Global Methacrylate Butadiene Styrene Market Size, Share, and COVID-19 Impact Analysis, Impact of Tariff and Trade War Analysis, By Application (Automotive Parts and Consumer Electronics), By Grade (Extrusion and Injection Molding), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Industry: Chemicals & MaterialsMethacrylate Butadiene Styrene Market Summary, Size & Emerging Trends

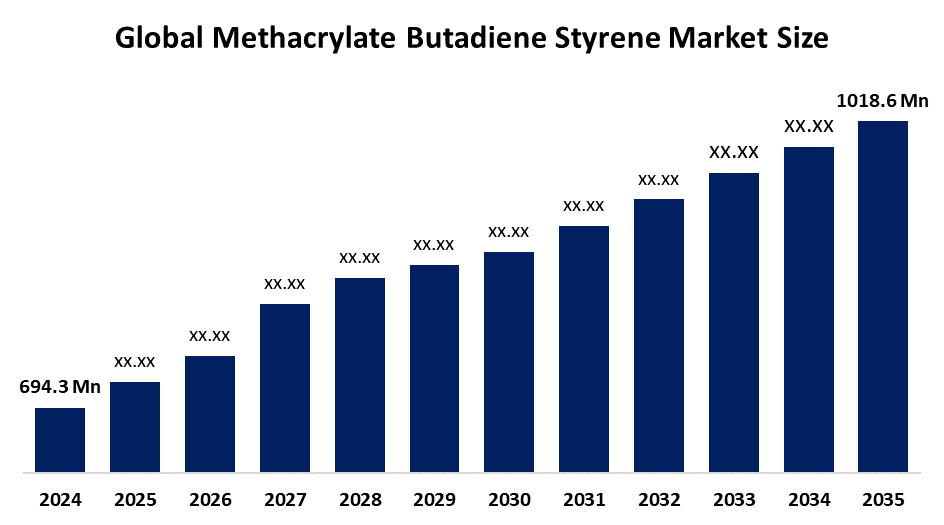

According to Decision Advisor, The Global Methacrylate Butadiene Styrene Market Size is Expected to Grow from USD 694.3 Million in 2024 to USD 1018.6 Million by 2035, at a CAGR of 3.55% during the forecast period 2025-2035. Growing demand for lightweight and durable plastic materials in automotive and consumer electronics sectors is a key driving factor for the methacrylate butadiene styrene market.

Get more details on this report -

Key Market Insights

- Asia Pacific is expected to account for the largest share in the methacrylate butadiene styrene market during the forecast period.

- In terms of application, automotive parts segment is projected to dominate the market revenue.

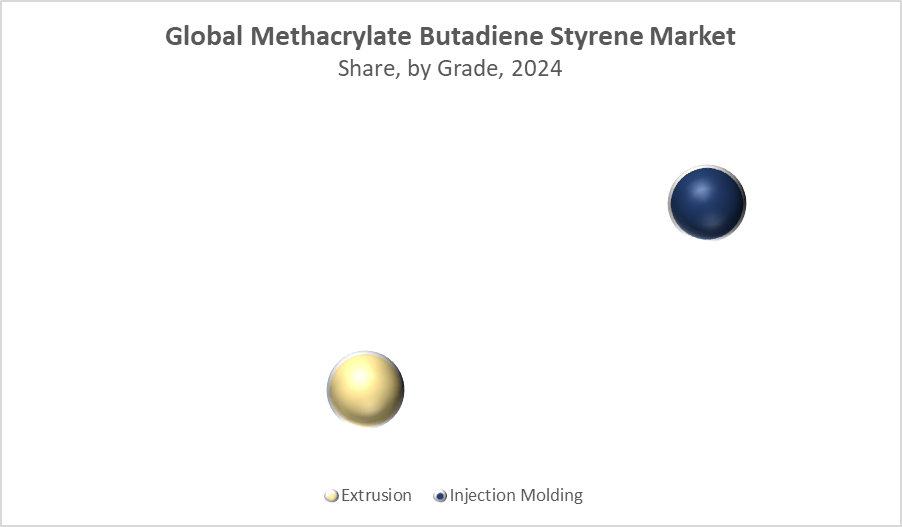

- In terms of grade, injection molding segment holds the largest revenue share globally during the forecast period.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 694.3 Million

- 2035 Projected Market Size: USD 1018.6 Million

- CAGR (2025-2035): 3.55%

- Asia Pacific: Largest market in 2024

- North America: Fastest growing market

Methacrylate Butadiene Styrene Market

The Methacrylate Butadiene Styrene (MBS) Market Size centers on the production of a versatile thermoplastic polymer widely used for its impact resistance, gloss, and weatherability. MBS is a copolymer designed to enhance the properties of plastics in automotive parts, consumer electronics, and other industries requiring lightweight and durable materials. Governments worldwide promote the use of sustainable and recyclable plastics, indirectly supporting the MBS market. The demand for MBS is fueled by rising automotive production, growing consumer electronics adoption, and increasing preference for aesthetically appealing yet robust materials. With technological advancements in polymer chemistry, the market is positioned for steady growth through 2035.

Methacrylate Butadiene Styrene Market Trends

- Increasing use of injection molding processes for manufacturing complex automotive components.

- Growing emphasis on lightweight materials in automotive and electronics to improve fuel efficiency and portability.

- Rising innovation in MBS grades to improve heat resistance and surface finish for premium electronics.

Global Methacrylate Butadiene Styrene Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 694.3 Million |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | CAGR of 3.55% |

| 2035 Value Projection: | USD 1018.6 Million |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 245 |

| Tables, Charts & Figures: | 117 |

| Segments covered: | By Application, By Grade |

| Companies covered:: | Kaneka Corporation, Dow Chemical Company, Mitsubishi Chemical Group, LG Chem, Arkema Group, Denka Company Limited, Formosa Plastics Corporation, INEOS Styrolution, Wanda Chemical Group, Shandong Repolyfine Chemical Co., Ltd., and Other Key Companies. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Methacrylate Butadiene Styrene Market Dynamics

Driving Factors: The automotive industry's shift towards fuel-efficient vehicles fuels demand for impact-resistant plastics

The methacrylate butadiene styrene (MBS) market is primarily driven by the increasing demand for lightweight, durable materials in automotive parts and consumer electronics. The automotive industry's shift towards fuel-efficient vehicles fuels demand for impact-resistant plastics, while the consumer electronics sector requires materials with excellent surface finish and heat resistance. Technological advances in polymer grades and molding processes improve product quality, boosting adoption. Additionally, growing infrastructure and rising disposable incomes in emerging markets further propel the market’s growth globally.

Restrain Factors: Availability of alternative polymer blends and composites poses stiff competition

Several factors restrain the growth of the MBS market. Volatile raw material prices increase production costs, affecting profit margins for manufacturers. Additionally, the availability of alternative polymer blends and composites poses stiff competition, limiting market share expansion. Environmental regulations focusing on reducing plastic waste and promoting biodegradable materials add compliance costs. Limited recycling infrastructure in some regions further impacts market acceptance. These combined factors create barriers for sustained growth, necessitating innovation and cost optimization.

Opportunity: Emerging economies with growing automotive

The MBS market holds promising opportunities due to the expanding electric vehicle (EV) industry, which requires lightweight and durable plastic components for better efficiency. Emerging economies with growing automotive and electronics sectors provide new markets for MBS products. Ongoing research into sustainable, eco-friendly polymer formulations aligns with global environmental goals and consumer preferences. Furthermore, advancements in polymer chemistry allow for enhanced performance grades, opening applications in high-demand segments, thus driving future growth and diversification in the MBS industry.

Challenges: Stringent environmental regulations require costly compliance measures

The methacrylate butadiene styrene market faces challenges such as supply chain disruptions impacting raw material availability and increasing lead times. High energy consumption during production escalates costs and environmental footprints. Competition from alternative polymers and composites threatens market share. Additionally, stringent environmental regulations require costly compliance measures. Limited technical expertise in some regions hampers manufacturing efficiency. These challenges demand continuous innovation, strategic partnerships, and investment in sustainable production methods to maintain competitiveness and market stability.

Global Methacrylate Butadiene Styrene Market Ecosystem Analysis

The global MBS market ecosystem includes raw material suppliers of methacrylate and butadiene monomers, manufacturers specializing in polymer compounding, and end-users in automotive and electronics industries. Regulatory bodies promote sustainable production and recycling. Key players invest in R&D for advanced grades and eco-friendly products to stay competitive.

Global Methacrylate Butadiene Styrene Market, By Application

The automotive parts segment dominates the global Methacrylate Butadiene Styrene (MBS) market, accounting for approximately 40% of the market share. This strong position is driven by the growing demand for lightweight and impact-resistant components such as bumpers, dashboards, and trims. MBS offers excellent mechanical strength and thermal stability, making it ideal for automotive applications where durability and safety are critical. Additionally, the increasing focus on electric vehicles and fuel efficiency is further boosting the demand for MBS materials in the automotive sector.

The consumer electronics segment holds an estimated 20% share of the global MBS market. This sector leverages MBS for manufacturing durable casings and internal components in devices like smartphones, laptops, and household appliances. The material’s superior surface finish and resistance to heat make it highly suitable for electronics applications where both aesthetic appeal and performance are important. Rising consumer demand for compact, lightweight, and high-performance electronics is driving the growth of MBS in this industry, supported by ongoing advancements in polymer grades designed specifically for electronic devices.

Global Methacrylate Butadiene Styrene Market, By Grade

The injection molding grade segment holds the largest share of the global Methacrylate Butadiene Styrene (MBS) market, estimated at around 60%. This dominance is attributed to its extensive use in producing complex and high-precision components, especially in the automotive and consumer electronics industries. Injection molding enables the manufacture of parts with intricate shapes and tight tolerances, making it ideal for bumpers, dashboards, electronic housings, and internal parts that demand both strength and aesthetic quality.

Get more details on this report -

The extrusion grade segment accounts for approximately 35% of the global MBS market. This grade is primarily preferred for manufacturing films, sheets, and profiles used across various industrial and consumer applications. Extrusion processes provide continuous shapes and surfaces, which are widely used in packaging, construction materials, and other functional applications. While it holds a smaller share compared to injection molding, extrusion grade MBS remains essential for products requiring consistent thickness and surface finish.

Asia Pacific is forecasted to dominate the global methacrylate butadiene styrene (MBS) market, primarily driven by rapid industrialization and robust growth in automotive production across major economies such as China, India, and Japan. China, being the world’s largest automotive manufacturer, has an expanding demand for lightweight and impact-resistant materials like MBS to improve fuel efficiency and vehicle safety. India’s growing middle class and infrastructure investments are boosting vehicle production, further increasing MBS consumption. Japan’s advanced automotive technologies and strong electronics sector also contribute significantly to the region’s market dominance. Moreover, ongoing urbanization, rising disposable incomes, and government initiatives supporting manufacturing innovation bolster demand across various applications, making Asia Pacific the largest and most influential market for MBS.

North America is witnessing the fastest growth rate in the MBS market, fueled by continuous technological advancements and the rising adoption of electric vehicles (EVs). The region’s automotive industry is rapidly transitioning to EVs, which require advanced polymers like MBS for lightweight and durable components that enhance battery efficiency and vehicle range. Additionally, North America’s well-established electronics manufacturing sector is investing in high-performance materials to meet consumer demand for innovative, compact, and reliable devices. Government policies encouraging clean energy and sustainability, along with strong R&D activities, also accelerate the adoption of MBS in the region, driving its rapid market expansion despite Asia Pacific’s larger overall size.

WORLDWIDE TOP KEY PLAYERS IN THE METHACRYLATE BUTADIENE STYRENE MARKET INCLUDE

- Kaneka Corporation

- Dow Chemical Company

- Mitsubishi Chemical Group

- LG Chem

- Arkema Group

- Denka Company Limited

- Formosa Plastics Corporation

- INEOS Styrolution

- Wanda Chemical Group

- Shandong Repolyfine Chemical Co., Ltd.

- Others

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Decision Advisor has segmented the Methacrylate Butadiene Styrene market based on the below-mentioned segments:

Global Methacrylate Butadiene Styrene Market, By Application

- Automotive Parts

- Consumer Electronics

Global Methacrylate Butadiene Styrene Market, By Grade

- Extrusion

- Injection Molding

Global Methacrylate Butadiene Styrene Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

Which application segment dominates the Global Methacrylate Butadiene Styrene Market?The automotive parts segment is projected to dominate the market revenue.

-

Which grade segment holds the largest revenue share globally in the MBS market?The injection molding grade segment holds the largest revenue share globally during the forecast period.

-

What are the key drivers for the growth of the Methacrylate Butadiene Styrene Market?Growing demand for lightweight and durable plastic materials in automotive and consumer electronics sectors, the shift towards fuel-efficient vehicles, and technological advancements in polymer grades and molding processes are key growth drivers.

-

What challenges are restraining the growth of the Methacrylate Butadiene Styrene Market?Challenges include volatile raw material prices, competition from alternative polymer blends and composites, stringent environmental regulations, and limited recycling infrastructure.

-

What opportunities exist in the Methacrylate Butadiene Styrene Market?Opportunities arise from the expanding electric vehicle industry, growth in emerging economies’ automotive and electronics sectors, and advancements in sustainable and eco-friendly polymer formulations.

-

What trends are shaping the Methacrylate Butadiene Styrene Market?Increasing use of injection molding for complex automotive parts, emphasis on lightweight materials for fuel efficiency and portability, and innovation in MBS grades improving heat resistance and surface finish are key trends.

-

Who are the key players in the Global Methacrylate Butadiene Styrene Market?Major players include Kaneka Corporation, Dow Chemical Company, Mitsubishi Chemical Group, LG Chem, Arkema Group, Denka Company Limited, Formosa Plastics Corporation, INEOS Styrolution, Wanda Chemical Group, and Shandong Repolyfine Chemical Co., Ltd.

-

How does the market segment by application break down in the Methacrylate Butadiene Styrene Market?The automotive parts segment accounts for approximately 40% of the market, while consumer electronics hold about 20%.

-

How does the market segment by grade break down in the Methacrylate Butadiene Styrene Market?Injection molding grade holds around 60% of the market share, while extrusion grade accounts for approximately 35%.

-

What are the main applications of Methacrylate Butadiene Styrene?MBS is primarily used in automotive parts such as bumpers and dashboards, and in consumer electronics for casings and internal components due to its impact resistance, gloss, and weatherability.

-

What is the impact of environmental regulations on the Methacrylate Butadiene Styrene Market?Environmental regulations increase compliance costs and encourage the development of sustainable, recyclable polymer products, impacting production and market dynamics.

Need help to buy this report?