Global Hydrocyclone Liners Market Size, Share, and COVID-19 Impact Analysis, By Type (Ceramic, Rubber, Polyurethane, Metal-Backed, Composite Materials, and Others), By Application (Mining & Mineral Processing, Oil & Gas, Pulp & Paper, Food and Beverage, Wastewater Treatment, Chemical Processing, and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Industry: Chemicals & MaterialsGlobal Hydrocyclone Liners Market Insights Forecasts to 2035

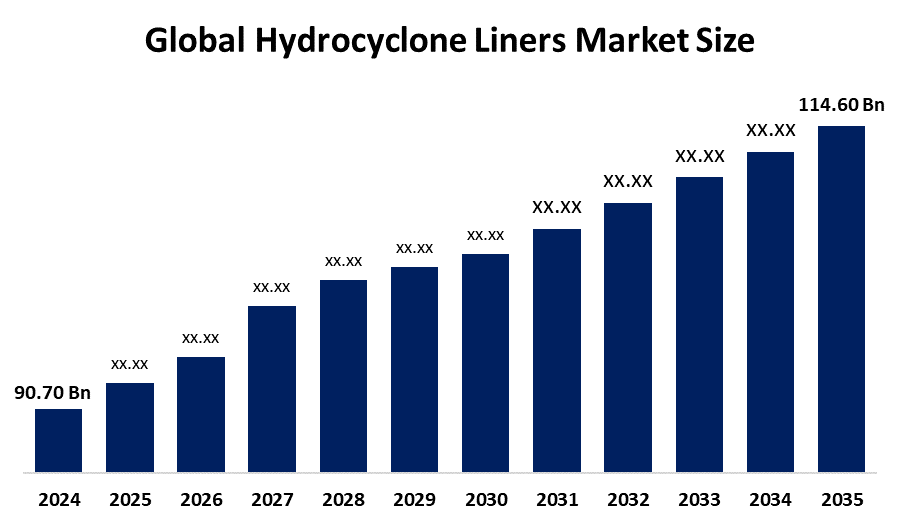

- The Global Hydrocyclone Liners Market Size Was Estimated at USD 90.70 Million in 2024

- The Market Size is Expected to Grow at a CAGR of around 2.15% from 2025 to 2035

- The Worldwide Hydrocyclone Liners Market Size is Expected to Reach USD 114.60 Million by 2035

- North America is expected to grow the fastest during the forecast period.

Get more details on this report -

According to a research report published by Spherical Insights and Consulting, the global hydrocyclone liners market size was worth around USD 90.70 million in 2024 and is predicted to grow to around USD 114.60 million by 2035 with a compound annual growth rate (CAGR) of 2.15% from 2025 to 2035. The market for hydrocyclone liners represents opportunities to improve the efficiency of mining and mineral processing, lower maintenance costs, increase applications in the chemical, oil, and gas industries, and spur innovation in sustainable industrial solutions and wear-resistant materials.

Market Overview

The manufacturing, distribution, and use of specific protective linings for hydrocyclone systems, centrifugal separation machines used in industrial processes to categorize particles in slurries according to size, density, and shape, are all included in the hydrocyclone liners market. These liners reduce wear in high-velocity situations, increasing equipment longevity, operational efficiency, and maintenance economics. They are usually made of abrasion-resistant materials, including rubber, polyurethane, and ceramics. For Instance, in October 2025, the U.S. Department of Energy announced $25 million in funding for critical mineral extraction from wastewater using advanced separation technologies, while EU environmental regulations and Asia-Pacific investments, including South Korea’s 2023 smart treatment projects, promote hydrocyclone-based efficient water management. Expanding mining operations in emerging nations, growing mineral processing activities in existing regions, and rising demand for effective separation technology in industrial applications are all predicted to contribute to the hydrocyclone liners market. The market for hydrocyclone liners is driven by a variety of variables, including technological, regulatory, and industrial dynamics.

Report Coverage

This research report categorizes the hydrocyclone liners market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the hydrocyclone liners market. Recent market developments and competitive strategies, such as expansion, product launch, development, partnership, merger, and acquisition, have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the hydrocyclone liners market.

Global Hydrocyclone Liners Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 90.70 Million |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | CAGR of 2.15% |

| 2035 Value Projection: | USD 114.60 Million |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 244 |

| Tables, Charts & Figures: | 105 |

| Segments covered: | By Type, By Application |

| Companies covered:: | Iracore, Blasch, UMAHU, SHANVIM, Multotec, GTEK MINING, NAN ATCERA, Sands Ceramic, Tega Industries, Matec Solutions, Swagath Urethane, Premier Rubber Mills, International Syalons, Morgan Advanced Materials, And Others Players |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

Hydrocyclone liners that withstand wear from abrasive slurries are in high demand due to the rise of the worldwide mining and mineral-processing sectors, which is driven by the need for key metals, minerals, and rising ore quantities. The market for hydrocyclone liners is expanding significantly due to the requirement for high-performance, reasonably priced, and long-lasting equipment solutions brought on by growing industrialization and the necessity for effective solid-liquid separation technologies. Infrastructure-driven industrialization and the expansion of emerging countries, particularly in Asia-Pacific, Latin America, and Africa, are driving up capital investments in industrial water treatment, mineral processing, and related separation systems, opening up new hydrocyclone liners market.

Restraining Factors

High starting costs, frequent maintenance needs, limited efficiency with ultra-fine or viscous materials, volatile raw material prices, and the demand for professional operation are all challenges to the hydrocyclone liners market's quick acceptance and growth.

Market Segmentation

The hydrocyclone liners market share is classified into type and application.

- The ceramic segment accounted for the largest share in 2024, and is anticipated to grow at a significant CAGR during the forecast period.

Based on the type, the hydrocyclone liners market is divided into ceramic, rubber, polyurethane, metal-backed, composite materials, and others. Among these, the ceramic segment accounted for the largest share in 2024 and is anticipated to grow at a significant CAGR during the forecast period. The high-abrasion mining applications and mineral processing processes that demand greater wear resistance and longer operating life, the ceramic sector is the material of choice. extensively used in iron ore processing and copper mining operations. Momentum for solid development in the mineral processing and mining expansion sectors.

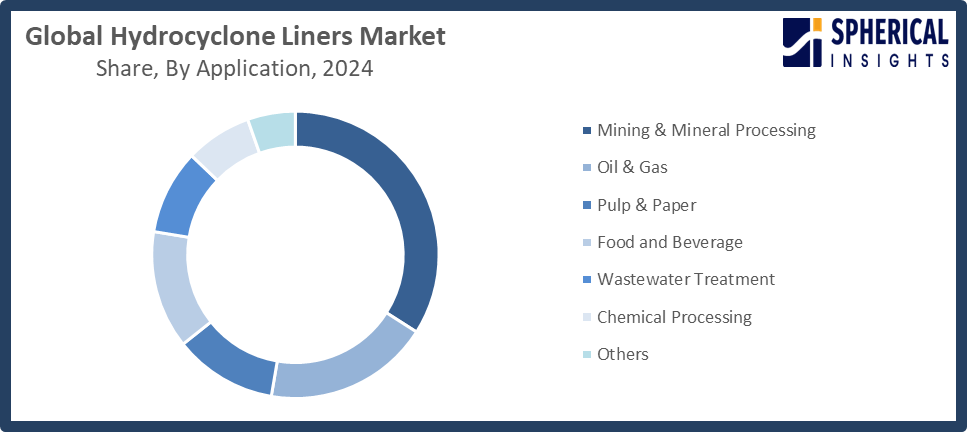

- The mining & mineral processing segment accounted for the highest market revenue in 2024, and is anticipated to grow at a significant CAGR during the forecast period.

Based on the application, the hydrocyclone liners market is divided into mining & mineral processing, oil & gas, pulp & paper, food and beverage, wastewater treatment, chemical processing, and others. Among these, the mining & mineral processing segment accounted for the highest market revenue in 2024 and is anticipated to grow at a significant CAGR during the forecast period. Global mining growth and improvements to mineral processing facilities, which need for efficient separation solutions for ore concentration, tailings management, and material classification operations, are the main drivers of the mining and mineral processing market. the strong expansion brought about by advancements in mineral extraction and mining infrastructure in new economies. Capital equipment investments in mining operations are impacted by fluctuations in commodity prices.

Get more details on this report -

Regional Segment Analysis of the Hydrocyclone Liners Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Asia Pacific is anticipated to hold the largest share of the hydrocyclone liners market over the predicted timeframe.

Asia Pacific is anticipated to hold the largest share of the hydrocyclone liners market over the predicted timeframe. Asia-Pacific is benefiting from strong mining operations, quick industrialization, and large infrastructural expenditures throughout the area. The growing need for metals, minerals, and industrial raw resources has led to significant contributions from nations like China, India, and Australia. Specialized separation liner systems are consistently in demand due to the nation's ambitious mining development programs, which include national resource extraction initiatives and automated processing facility expansion. High-performance hydrocyclones with sturdy liners are required to improve operating efficiency, lower wear and maintenance costs, and increase equipment lifespan due to the Asia Pacific region's substantial growth in mining and mineral processing operations.

North America is expected to grow at a rapid CAGR in the hydrocyclone liners market during the forecast period. The modernization and growth of the mining, oil and gas, and wastewater treatment sectors is what propel North America. The region's focus on modernizing its mineral processing infrastructure and using cutting-edge separation technologies raises the need for robust and efficient hydrocyclone liners. High-performance separation liner components that support operational development and safety requirements are in high demand due to the nation's longstanding mining technological legacy, which includes major equipment manufacturers and processing facilities. Furthermore, effective solid-liquid separation solutions are required due to strict environmental regulations and sustainability mandates in the US and Canada, which further supports market expansion.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the hydrocyclone liners market, along with a comparative evaluation primarily based on their type of offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes type development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Iracore

- Blasch

- UMAHU

- SHANVIM

- Multotec

- GTEK MINING

- NAN ATCERA

- Sands Ceramic

- Tega Industries

- Matec Solutions

- Swagath Urethane

- Premier Rubber Mills

- International Syalons

- Morgan Advanced Materials

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In September 2024, Metso has launched the MHCTM CB (curved bottom) hydrocyclone, delivering superior particle separation, higher capacity, and coarser cut sizes while minimizing fines bypass. Ben Klein calls it an innovative upgrade to the proven MHCTM Hydrocyclone, marking a breakthrough in classification technology.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the hydrocyclone liners market based on the below-mentioned segments:

Global Hydrocyclone Liners Market, By Type

- Ceramic

- Rubber

- Polyurethane

- Metal-Backed

- Composite Materials

- Others

Global Hydrocyclone Liners Market, By Application

- Mining & Mineral Processing

- Oil & Gas

- Pulp & Paper

- Food and Beverage

- Wastewater Treatment

- Chemical Processing

- Others

Global Hydrocyclone Liners Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the hydrocyclone liners market over the forecast period?The global hydrocyclone liners market is projected to expand at a CAGR of 2.15% during the forecast period.

-

2. What is the market size of the hydrocyclone liners market?The global hydrocyclone liners market size is expected to grow from USD 90.70 million in 2024 to USD 114.60 million by 2035, at a CAGR of 2.15% during the forecast period 2025-2035.

-

3. Which region holds the largest share of the hydrocyclone liners market?The global hydrocyclone liners market size is expected to grow from USD 90.70 million in 2024 to USD 114.60 million by 2035, at a CAGR of 2.15% during the forecast period 2025-2035.

-

3. Which region holds the largest share of the hydrocyclone liners market?Asia Pacific is anticipated to hold the largest share of the hydrocyclone liners market over the predicted timeframe.

-

4. Who are the top 10 companies operating in the global hydrocyclone liners market?Iracore, Blasch, UMAHU, SHANVIM, Multotec, GTEK Mining, NAN Atcera, Sands Ceramic, Tega Industries, Matec Solutions, Swagath Urethane, Premier Rubber Mills, International Syalons, Morgan Advanced Materials, others.

-

5. What factors are driving the growth of the hydrocyclone liners market?The Hydrocyclone Liners market growth is driven by rising mining and mineral processing demand, industrialization, technological advancements in wear-resistant materials, stringent environmental regulations, and increasing operational efficiency requirements globally.

-

6. What are the market trends in the hydrocyclone liners market?The market trends include the adoption of advanced ceramic and composite liners, a focus on sustainable materials, the integration of automation and monitoring technologies, and the expansion into emerging economies with growing mining and industrial activities.

-

7. What are the main challenges restricting wider adoption of the hydrocyclone liners market?The market adoption is restricted by high initial costs, frequent maintenance requirements, raw material price volatility, operational complexity, and limited efficiency in handling ultra-fine particles or highly viscous industrial slurries.

Need help to buy this report?