Global Thermoplastic Vulcanizates Market Size, Share, and COVID-19 Impact By Application (Automotive, Medical, Fluid Handling, Consumer Goods), by Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 – 2032.

Industry: Chemicals & MaterialsGlobal Thermoplastic Vulcanizates Market Insights Forecasts to 2032

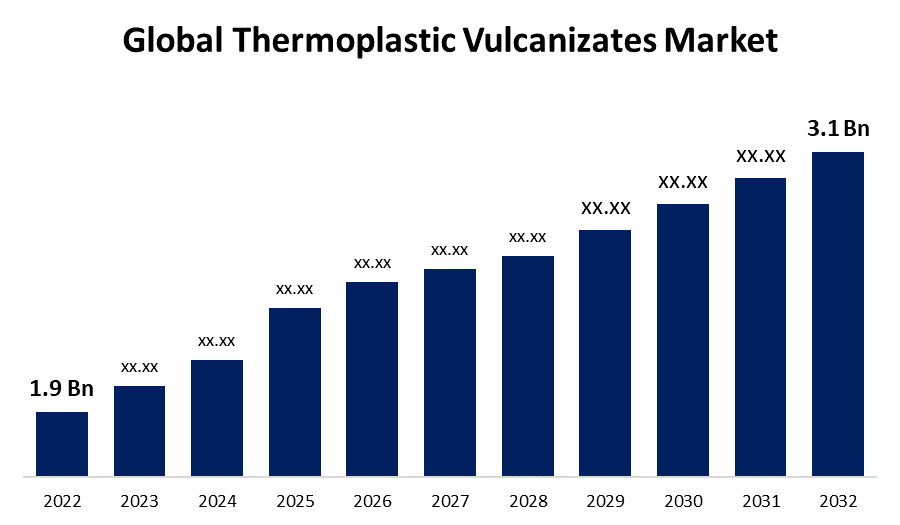

- The Thermoplastic Vulcanizates Market Size was valued at USD 1.9 Billion in 2022.

- The Market Size is Growing at a CAGR of 7.4% from 2022 to 2032

- The Worldwide Thermoplastic Vulcanizates Market Size is expected to reach USD 3.1 Billion by 2032

- Asia Pacific is expected To Grow the fastest during the forecast period.

Get more details on this report -

The Global Thermoplastic Vulcanizates Market Size is expected to reach USD 3.1 Billion by 2032, at a CAGR of 7.4% during the forecast period 2022 to 2032.

A form of thermoplastic elastomer known as Thermoplastic Vulcanizates (TPVs) combines the properties of thermoplastics and elastomers. In a thermoplastic matrix, cross-linked rubber or elastomer particles are mixed together to form these materials. Because of their versatility, toughness, and processability, TPVs are well suited for a variety of industrial applications. such conventional rubber materials, TPVs have elastomeric qualities such high elasticity and flexibility. They are therefore appropriate for uses that call for resilience and impact resistance. TPVs can be processed using common thermoplastic processing techniques like injection molding, extrusion, and blow molding, unlike conventional vulcanized rubber. This quality enables productive and economical manufacturing.

Impact of COVID 19 On Global Thermoplastic Vulcanizates Market

Supply chains were disrupted by the pandemic as a result of lockdowns, factory closures, and transportation limitations. This had an effect on the supply of components and raw materials for TPV manufacture. Construction, consumer products, and other TPV-using industries all experienced a drop in demand as a result of the slowdown in economic activity. This had a domino effect on TPV suppliers and manufacturers. Demand for TPVs and other plastics started to rebound as regulations loosened and economic activity picked up, especially in sectors that had adapted to the "new normal," including growing e-commerce and remote labor. Manufacturers of TPVs and other companies in the plastics and polymer sector have been working to adjust their supply chains and internal processes to the market's shifting dynamics, including shifts in demand and shifting consumer preferences.

Global Thermoplastic Vulcanizates Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 1.9 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 7.4% |

| 2032 Value Projection: | USD 3.1 Billion |

| Historical Data for: | 2018-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Application, by Region, and COVID-19 Impact Analysis. |

| Companies covered:: | Exxon Mobil Chemical, Arkema Inc., The Dow Chemical Company, Dexco Polymers, DuPont Performance Elastomers, Kraton Polymers, and Other Key Venders. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Key Market Drivers

Numerous industries, including the automotive, consumer goods, industrial, healthcare, and more have used TPVs. The adaptability, weather resilience, and processing simplicity of TPVs make them desirable for a variety of tasks. The largest market for TPVs is the automotive industry. Due to their dependability, adaptability, and resistance to environmental conditions, these materials were utilized for under-the-hood, interior, sealing, and gasket applications in automobiles. The introduction of TPVs for uses including grips, handles, overmolded components, and more was sparked by the desire for soft-touch and flexible materials in consumer products, electronics, and appliances. TPVs were chosen as substitutes for heavier rubber materials in areas like the automobile where lightweighting is important for fuel efficiency due to their lighter weight and comparable performance. Due to their protective and impact-absorbing qualities, TPVs are used in packaging materials as a result of the move to e-commerce and customer demand for effective packaging solutions.

Key Market Challenges

As TPVs have elastomeric components, they occasionally cost more than conventional thermoplastics. It can be difficult to strike a balance between performance and cost-effectiveness, particularly in cost-sensitive businesses. Standardization and quality control can be difficult due to the range of TPV formulations offered by various producers, particularly when particular performance requirements must be routinely met. Other elastomers and thermoplastic elastomers, each with its own set of benefits and drawbacks, compete for market share with TPV. To stay competitive, TPVs must successfully distinguish themselves from one another. It can be difficult to inform potential clients about the advantages, uses, and appropriate usage of TPVs. There's a chance that some sectors aren't entirely aware of the benefits TPVs have over conventional materials.

Market Segmentation

Application Insights

Automotive industry segment is dominating the market over the forecast period

On the basis of application, the global thermoplastic vulcanizate market is segmented into Automotive, Medical, Fluid Handling, Consumer Goods. Among these, the automotive industry segment is dominating the market with the largest market share over the forecast period. TPVs were used in console parts, dashboard panels, and armrests as interior accessories. They provided the benefits of soft-touch surfaces, aesthetic appeal, and durability. TPVs were applied to exterior components such as bumpers, fender flares, and trim. It was advantageous that they could survive impacts, resist fading, and keep their appearance in many weather scenarios. TPVs have been used in internal components such cable jackets, connections, and seals. They were appropriate for engine compartments because of their resistance to oils, greases, and high temperatures. With the security of elastomeric qualities, TPVs gave vehicle designers the opportunity to build complicated and complex designs. Because TPVs are thermoplastic, they can be processed effectively using techniques like injection molding, which leads to shorter manufacturing cycle times and higher output.

Regional Insights

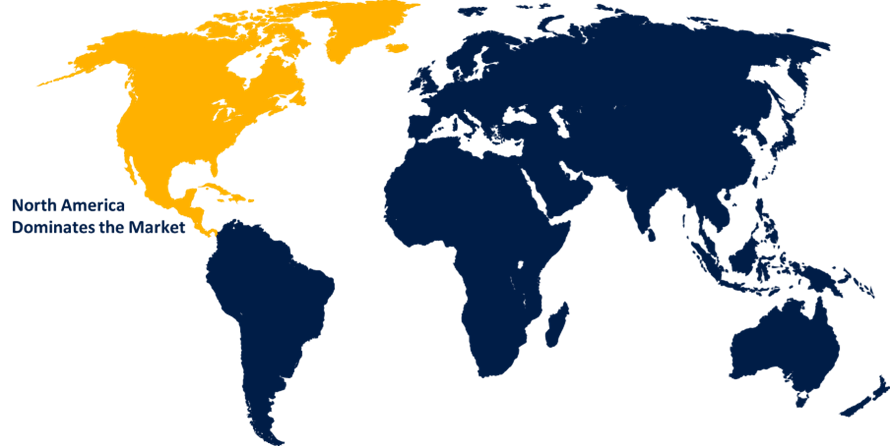

North America is dominating the market with the largest market share over the forecast period

Get more details on this report -

Among all other regions, North America is dominating the market with the largest market share over the forecast period. The automobile industry in North America is a sizable manufacturing sector, and TPVs are widely used in the sector. Due to its characteristics, TPVs can be used for a number of automobile parts, such as gaskets, interior parts, and under-the-hood and sealing systems. In industrial settings where toughness, impact resistance, and environmental resistance were required, TPVs were used. Gaskets, vibration-dampening parts, and industrial equipment parts were some of these applications. North America's TPVs market fluctuated depending on regional demand, industrial activity, and economic conditions.

Asia Pacific region is witnessing the fastest market share over the forecast period. The APAC region is a significant center for the production of automobiles, and TPVs are widely used in this industry. Weather resistance, toughness, and flexibility of TPVs make them appropriate for use in a variety of automobile components. TPVs were used in industrial applications in the APAC region for parts that needed impact resistance, vibration dampening, and environmental resistance. The use of TPVs in applications including soft-touch grips, handles, and overmolded components was influenced by the need for consumer products and electronics with ergonomic and comfortable features. The demand for TPVs in many applications was driven by the rapid industrialization and manufacturing boom in nations like China and India.

Recent Market Developments

- In June 2021, The SantopreneTM TPV elastomers business of Exxon Mobil Corporation will be acquired by Celanese Corporation (NYSE: CE), a multinational chemical and speciality materials firm.

List of Key Companies

- Exxon Mobil Chemical

- Arkema Inc.

- The Dow Chemical Company

- Dexco Polymers

- DuPont Performance Elastomers

- Kraton Polymers

Market Segment

This study forecasts revenue at global, regional, and country levels from 2019 to 2032. Spherical Insights has segmented the global Thermoplastic Vulcanizates Market based on the below-mentioned segments:

Thermoplastic Vulcanizates Market, Application Analysis

- Automotive

- Medical

- Fluid Handling

- Consumer Goods

Thermoplastic Vulcanizates Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

Frequently Asked Questions (FAQ)

-

1.What is the market size of Thermoplastic Vulcanizates Market?The global Thermoplastic Vulcanizates Market is expected to grow from USD 1.9 Billion in 2022 to USD 3.1 Billion by 2032, at a CAGR of 7.4% during the forecast period 2022-2032.

-

2.Who are the key market players of Thermoplastic Vulcanizates Market?Some of the key market players of Exxon Mobil Chemical, Arkema Inc., The Dow Chemical Company, Dexco Polymers, DuPont Performance Elastomers, Kraton Polymers.

-

3.Which segment hold the largest market share?Automotive industry segment holds the largest market share is going to continue its dominance.

-

4.Which region is dominating the Thermoplastic Vulcanizates Market?North America is dominating the Thermoplastic Vulcanizates Market with the highest market share.

Need help to buy this report?