Global Iron & Steel Casting Market Size, Share, and COVID-19 Impact Analysis, By Type (Grey Iron, Malleable Iron, and Ductile Iron), By Application (Automotive Segment, Infrastructure & Construction Machine, and Industrial Machinery Segment), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2021 - 2030.

Industry: Advanced MaterialsGlobal Iron & Steel Casting Market Insights Forecasts to 2030

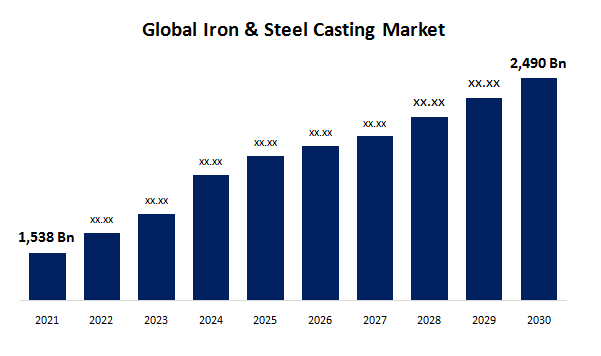

- The Global Iron & Steel Casting Market was valued at USD 1,538 billion in 2021.

- The market is growing at a CAGR of 5.5% from 2022 to 2030

- The Global Iron & Steel Casting Market is expected to reach USD 2,490 billion by 2030

- Europe is expected to grow the fastest during the forecast period

Get more details on this report -

The Global Iron & Steel Casting Market is expected to reach USD 2,490 billion by 2030, at a CAGR of 5.5% during the forecast period 2022 to 2030. The iron & steel casting market has grown due to the increasing investments in the residential construction industry. In addition, expanding smart city initiatives is anticipated to continue to be a major force behind the trend mentioned above.

Market Overview

A manufacturing process called iron casting creates metal pieces with exact forms and inexpensive production costs. Grey iron, ductile iron, malleable iron, etc., are several iron casting types with highly varied structural shapes. Every casting is produced by melting an alloying component (often scrap steel) in the sand, creating molten metal that is subsequently forced into moulds. The complexity of the shape relies on the material type and if cooling is required during solidification. Cast iron products often have solid mechanical qualities like tensile strength and hardness. Still, they suffer from poor corrosion resistance because of the familiar presence of free carbon or other nonmetallic components like silicon carbide on their surfaces. Due to their qualities, iron and steel are utilized in large-scale endeavours. Iron and steel are commonly used in the building sector in steel cast pipes, cast iron beams, columns, sewer pipes, cisterns, and ducts. The rising demand for automotive items will primarily fuel the global iron and steel casting market.

Components for suspension, engines, cylinder heads, pistons, engine blocks, gears, and drivelines are frequently made from iron and steel casting. Government infrastructure spending will also offer the iron and steel casting industry many opportunities. Governments from all across the world are exploring efforts to develop their infrastructure. The industrialized nations are anticipated to invest in the upkeep and expansion of existing infrastructure projects. On the other hand, developing nations fund new programs' development. Large quantities of steel plates and other iron and steel casting products, as well as construction tools like loaders, are needed by railroads, ports, bridges, factories, and other industrial and manufacturing facilities. Therefore, increasing infrastructure development investments are anticipated to fuel the worldwide iron and steel casting market during the forecast period.

Global Iron & Steel Casting Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2021 |

| Market Size in 2021: | USD 1,538 Billion |

| Forecast Period: | 2022-2030 |

| Forecast Period CAGR 2022-2030 : | 5.5% |

| 2030 Value Projection: | USD 2,490 Billion |

| Historical Data for: | 2019-2020 |

| No. of Pages: | 272 |

| Tables, Charts & Figures: | 104 |

| Segments covered: | By Product Type, By Application |

| Companies covered:: | Arcelor Mittal, China BaoWu Steel Group Corporation Limited, Nippon Steel Corporation, HBIS Group, Jiangsu Shagang Group, POSCO HOLDINGS INC., Tata Steel, JFE Steel Corporation, Shougang Group, Nucor Corporation, JSW, SAIL, NLMK, Techint Group, and U.S. Steel Corporation. |

| Growth Drivers: | The Global Iron & Steel Casting Market is expected to grow from USD 1,538 billion in 2021 to USD 2,490 billion by 2030, at a CAGR of 5.5% during the forecast period 2022-2030. |

| Pitfalls & Challenges: | Iron and steel are commonly used in the building sector in steel cast pipes, cast iron beams, columns, sewer pipes, cisterns, and ducts. The rising demand for automotive items will primarily fuel the global iron and steel casting market. |

Get more details on this report -

Report Coverage

This research report categorizes the market for global iron & steel casting based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global iron & steel casting market.

Recent market developments and competitive strategies such as expansion, product launch and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each global iron & steel casting market sub-segments.

Segmentation Analysis

- In 2021, the grey iron segment dominated the market with the largest market share of 37% and market revenue of 569.0 billion.

Based on the type, the global iron & steel casting market is categorized into Grey Iron, Malleable Iron, and Ductile Iron. In 2021, the grey iron segment dominated the market with the largest market share of 37% and market revenue of 569.0 billion. The most popular variety of cast iron is grey iron, which is created by combining pig iron and limestone. When creating grey steel, hot-rolled coils are cold-drawn to increase their malleability because it has an intermediate carbon concentration and qualities that fall between those of malleable and ductile irons. The metal can then be rolled into sheets, which are strong enough but also simple to bend.

- In 2021, the automotive segment accounted for the largest share of the market, with 40% and market revenue of 615.2 billion.

Based on the application, the iron & steel casting market is categorized into Automotive Segment, Infrastructure & Construction Machine, and Industrial Machinery Segment. In 2021, the automotive segment accounted for the largest share of the market, with 40% and a market revenue of 615.2 billion. Due to its affordability and ease of mass production, the use of iron casting in the automotive industry has been growing over time. The structural elements of engine blocks and cylinder heads are made of iron casting. It can also be found inside the bodies of carburettor engines and gearbox housings, among other crucial components. Comparing cast-iron components to those produced from steel or aluminium alloys resulted in a cost reduction of almost 15% per car. Cast iron products are less expensive because they may be scraped down if there is too much metal left on them; this decreases production waste and lowers costs.

Regional Segment Analysis of the Iron & Steel Casting Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Get more details on this report -

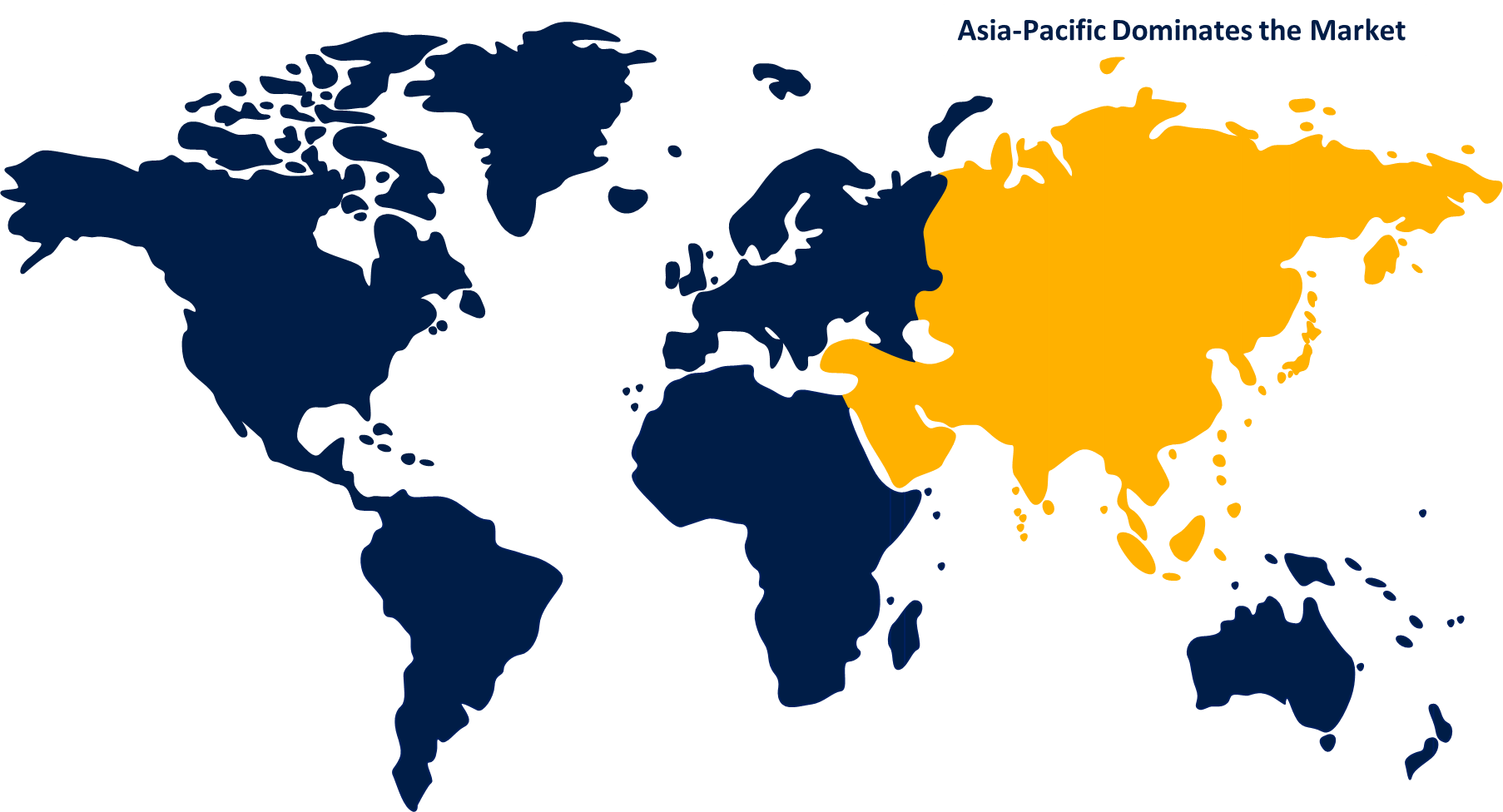

Asia-Pacific emerged as the largest market for the global iron & steel casting market, with a market share of around 33.5% and 1,538 billion of the market revenue in 2021.

- In 2021, Asia-Pacific emerged as the largest market for the global iron & steel casting market, with a market share of around 33.5% and 1,538 billion of the market revenue. It can be ascribed to the region's significant end-use industries' growing product consumption, the region's abundance of casting foundries, established production facilities, and the availability of raw materials.

- The Europe market is expected to grow at the fastest CAGR between 2021 and 2030, In an effort to increase rail connectivity and stop the collapse of the rail freight sector, Europe is making improvements. By 2030, the European Union (EU) wants to reduce CO2 emissions from the transportation sector and quadruple its use of freight rail. The EU is investing in infrastructure improvement in order to improve its water supply and sanitation.

Competitive Landscape

The report offers the appropriate analysis of the key organizations/companies involved within the global iron & steel casting market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the companies' current news and developments, including product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Market Players:

- Arcelor Mittal

- China BaoWu Steel Group Corporation Limited

- Nippon Steel Corporation

- HBIS Group

- Jiangsu Shagang Group

- POSCO HOLDINGS INC.

- Tata Steel

- JFE Steel Corporation

- Shougang Group

- Nucor Corporation

- JSW

- SAIL

- NLMK

- Techint Group

- U.S. Steel Corporation

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Third-party knowledge providers

- Value-Added Resellers (VARs)

Some of the Key Developments:

- In July 2020, A licence agreement for the use of a hot stamping technology owned by Arcelor Mittal was signed by Hyundai Steel. According to the agreement, Hyundai Steel is free to conduct manufacturing and sales operations aggressively in China, Korea, and ASEAN member states without fear of violating any patents.

- In July 2020, Tata Steel announced that it had reached a settlement with the Dutch unions over the problems that had led to the steel factory in IJmuiden, the Netherlands. As part of the agreement, the employment contract for employees in the Netherlands will be extended by five years, and no mandatory layoffs will come from the company's transformation programme.

Market Segment

This study forecasts global, regional, and country revenue from 2019 to 2030. Spherical Insights has segmented the global iron & steel casting market based on the below-mentioned segments:

Global Iron & Steel Casting Market, By Type

- Grey Iron

- Malleable Iron

- Ductile Iron

Global Iron & Steel Casting Market, By Application

- Automotive Segment

- Infrastructure & Construction Machine

- Industrial Machinery Segment

Global Iron & Steel Casting Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

Rest of Middle East & Africa

Frequently Asked Questions (FAQ)

-

What is the market size of the Iron & Steel Casting market?As per Spherical Insights, the size of the Iron & Steel Casting market was valued at USD 1,538 billion in 2022 to USD 2,490 billion by 2030.

-

What is the market growth rate of the Iron & Steel Casting market?The Iron & Steel Casting market is growing at a CAGR of 5.5% from 2022 to 2030.

-

Which country dominates the Iron & Steel Casting market?Asia- Pacific emerged as the largest market for Iron & Steel Casting.

-

Who are the key players in the Iron & Steel Casting market?Key players in the Iron & Steel Casting market are ArcelorMittal, China BaoWu Steel Group Corporation Limited, Nippon Steel Corporation, HBIS Group, Jiangsu Shagang Group, POSCO HOLDINGS INC., Tata Steel, JFE Steel Corporation, Shougang Group, Nucor Corporation, JSW, SAIL, NLMK, Techint Group, and U.S. Steel Corporation.

-

Which factor drives the growth of the Iron & Steel Casting market?Rising investments are expected to drive the market's growth over the forecast period.

Need help to buy this report?