Japan Magnesium Alloy Market Size, Share, By Product Type (Extrusions, Sheets and Plates, Castings, Tubes and Pipes, and Others), By Application (Automotive & Transportation, Aerospace & Defense, Electronics, and Others), Japan Magnesium Alloy Market Insights, Industry Trend, Forecasts to 2035

Industry: Chemicals & MaterialsJapan Magnesium Alloy Market Insights Forecasts to 2035

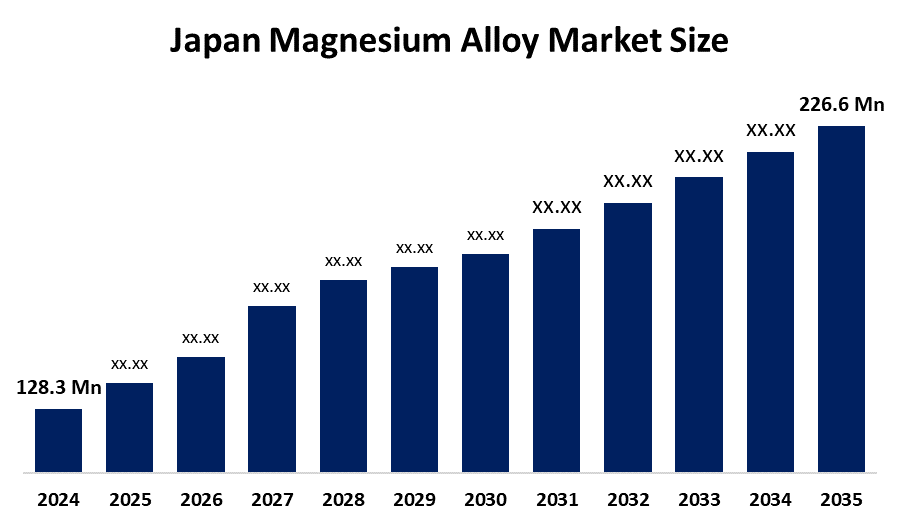

- Japan Magnesium Alloy Market Size 2024: USD 128.3 Mn

- Japan Magnesium Alloy Market Size 2035: USD 226.6 Mn

- Japan Magnesium Alloy Market CAGR 2024: 5.31%

- Japan Magnesium Alloy Market Segments: Product Type and Application.

Get more details on this report -

The Japanese magnesium alloy market is an important niche market within the broader lightweight metal market. Magnesium alloys typically consist of magnesium combined with other metallic materials or chemical elements such as aluminium, zinc, manganese, rare earth metals, etc. With relatively low density and high strength-to-weight ratios, excellent machining capabilities and anti-vibrational qualities, Magnesium Alloys are beneficial to many industries, including but not limited to automotive, electronic products, aerospace, industrial products, and medical devices, thereby strengthening Japan’s huge capacity for manufacturing and high-quality precision engineering.

The Japanese government continues to actively promote the use of magnesium alloys through policy initiatives promoting the use of lightweight materials, the need to reduce carbon footprints through decarbonization, and innovations to help grow the advanced manufacturing sector of Japan. The Ministry of Economy, Trade and Industry (METI) advocates for the increased use of lightweight Metals as a means of reducing fuel consumption and CO2 emissions within the Auto and Transportation sectors. National Strategies have indirectly positively impacted the demand for magnesium alloys by promoting energy-efficient mobility, Next Generation Vehicles, and Smart Manufacturing.

Japan's magnesium alloy industry is focusing on improving magnesium alloys in terms of strength, corrosion resistance, heat resistance, formability, and developing new high-performance magnesium alloys primarily for auto manufacturing applications and the growing usage of magnesium alloys in harsher industrial atmospheres. In addition, the coating of magnesium-alloy products with newer types of coatings, as well as newer surface treatment technologies that can mitigate corrosion, will continue to expand the possibilities for magnesium alloys to be used in more extreme environments. A focus on sustainability and continued work to improve the recycling process for magnesium alloys and the production of magnesium alloys through low-carbon processes continues to be significant within the Japanese magnesium alloy industry.

Japan Magnesium Alloy Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 128.3 Mn |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | 5.31% |

| 2035 Value Projection: | USD 226.6 Mn |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 120 |

| Segments covered: | By Product Type, By Application |

| Companies covered:: | UACJ Corporation, Kobe Steel, Ltd., Nippon Kinzoku Co., Ltd., Nippon Kinzoku Magnesium Alloy Division, Riken Technos Corp, Nippon Kinzoku (broader metals), Toho Zinc Co., Ltd., Asia Sanpo Co. Ltd., OM Digital Solutions, and other key players |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics of the Japan Magnesium Alloy Market:

The Japanese magnesium alloy market is driven by strong demand for lightweight materials in the automotive and transportation sectors to improve fuel efficiency and reduce carbon emissions. Growth in electric vehicles, aerospace components, and consumer electronics further supports magnesium alloy adoption due to its high strength-to-weight ratio and excellent vibration-damping properties. Additionally, government initiatives promoting decarbonization and advanced manufacturing also accelerate market growth.

There are barriers to the wider adoption of magnesium alloy, as the production and processing costs and the volatility of raw magnesium pricing impede the broad adoption of magnesium alloys in the production of automotive and transportation products. Magnesium alloys also have limitations around corrosion resistance and flammability, creating additional handling and safety considerations. There is also competition from aluminium alloy and advanced composite materials, further hindering the growth of the magnesium alloys market.

Growth opportunities exist through the development of high-performance and rare-earth magnesium alloys, improved corrosion-resistant coatings, expanding application in electric vehicles and aerospace parts, and the growth of recycling and low-carbon magnesium production supported by the Japanese green and circular economy efforts.

Market Segmentation

The Japan Magnesium Alloy market share is classified into product type and application.

By Product Type:

The Japan magnesium alloy market is divided by product type into extrusions, sheets and plates, castings, tubes and pipes, and others. Among these, the extrusions segment held the largest market share in 2024 and is anticipated to grow at the highest CAGR during the predicted timeframe. This is due to the increasing demand for lightweight, high-strength materials in the automotive and aerospace industries, which is driven by strict environmental regulations and the rise of electric vehicles (EVs).

By Application:

The Japan magnesium alloy market is divided by application into automotive & transportation, aerospace & defence, electronics, and others. Among these, the automotive segment held the largest market share in 2024 and is anticipated to grow at a significant CAGR during the forecast period. The Automotive and Transportation sector utilises magnesium alloys for their lightweight yet sturdy properties, enhancing fuel efficiency and performance.

Competitive Analysis:

The report offers the appropriate analysis of the key organisations/companies involved within the Japan Magnesium Alloy market, along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborate analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

Top Key Companies in Japan Magnesium Alloy Market:

- UACJ Corporation

- Kobe Steel, Ltd.

- Nippon Kinzoku Co., Ltd.

- Nippon Kinzoku Magnesium Alloy Division

- Riken Technos Corp

- Nippon Kinzoku (broader metals)

- Toho Zinc Co., Ltd.

- Asia Sanpo Co. Ltd.

- OM Digital Solutions

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at the Japan, regional, and country levels from 2020 to 2035. Decisions Advisors has segmented the Japan magnesium alloy market based on the below-mentioned segments:

Japan Magnesium Alloy Market, By Product Type

- Extrusions

- Sheets and Plates

- Castings

- Tubes and Pipes

- Others

Japan Magnesium Alloy Market, Application

- Automotive & Transportation

- Aerospace & Defense

- Electronics

- Others

Frequently Asked Questions (FAQ)

-

Q: What is the current and forecasted market size of Japan’s magnesium alloy market?A: Japan’s magnesium alloy market was valued at USD 128.3 million in 2024 and is projected to reach USD 226.6 million by 2035, growing at a CAGR of 5.31% during the forecast period from 2025 to 2035.

-

Q: Which product type segment dominates the Japanese magnesium alloy market?A: The extrusions segment held the largest market share in 2024 and is expected to grow at the highest CAGR, driven by increasing demand for lightweight and high-strength materials in automotive and aerospace applications.

-

Q: Which application segment leads the Japan magnesium alloy market?A: Automotive & Transportation is the leading application segment, supported by the need to improve fuel efficiency, reduce vehicle weight, and meet strict environmental regulations.

-

Q: What are the key drivers of the Japan magnesium alloy market?A: Key drivers include growing demand for lightweight materials, rising electric vehicle production, increased use in aerospace and electronics, and strong government support for decarbonization and advanced manufacturing.

-

Q: What challenges limit the growth of the Japanese magnesium alloy market?A: High production and processing costs, volatility in raw magnesium prices, corrosion and flammability concerns, and competition from aluminium alloys and advanced composites restrain market growth.

-

Q: Who are the major players in the Japanese magnesium alloy market?A: Major companies include UACJ Corporation, Kobe Steel, Ltd., Nippon Kinzoku Co., Ltd., Riken Technos Corp, Toho Zinc Co., Ltd., Asia Sanpo Co., Ltd., OM Digital Solutions, and other regional players.

-

Q: Who are the target audiences for this market report?A: The report targets market players, investors, end-users, government authorities, consulting and research firms, venture capitalists, and value-added resellers (VARs).

Need help to buy this report?