Global Impact Modifiers Market Size, Share, and COVID-19 Impact Analysis, By Type (AIM, ABS, MBS, CPE, EPDM, ASA), By Application (Nylon, PVC, PBT), By End Use (Packaging, Construction), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 - 2033

Industry: Advanced MaterialsGlobal Impact Modifiers Market Insights Forecasts to 2033

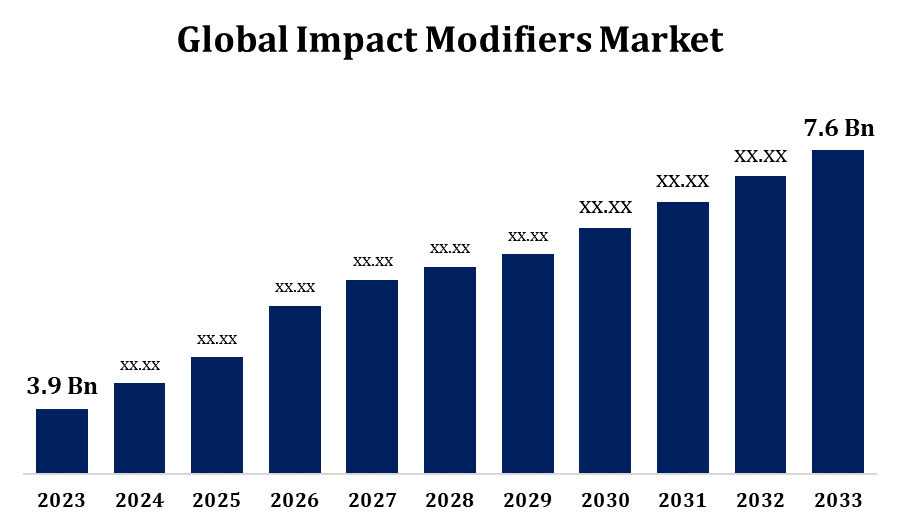

- The Impact Modifiers Market Size was valued at USD 3.9 Billion in 2023.

- The Market Size is Growing at a CAGR of 6.90% from 2023 To 2033.

- The Global Impact Modifiers Market Size is expected to reach USD 7.6 Billion By 2033.

- Asia Pacific is expected to grow the fastest during the forecast period.

Get more details on this report -

The Global Impact Modifiers Market Size is Expected to reach USD 7.6 Billion By 2033, at a CAGR of 6.90% during the forecast period 2023 to 2033.

The global impact modifiers market is experiencing steady growth, driven by rising demand for durable and high-performance plastics across various industries such as automotive, construction, packaging, and consumer goods. Impact modifiers are additives used to enhance the toughness and impact resistance of polymers like PVC, ABS, and polycarbonate without compromising other physical properties. The construction sector, especially in developing economies, is a major driver due to increasing use of weather-resistant materials in pipes, doors, and windows. Additionally, the automotive industry is adopting lightweight plastics to improve fuel efficiency, further boosting market demand. Asia-Pacific dominates the market owing to rapid industrialization, urbanization, and expansion of manufacturing activities in China and India. Ongoing R&D efforts to develop sustainable and bio-based modifiers also present growth opportunities.

Impact Modifiers Market Value Chain Analysis

The impact modifiers market value chain comprises several interconnected stages, starting with raw material suppliers who provide key components such as acrylics, elastomers, and chlorinated polyethylene. These materials are then processed by manufacturers to produce various types of impact modifiers tailored for different polymers. Compounders and resin producers incorporate these modifiers into plastic formulations to enhance mechanical properties like toughness and durability. The modified resins are supplied to end-use industries including automotive, construction, packaging, and electronics, where they are molded into final products. Distributors and channel partners play a vital role in ensuring the efficient flow of materials across regions. Research institutions and technology providers contribute to innovation and product optimization. Regulatory bodies also influence the value chain through safety and environmental compliance standards.

Impact Modifiers Market Opportunity Analysis

The impact modifiers market offers considerable growth potential fueled by several emerging trends. Rapid urbanization and industrial expansion, particularly in Asia-Pacific regions like China and India, are driving demand across construction, automotive, electronics, and packaging sectors. The packaging industry, especially for food and pharmaceuticals, increasingly requires tough and clear plastics, boosting the need for impact modifiers. In the automotive sector, the push for lightweight components and the rise of electric vehicles are creating new applications for advanced modifiers. Additionally, the growing emphasis on sustainability is encouraging the development of bio-based, biodegradable, and recycled polymer-compatible additives. New opportunities are also emerging in specialized areas such as medical devices, solar energy, and 3D printing with recycled plastics. Collaborations among manufacturers, OEMs, and research institutions are enhancing innovation and market expansion.

Global Impact Modifiers Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 3.9 Billion |

| Forecast Period: | 2023 - 2033 |

| Forecast Period CAGR 2023 - 2033 : | 6.90% |

| 2033 Value Projection: | USD 7.6 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 199 |

| Tables, Charts & Figures: | 100 |

| Segments covered: | By Type, By Application, By Region and COVID-19 Impact Analysis |

| Companies covered:: | Arkema, Dow, LG Chem, BASF SE, Mitsubishi Chemical Group Corporation, Evonik Industries AG, KANEKA CORPORATION, Solvay, Akzo Nobel N.V., Shandong Ruifeng Chemical Co., Ltd., Wacker Chemie AG, Denka Company Limited, LANXESS, Sundow Polymers Co., Ltd, SI Group, Inc. (Addivant), and other key vendors. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics

Impact Modifiers Market Dynamics

Rising Demand from the Automotive Sector to Boost the Market Growth

The rising demand from the automotive sector is a key driver for the growth of the impact modifiers market. As automakers increasingly prioritize lightweight and fuel-efficient vehicles, the use of high-performance plastics has surged. Impact modifiers enhance the toughness and durability of these plastics, making them suitable for critical automotive components such as bumpers, interior trims, and under-the-hood applications. Additionally, the shift toward electric vehicles (EVs) is accelerating the adoption of advanced polymer solutions, further increasing the need for effective impact modification. These materials help improve safety, reduce vehicle weight, and lower emissions. The trend is especially strong in emerging markets like China and India, where automotive production is expanding rapidly. As the industry evolves, impact modifiers will remain essential in meeting performance, safety, and sustainability standards.

Restraints & Challenges

The impact modifiers market faces several significant challenges that could hinder its growth. One major concern is the volatility in raw material prices, particularly for petrochemical-based inputs such as acrylics and butadiene, which affects production costs and profit margins. Additionally, the high cost of advanced impact modifiers makes them less accessible for cost-sensitive applications, limiting broader adoption. Compliance with stringent environmental and safety regulations especially concerning substances like BPA and phthalates adds to operational burdens and delays product development. Technical challenges also arise from compatibility issues with various polymers, often requiring additional R&D and adjustments to processing equipment. Moreover, the market faces stiff competition from alternative additives and unmodified polymers, which can lead to price wars and reduce incentives for innovation. These factors collectively create obstacles for market expansion.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Impact Modifiers Market from 2023 to 2033. North America’s impact modifiers market stands out due to its strong industrial backbone, mature regulatory environment, and innovation-driven growth. The region’s focus on producing high-performance and lightweight materials for automotive, aerospace, and construction applications fuels steady demand for advanced modifiers. The U.S., in particular, is investing heavily in electric vehicles and infrastructure modernization, both of which require durable, weather-resistant polymers enhanced with impact modifiers. Additionally, the presence of leading chemical companies and polymer research hubs encourages the development of next-generation, sustainable impact modifiers tailored for bio-based and recycled plastics. Regulatory agencies like the EPA are also pushing for eco-friendly formulations, prompting a shift toward non-toxic, compliant additives. With consumer demand aligning closely with durability, safety, and sustainability, North America remains a key innovation center and high-value market for impact modifiers.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. In Asia-Pacific, the impact modifiers market is rewriting the rules of polymer performance amid rapid transformation. Here, sprawling megacities and electrified highways fuel an insatiable appetite for plastics that don’t just endure but excel under pressure. Unlike traditional markets, Asia-Pacific blends youthful industrial vigor with a burgeoning green consciousness, spurring innovations in bio-based and recycled impact modifiers tailored to local needs. China’s vast automotive hubs and India’s construction boom act as twin engines, while tech-savvy South Korea and Japan push boundaries with cutting-edge research. This region’s market isn’t just growing, it is evolving, driven by a unique fusion of cost-efficiency, regulatory shifts, and a drive to leapfrog into sustainable materials. Asia-Pacific is shaping not only volume but the very future of impact modifiers globally.

Segmentation Analysis

Insights by Type

The Acrylonitrile Butadiene Styrene (ABS) segment accounted for the largest market share over the forecast period 2023 to 2033. The Acrylonitrile Butadiene Styrene (ABS) segment plays a vital role in the impact modifiers market due to its broad applications in automotive, construction, and consumer electronics sectors. Known for its superior impact resistance, strength, and toughness, ABS is commonly used in manufacturing vehicle components, piping systems, and electronic device housings. The automotive industry’s focus on lightweight and fuel-efficient vehicles significantly drives the adoption of ABS-based impact modifiers, helping reduce overall weight without compromising safety. Likewise, the construction sector favors ABS-modified plastics for their durability and ability to withstand harsh conditions. As industries increasingly demand materials that balance performance with sustainability, the ABS segment continues to be a cornerstone for innovation and growth in the impact modifiers market.

Insights by Application

The Polyvinyl Chloride (PVC) segment accounted for the largest market share over the forecast period 2023 to 2033. The Polyvinyl Chloride (PVC) segment is a vital part of the impact modifiers market, largely due to its widespread use in construction, automotive, packaging, and consumer goods. Because PVC is naturally brittle, impact modifiers are essential to improve its toughness and durability. In construction, PVC is commonly used for pipes, window frames, and siding, where impact modifiers help prevent cracking and damage from harsh weather and installation stresses. The automotive industry relies on impact-modified PVC to produce lightweight yet safe components. Additionally, the packaging sector benefits from PVC’s enhanced clarity and strength when combined with impact modifiers, ensuring both protection and visual appeal. With growing emphasis on materials that deliver durability and sustainability, the PVC segment continues to drive significant growth within the impact modifiers market.

Insights by End Use

The packaging segment accounted for the largest market share over the forecast period 2023 to 2033. The growth is fueled by increasing demand for strong and flexible packaging solutions across industries like food and beverage, pharmaceuticals, and consumer goods. Impact modifiers improve the durability and flexibility of plastics, making them well-suited to protect products during shipping and handling. The rapid growth of e-commerce has intensified the need for packaging that can endure rough transportation conditions. Furthermore, rising consumer awareness about sustainability has encouraged the development of bio-based impact modifiers that support recyclable and eco-friendly packaging materials. These innovations not only enhance the performance of packaging plastics but also help reduce their environmental footprint, significantly contributing to the expansion of the impact modifiers market within the packaging sector.

Recent Market Developments

- In September 2022, BASF has announced a partnership with RI Karbon to develop emollients derived from bio-waste. This collaboration enables BASF to utilize RI Karbon’s patented technology, which upcycles bio-waste into bio-based, biodegradable emollients, catering to the global personal care market.

Competitive Landscape

Major players in the market

- Arkema

- Dow

- LG Chem

- BASF SE

- Mitsubishi Chemical Group Corporation

- Evonik Industries AG

- KANEKA CORPORATION

- Solvay

- Akzo Nobel N.V.

- Shandong Ruifeng Chemical Co., Ltd.

- Wacker Chemie AG

- Denka Company Limited

- LANXESS

- Sundow Polymers Co., Ltd

- SI Group, Inc. (Addivant)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Impact Modifiers Market, Type Analysis

- AIM

- ABS

- MBS

- CPE

- EPDM

- ASA

Impact Modifiers Market, Application Analysis

- Nylon

- PVC

- PBT

Impact Modifiers Market, End Use Analysis

- Packaging

- Construction

Impact Modifiers Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Impact Modifiers Market?The global Impact Modifiers Market is expected to grow from USD 3.9 billion in 2023 to USD 7.6 billion by 2033, at a CAGR of 6.90% during the forecast period 2023-2033.

-

2. Who are the key market players of the Impact Modifiers Market?Some of the key market players of the market are Arkema; Dow; LG Chem; BASF SE; Mitsubishi Chemical Group Corporation; Evonik Industries AG; KANEKA CORPORATION; Solvay; Akzo Nobel N.V.; Shandong Ruifeng Chemical Co., Ltd.; Wacker Chemie AG; Denka Company Limited; LANXESS; Sundow Polymers Co., Ltd; SI Group, Inc. (Addivant).

-

3. Which segment holds the largest market share?The packaging segment holds the largest market share and is going to continue its dominance.

Need help to buy this report?