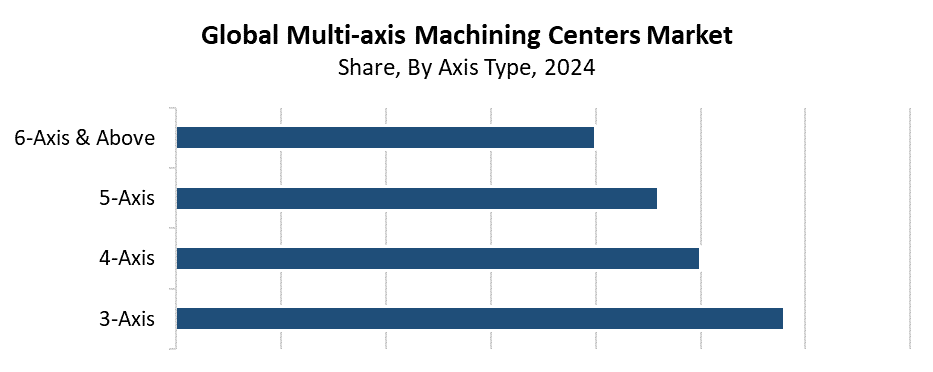

- In 2024, the 3-axis segment held the highest revenue share of 29.5% and dominated the global market by axis type.

- With the biggest revenue share of 52.3% in 2024, the vertical machining centers (VMC) segment led the worldwide multi-axis machining centers market by machine type.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 77124.5 Million

- 2035 Projected Market Size: USD 151061.7 Million

- CAGR (2025-2035): 6.3%

- Asia Pacific: Largest market in 2024

The Market Size for Multi-Axis Machining Centers operates as an industry which focuses on advanced computer numerical control (CNC) systems that perform simultaneous tool or workpiece movement across multiple axes, starting from three up to five or more. These machines serve aerospace, automotive, medical devices, and military industries to produce complex, high-precision components. The market operates based on three main drivers, which include production time and operational cost reduction needs, manufacturing process automation growth, and precision component requirements. The market growth receives support from three main factors, which include the need for advanced lightweight components, industrial expansion, and increasing automotive and aerospace industry activities. The manufacturing industry dedicates funds to purchase multi-axis machining centers because these machines deliver enhanced operational efficiency, production flexibility, and superior manufacturing results.

Technological advancements have brought major changes to the multi-axis machining centers industry. The combination of robotics-assisted automation with AI-integrated controls, high-speed machining, and 5-axis and 6-axis CNC machines results in better precision, speed, and operational efficiency. Through subsidies, incentives, and skill-development programs, governments from all around the world are supporting sophisticated industrial automation, Industry 4.0 projects, and smart manufacturing. The market grows because manufacturers use environmentally friendly technology which meets strict quality standards to create complex products. This reduces waste and operational costs. The multi-axis machining centres market experiences ongoing worldwide expansion because all of these elements work together to drive its growth.

Axis Type Insights

What Factors Enabled the 3-Axis segment to Hold the Largest Revenue Share of 29.5% and Dominate the Global Multi-Axis Machining Center Market in 2024?

The 3-axis segment held the largest revenue share of 29.5% and dominated the global multi-axis machining center market in 2024. The wide application of 3-axis machines across metalworking, automotive, and general manufacturing industries drives this dominance because these machines deliver cost-effective precision manufacturing solutions. These devices are preferred because they deliver simple operation combined with reliable performance. This produces exact machining results across multiple tasks. The segment maintains its market strength through CNC technology, automation systems, and digital controls, which boost operational efficiency and decrease operational costs. Manufacturers looking for a compromise between price, performance, and versatility continue to favour the 3-axis market.

The 4-axis segment is expected to grow significantly during the forecast period. The market growth stems from the requirement for complex and exact parts, which defence, automotive, aerospace, and medical device industries need. The extra rotational axis in 4-axis machines allows manufacturers to produce complex shapes and multi-sided products through single setups, which reduces manufacturing duration while enhancing operational output. The segment growth receives backing from the expanding adoption of automation systems, CNC technology, and enhanced tooling solutions. The manufacturing industry requires 4-axis machining centers because they provide high-precision operations and flexible manufacturing capabilities. These generate cost-effective quality results. The market segment functions as a key growth engine which drives the expansion of multi-axis machining centers.

Machine Type Insights

Why Did the Vertical Machining Centers (VMC) segment Hold a 52.3% Revenue Share in the Global Multi-Axis Machining Centers Market in 2024?

The vertical machining centers (VMC) segment led the global multi-axis machining centers market by holding the largest revenue share of 52.3% in 2024. The automotive and aerospace industries, together with metalworking and general manufacturing sectors, use VMCs because these machines deliver high precision and efficiency and perform multiple machining operations. VMCs are preferred because they offer solid construction and simple operation while performing complex tapping, drilling, and milling tasks with minimum setup requirements. The combination of automation systems with smart controls and CNC technology integration leads to better operational efficiency and enhanced precision. Higher production output. VMCs maintain their position as market leaders in multi-axis machining centers because of their high performance and reliability combined with cost-effectiveness.

The universal machining center segment is expected to grow at a significant rate throughout the forecast period. The market growth stems from increasing demand for flexible machining systems, which perform multiple operations, including milling, drilling, and turning, on one platform. Heavy machinery, aerospace, automotive, and defence industries depend on universal machining centers to produce their complex multi-sided components. The manufacturing process becomes more efficient through fewer setups because it delivers high-precision complex geometry processing. This leads to lower production costs and shorter operating durations. The worldwide multi-axis machining centers market undergoes development through universal machining centers because automation advancements and smart control systems, CNC technology integration, creating better precision and productivity, and operational efficiency.

Regional Insights

The North American region experiences ongoing growth in the multi-axis machining centers market because various industries require complex precision components for medical devices, automotive, aerospace, and defence applications. The US and Canada serve as leading contributors through their advanced industrial infrastructure and expanding CNC and automation technology applications, and their focus on reducing production expenses and operational durations. The combination of robotic technology with 5-axis and 6-axis machines and smart monitoring systems results in better operational efficiency and precision. The development of multi-axis machining facilities receives additional support from government programs which promote Industry 4.0 and advanced manufacturing. Workforce training. North America maintains its position as a leading global market because the region upholds standards for quality manufacturing, sustainable production methods and operational efficiency.

Europe Multi-axis Machining Centers Market Trends

The European multi-axis machining centres market grows significantly because precision engineering and automotive, aerospace, and defence industries drive strong demand. The manufacturing precision and quality excellence of Germany, Italy, France, and the UK enable these countries to lead the adoption process. The market experiences growth because industrial automation continues to expand and CNC-controlled multi-axis machines become more common, and customers seek out complex multi-part components. The operational precision and efficiency of modern technology systems get better through robotic integration and 5-axis, 6-axis machining, and intelligent monitoring systems. The market expansion receives backing from government programs, which promote Industry 4.0 and sustainable manufacturing practices. Energy-efficient equipment. Europe leads the worldwide market for multi-axis machining centres because of its commitment to innovation, precision, and operational excellence.

Asia Pacific Multi-axis Machining Centers Market Trends

The Asia Pacific multi-axis machining centers market led globally with the largest revenue share of 53.7% in 2024. The main factors behind this dominance stem from rapid industrial growth and expanding manufacturing operations, and rising demands for precision components in China, Japan, India, and South Korea. The region benefits from strong automotive, aerospace, electronics, and defence sectors, which drive the expansion of automation and robotic-assisted machining and CNC technology. The market expansion receives support from smart factory development and government initiatives. These promote both advanced manufacturing practices and workforce skill development. The Asia Pacific region stands as the largest and most rapidly expanding market for multi-axis machining centres because of technological advancements, cost-effective labour, and growing infrastructure development.

Key Multi-axis Machining Centers Companies:

The following are the leading companies in the multi-axis machining centers market. These companies collectively hold the largest market share and dictate industry trends.

- DMG MORI

- Starrag Group Holding AG

- Matsuura Machinery Corporation

- Haas Automation

- GF Machining Solutions

- Hurco Companies, Inc.

- Makino Milling Machine Co.

- GROB-WERKE GmbH & Co. KG

- Yamazaki Mazak

- FANUC Corporation

- Hardinge Inc.

- Others

Recent Developments

- In September 2025, Nidec OKK created the HX500, a 5-axis horizontal machining center intended for high-precision, high-performance machining of intricate parts for robotics, electric cars, and aeroplanes. The HX500 responds to the increasing industrial requirement for precision and efficiency in producing sophisticated parts in these quickly changing industries.

- In August 2025, Starrag unveiled the Heckert X80, a brand-new five-axis machining center intended to improve accuracy and productivity. This type, which builds on the Heckert HEC series, has a workpiece-side swivel unit that allows for complete 5-axis machining from a single clamping position.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Decision Advisors has segmented the multi-axis machining centers market based on the below-mentioned segments:

Global Multi-axis Machining Centers Market, By Axis Type

- 3-Axis

- 4-Axis

- 5-Axis

- 6-Axis & Above

Global Multi-axis Machining Centers Market, By Machine Type

- Vertical Machining Centers (VMC)

- Horizontal Machining Centers (HMC)

- Universal Machining Centers

Global Multi axis Machining Centers Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa