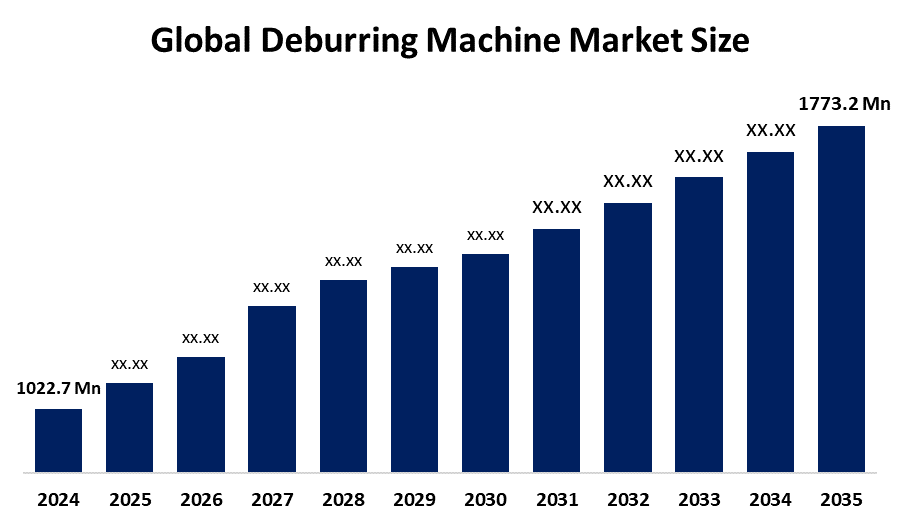

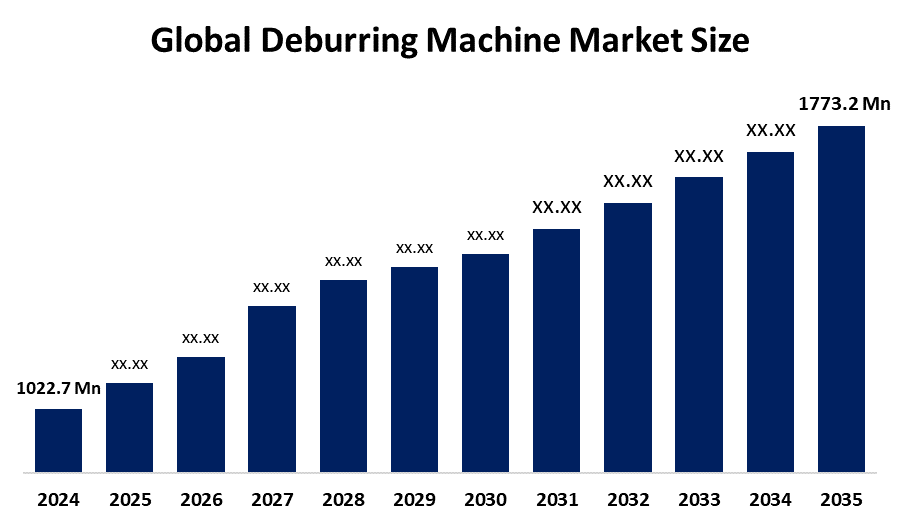

Global Deburring Machine Market Insights Forecasts to 2035

- The Global Deburring Machine Market Size Was Estimated at USD 1022.7 million in 2024

- The Market Size is Expected to Grow at a CAGR of around 5.13% from 2025 to 2035

- The Worldwide Deburring Machine Market Size is Expected to Reach USD 1773.2 million by 2035

- Europe is expected to grow the fastest during the forecast period.

Deburring Machine Market

The Deburring Machine Market Size includes machines that are used to remove small, rough edges or extra material left on parts after cutting, drilling, or shaping. These machines help make the surface of a product smooth and safe to handle. They are important in industries like automotive, aerospace, electronics, and metalworking, where clean and precise parts are needed. There are different types of deburring machines, such as manual, automatic, vibratory, and brush types, depending on the job and material. These machines improve the quality of products, save time by reducing the need for hand-finishing, and help make manufacturing more efficient. They can be used as separate machines or as part of a larger production system. As industries continue to focus on better quality and faster production, deburring machines remain an important tool in modern manufacturing processes.

Attractive Opportunities in the Deburring Machine Market

- The rising trend of Industry 4.0, including IoT and AI integration enables real-time monitoring, predictive maintenance, and enhanced machine performance. These smart technologies add value by improving operational efficiency and reducing downtime.

- As industries shift toward sustainable manufacturing, there is growing interest in dry or low-water deburring methods that minimize environmental impact, creating opportunities for green, energy-efficient deburring technologies.

- The expansion of additive manufacturing increases the need for post-processing solutions, including specialized deburring machines tailored to the unique requirements of 3D printed components.

Global Deburring Machine Market Dynamics

DRIVER: Rising demand for high-quality, precision-engineered components in industries

One major factor is the rising demand for high-quality, precision-engineered components in industries such as automotive, aerospace, and electronics. As these sectors require smooth and accurate parts for safety and performance, the need for reliable deburring solutions has increased. The growing adoption of automation in manufacturing processes is another important driver, as companies look to improve efficiency, reduce manual labor, and maintain consistent product quality. Technological advancements in deburring machines, including integration with robotics and CNC systems, also support market growth by offering faster and more precise finishing. Additionally, the increasing use of advanced materials in production, such as composites and high-strength metals, has created a demand for specialized deburring methods. The overall focus on improving productivity, reducing production time, and minimizing defects continues to push manufacturers toward modern deburring technologies and solutions.

RESTRAINT: High initial cost of advanced deburring equipment

One of the main challenges is the high initial cost of advanced deburring equipment, which can be a barrier for small and medium-sized enterprises. These machines often require significant investment in installation, maintenance, and skilled labor for operation, which can limit adoption. Additionally, the presence of alternative, lower-cost manual deburring methods in some industries can reduce the demand for automated solutions. Another challenge is the complexity of integrating deburring machines into existing production lines, especially in older facilities that may lack the infrastructure for automation. Some deburring processes also produce waste or require specific environmental controls, adding to operational costs. Moreover, varying material types and part geometries can make it difficult to find one-size-fits-all deburring solutions, leading to the need for customized machines that are more expensive and less flexible. These factors collectively slow down wider adoption in certain segments.

OPPORTUNITY: Rising trend of Industry 4.0 and the integration of smart technologies

One significant opportunity lies in the rising trend of Industry 4.0 and the integration of smart technologies, such as IoT and AI, into manufacturing systems. These innovations enable real-time monitoring, predictive maintenance, and improved machine performance, offering added value to end-users. Another growing opportunity is the demand for eco-friendly and energy-efficient deburring solutions as industries shift toward sustainable practices. This includes the development of dry or low-water deburring methods that reduce environmental impact. The expansion of 3D printing and additive manufacturing also opens new doors, as components produced through these methods often require post-processing, including deburring. Additionally, there is increasing potential in niche and custom applications, such as medical devices and precision electronics, where ultra-fine deburring is essential. Offering compact, modular, and easily programmable machines can also appeal to smaller manufacturers and workshops seeking flexible and affordable solutions.

CHALLENGES: Rapidly evolving manufacturing technologies and materials

One key challenge is keeping up with rapidly evolving manufacturing technologies and materials, which demand continuous innovation in deburring techniques. As new materials such as composites and alloys are introduced, traditional deburring methods may become less effective or even damaging, requiring ongoing R&D investment. Another challenge is ensuring consistent quality and performance across complex and intricate part geometries, especially in high-precision industries like aerospace and medical devices. Additionally, there is a lack of skilled operators and technicians who can manage and maintain advanced deburring systems, particularly in emerging markets. Customization requirements for different applications also pose a challenge, as they limit scalability and increase production complexity for manufacturers. Finally, meeting strict safety and compliance standards across various industries adds to design and certification burdens, making it more difficult for companies to launch new machines quickly and cost-effectively.

Global Deburring Machine Market Ecosystem Analysis

The global deburring machine market ecosystem includes machine manufacturers, raw material and component suppliers, technology providers, and system integrators. These entities work together to develop and deliver various deburring solutions. End-users from industries like automotive, aerospace, and electronics drive demand, while distributors and service providers ensure global reach and maintenance support. Regulatory bodies, research institutions, and industry associations contribute to safety compliance, innovation, and standardization. This interconnected ecosystem supports the continuous evolution and adoption of advanced deburring technologies across diverse manufacturing sectors.

Based on the type, the vibratory deburring segment led the market with the largest revenue share and is expected to grow at a significant CAGR over the forecast period

The vibratory deburring segment holds the largest revenue share in the global deburring machine market due to its widespread use and effectiveness. Vibratory deburring machines are highly efficient at processing large batches of parts simultaneously, making them ideal for industries that require mass production. They work by using vibration to create friction between parts and abrasive media, which helps remove burrs and smooth surfaces quickly and uniformly. This method is versatile and can be applied to various materials, including metals and plastics. Additionally, vibratory deburring reduces the need for manual labor, lowering production costs and improving consistency in finishing quality. These advantages make vibratory deburring machines a popular choice among manufacturers, contributing to their dominant market position and expected strong growth during the forecast period.

Based on the end-use, the automotive segment led the market with the largest revenue share and is expected to grow at a remarkable CAGR over the forecast period

The automotive segment dominance is due to the automotive industry’s high demand for precision and safety in components, which requires efficient deburring processes to remove sharp edges and improve part quality. As vehicles become more complex and manufacturers focus on lightweight materials and advanced designs, the need for reliable deburring solutions increases. The automotive sector’s emphasis on automation and high production volumes further drives the adoption of advanced deburring machines.

North America is anticipated to hold the largest market share of the deburring machine market during the forecast period

North America is anticipated to hold the largest market share in the deburring machine market during the forecast period. This is driven by the region’s well-established manufacturing base, particularly in the automotive, aerospace, and electronics industries, which demand high-precision deburring solutions. Advanced technological adoption, strong investment in automation, and stringent quality and safety standards further support market growth. Additionally, the presence of key market players and ongoing research and development activities contribute to North America’s leading position, making it a significant contributor to the global deburring machine market throughout the forecast period.

Europe is expected to grow at the fastest CAGR in the deburring machine market during the forecast period

Europe is expected to grow at the fastest CAGR in the deburring machine market during the forecast period. This rapid growth is attributed to the region’s strong focus on advanced manufacturing technologies and automation, particularly in sectors like automotive, aerospace, and industrial machinery. Increasing demand for high-precision components, along with strict environmental and safety regulations, drives the adoption of efficient deburring solutions. Additionally, Europe’s emphasis on innovation and sustainability encourages the development and use of eco-friendly deburring machines, further fueling market expansion. These factors collectively position Europe as the fastest-growing region in the global deburring machine market.

Recent Development

- In December 2024, PROCECO launched the ProClean 4000, a high-pressure water jet deburring system that utilizes advanced nozzle technology to effectively remove burrs from intricate parts without causing damage. This system is particularly advantageous for the electronics and aerospace industries, where component integrity is paramount.

Key Market Players

KEY PLAYERS IN THE DEBURRING MACHINE MARKET INCLUDE

- Cincinnati Incorporated

- Suhner Group

- Brush Research Manufacturing (BRM)

- Ercolina

- Cecil Wright Machinery Limited

- Buhler Group

- Rollwasch

- Baldwin Technology Company, Inc.

- Vikram Deburring Technologies

- Timesavers International B.V.

- Others

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the deburring machine market based on the below-mentioned segments:

Global Deburring Machine Market, By Type

- Vibratory Deburring

- Barrel Tumbling

- Thermal Deburring

Global Deburring Machine Market, By End-use

- Automotive

- Aerospace & Defense

Global Deburring Machine Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa