Global Prepreg Market Size By Manufacturing Process (Solvent Dip, Hot-Melt); By End-Use (Automotive, Aerospace, Electronics, Wind Energy, Others); By Resin (Thermoset Prepreg, Thermoplastic Prepreg), By Fiber (Carbon Fiber Prepreg, Glass Fiber Prepreg, Aeamid Fiber Prepreg, Other), By Region, And Segment Forecasts, By Geographic Scope And Forecasts to 2032

Industry: Chemicals & MaterialsGlobal Prepreg Market Insights Forecasts to 2032

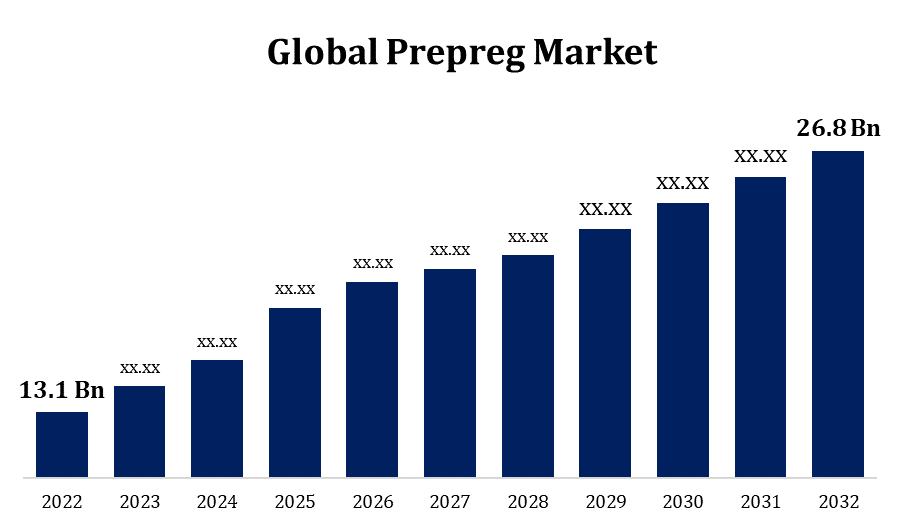

- The Prepreg Market Size was valued at USD 13.1 Billion in 2022.

- The Market Size is Growing at a CAGR of 11.9% from 2022 to 2032

- The Worldwide Prepreg Market Size is Expected to Reach USD 26.8 Billion by 2032

- Asia Pacific is Expected to Grow the fastest during the forecast period

Get more details on this report -

The Global Prepreg Market Size is Expected to Reach USD 26.8 Billion by 2032, at a CAGR of 11.9% during the forecast period 2022 to 2032.

This growth was fueled by rising demand for lightweight and high-strength materials, particularly in industries such as aerospace, automotive, and wind energy. The rising use of composites was also influenced by the shift towards more fuel-efficient and ecologically friendly solutions. Manufacturing process innovations and the introduction of sophisticated prepreg materials were also significant. Continuous R&D efforts were directed towards enhancing the performance, durability, and cost-effectiveness of prepreg materials, hence fueling market expansion.

Global Prepreg Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 13.1 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 11.9% |

| 2032 Value Projection: | USD 26.8 Billion |

| Historical Data for: | 2018-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By End-Use, By Resin, By Fiber, By Region. |

| Companies covered:: | Evonik Industries AG (Germany), Teijin Limited (Japan), SGL Group (Germany), DSM (Netherlands), SABIC (Saudi Arabia), Solvay (Belgium), Hexcel Corporation (U.S.), Toray Industries Inc,, (Japan), 3M (U.S.), BASF SE (Germany), Covestro AG (Germany), Dow (U.S.), Borealis AG (Austria), ZOLTEK (U.S.), Celanese Corporation (U.S.), Mitsubishi Chemical Corporation (Japan), PARK AEROSPACE CORP (U.S.), Gurit (Switzerland), Teijin Aramid B.V (Japan), Axiom Materials (U.S.), and Others |

| Growth Drivers: | Increase in demand for passenger vehicles |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Prepreg Market Value Chain Analysis

The manufacturing of raw materials, such as reinforcing fibres like carbon, glass, or aramid, and resin systems like epoxy, phenolic, or thermoplastic resins, begins the process. The manufacture of reinforcing fibres is the next phase. Carbonisation for carbon fibres or spinning for glass fibres are examples of such procedures. Resin systems are designed to meet the specific needs of the application. This could entail combining different chemicals to produce desired qualities such as flexibility, strength, and cure time. The resin system is impregnated into the reinforcing fibres to create the actual prepreg. This is an important stage since it determines the final properties of the composite material. Pregnancies are then cured, often with heat and pressure. This solidifies the resin, providing a strong link between the fibres and a composite material with improved characteristics. The cured prepreg material is then cut into the shapes and sizes specified by the customer. It has been packaged and is ready for shipment. Distributors are responsible for delivering prepreg materials to producers. Prepreg materials are used to make components by manufacturers in a variety of industries, including aerospace, automotive, and sports.

Prepreg Market Opportunity Analysis

With the aerospace industry constantly pursuing lightweight materials for increased fuel efficiency and performance, prepreg materials have a huge possibility in aircraft manufacture. With the aerospace industry constantly pursuing lightweight materials for increased fuel efficiency and performance, prepreg materials have a huge possibility in aircraft manufacture. Prepreg materials have a prospective market in the wind energy sector, particularly in the fabrication of wind turbine blades. Composites' strength-to-weight ratio is ideal for large, long-lasting blades. Because of their strength and flexibility, prepreg materials present an opportunity in the sports equipment market, which includes the production of high-performance bicycles, tennis rackets, and other sporting products. The use of composites in bridge, building, and other infrastructure projects is a growing possibility.

Market Dynamics

Prepreg Market Dynamics

Increase in demand for passenger vehicles

Automobile manufacturers are looking for solutions to reduce vehicle weight in order to improve fuel efficiency and environmental sustainability. Because prepreg materials are lightweight yet sturdy, they are appealing for use in automotive components, helping to total fuel efficiency. Prepregs have a high strength-to-weight ratio and good mechanical characteristics. As a result, they are appropriate for use in high-performance automobiles where weight reduction is critical for increased acceleration, handling, and overall performance. As the automotive industry shifts to electric vehicles (EVs), there is an increasing demand for lightweight materials to counteract the weight of batteries. Prepregs can help in the design of lightweight, structurally durable EV components.

Restraints & Challenges

High-quality fibres and resins, for example, can be costly raw materials in prepreg manufacture. This expense is frequently passed on to end users, reducing the competitiveness of prepreg materials in price-sensitive markets. Prepreg materials are created by a series of complex processes, including fibre impregnation with resin and curing. This intricacy might raise manufacturing costs since it necessitates specialised equipment and trained labour. The lack of standardised testing and processing procedures for prepreg materials can make assuring uniform quality across manufacturers and applications difficult. This can be an obstacle to widespread adoption, particularly in businesses with high-quality standards. Due to familiarity, potential users may stick to traditional materials due to a lack of awareness.

Regional Forecasts

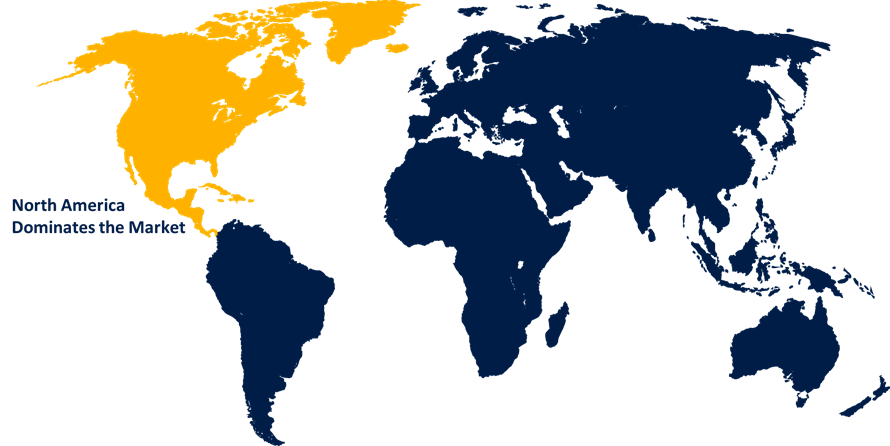

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Prepreg Market from 2023 to 2032. In North America, the aerospace sector has been a major consumer of prepreg materials. Prepregs are perfect for aeroplane components due to their lightweight and high-strength qualities, contributing to the region's aerospace dominance. With a focus on fuel efficiency and emission reduction, the North American automobile industry has been introducing lightweight materials, such as prepregs, into vehicle design. As electric vehicles gain popularity, this trend is projected to continue. Wind energy has grown significantly in response to the increased demand for renewable energy. Prepreg materials are widely employed in the manufacture of wind turbine blades, and wind farm installations in North America have increased. Companies in the North American prepreg sector may engage in international trade and export activities.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2032. The Asia-Pacific region is a global manufacturing hub, and the demand for lightweight and high-performance materials in industries like as aerospace and automotive has accelerated the adoption of prepreg materials. Rapid development in nations such as China and India has boosted demand for sophisticated materials. Prepregs are valued for their versatility and strength, making them useful in a variety of manufacturing applications. The Asia-Pacific aerospace and defence industries have been growing. Because of their lightweight and durable qualities, prepreg materials are commonly employed in aircraft components, satellites, and defence applications. Sports and leisure products are becoming increasingly popular in the Asia-Pacific area. Prepreg materials are used to make athletic products such as bicycles, golf clubs, and racquets.

Segmentation Analysis

Insights by Resin

The thermoset resin segment accounted for the largest market share over the forecast period 2023 to 2032. Epoxy, phenolic, and other thermoset resins have a wide range of applications in a variety of sectors. Because of their superior mechanical qualities and strong heat resistance, they are extensively utilised in aerospace, automotive, wind energy, and sports equipment manufacturing. The aerospace industry heavily relies on thermoset resin-based prepregs to produce lightweight and high-strength components. This category is growing because to the desire for fuel-efficient aircraft and the necessity for strong yet lightweight materials. Wind turbine blades require the use of thermoset resin-based prepregs. The expansion of the wind energy sector, spurred by increased investments in renewable energy, adds to the need for these materials.

Insights by Fiber

The carbon fiber segment accounted for the largest market share over the forecast period 2023 to 2032. Carbon fiber-reinforced prepregs are widely utilised in the aerospace sector to produce lightweight, high-strength components such as aircraft fuselages, wings, and interior structures. The increased demand for fuel-efficient aircraft has accelerated the rise of carbon fibre composites in this industry. Lightweighting is becoming increasingly important in the automotive industry in order to increase fuel efficiency and overall performance. Carbon fibre prepregs are used to make automotive components such as body panels, chassis sections, and interior elements. Carbon fibre prepregs are used in the sports and leisure industry to make high-performance equipment such as bicycles, tennis rackets, golf clubs, and sports gear. Carbon fiber's lightweight and strong properties contribute to increased athletic performance.

Insights by Manufacturing Process

The hot melt process segment accounted for the largest market share over the forecast period 2023 to 2032. The hot melt technique employs thermoplastic polymers, which melt when heated and solidify when cooled. When compared to standard prepreg production methods, this technology is noted for its efficiency and reduced processing time. The hot melt technique is extremely well-suited for applications in the automotive sector, particularly for the production of interior components. It enables the rapid manufacture of interior panels, trim pieces, and acoustic components. The hot melt process's capacity to accomplish fast cycle times is helpful in industries where quick production turnaround is required. This is especially useful in the automotive industry and other businesses with high-volume production requirements.

Insights by End Use

The aerospace segment accounted for the largest market share over the forecast period 2023 to 2032. Electric and hybrid-electric aircraft are rising developments in the aerospace industry. These aircraft designs frequently prioritise lightweight materials for enhanced economy, opening up possibilities for the use of prepreg materials. Aerospace manufacturers are raising their production rates in response to rising demand for air travel. As a result, there is a greater demand for innovative materials such as prepregs to suit the production needs of modern aircraft. Globally, the aerospace industry is increasing, with emerging markets playing an important role. As new aircraft production facilities are built, the demand for sophisticated materials like as prepregs grows.

Recent Market Developments

- In April 2022, Hitachi Power Solution has announced the launch of innovative services such as "Blade Total Service."

Competitive Landscape

Major players in the market

- Evonik Industries AG (Germany)

- Teijin Limited (Japan)

- SGL Group (Germany)

- DSM (Netherlands)

- SABIC (Saudi Arabia)

- Solvay (Belgium)

- Hexcel Corporation (U.S.)

- Toray Industries Inc, (Japan)

- 3M (U.S.)

- BASF SE (Germany)

- Covestro AG (Germany)

- Dow (U.S.)

- Borealis AG (Austria)

- ZOLTEK (U.S.)

- Celanese Corporation (U.S.)

- Mitsubishi Chemical Corporation (Japan)

- PARK AEROSPACE CORP (U.S.)

- Gurit (Switzerland)

- Teijin Aramid B.V (Japan)

- Axiom Materials (U.S.)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2032.

Prepreg Market, Manufacturing Process Analysis

- Solvent Dip

- Hot-Melt

Prepreg Market, Fiber Analysis

- Carbon Fiber

- Glass Fiber

- Aeamid Fiber

- Other

Prepreg Market, Resin Analysis

- Thermoset

- Thermoplastic

Prepreg Market, End Use Analysis

- Automotive

- Aerospace

- Electronics

- Wind Energy

- Others

Prepreg Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Prepreg Market?The global Prepreg Market is expected to grow from USD 13.1 Billion in 2023 to USD 26.8 Billion by 2032, at a CAGR of 11.9% during the forecast period 2023-2032.

-

2. Who are the key market players of the Prepreg Market?Some of the key market players of market are Evonik Industries AG (Germany), Teijin Limited (Japan), SGL Group (Germany), DSM (Netherlands), SABIC (Saudi Arabia), Solvay (Belgium), Hexcel Corporation (U.S.), Toray Industries Inc, (Japan) 3M (U.S.), BASF SE (Germany), Covestro AG (Germany), Dow (U.S.), Borealis AG (Austria), ZOLTEK (U.S.), Celanese Corporation (U.S.), Mitsubishi Chemical Corporation (Japan), PARK AEROSPACE CORP (U.S.), Gurit (Switzerland), Teijin Aramid B.V (Japan), Axiom Materials (U.S.).

-

3. Which segment holds the largest market share?The carbon fiber segment holds the largest market share and is going to continue its dominance.

-

4. Which region is dominating the Prepreg Market?North America is dominating the Prepreg Market with the highest market share.

Need help to buy this report?