Japan Electrical Discharge Machining Market Size, Share, By Workload Capacity (Below 2,000 lbs, 2,000 to 4,000 lbs, 4,000 to 8,000 lbs, and Above 8,000 lbs), By Machine Type (Die Sink Electrical Discharge Machining, Wire Electrical Discharge Machining, and Hole Drilling Electrical Discharge Machining), By End Use (Automotive, Electrical & Electronics, Healthcare, Aerospace & Defence, and Others), Japan Electrical Discharge Machining Market Insights, Industry Trends, and Forecasts to 2035.

Industry: Machinery & EquipmentJapan Electrical Discharge Machining Market Insights Forecasts to 2035

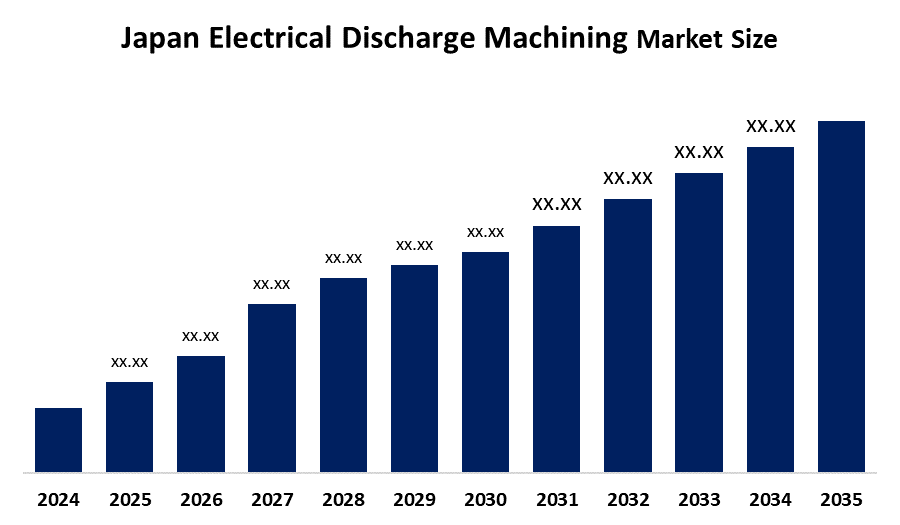

- Japan Electrical Discharge Machining Market CAGR 2024: 5.3%

- Japan Electrical Discharge Machining Market Segments: Workload Capacity, Machine Type, and End Use

Get more details on this report -

The Japan Electrical Discharge Machining (EDM) Market Size refers to a process of high precision manufacturing which is used to manufacture complex engineered parts with extremely tight tolerances that traditional machining methods fail to achieve. EDM is widely used in the automotive, electrical & electronics, aerospace & defence, healthcare, and industrial machinery industries where precision and surface finish are key requirements. The demand for the market is mainly influenced by Japan's advanced industrial ecosystem, its leadership in machine tool engineering, and the prominence of the automotive and electronics manufacturing sectors. Moreover, the escalating necessity for miniaturized components, lightweight materials, and complex moods and dies is resulting in the increasing utilization of EDM technology.

Innovations in technology including CNC integration, automation systems, high, speed machining, digital control platforms, and smart factory adoption have been contributing to the improvement of precision, efficiency, and productivity. Government actions are a key factor in the growth of the market. Initiatives by the Ministry of Economy, Trade and Industry (METI), including the Mono zukuri Subsidy Program and Connected Industries policy, encourage automation, robotics, machine tool upgrading, and the utilization of digital technologies in manufacturing. Furthermore, investment tax credits for the purchase of state, of, the, art equipment and the industry strategies in line with Society 5.0 facilitate the upgrading of the precision machining sectors.

The future opportunities are anticipated from higher electrification of automotive, growth in semiconductor and medical device manufacturing, and reshoring of high, precision production activities, which together will strengthen the market growth outlook over the forecast period.

Market Dynamics of the Japan Electrical Discharge Machining Market:

The Japan Electrical Discharge Machining Market Size is witnessing a surge in demand for ultra, precision manufacturing in various sectors such as automotive, electrical & electronics, aerospace & defence, and healthcare. The trend of using hard to machine materials, complex geometries, the miniaturization of components, and high, precision moods and dies is leading to the rapid adoption of EDM technologies. Market growth is further boosted by continuous innovations in automation, CNC control systems, and smart manufacturing.

The market is limited to some extent due to the high cost of capital required for the purchase of cutting, edge EDM machines, as well as high maintenance and operating expenses, and a lack of highly skilled operators. Furthermore, smaller and mid, sized manufacturers that are more cost, conscious and seeking to limit expenses may be discouraged from adopting the technology due to longer machining times when compared to conventional methods and process parameter sensitivity, thus impacting overall market penetration.

Japan manufacturing modernization initiatives, electric vehicles growth, semiconductor manufacturing, and medical devices production are opening up new avenues for the market. The rise in integration of Industry 4.0, AI, based process optimization, and the need for precision components in renewable energy and aerospace applications are some of the factors that will keep the EDM market on a growth path during the forecast period.

Japan Electrical Discharge Machining (EDM) Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Forecast Period: | 2024-2035 |

| Forecast Period CAGR 2024-2035 : | CAGR Of 5.3% |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 210 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Machine Type, By End Use |

| Companies covered:: | Mitsubishi Electric Corporation Makino Milling Machine Co., Ltd. Sodic Co., Ltd. FANUC Corporation Seibu Electric & Machinery Co., Ltd. DMG MORI Co., Ltd. GF Machining Solutions MC Machinery Systems, Inc. Or bray Co., Ltd. Others Key Players |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Market Segmentation

The Japan electrical discharge machining market share is classified into workload capacity, machine type, and end use.

By Workload Capacity:

The Japan electrical discharge machining market is divided by workload capacity into below 2000 lbs, 2000 to 4000 lbs, 4000 to 8000 lbs, and above 8000 lbs. Among these, the 4000 to 8000 lbs segment dominated the share in 2024 and is anticipated to grow at a remarkable CAGR during the forecast period. This is due to the adoption of this capacity range in the automotive, aerospace, and industrial manufacturing sectors, where medium to heavy machining, high precision, balanced flexibility, and cost-effectiveness make this capacity range the most preferred.

By Machine Type:

The Japan electrical discharge machining market is divided by machine type into die sink electrical discharge machining, wire electrical discharge machining, and hole drilling electrical discharge machining. Among these, the wire electrical discharge machining segment dominated the share in 2024 and is anticipated to grow at a remarkable CAGR during the forecast period. The market is fuelled by the growing demand for complex geometries, high precision cutting, material conservation, excellent surface finish, and usage in the electronics, automotive, and aerospace industries in Japan.

By End Use:

The Japan electrical discharge machining market is divided by end use into automotive, electrical & electronics, healthcare, aerospace & defence, and others. Among these, the automotive segment dominated the share in 2024 and is anticipated to grow at a remarkable CAGR during the forecast period. The market growth can be attributed to the high production of vehicles, the adoption of electric vehicles, the demand for precision moods and dies, the production of lightweight components, and investments in advanced machining technology by Japanese automakers.

Competitive Analysis:

The report offers the appropriate analysis of the key organisations/companies involved within the Japan electrical discharge machining market, along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

Top Key Companies in Japan Electrical Discharge Machining Market:

- Mitsubishi Electric Corporation

- Makino Milling Machine Co., Ltd.

- Sodic Co., Ltd.

- FANUC Corporation

- Seibu Electric & Machinery Co., Ltd.

- DMG MORI Co., Ltd.

- GF Machining Solutions

- MC Machinery Systems, Inc.

- Or bray Co., Ltd.

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at the Japan, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the Japan electrical discharge machining market based on the below-mentioned segments:

Japan Electrical Discharge Machining Market, By Workload Capacity

- Below 2000 lbs

- 2000 to 4000 lbs

- 4000 to 8000 lbs

- Above 8000 lbs

Japan Electrical Discharge Machining Market, By Machine Type

- Die Sink EDM

- Wire EDM

- Hole Drilling EDM

Japan Electrical Discharge Machining Market, By End Use

- Automotive

- Electrical & Electronics

- Healthcare

- Aerospace & Defence

- Others

Frequently Asked Questions (FAQ)

-

What is the Japan electrical discharge machining (EDM) market size?Japan electrical discharge machining market is expected to grow at a CAGR of 5.3% during the forecast period 2025-2035.

-

What are the key growth drivers of the Japan electrical discharge machining market?Market growth is driven by increasing demand for high-precision machining, rising adoption of hard-to-machine materials, growth in automotive and electronics manufacturing, expansion of electric vehicle production, demand for complex molds and dies, and continuous investments in advanced machining technologies.

-

What factors restrain the Japan electrical discharge machining market?Constraints include high capital investment requirements for advanced EDM equipment, elevated operating and maintenance costs, longer machining cycles compared to conventional methods, process complexity, and shortages of skilled EDM operators, particularly affecting small and mid-sized manufacturers.

-

How is the Japan electrical discharge machining market segmented by end use?The market is segmented into automotive, electrical & electronics, healthcare, aerospace & defense, and others.

-

Who are the key players in the Japan electrical discharge machining market?Key companies include Mitsubishi Electric Corporation, Makino Milling Machine Co., Ltd., Sodick Co., Ltd., FANUC Corporation, Seibu Electric & Machinery Co., Ltd., DMG MORI Co., Ltd., GF Machining Solutions, MC Machinery Systems, Inc., Orbray Co., Ltd., and others.

-

Who are the target audiences for this market report?The report targets market players, investors, end-users, government authorities, consulting and research firms, venture capitalists, and value-added resellers (VARs).

Need help to buy this report?