Top 40 Companies in Binder Jetting 3D Printing Market: Statistics Report Till 2035

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

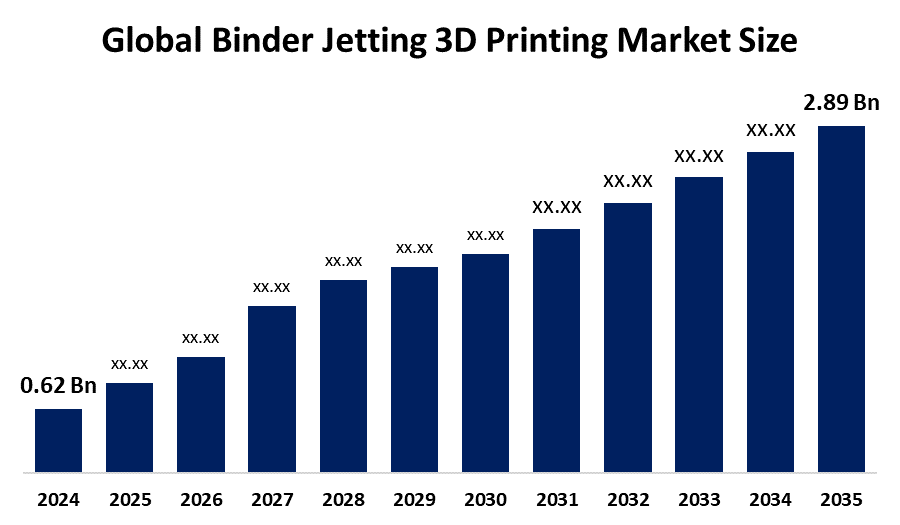

According to a research report published by Spherical Insights & Consulting, The Global Binder Jetting 3D Printing Market Size is projected To Grow from USD 0.62 Billion in 2024 to USD 2.89 Billion by 2035, at a CAGR of 15.02% during the forecast period 2025–2035. The expansion of the binder jetting 3D printing market is greatly affected by the adaptability and scalability provided by binder jetting technology. In contrast to other additive manufacturing techniques, binder jetting allows for the creation of intricate shapes and sizable parts rapidly while generating little material waste. This effectiveness attracts sectors like automotive and aerospace, where there is a strong need for lightweight designs and tailored components. Moreover, the capability of binder jetting to utilise various materials like metals, ceramics, and sand has expanded its range of applications, driving market growth even further.

Introduction

The Binder Jetting 3D Printing Market Size refers to the global sector focused on the creation, manufacturing, and application of binder jetting technology—a distinct additive manufacturing technique that utilises a liquid binding agent to selectively unite powder particles layer by layer. Binder Jetting is an additive manufacturing technique where an industrial printhead accurately applies a liquid binder onto successive layers of a powder bed, uniting the designated regions. This method constructs a 3D object layer by layer directly from digital CAD designs. The technology eliminates the use of lasers or heat in the printing process, leading to fast, energy-efficient, and economical production. Completed components usually go through post-processing procedures like curing, sintering, or infiltration, particularly for metallic or ceramic items. This market is propelled by the demand for rapid, scalable, and economical production of precise components. Industries such as automotive, aerospace, construction, dental, and healthcare are leading adopters, driven by the need for efficiency, enhanced design flexibility, and superior material performance.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Binder Jetting 3D Printing Market.

Binder Jetting 3D Printing Market Size & Statistics

- The Market Size for Binder Jetting 3D Printing Was Estimated to be worth USD 0.62 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 15.02% between 2025 and 2035.

- The Global Binder Jetting 3D Printing Market Size is anticipated to reach USD 2.89 Billion by 2035.

- Asia Pacific is projected to generate the highest demand during the forecast period in the binder jetting 3D printing market.

- Europe is anticipated to grow the fastest during the forecast period in the binder jetting 3D printing market.

Regional growth and demand

Europe is anticipated to grow at the fastest CAGR during the forecast period in the binder jetting 3D printing market. The region is marked by a significant emphasis on sustainability, precision engineering, and high-value production, with nations like Germany, the United Kingdom, and France leading in the uptake of additive manufacturing. European producers are utilising binder jetting technology to improve product quality, shorten lead times, and facilitate the shift to Industry 4.0. The area also hosts a dynamic ecosystem of research facilities, emerging companies, and industry coalitions promoting cooperative innovation and the creation of new applications for binder jetting.

Asia Pacific is expected to grow at the highest share during the forecast period in the binder jetting 3D printing market. The Asia Pacific area is propelled by swift industrial growth, substantial investments in cutting-edge manufacturing, and the development of a strong startup ecosystem. Nations like China, Japan, and South Korea are at the forefront of binder jetting technology adoption, backed by government programs, an expanding workforce of skilled experts, and heightened cooperation between academia and industry. With ongoing investments in infrastructure, research, and talent development within the region, the Asia Pacific Binder Jetting 3D Printing market is set for ongoing growth and advancement.

Top 10 trends in the Binder Jetting 3D Printing Market

- AI and Automation Integration

- Sustainability and Eco-Friendly Materials

- Material Diversification

- Industrial Adoption Surge

- Full-Colour and Multi-Material Printing

- On-Demand and Digital Manufacturing

- Enhanced Post-Processing

- Regional Expansion

- Rapid Growth

1. AI and Automation Integration

Growing application of artificial intelligence and automated processes to enhance design, printing, and post-processing.

2. Sustainability and Eco-Friendly Materials

Increasing demand for eco-friendly, reusable, and low-waste materials, particularly in consumer goods and interior design.

3. Material Diversification

Growth in metals, ceramics, sand, plastics, and composites, facilitating wider industrial uses.

4. Industrial Adoption Surge

Significant growth in automotive, aerospace, healthcare, and architecture sectors, fueled by the demand for tailored, lightweight, and intricate components.

5. Full-Colour and Multi-Material Printing

Improvements in binder chemistry enable realistic prototypes, figurines, and multi-material integration, particularly in consumer and educational fields.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the binder jetting 3D printing market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the Binder Jetting 3D Printing Market

- ExOne

- Desktop Metal

- HP Inc.

- GE Additive

- Voxeljet AG

- 3D Systems Corporation

- Stratasys Ltd.

- Digital Metal (Höganäs AB)

- Markforged

- Ricoh Company, Ltd.

- Sandvik AB

- EOS GmbH

- Renishaw plc

- Sinterit

- AddUp

- Mimete S.r.l.

- Xerox Corporation

- BeAM Machines (AddUp Group)

- Triditive

- Aurora Labs Limited

1. ExOne

Headquarters: Pennsylvania, United States

ExOne is a forerunner and worldwide leader in the Binder Jetting 3D Printing sector, focusing on industrial quality 3D printing systems employing binder jet technology to create intricate metal, sand, ceramic, and composite components. ExOne has been a leader in binder jetting additive manufacturing since 1995, introducing the first commercial binder jet 3D printer for metals (RTS-300) in 1998 and subsequently for sand moulds and cores in 2002. Their patented method carefully applies a liquid binder onto a powder layer to bond particles successively, allowing for the quick production of complex components and tools without relying on conventional hard tooling. Commonly utilised in metal casting, automotive tooling, aerospace, and industrial manufacturing industries.

2. Desktop Metal

Headquarters: Burlington, United States

Desktop Metal is a significant contender in the binder jetting 3D printing market, providing innovative metal additive manufacturing solutions aimed at high-resolution, rapid, and economical production of metal components. Desktop Metal’s shop system is the first metal binder jetting system globally created exclusively for machine shops and smaller production settings. It uses single-pass binder jetting technology to quickly create high-resolution components with better surface quality than conventional laser-based metal 3D printing. The X-Series lineup (comprising InnoventX, X25Pro, and X160Pro) includes industrial piezoelectric printheads along with the patented Triple ACT (advanced compaction technology).

3. HP Inc.

Headquarters: California, United States

HP Inc. stands out in the Binder Jetting 3D Printing Market, especially with its Metal Jet technology, aimed at scalable, high-output metal additive manufacturing for industrial uses. HP Metal Jet represents an advanced binder jetting technique that utilises HP Thermal Inkjet printheads to deposit a binding agent onto layers of metal powder. The method constructs intricate metal components layer by layer without requiring support structures, utilising industry-standard metal injection moulding (MIM) powders and providing build volumes of up to 430 x 309 x 140 mm. The system allows for significant productivity while providing the capability to arrange numerous or sizable components in a build volume of 430 x 309 x 140 mm, and accommodates materials such as stainless steel 316L and 17-4PH.

4. GE Additive

Headquarters: Cincinnati, Ohio, United States

GE Additive is a prominent innovator and supplier of equipment in the binder jetting 3D printing industry, emphasising metal additive manufacturing systems intended for large-scale, high-volume serial production. GE Additive's Binder Jet Line and Series 3 printers utilise cutting-edge binder jetting technology to consistently and reliably produce intricate metal components in both small and large sizes. Their systems are highly effective at creating both complex geometries and large parts with superior material qualities often exceeding conventional casting regarding throughput, accuracy, and wall thickness (under 500 μm). GE Additive utilises smart software (GE Amp) for immediate monitoring and distortion adjustment during sintering.

5. Voxeljet AG

Headquarters: Friedberg (Bavaria), Germany

Voxeljet AG is known worldwide for its cutting-edge binder jetting 3D printing technologies, offering scalable, material-flexible options crucial for quick prototyping, extensive manufacturing, and the creation of complex, functional parts in various industrial fields. Voxeljet’s binder jetting 3D printing method utilises industrial printheads to apply liquid binders on thin layers of powder materials, including sand, plastics (PMHarness AI's Potential in 2025MA), and ceramics, constructing objects layer by layer directly from digital CAD designs. This method is highly effective for creating large parts, intricate shapes, and mass production, accommodating various processable materials.

Are you ready to discover more about the binder jetting 3D printing market?

The report provides an in-depth analysis of the leading companies operating in the global binder jetting 3D printing market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- ExOne

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Desktop Metal

- HP Inc.

- GE Additive

- Voxeljet AG

- 3D Systems Corporation

- Stratasys Ltd.

- Digital Metal (Höganäs AB)

- Markforged

- Ricoh Company, Ltd.

- Sandvik AB

- EOS GmbH

- Renishaw plc

- Sinterit

- AddUp

- Mimete S.r.l.

- Xerox Corporation

- BeAM Machines (AddUp Group)

- Triditive

- Aurora Labs Limited

- Others

Conclusion

The Global Binder Jetting 3D Printing Market Size is experiencing significant growth, expected to increase from USD 0.62 Billion in 2024 to USD 2.89 Billion by 2035, showcasing a robust CAGR of 15.02%. This rapid growth is propelled by the technology's intrinsic benefits scalability, velocity, material diversity (metals, ceramics, sand), and economical manufacturing of complex, lightweight parts. The industrial uptake is escalating in high value industries such as automotive, aerospace, and healthcare, driven by trends like AI/Automation Integration and Material Diversification. Regionally, the Asia-Pacific region is expected to possess the largest market share because of swift industrial growth and significant manufacturing investments, whereas Europe is projected to experience the quickest CAGR, capitalizing on its emphasis on precision engineering and the implementation of Industry 4.0. The market is fierce, featuring major companies such as ExOne, Desktop Metal, HP Inc., GE Additive, and Voxeljet AG spearheading advancements in high-volume, production-quality metal and sand binder jetting technologies.

Browse Related Reports:

Global 5G System Integration Market Size To Exceed USD193.77 Billion by 2035 | CAGR of 26.88% : Market Study Report

Global Soft Facility Management Market Size To Exceed USD 1.24 Trillion by 2035 | CAGR of 5.2% : Market Study Report

Global Tungsten Market Size To Exceed USD 2.83 Billion by 2035 | CAGR of 4.91% : Market Size Report

Global Conductive Textiles Market Size To Exceed USD 6.83 Billion by 2035 | CAGR of 6.98% : Market Study Report

Global Performance Fabric Market Size To Exceed USD 125.73 Billion by 2035 | CAGR of 6.67% : Market Study Report

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?