Global Aseptic Connectors & Welders Market Insights Forecasts To 2035

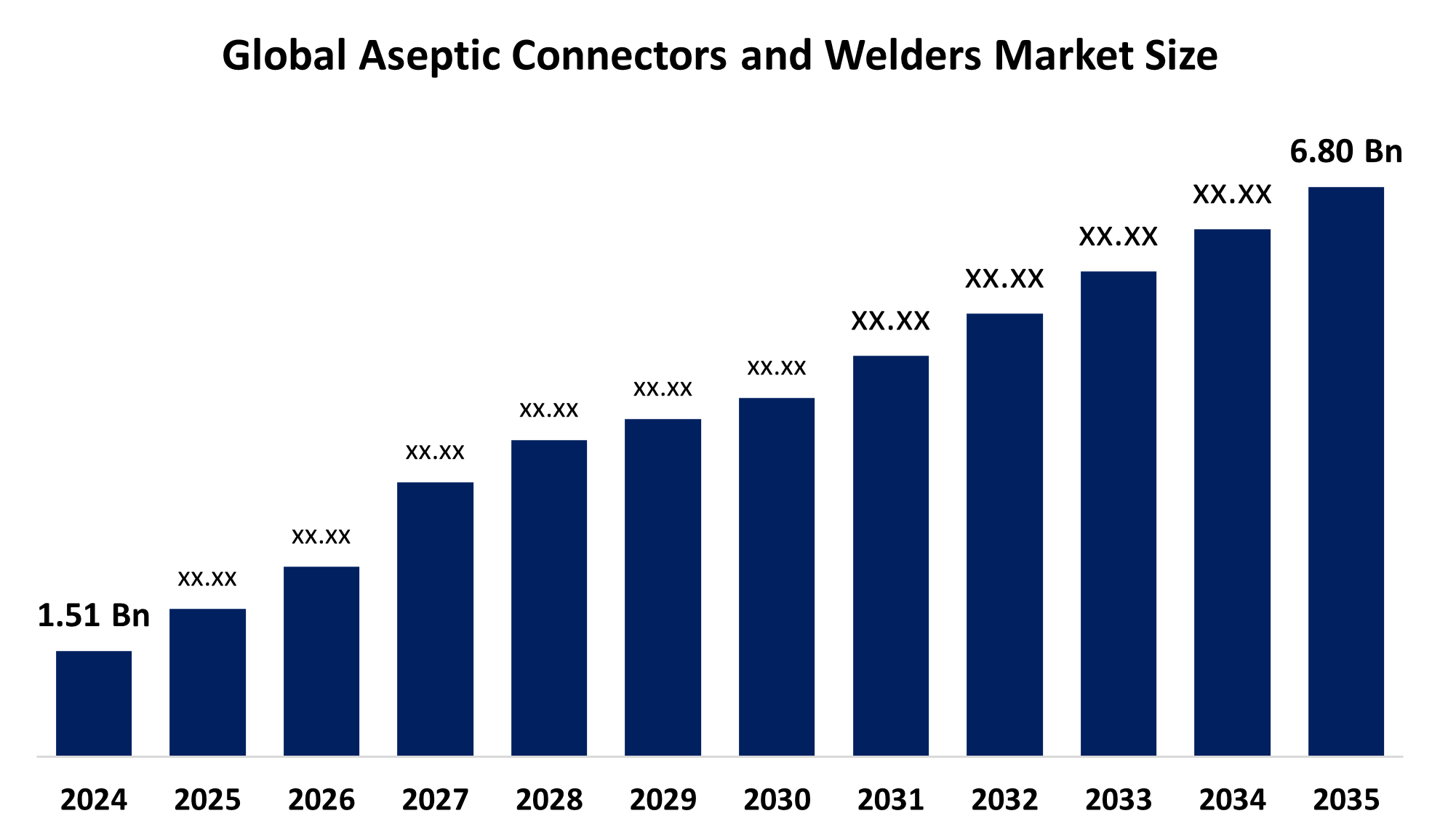

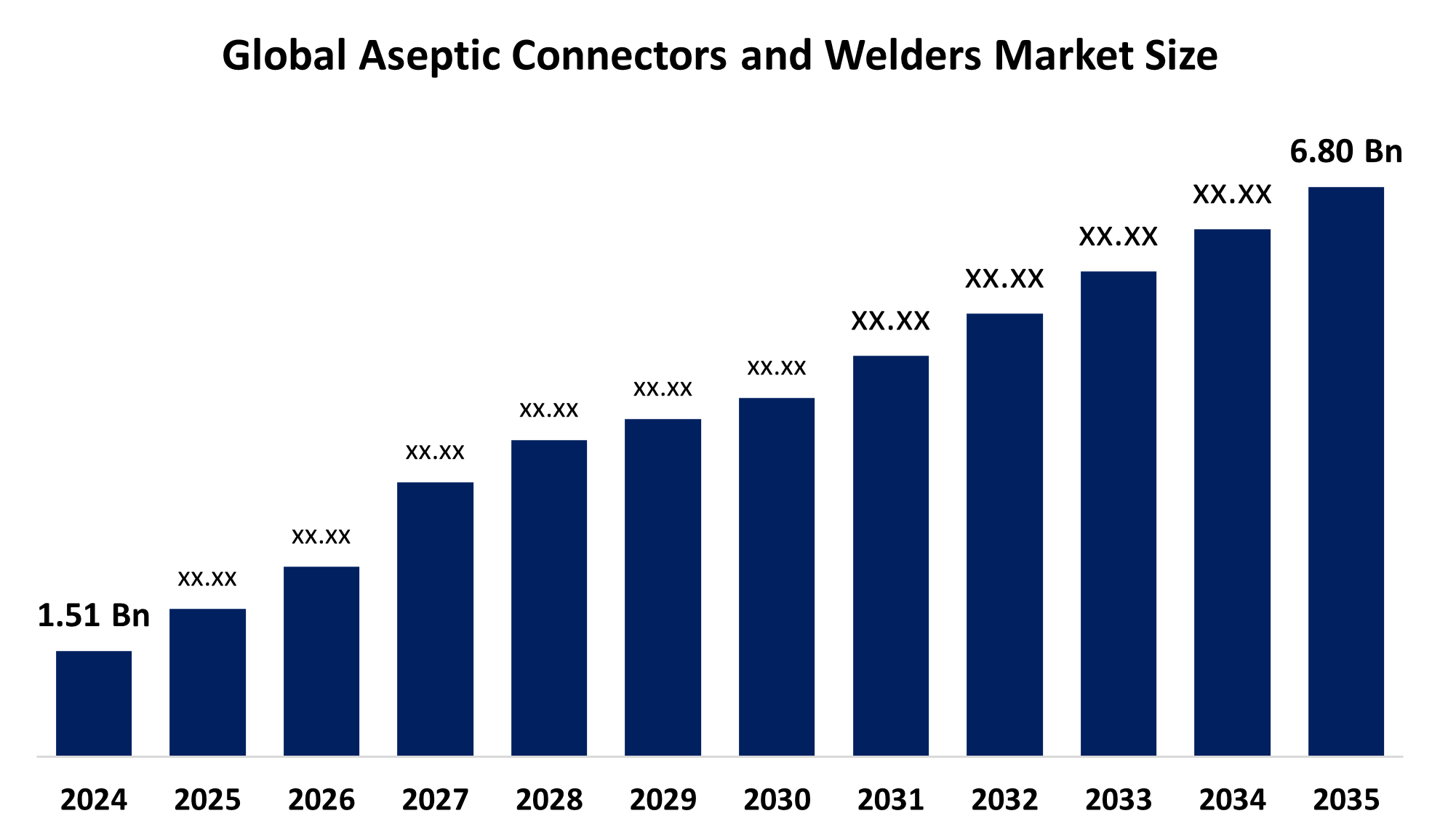

- The Global Aseptic Connectors and Welders Market Size Was Estimated at USD 1.51 Billion in 2024

- The Market Size is Expected to Grow at a CAGR of around 14.66% from 2025 to 2035

- The Worldwide Aseptic Connectors & Welders Market Size is Expected to Reach USD 6.80 Billion by 2035

- Asia Pacific is expected To Grow the fastest during the forecast period.

Aseptic Connectors & Welders Market

The aseptic connectors & welders market comprises products designed to ensure sterile fluid transfer and secure tubing connections, primarily serving the pharmaceutical and biopharmaceutical industries. Aseptic connectors play a vital role in maintaining contamination-free environments by providing reliable, sterile connections between equipment and tubing during drug manufacturing and packaging. These connectors are available in various types, including single-use and reusable, to meet different operational needs. Aseptic welders complement this technology by enabling sterile joining of tubing without adhesives or fittings, preserving the integrity of the product throughout the manufacturing process. The market is characterized by ongoing innovation and is dominated by key players such as Sartorius AG, Merck KGaA, Pall Corporation, and Thermo Fisher Scientific. These companies focus on developing advanced solutions that improve efficiency, safety, and compliance in sterile processing environments, reflecting the increasing demand for high-quality aseptic systems in drug production.

Attractive Opportunities in the Aseptic Connectors & Welders Market

- Leveraging digitalization and Industry 4.0 technologies for enhanced process control and traceability.

- Partnerships between connector manufacturers and pharmaceutical companies to develop application-specific aseptic products.

- Growing need for flexible aseptic connection systems that support seamless, uninterrupted production.

- New growth opportunities in industries like food & beverage and cosmetics requiring sterile fluid transfer.

Global Aseptic Connectors & Welders Market Dynamics

DRIVER: Rise of biologics, personalized medicines, and complex therapies

The rise of biologics, personalized medicines, and complex therapies requires advanced aseptic technologies to maintain product integrity and patient safety. Additionally, stringent regulatory standards and quality requirements compel manufacturers to adopt reliable aseptic connectors and welders that minimize contamination risks. The shift towards single-use systems also supports market growth by reducing cleaning validation and cross-contamination concerns. Innovations such as genderless connectors and automated welding solutions improve operational efficiency and simplify manufacturing workflows, further fueling adoption. Growing investments in sterile manufacturing facilities worldwide, alongside the expansion of contract manufacturing organizations (CMOs), also contribute to increased demand. Together, these factors create a robust market environment focused on enhancing sterility assurance, process reliability, and compliance with evolving industry standards.

RESTRAINT: High initial costs associated with advanced aseptic technologies

High initial costs associated with advanced aseptic technologies and equipment can be a barrier, especially for small and mid-sized manufacturers. Additionally, the complexity of integrating aseptic connectors and welders into existing manufacturing systems may require significant process adjustments and staff training, increasing operational challenges. Regulatory compliance demands, while driving adoption, also pose challenges due to evolving standards and the need for continuous validation and documentation, which can be time-consuming and costly. The limited awareness and understanding of newer aseptic technologies in certain regions or among smaller manufacturers may slow market penetration. Furthermore, competition from alternative connection and welding methods, such as traditional mechanical fittings or robotic welding systems, can restrict widespread adoption. Lastly, supply chain disruptions and raw material shortages could affect the availability and cost of aseptic components, potentially hindering market expansion.

OPPORTUNITY: Collaborations between connector manufacturers and pharmaceutical companies

Advances in digitalization and Industry 4.0, such as smart connectors with sensors for real-time monitoring and data analytics, offer opportunities to enhance process control and traceability. Collaborations between connector manufacturers and pharmaceutical companies to develop customized, application-specific solutions can create niche markets. The growing trend toward continuous manufacturing processes also drives demand for flexible, aseptic connection systems that support uninterrupted production. Additionally, expanding applications in non-pharmaceutical sectors, like food and beverage or cosmetics, provide new market segments. Investments in sustainable and eco-friendly aseptic solutions, such as recyclable or biodegradable materials, align with increasing environmental concerns and regulatory pressures, presenting another growth avenue. These opportunities collectively encourage innovation and diversification in the aseptic connectors and welders industry.

CHALLENGES: Ensuring compatibility between connectors and welders from different manufacturers

One significant challenge is ensuring compatibility between connectors and welders from different manufacturers, which can limit flexibility and create supply chain complexities. The development and validation of aseptic technologies must keep pace with rapidly evolving drug formulations and manufacturing techniques, requiring constant innovation and adaptation. Additionally, maintaining sterility during high-volume, continuous manufacturing processes presents technical difficulties, demanding robust and fail-safe connection systems. Skilled labor shortages and the need for specialized training to operate advanced aseptic equipment can hinder smooth implementation. Moreover, balancing the cost-effectiveness of single-use systems with environmental sustainability remains a challenge, as waste disposal regulations tighten globally.

Global Aseptic Connectors & Welders Market Ecosystem Analysis

The global aseptic connectors & welders market ecosystem involves key manufacturers like Sartorius, Merck, and Pall Corporation, who develop sterile connectors and welding technologies. Raw material suppliers provide medical-grade plastics essential for production. End-users include pharmaceutical companies and CMOs relying on these products for contamination-free drug manufacturing. Regulatory bodies such as the FDA set quality and safety standards, while service providers offer validation and training to ensure compliance. Collaboration among these players drives innovation, quality, and reliable sterile processing across the pharmaceutical and biopharmaceutical industries.

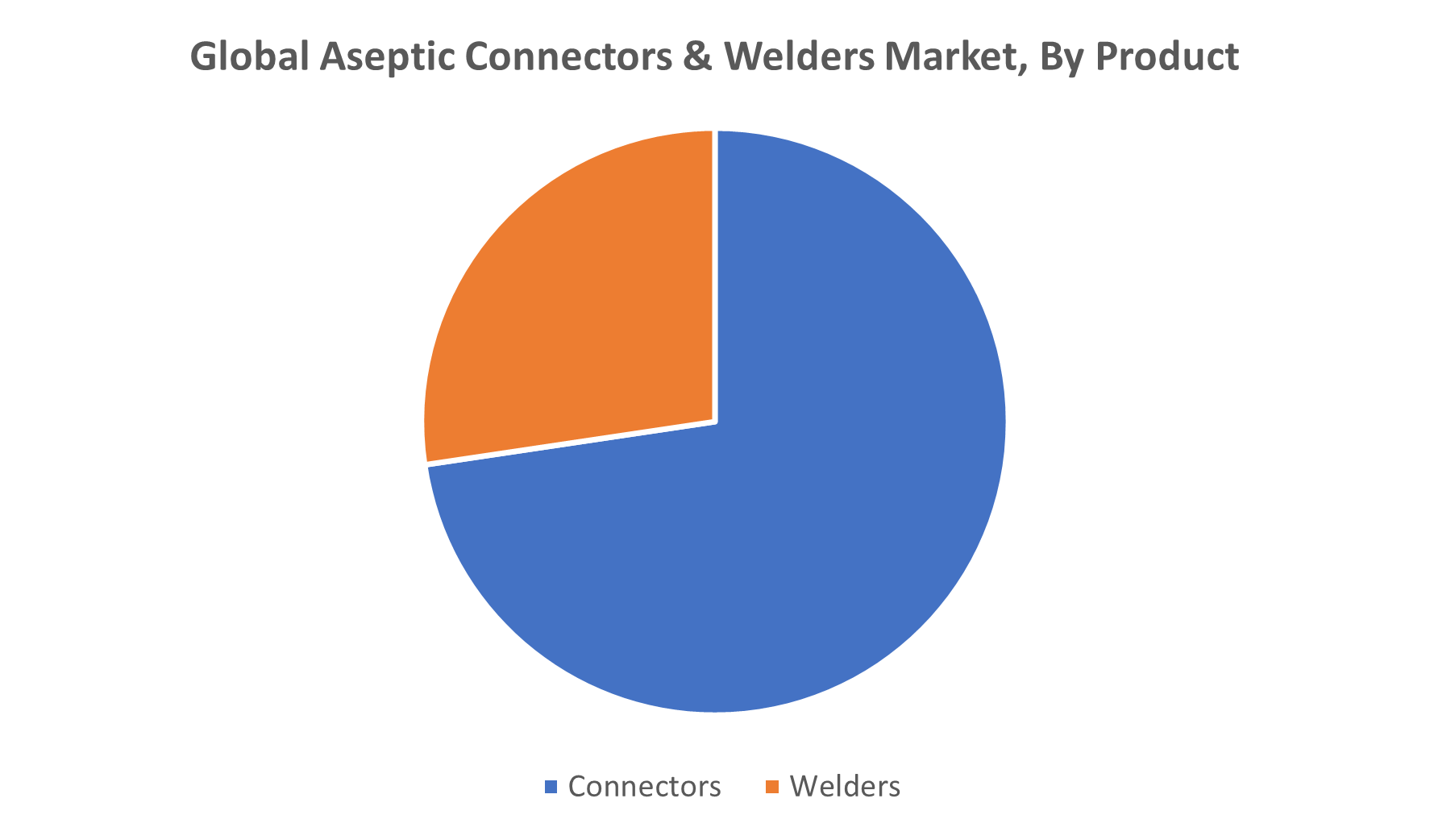

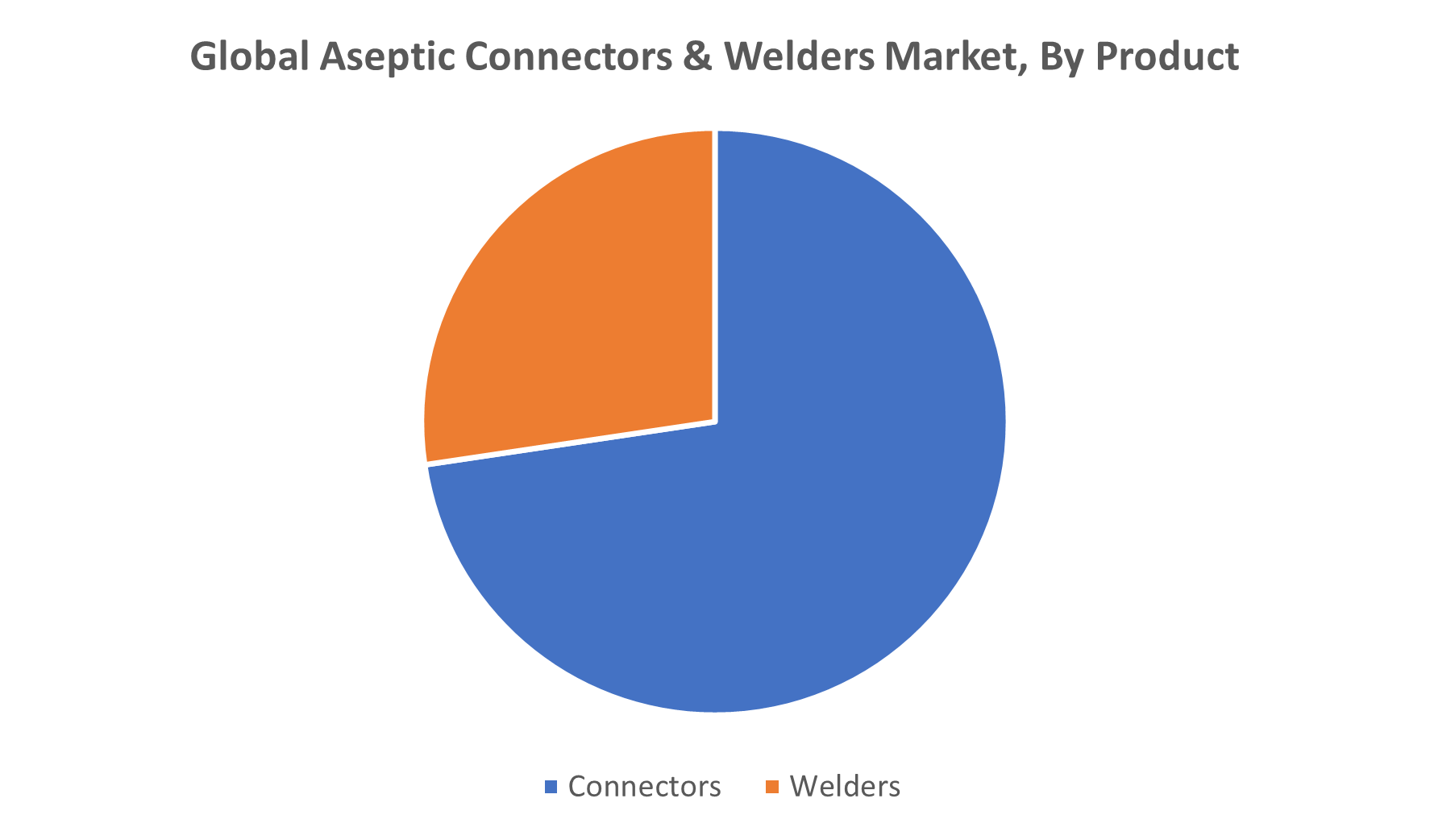

Based on the product, the connectors segment held the largest market share and is expected to grow at a substantial CAGR over the forecast period

The connectors segment holds the largest share in the global aseptic connectors & welders market due to its critical role in maintaining sterile fluid pathways in pharmaceutical and biopharmaceutical manufacturing. Increasing adoption of single-use systems drives demand by simplifying sterile connections and reducing contamination risks. Innovations like genderless connectors improve ease of use and reduce errors, enhancing operational efficiency. Growth in biologics and personalized medicines, which require stringent sterility, also boosts this segment. Additionally, connectors support scalable and flexible manufacturing, helping producers adapt quickly to changing needs.

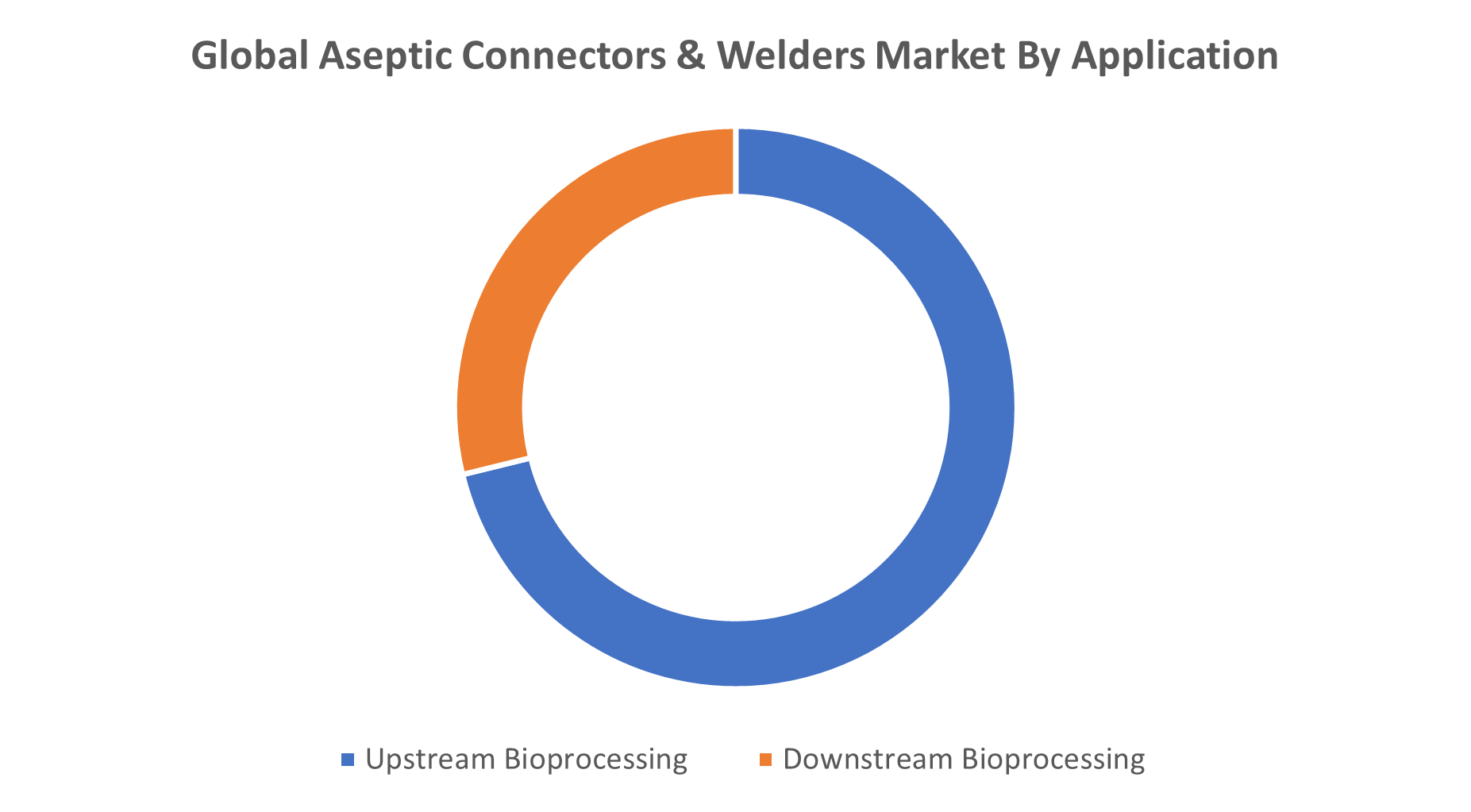

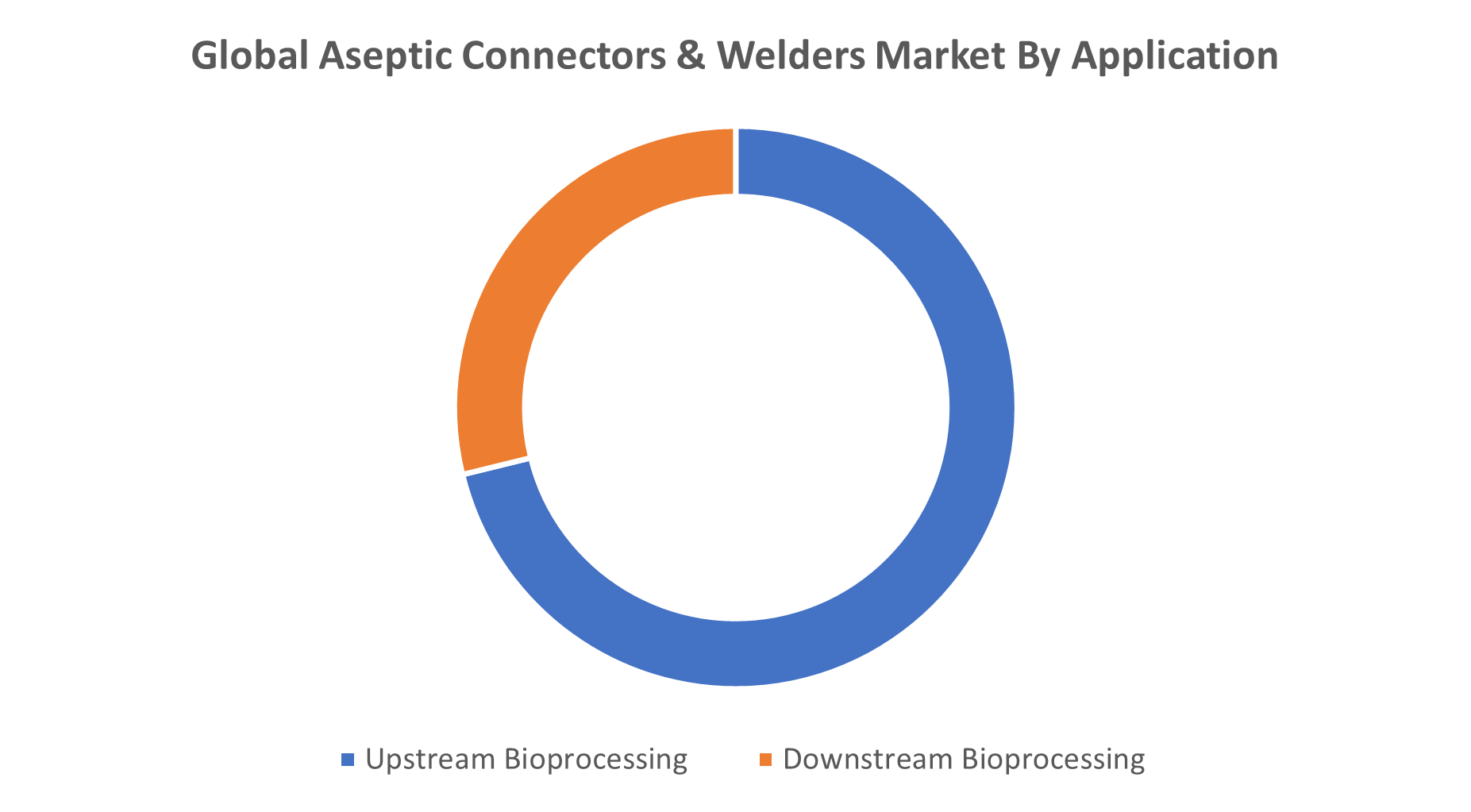

Based on the application, the upstream bioprocessing segment is projected to grow at the fastest CAGR over the forecast period

The growth is driven by increasing demand for sterile fluid transfer during early-stage biopharmaceutical production processes such as cell culture and fermentation. Aseptic connectors and welders play a crucial role in maintaining contamination-free environments essential for sensitive biological materials. As biopharmaceutical companies expand upstream operations to meet rising biologics demand, the need for reliable aseptic technologies in this segment is rapidly increasing, fueling strong market growth.

North America is anticipated to hold the largest market share of the aseptic connectors & welders market during the forecast period

North America is anticipated to hold the largest market share in the aseptic connectors & welders market during the forecast period. This dominance is driven by the region’s well-established pharmaceutical and biopharmaceutical industries, strong presence of key market players, and advanced manufacturing infrastructure. Additionally, stringent regulatory standards from agencies like the FDA promote the adoption of high-quality aseptic technologies to ensure product safety and compliance. Significant investments in research and development, along with growing demand for biologics and personalized medicines, further contribute to market growth. These factors collectively position North America as the leading regional market for aseptic connectors and welders.

Asia Pacific is expected to grow at a significant CAGR in the aseptic connectors & welders market during the forecast period

Asia Pacific is expected to grow at a significant CAGR in the aseptic connectors & welders market during the forecast period. This growth is fueled by the rapid expansion of the pharmaceutical and biopharmaceutical industries in countries like China, India, and Japan. Increasing investments in sterile manufacturing facilities, rising demand for biologics, and growing adoption of advanced aseptic technologies contribute to the region’s strong market potential. Additionally, improving healthcare infrastructure and supportive government initiatives aimed at boosting local drug production further accelerate market growth in the Asia Pacific, making it one of the fastest-growing regions globally.

Recent Development

- In April 2023, Colder Products Company (CPC), part of Dover Corporation, launched the AseptiQuik® W Series, the industry's largest genderless aseptic connectors. These 1-1/2-inch flow path connectors enable the transfer of hundreds of liters per minute, significantly reducing fluid transfer times across bioprocesses. This innovation supports the growing trend toward large-scale, single-use bioprocessing systems.

Key Market Players

KEY PLAYERS IN THE ASEPTIC CONNECTORS & WELDERS MARKET INCLUDE

- Sartorius AG

- Merck KGaA

- Pall Corporation

- Colder Products Company (CPC)

- Thermo Fisher Scientific

- Aseptic Group

- Saint-Gobain Performance Plastics

- Watson-Marlow Fluid Technology Group

- Bürkert Fluid Control Systems

- Tecan Group

- Others

Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the aseptic connectors & welders market based on the below-mentioned segments:

Global Aseptic Connectors & Welders Market, By Product

Global Aseptic Connectors & Welders Market, By Application

- Upstream Bioprocessing

- Downstream Bioprocessing

Global Aseptic Connectors & Welders Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa