World’s Top 40 Companies in Non-Woven Glass Fibre Prepreg Market 2025 Watchlist: Statistical Report (2024–2035)

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

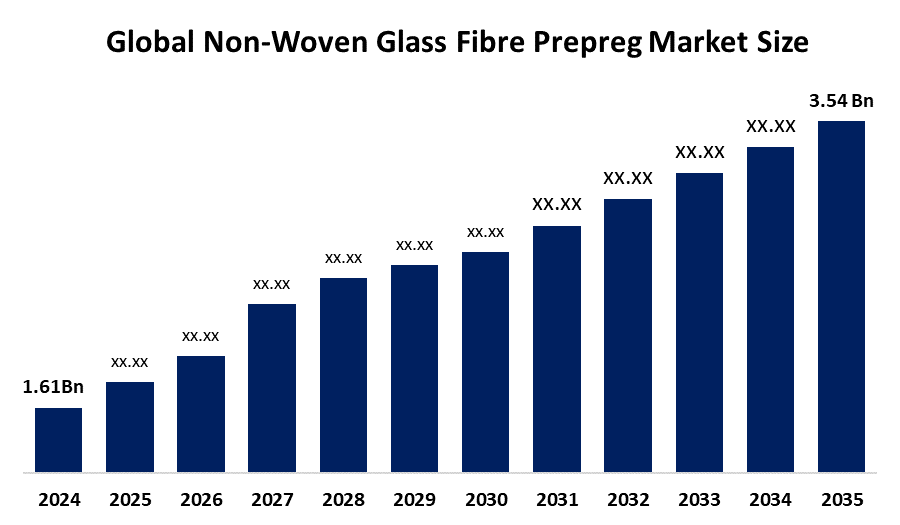

According to a research report published by Spherical Insights & Consulting, The Global Non-Woven Glass Fibre Prepreg Market Size is projected to Grow from USD 1.61 Billion in 2024 to USD 3.54 Billion by 2035, at a CAGR of 7.43% during the forecast period 2025–2035. The rising need for lightweight, durable, and high-performance materials across industries like aerospace, automotive, and construction is fueling the market's expansion. The growing emphasis on sustainability and energy efficiency is driving the market's growth as producers look for materials that provide better strength-to-weight ratios and improved performance traits.

Introduction

The non-woven glass fibre prepreg industry pertains to the field centred on materials made of glass fibres that are pre-impregnated with resin systems, creating a composite utilised for high-performance structural purposes. These prepregs are made using a non-woven technique, where glass fibre mats are fused with resins like epoxy, phenolic, or bismaleimide to form sheets that exhibit consistent strength, lightweight characteristics, and superior dimensional stability. Non-woven glass fibre prepregs offer excellent mechanical strength, corrosion resistance, and thermal stability, rendering them vital in sectors like aerospace, wind energy, automotive, construction, and electronics. These materials promote sustainable manufacturing practices by lowering energy consumption and emissions, while offering remarkable durability across various industrial uses. The growth of the non-woven glass fibre prepreg market is also being driven by the construction industry. The demand for lightweight, strong, and long-lasting materials in construction, especially for high-rise structures and infrastructure projects, has resulted in a rise in the use of non-woven glass fibre prepregs. These materials offer great load-bearing strength, durability against environmental elements, and simple installation, making them perfect for contemporary building uses.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Non-Woven Glass Fibre Prepreg Market.

Non-Woven Glass Fibre Prepreg Market Size & Statistics

- The Market Size for Non-Woven Glass Fiber Prepreg Was Estimated to be worth USD 1.61 Billion in 2024.

- The Market size is Going to Expand at a CAGR of 7.43% between 2025 and 2035.

- The Global Non-Woven Glass Fibre Prepreg Market Size is anticipated to reach USD 3.54 Billion by 2035.

- Asia Pacific is anticipated to generate the highest demand during the forecast period in the non-woven glass fibre prepreg market.

- Europe is projected to grow the fastest during the forecast period in the non-woven glass fibre prepreg market.

Regional growth and demand

Europe is estimated to grow the fastest during the forecast period in the non-woven glass fibre prepreg market. Europe represents a key market for non-woven glass fibre prepregs, spurred by the robust automotive and aerospace sectors in the region. The growing use of lightweight and strong materials in these industries, along with strict emission standards, is anticipated to increase the need for non-woven glass fibre prepregs in Europe. Moreover, the area's emphasis on renewable energy, especially wind power, is expected to bolster market expansion. Nations like Germany, France, and the United Kingdom are anticipated to play significant roles in the market's growth in Europe.

Asia Pacific is expected to generate the highest demand during the forecast period in the non-woven glass fibre prepreg market. The Asia Pacific area is expected to experience the fastest growth in the non-woven glass fibre prepreg market, fueled by swift industrialisation, urban development, and the expanding aerospace and automotive industries. Nations such as China, Japan, and India are making significant investments in infrastructure expansion and cutting-edge manufacturing technologies, anticipated to boost the need for non-woven glass fibre prepregs. The area's emphasis on sustainability and energy efficiency, combined with supportive government policies and rising foreign investments, is expected to fuel market expansion.

Top 10 trends in the Non-Woven Glass Fiber Prepreg Market

- Thermosetting Prepreg Dominance

- Vacuum Bag Processing Preference

- Wind Energy Expansion

- Automotive Lightweighting

- Marine and Aerospace Applications

- Epoxy Resin Leadership

- E-Glass Fibre Preference

- Asia-Pacific Market Surge

- Sustainability and Recycling Focus

- Digital Manufacturing Integration

1. Thermosetting Prepreg Dominance

Thermosetting types (notably epoxy-based) are projected to maintain more than 60% of the market share because of their excellent mechanical characteristics and heat resistance.

2. Vacuum Bag Processing Preference

Vacuum bagging is the predominant processing technique, representing almost 55% of demand, fueled by its effectiveness in the aerospace and automotive sectors.

3. Wind Energy Expansion

Wind turbine blades represent a significant growth area, as rising global installations are driving the need for strong, lightweight prepregs.

4. Automotive Lightweighting

OEMs are utilising non-woven glass fibre prepregs to decrease vehicle weight and enhance fuel efficiency, particularly in EVs.

5. Marine and Aerospace Applications

High-performance composites are becoming popular in marine hulls and aerospace interiors because of their corrosion resistance and strength-to-weight ratio.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the non-woven glass fibre prepreg market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the Non-Woven Glass Fibre Prepreg Market

- Owens Corning

- Hexcel Corporation

- Gurit Holding AG

- SGL Carbon SE

- Toray Industries, Inc.

- Teijin Limited

- Mitsubishi Chemical Corporation

- Jushi Group Co., Ltd.

- Chomarat Group

- Saertex GmbH & Co. KG

- Axiom Materials, Inc.

- Porcher Industries

- Gurit Holding AG

- Royal DSM

- Johns Manville

- PPG Industries, Inc.

- Bally Ribbon Mills

- Huntsman Corporation

- Solvay S.A.

- AGY Holding Corp.

1. Owens Corning

Headquarters: Ohio, USA

Owens Corning is a worldwide frontrunner in glass fibre reinforcements and engineered composite materials, featuring non-woven glass fibre prepregs utilised across various sectors like wind energy, industrial, transportation, and consumer markets. The firm provides enhanced glass fibre reinforcements that boost mechanical performance, corrosion resistance, and lightweight structural qualities vital for composite applications. Owens Corning’s non-woven glass fibre offerings aid in producing prepregs that are essential in sectors requiring resilience, strength, and eco-friendly material options. Owens Corning recently disclosed the sale of its glass fibre reinforcements division to Praana Group as a strategic move to concentrate on residential and commercial building products, while still providing innovative materials for global composites markets.

2. Hexcel Corporation

Headquarters: Stamford, Connecticut, USA

Hexcel Corporation is a worldwide leader in the production of advanced composites, focusing on prepregs, particularly glass fibre prepreg solutions intended for aerospace, wind energy, marine, automotive, and various industrial uses. Hexcel’s HexPly range includes prepregs that are reinforced with woven, multiaxial, and unidirectional glass fibres along with different resin matrix systems (epoxy, phenolic, and BMI). These fabric-reinforced and non-woven prepregs provide excellent strength, durability, controlled flow, fire resistance, and dimensional stability. Widely utilised for substantial structural elements and sandwich constructions, Hexcel's offerings deliver outstanding mechanical and adhesive characteristics ideal for exacting, high-performance needs. The firm’s advancements in prepreg technology and worldwide supply chain establish it as a major provider in the non-woven glass fibre prepreg sector.

3. Gurit Holding AG

Headquarters: Wattwil, Switzerland

Gurit Holding AG is a prominent worldwide producer and provider of advanced composite materials, focusing on fibre-reinforced prepregs, including non-woven glass fibre prepregs, structural core materials, adhesives, and formulated resins. The firm offers an extensive selection of prepregs tailored for marine and industrial structural uses, in addition to wind energy, automotive, and civil engineering. Gurit’s non-woven glass fibre prepreg offerings integrate E-glass and additional high-performance fibres with cutting-edge resin systems to provide outstanding mechanical properties, lightweight design, and simplified processing for large intricate structures. Gurit holds a considerable position in the worldwide non-woven glass fibre prepreg sector, emphasising innovation and comprehensive composite solutions with a robust international presence.

4. SGL Carbon SE

Headquarters: Wiesbaden, Germany

SGL Carbon SE is a leading German producer focused on carbon-based and composite materials, featuring premium non-woven glass fibre prepregs. SGL Carbon provides pre-impregnated materials in its SIGRAPREG product line, utilising carbon, glass, and aramid fibres in various formats, such as non-woven structures. These prepregs are designed for peak performance in applications demanding lightweight, high-strength reinforcement, including wind energy, automotive, aerospace, marine, and construction industries. SGL Carbon’s knowledge in advanced fibre processing and resin infusion technology guarantees dependable mechanical characteristics, corrosion resistance, and outstanding stability, positioning it as a key supplier to the expanding worldwide non-woven glass fibre prepreg market.

5. Toray Industries, Inc.

Headquarters: Chuo-ku, Tokyo

Toray Industries, Inc. is a top worldwide producer and innovator in advanced composite materials, such as non-woven glass fibre prepregs. Toray utilises more than 40 years of experience in thermoplastic and thermoset composite technologies to provide tailored prepreg solutions for aerospace, automotive, wind energy, industrial, and sports equipment sectors. The firm’s non-woven glass fibre prepregs integrate high-performance glass fibre mats with superior resin systems, offering lightweight, high-strength composite sheets that exhibit excellent mechanical properties, corrosion resistance, and stability. Toray’s worldwide reach and research capabilities reinforce its status as a leading supplier, meeting the increasing demand for lightweight and eco-friendly materials across global sectors.

Are you ready to discover more about the non-woven glass fibre prepreg market?

The report provides an in-depth analysis of the leading companies operating in the global non-woven glass fibre prepreg market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Owens Corning

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Hexcel Corporation

- Gurit Holding AG

- SGL Carbon SE

- Toray Industries, Inc.

- Teijin Limited

- Mitsubishi Chemical Corporation

- Jushi Group Co., Ltd.

- Chomarat Group

- Saertex GmbH & Co. KG

- Axiom Materials, Inc.

- Porcher Industries

- Gurit Holding AG

- Royal DSM

- Johns Manville

- PPG Industries, Inc.

- Bally Ribbon Mills

- Huntsman Corporation

- Solvay S.A.

- AGY Holding Corp.

- Others

Conclusion

The worldwide non-woven glass fibre prepreg market is poised for significant growth, with its worth expected to increase from USD 1.61 billion in 2024 to USD 3.54 billion by 2035, reaching a strong CAGR of 7.43%. This expansion is mainly fueled by the increasing need for lightweight, durable, and high-performance composites in key end-use industries, notably wind energy, automotive lightweighting (especially for electric vehicles), and construction. The Asia-Pacific region is expected to capture the largest market share, driven by rapid industrialisation, whereas Europe is estimated to experience the quickest growth, backed by strict emission regulations and a strong emphasis on renewable energy. The competitive environment includes worldwide composites frontrunners such as Owens Corning, Hexcel, Gurit Holding AG, and SGL Carbon SE, all focusing on advanced thermosetting (epoxy-based) prepregs to address the increasing demand for effective and sustainable structural materials.

Browse Related Reports

Global Fluid Catalytic Cracking Market Size Exceed to USD 34.78 Billion by 2035| CAGR of 3.88% : Forecast Analysis Report

Global Beauty And Personal Care Surfactants Market Size Exceed to USD 20.05 Billion by 2035| CAGR of 5.6% : Market Statistics Report

Global Release Agents Market Size Exceed to USD 2.22 Billion by 2035| CAGR of 5.83% : Market Insight Report

Global Flame Retardant Market Size Exceed to USD 20.88 Billion by 2035| CAGR of 7.02% : Industry Report

Global Medical Waste Management Market Size: Key Insights & Innovations (2024-2035)

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?