North America Heavy Duty Connector Market Size, Share, and COVID-19 Impact Analysis, By Type (Circular Connectors, Rectangular Connectors, Miniature Connectors, Modular Connectors, and Others), By Application (Industrial Equipment, Automotive, Railway Systems, Aerospace, Marine, and Others), and North America Heavy Duty Connector Market Insights, Industry Trend, Forecasts to 2035.

Industry: Semiconductors & ElectronicsNorth America Heavy Duty Connector Market Insights and Forecast to 2035

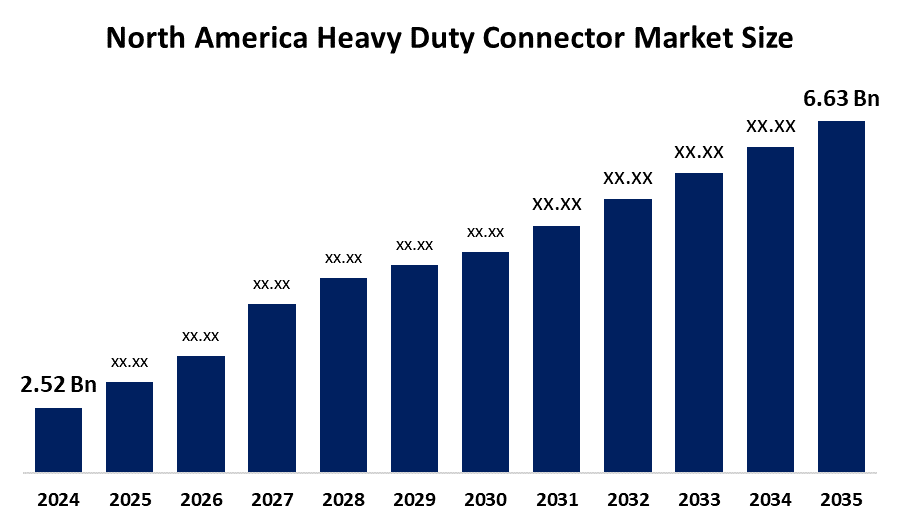

- The North America Heavy Duty Connector Market was valued at USD 2.52 billion in 2024.

- The market is expected to grow at a CAGR of approximately 9.19% from 2025 to 2035.

- The market size is projected to reach USD 6.63 billion by 2035.

Get more details on this report -

According to a research report published by Spherical Insights & Consulting, the North America Heavy Duty Connector Market is projected to reach USD 6.63 billion by 2035, growing at a CAGR of 9.19% from 2025 to 2035. The primary market drivers include industrial automation, robotics, aerospace and defense modernization, renewable energy expansion, and electric vehicle infrastructure.

Market Overview

The North American heavy-duty connector market comprises rugged, modular electrical connectors designed to provide secure power and data transmission in demanding industrial environments. These connectors are engineered for high mechanical strength and resistance to vibration, dust, moisture, and electromagnetic interference, and often include customized inserts for power, signal, or hybrid applications. They are widely used in aerospace, defense, industrial automation, renewable energy, transportation, and electric vehicle (EV) infrastructure, where reliability and safety are critical for performance.The growing trend of digitalization and electrification across industries in North America has increased the demand for high-power and data interfaces. These systems are designed to be safe, modular, and easy to maintain in complex electrical setups. As enterprises transition to Industry 4.0, the reliability of electrical connections becomes essential for uninterrupted operations, making heavy-duty connectors critical components for effective power and data transfer across industrial environments.Material innovations are further enhancing the performance of heavy-duty connectors. The use of modern thermoplastics, nickel-plated alloys, and corrosion-resistant composites improves mechanical strength and thermal stability. Advanced sealing techniques provide protection against moisture, dust, and chemicals. Manufacturers are also adopting ergonomic, modular designs that enable faster assembly and disassembly during field operations. Compact and lightweight connectors are increasingly used in aerospace and defense applications, improving longevity and operational efficiency across industrial sectors.Eaton, for example, has invested more than USD 500 million in North American manufacturing to meet rapidly rising demand for its electrical solutions across utility, commercial, data center, healthcare, industrial, and residential sectors. The company operates manufacturing plants in Texas, Wisconsin, and South Carolina, along with new distribution centers in Chicago and Dallas.

Report Coverage

This research report categorizes the North America heavy-duty connector market based on various segments and regions, providing revenue forecasts and trend analysis for each submarket. The report examines the key growth drivers, opportunities, and challenges influencing the market. It also highlights recent developments and competitive strategies, including expansions, product launches, innovations, partnerships, mergers, and acquisitions, to provide a clear view of the competitive landscape.Furthermore, the report strategically identifies and profiles key market players, analyzing their core competencies and performance across each sub-segment of the North America heavy-duty connector market.

North America Heavy Duty Connector Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 2.52 billion |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | CAGR of 9.19% |

| 2035 Value Projection: | USD 6.63 billion |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 161 |

| Tables, Charts & Figures: | 132 |

| Segments covered: | By Type, By Application |

| Companies covered:: | TE Connectivity, Amphenol Corporation, Molex LLC, Eaton Corporation, Phoenix Contact, Harting Technology Group, ITT Cannon, Bel Fuse Inc., and Others key players |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The North American heavy-duty connector market is rapidly expanding, driven by growing demand across industries such as automation, renewable energy, electric vehicles, data centers, aerospace, and defense, where reliable and durable connectors are essential for transmitting power and data in harsh environments. Technological advancements that enhance resistance to vibration, temperature, and electromagnetic interference further support market growth.The acceleration of renewable energy projects in North America including wind, solar, and hydroelectric installations is significantly driving demand for heavy-duty connectors. These connectors are widely used in power distribution, inverter systems, and grid-connection applications. As industrial electrification advances, manufacturers are investing in standardized, high-voltage connector solutions, with electrification trends continually reshaping market applications and requirements.

Restraining Factors

The North America heavy-duty connector market faces key challenges, including high costs, complex compliance standards, supply chain constraints, technological complexity, and intense competition.

Market segmentation

The North America heavy duty connector market share is classified into type and application.

- The rectangular connectors segment held a substantial share in 2024 and is anticipated to grow at a remarkable CAGR during the forecast period.

The North America heavy-duty connector market is divided by type into circular connectors, rectangular connectors, miniature connectors, modular connectors, and others. Among these, the rectangular connectors segment held a substantial market share in 2024 and is expected to grow at a remarkable CAGR during the forecast period. This growth is driven by its versatile multi-pin configurations, which are well-suited for complex industrial systems, its durability to withstand harsh conditions in sectors such as automation, aerospace, and automotive, and its user-friendly design that simplifies assembly and maintenance compared to circular alternatives.

- The industrial equipment segment dominated the market in 2024 and is anticipated to grow at a substantial CAGR over the forecast period.

The North America heavy-duty connector market is segmented by application into industrial equipment, automotive, railway systems, aerospace, marine, and others. Among these, the industrial equipment segment dominated the market in 2024 and is expected to grow at a substantial CAGR during the forecast period. This dominance is driven by the reliance of automation, robotics, and smart factories on these connectors for reliable control systems. Their versatility enables efficient power and data transmission in demanding environments, while the ongoing energy transition, including renewable energy adoption and electrification, further boosts demand across industrial sectors.

Competitive Analysis

The report provides a comprehensive analysis of key organizations operating in the North America heavy-duty connector market, along with a comparative evaluation based on product offerings, business overviews, geographic presence, corporate strategies, segment market share, and SWOT analysis. Additionally, the report includes an in-depth assessment of recent company developments, such as product launches, technological innovations, joint ventures, partnerships, mergers and acquisitions, and strategic alliances, enabling a thorough evaluation of the competitive landscape within the market.

List of Key Companies

- TE Connectivity

- Amphenol Corporation

- Molex LLC

- Eaton Corporation

- Phoenix Contact

- Harting Technology Group

- ITT Cannon

- Bel Fuse Inc.

- Others

Recent Developments

-

March 2025: HARTING Technology Group announced its new Han-Modular Domino modules, featuring a vibration-proof USB-C interface with data transfer rates of up to 20 Gbit/s. Designed for compact industrial installations, these modules offer enhanced space efficiency and are part of the Han-Modular series, enabling customization and scalability across diverse applications.

-

July 2024: ITT Cannon launched lightweight Aluminum D-Sub Backshells made from A380-grade aluminum with electroless nickel plating. These backshells are built for harsh environments, offering over 50% weight reduction compared to traditional D-Sub backshells while maintaining full 360° EMI/RFI shielding and rugged front-mounting capability.

Key Target Audience

- Market Players

- Investors

- End Users

- Government Authorities

- Consulting and Research Firms

- Venture Capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at North America, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the North America heavy-duty connector market as follows:

By Type

- Circular Connectors

- Rectangular Connectors

- Miniature Connectors

- Modular Connectors

- Others

By Application

- Industrial Equipment

- Automotive

- Railway Systems

- Aerospace

- Marine

- Others

Frequently Asked Questions (FAQ)

-

Q: What is the current and forecasted size of the North America heavy duty connector market?A: The market was valued at approximately USD 2.52 billion in 2024 and is projected to grow at a CAGR of 9.19%, reaching around USD 6.63 billion by 2035.

-

Q: What are the primary types in the North America heavy duty connector market?A: The primary types are circular connectors, rectangular connectors, miniature connectors, modular connectors, and others. Among these, the rectangular connectors segment held a substantial share in 2024. The segment is driven by offering versatile multi-pin configurations suited for complex industrial systems.

-

Q: What is the main application in the market?A: The main application is industrial equipment, automotive, railway systems, aerospace, marine, and others. Among these, the industrial equipment segment dominated the market in 2024. This is the dominant segment because automation in robotics and smart factories relies on them for reliable control systems.

-

Q: What are the key driving factors for market growth?A: Growth is driven by industrial automation, robotics, aerospace & defense modernization, renewable energy expansion, and electric vehicle infrastructure.

-

Q: What challenges does the market face?A: Challenges include high costs, complex compliance standards, supply chain challenges, technological complexity, and intense competition.

-

Q: Who are some key players in the market?A: Key companies include TE Connectivity, Amphenol Corporation, Molex LLC, Eaton Corporation, Phoenix Contact, Harting Technology Group, ITT Cannon, Bel Fuse Inc., and others.

Need help to buy this report?