Global Smart Manufacturing Platform Market Size, Share, and COVID-19 Impact Analysis, By Type (Device Management, Connectivity Management, Application Enablement Platform), By Organization Size (Small & Medium Enterprises and Large Enterprises) By Application (Performance, Optimization, Asset Condition Monitoring, Others), By Verticals (Process Industry, Discrete Industry), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 - 2032

Industry: Electronics, ICT & MediaGlobal Smart Manufacturing Platform Market Insights Forecasts to 2032

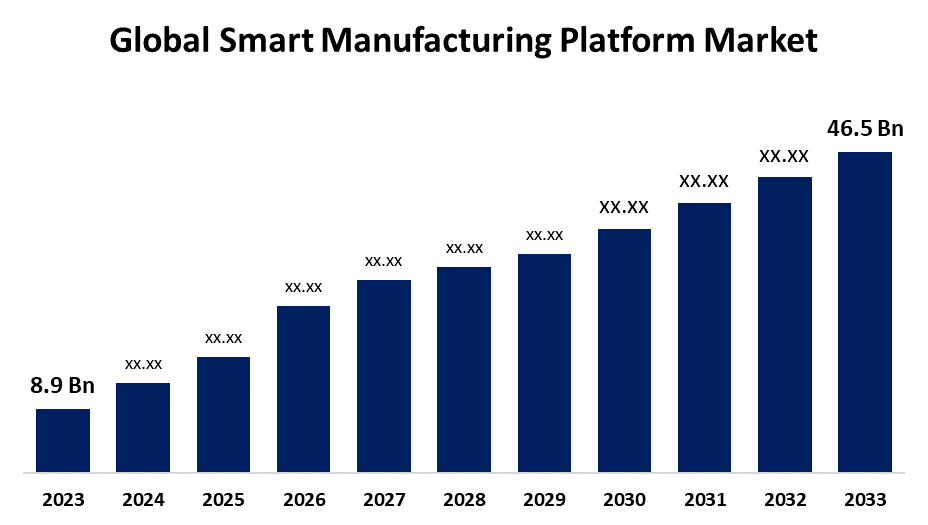

- The Global Smart Manufacturing Platform Market Size was valued at USD 8.9 Billion in 2022.

- The Market Size is growing at a CAGR of 17.9% from 2022 to 2032

- The Worldwide Smart Manufacturing Platform Market is expected to reach USD 46.5 Billion by 2032

- Asia Pacific is expected to grow the fastest during the forecast period

Get more details on this report -

The Global Smart Manufacturing Platform Market Size is expected to reach USD 46.5 Billion by 2032, at a CAGR of 17.9% during the forecast period 2022 to 2032.

A smart manufacturing platform is an all-encompassing framework that uses technologies such as the Internet of Things (IoT), artificial intelligence (AI), machine learning, large-scale data analysis, and cloud-based services to make manufacturing more cognizant, versatile, and productive. It extends beyond typical automation systems resulting in a more connected, flexible, and data-driven manufacturing strategy. The platform gathers and processes data in real-time, allowing for rapid decisions, immediate problem recognition, and dynamic process modifications. The platform is capable of identifying shortcomings and offering process modifications that maximize energy consumption, utilization of assets, and manufacturing efficiency through continuous monitoring and data analysis. In a marketplace where consumers expect speed, quality, and customization, smart manufacturing platforms provide producers with the tools they need to achieve these expectations. Industry 4.0 initiatives, fueled by the integration of digital and physical innovations, are compelling manufacturers to implement these platforms in order to remain competitive, adaptable, and efficient in a constantly changing market. As companies around the world envision higher productivity, customization, and long-term viability the implementation and development of smart manufacturing platforms will be critical in transforming the global economy.

Global Smart Manufacturing Platform Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 8.9 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 17.9% |

| 2032 Value Projection: | USD 46.5 Billion |

| Historical Data for: | 2019-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 120 |

| Segments covered: | COVID-19 Impact Analysis, By Type, By Organization Size, By Application, By Verticals, and By Region |

| Companies covered:: | IBM, PTC Inc., SAP SE, ABB, Siemens, Schneider Electric, Emerson Electric Co., General Electric, Telit, Accenture, Cisco Systems, Altizon Systems, Rockwell Automation, Atos SE, Software AG, C3 IoT, Fujitsu Limited, Seebo Interactive, Qiu Technologies, Hitachi Consulting Corporation, and other Key venders |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The rising penetration of the smart manufacturing platform market is ascribed to higher levels of automation in industrial processes, growing use of smart manufacturing platforms in the automotive sector, increased government funding for industrial automation, and rising demands for optimized and data-driven systems for maximizing efficiency. Enterprises that specialize in industrial manufacturing are under severe scrutiny to boost efficiency while lowering manufacturing costs. As a result, in order to minimize manufacturing costs, boost productivity, and conserve resources, companies are using industrial automation, which is fueling the growth of the smart manufacturing platform market. In addition, industrial automation systems tend to reduce work, waste, and labor costs, limit delays and inaccuracies, improve process efficiency, and reduce reaction and execution time. Additionally, the systems track and gather relevant data in order to improve the production process, recognize patterns, and apply adjustments to forestall future incidents.

Furthermore, increased adoption of IIoT and cloud-based services, as well as partnerships between platform providers and cloud service providers, are likely to generate growth possibilities for the smart manufacturing platform market in the coming years. Plant managers receive full oversight of assets, resources, processes, and output with the help of IIoT. Plant floors are becoming more connected and seamless as a result of IIoT, which has resulted in the development of industrial automation into smart automation, allowing manufacturers to get better returns on investment. The IIoT helps manufacturing processes more efficient, profitable, and dynamic since its framework offers real-time information on functioning and organizational structures.

Market Segmentation

By Type Insights

The device management segment is dominating the market with the largest revenue share over the forecast period.

On the basis of type, the global smart manufacturing platform market is segmented into device management, connectivity management, and application enablement platform. Among these, the device management segment is dominating the market with the largest revenue share of 38.6% over the forecast period. The growth of artificial intelligence (AI), the Industrial Internet of Things, technologically advanced manufacturing, the fourth industrial revolution, digital transformation, and connected organizations have encouraged numerous industries to install sophisticated technologies in their operations. As a considerable amount of data is generated from numerous devices that are utilized in industrial facilities, managing the devices and data collected has become critical. The device management platform enables administrators to connect and disconnect new devices, operate various devices, view device data and status, and remotely monitor devices.

By Organization Size Insights

The small & medium enterprises segment is witnessing significant CAGR growth over the forecast period.

On the basis of organization size, the global smart manufacturing platform market is segmented into small & medium enterprises and large enterprises. Among these, the small & medium enterprises segment is witnessing significant CAGR growth over the forecast period. The popularity of smart manufacturing systems is gradually increasing as they have grown more versatile and economical, and as more SMEs comprehend the economic advantages that these platforms provide. Budget constraints, a lack of technical competence, or infrastructure limitations may prevent SMEs from adopting innovative smart manufacturing platforms promptly. Despite SMEs may have smaller spending individually, the sheer quantity of these organizations worldwide makes them a large segment. This sector has a considerable growth possibility as technology becomes increasingly readily available and cost-effective.

By Application Insights

The asset condition monitoring segment is expected to hold the largest share of the Global Smart Manufacturing Platform Market during the forecast period.

Based on the application, the global smart manufacturing platform market is classified into performance, optimization, asset condition monitoring, and others. Among these, the asset condition monitoring segment is expected to hold the largest share of the Smart Manufacturing Platform market during the forecast period. This is due to an increased focus on predictive maintenance and a global effort to reduce operational expenses and periods of inactivity in many industrial sectors. Asset condition monitoring entails monitoring the functioning of equipment and machines in real-time and determining when repairs or routine maintenance may be required depending on the existing condition of the assets. Predictive maintenance, a subset of asset condition monitoring, can dramatically reduce accidental interruptions while also maintaining continuous functioning and increasing the life of machines. It detects the earliest indications of equipment failure using sensors, data analytics, and deep learning algorithms.

By Verticals Insights

The process industry segment accounted for the largest revenue share of more than 52.7% over the forecast period.

On the basis of verticals, the global smart manufacturing platform market is segmented into process industry and discrete industries. Among these, the process industry segment is dominating the market with the largest revenue share of 52.7% over the forecast period. The process industry is divided into sub-segments such as chemicals, oil and gas, power and energy, pharmaceuticals, metals and mining, food and beverages, and others. The power & energy sector is currently leading the smart manufacturing platform market and will continue to do so throughout the forecast period. The power and energy industry has to cope with a number of difficulties, including environmental consequences and a lack of conventional energy sources, which could lead to a looming energy crisis in the years to come. As such, in the energy and power industry, effective optimization has grown critical to increasing productivity, functionality, and utilization, which has led to an increase in the usage of smart manufacturing platforms market. Furthermore, the oil and gas sector also encounter many obstacles such as unanticipated outages and a shortage of synergy across multiple operations throughout the supply line, which has driven the widespread use of smart manufacturing platforms in the energy sector, leading to an important percentage of the smart manufacturing platform market.

Regional Insights

North America dominates the market with the largest market share over the forecast period.

Get more details on this report -

North America is dominating the market with more than 43.6% market share over the forecast period. North America, particularly the United States, has a substantial market share due to its strong manufacturing industry and technological capabilities. The region boasts a thriving industrial sector that includes automotive, aerospace, pharmaceuticals, and other industries. This diverse base is quickly adopting smart manufacturing techniques. Furthermore, the region's emphasis on digital evolution and Industry 4.0 concepts drives the market's willingness to embrace smart manufacturing platforms over the projection period.

Asia Pacific, on the contrary, is expected to grow the fastest during the forecast period. This region has experienced a major expansion in the smart manufacturing platform market owing to growing industrialization, particularly in countries such as China and India, and the implementation of Industry 4.0 principles. The majority of governments in the region are pursuing Industry 4.0 initiatives, such as smart factories and the integration of IoT, AI, and automation into the manufacturing industry. Furthermore, cities such as Shenzhen, China, and Bengaluru, India, have emerged as key technical and startup hubs, promoting advancement in the smart manufacturing sector during the research period.

List of Key Market Players

- IBM

- PTC Inc.

- SAP SE

- ABB

- Siemens

- Schneider Electric

- Emerson Electric Co.

- General Electric

- Telit

- Accenture

- Cisco Systems

- Altizon Systems

- Rockwell Automation

- Atos SE

- Software AG

- C3 IoT

- Fujitsu Limited

- Seebo Interactive

- Qiu Technologies

- Hitachi Consulting Corporation

Key Market Developments

- On April 2023, Snowflake announced the launch of the Manufacturing Data Cloud, which enables companies in the automotive, technology, energy, and industrial sectors to unlock the value of their critical siloed industrial data by leveraging Snowflake's data platform, Snowflake- and partner-delivered solutions, and industry-specific datasets. In today's digital-industrial world, enterprises may use Snowflake's Manufacturing Data Cloud to develop a data foundation for their business, boost supply chain performance, and fuel smart manufacturing efforts.

- On January 2023, TDK Corporation has agreed to acquire Qeexo, a venture-backed firm based in the United States that was created out of Carnegie Mellon University and specializes in the automation of end-to-end machine learning for edge devices. Customers can use Qeexo's AutoML platform to quickly build machine learning solutions optimized for ultra-low latency and power consumption, with an incredibly small memory footprint, for highly constrained environments such as industrial, IoT, wearables, automotive, mobile, and more.

- On November 2022, SIASUN Robot & Automation and Huawei have inked a Memorandum of Understanding (MOU) to accelerate Robotic Automation applications for 5G smart manufacturing businesses in Thailand and the Asia Pacific region. Both parties are also working together to bring total smart factory solutions with industrial automation solutions to smart manufacturing via SIASUN's AGV, ASRS, Robotics, and industrial software platforms, which can be created massively and fast on the HUAWEI cloud with 5G connectivity and accessibility.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2032. Spherical Insights has segmented the Global Smart Manufacturing Platform Market based on the below-mentioned segments:

Smart Manufacturing Platform Market, Type Analysis

- Device Management

- Connectivity Management

- Application Enablement Platform

Smart Manufacturing Platform Market, Organization Size Analysis

- Small & Medium Enterprises

- Large Enterprises

Smart Manufacturing Platform Market, Application Analysis

- Performance

- Optimization

- Asset Condition Monitoring

- Others

Smart Manufacturing Platform Market, Verticals Analysis

- Process Industry

- Chemicals

- Oil & Gas

- Power & Energy

- Pharmaceuticals

- Metals & Mining

- Food & Beverages

- Others

- Discrete Industry

- Automotive

- Medical Devices

- Aerospace & Defense

- Industrial Manufacturing

- Electronics & Semiconductor

- Others

Smart Manufacturing Platform Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Smart Manufacturing Platform market?The Global Smart Manufacturing Platform Market is expected to grow from USD 8.9 billion in 2022 to USD 46.5 billion by 2032, at a CAGR of 17.9% during the forecast period 2022-2032.

-

2. Which are the key companies in the market?IBM, PTC Inc., SAP SE, ABB, Siemens, Schneider Electric, Emerson Electric Co., General Electric, Telit, Accenture, Cisco Systems, Altizon Systems, Rockwell Automation, Atos SE, Software AG, C3 IoT, Fujitsu Limited, Seebo Interactive, Qiu Technologies, Hitachi Consulting Corporation

-

3. Which segment dominated the Smart Manufacturing Platform market share?The process industry segment in verticals type dominated the Smart Manufacturing Platform market in 2022 and accounted for a revenue share of over 52.7%.

-

4. What are the elements driving the growth of the Smart Manufacturing Platform market?Increased utilization of smart manufacturing platforms in the automotive industry, rising government funding for industrial automation, and higher demands for optimized and data-driven systems for maximizing efficiency

-

5. Which region is dominating the Smart Manufacturing Platform market?North America is dominating the Smart Manufacturing Platform market with more than 43.6% market share.

-

6. Which segment holds the largest market share of the Smart Manufacturing Platform market?The process industry segment based on type holds the maximum market share of the Smart Manufacturing Platform market.

Need help to buy this report?