World’s Top 40 Aluminum Alloys Market 2025: Watchlist Statistical Report (2024–2035)

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

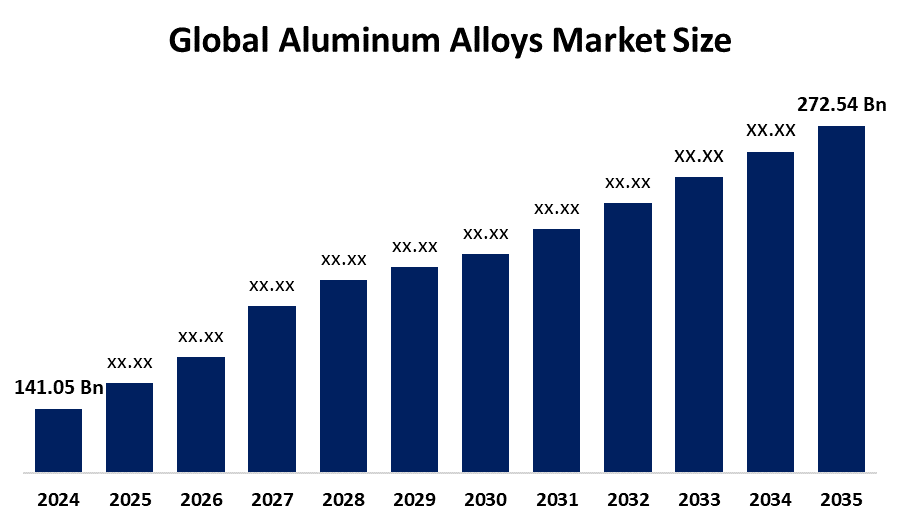

According to a research report published by Spherical Insights & Consulting, The Global Aluminum Alloys Market Size is projected to Grow from USD 141.05 Billion in 2024 to USD 272.54 Billion by 2035, at a CAGR of 6.17% during the forecast period 2025–2035. The global aluminum alloys market is witnessing strong, fueled by automotive industry demand, aerospace applications, and innovations in alloying, additive manufacturing.

Introduction

The Aluminum Alloys Market Size refers to the global industry involved in producing and supplying alloys primarily composed of aluminum combined with elements such as copper, magnesium, silicon, or zinc. These alloys are prized for their lightweight, high strength, corrosion resistance, and excellent thermal and electrical conductivity, making them suitable for diverse applications across automotive, aerospace, construction, electronics, and medical industries. Aluminum alloys enable manufacturers to reduce structural weight, enhance fuel efficiency, and improve overall product performance. Artificial intelligence (AI) in manufacturing improves alloy composition, optimizes resource use, reduces mistakes, and increases production efficiency. The expanding use of 3D printing for aluminum components enables the creation of complicated geometries with minimum waste, especially in aerospace, automotive, and medical applications. Rising demand for lightweight automotive components and environmentally friendly building materials is propelling market expansion. However, price volatility and the availability of replacement materials, such as carbon fiber and thermoplastics, pose obstacles. Germany's Aluminum Alloys Market is rising due to strong automotive and aerospace industries, emphasis on light weighting, and the country's focus on innovation and sustainable manufacturing.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Aluminum Alloys Market.

Aluminum Alloys Market Size & Statistics

- The Market Size for Aluminum Alloys Was Estimated to be worth USD 141.05 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 6.17% between 2025 and 2035.

- The Global Aluminum Alloys Market Size is anticipated to reach USD 272.54 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Aluminum Alloys Market

- North America is expected to grow the fastest during the forecast period in the Aluminum Alloys Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Aluminum Alloys market. North America is expected to grow fastest due to strong automotive and aerospace industries, increasing adoption of lightweight aluminum components, advanced manufacturing technologies like AI and 3D printing, and strict regulatory focus on fuel efficiency and emission reduction.

Asia Pacific is expected to generate the highest demand during the forecast period in the Aluminum Alloys market. Asia Pacific is expected to generate the highest demand due to rapid industrialization, expanding automotive and aerospace sectors, growing electronics and construction industries, increasing infrastructure development, and rising adoption of lightweight, high-performance aluminum components in countries like China, India, and Japan.

Top 10 Trends in the Aluminum Alloys Market

- Heat-Treatment-Free High-Strength Alloys

- Electric Vehicle (EV) Dominance

- Aerospace and Defense Light weighting

- Additive Manufacturing (3D Printing)

- Sustainable and Recycled Materials

- High-Strength Alloys for Infrastructure

- New Energy Applications

- Advanced Composite Materials

- Increased Use of Rare Earth Elements

- Focus on Corrosion and Weldability

1. Heat-Treatment-Free High-Strength Alloys

New aluminum alloys that reach high strength without heat treatment are becoming popular. These alloys save production time and energy consumption while preserving mechanical performance, making them excellent for automotive, aerospace, and industrial applications that need efficiency and durability.

2. Electric Vehicle (EV) Dominance

The popularity of electric vehicles is increasing demand for lightweight aluminum alloys for battery housings, chassis, and structural components. Reducing vehicle weight increases battery efficiency and driving range, pushing OEMs to utilize more aluminum alloys in EV production.

3. Aerospace and Defense Light weighting

Aluminum alloys are used extensively in aerospace and defense for airframes, fuselages, wings, and missile components. Their strength-to-weight ratio enables fuel-efficient airplanes, larger payloads, and durable defense equipment, promoting continuing usage in these industries.

4. Additive Manufacturing (3D Printing)

3D printing with aluminum alloys enables the creation of complicated, lightweight components with little material waste and quicker manufacturing cycles. This trend serves applications in the aerospace, automotive, and medical industries, which require accuracy and customization.

5. Sustainable and Recycled Materials

The market is increasingly focusing on recycled aluminum alloys and environmentally friendly manufacturing processes. High recyclability reduces energy consumption and carbon emissions, supporting global sustainability goals and lowering production costs.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the aluminum alloys market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the Aluminum Alloys Market

- Alcoa Corporation

- Rio Tinto Group

- Norsk Hydro ASA

- China Hongqiao Group Limited

- Rusal (United Company RUSAL Plc)

- Emirates Global Aluminium (EGA)

- Hindalco Industries Limited

- Aluminium Bahrain B.S.C. (Alba)

- South32 Limited

- Century Aluminum Company

- Kaiser Aluminum Corporation

- Constellium SE

- Vedanta Limited

- Novelis Inc.

- Arconic Corporation

- Aleris Corporation

- EGA (Emirates Global Aluminium)

- Alumina Limited

- Chalco (Aluminum Corporation of China Limited)

- JW Aluminum Company

- Shandong Xinfa Aluminium Group

- East Hope Group Company Limited

- UACJ Corporation

- Gränges AB

- Zetwerk

1. Alcoa Corporation

Headquarters: Pittsburgh, Pennsylvania, USA

Alcoa Corporation, based in Pittsburgh, Pennsylvania, is a major global manufacturer of aluminum and aluminum alloys. The firm provides high-quality materials to the aerospace, automotive, construction, and packaging sectors, offering lightweight, long-lasting, corrosion-resistant solutions. Its aluminum alloys are utilized in aircraft constructions, car components, building facades, and packaging materials to promote efficiency and sustainability. Alcoa runs production and recycling plants in more than ten countries, including North America, South America, Europe, and Australia. Alcoa is a key driver of growth and technical progress in the worldwide aluminum alloys market, thanks to innovation, superior manufacturing processes, and a focus on sustainable practices.

2. Rio Tinto Group

Headquarters: London, United Kingdom

Rio Tinto Group, based in London, United Kingdom, is a significant worldwide mining and metals corporation that produces aluminum, bauxite, and alumina. The firm provides high-quality aluminum products to the automotive, aerospace, construction, and packaging sectors, promoting light weighting and environmentally friendly solutions. Rio Tinto is present in approximately 35 countries, with large activities in Australia, Canada, the United States, and South America. Its modern manufacturing processes and commitment to environmental responsibility provide constant quality and performance. Rio Tinto makes important contributions to global industrial applications and the growth of the aluminum alloys industry by supplying robust and adaptable aluminum alloys.

3. NORSK HYDRO ASA

Headquarters: Oslo, Norway

Norsk Hydro ASA, based in Oslo, Norway, is a major aluminum company that manufactures rolled products, extrusions, and raw aluminum. The firm, which serves the automotive, construction, and industrial sectors, stresses lightweight, durable, and sustainable materials. Norsk Hydro operates in approximately 40 countries, including Europe, North America, and Asia, ensuring a broad market reach. Its emphasis on recycling and environmentally responsible production contributes to global sustainability goals while producing high-performance aluminum alloys. Norsk Hydro, through innovation, innovative processing processes, and devotion to quality, plays a crucial role in satisfying rising industrial demand and expanding the worldwide aluminum alloys industry.

4. China Hongqiao Group Limited

Headquarters: Shandong, China

China Hongqiao Group Limited, based in Shandong, China, is the world's largest aluminum producer by output. The firm produces primary aluminum, rolled products, and alloys for the automotive, packaging, and construction sectors. It has a substantial international reach, operating and partnering in over ten countries, including Asia, Europe, and Africa. China Hongqiao specializes in large-scale production, cost-effectiveness, and innovation in aluminum alloy technology. Its products promote light weighting, structural strength, and sustainability objectives. China Hongqiao helps industrial growth by delivering high-quality aluminum alloys internationally, meeting expanding demand across diverse sectors.

5. Rusal

Headquarters: Moscow, Russia

Rusal, headquartered in Moscow, Russia, is one of the world’s largest aluminum producers, offering primary aluminum, value-added products, and alloys. Serving aerospace, automotive, packaging, and construction industries, Rusal provides lightweight, strong, and corrosion-resistant aluminum solutions. The company operates in over 20 countries, including Russia, Guinea, Ireland, and Italy, ensuring a global supply network. Rusal emphasizes innovation, advanced production technologies, and sustainable practices, including recycling initiatives. By delivering high-performance aluminum alloys for diverse industrial applications, Rusal plays a significant role in meeting global demand, supporting technological advancement, and driving growth in the worldwide aluminum alloys market.

Are you ready to discover more about the aluminum alloys market?

The report provides an in-depth analysis of the leading companies operating in the global aluminum alloys market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Alcoa Corporation

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Rio Tinto Group

- NORSK HYDRO ASA

- China Hongqiao Group Limited

- Rusal

- Emirates Global Aluminium (EGA)

- Hindalco Industries Limited

- Aluminium Bahrain B.S.C. (Alba)

- South32 Limited

- Others.

Conclusion

The Global Aluminum Alloys Market Size is experiencing robust growth, driven by increasing demand from automotive, aerospace, construction, electronics, and packaging industries. Aluminum alloys’ lightweight, high-strength, corrosion-resistant, and versatile properties make them ideal for fuel-efficient vehicles, aircraft, durable infrastructure, and electronic devices. Technological advancements, including AI-assisted manufacturing, 3D printing, and sustainable recycling practices, are enhancing production efficiency, precision, and environmental sustainability. Rising adoption of electric vehicles and the push for lightweight, energy-efficient solutions further accelerate market expansion. Despite challenges such as price fluctuations and competition from substitutes like carbon fiber, aluminum alloys remain essential for industrial innovation and global demand growth.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?