Global Hastelloy Market Size, Share, and COVID-19 Impact Analysis, By Form (Sheets, Bars, Wires, Pipes, and Fittings), By Grade (Hastelloy C-276, Hastelloy C-22, Hastelloy B-2, Hastelloy X, and Hastelloy S), By Application (Aerospace, Oil and Gas, Chemical Processing, Marine, and Power Generation), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Industry: Chemicals & MaterialsGlobal Hastelloy Market Size Insights Forecasts to 2035

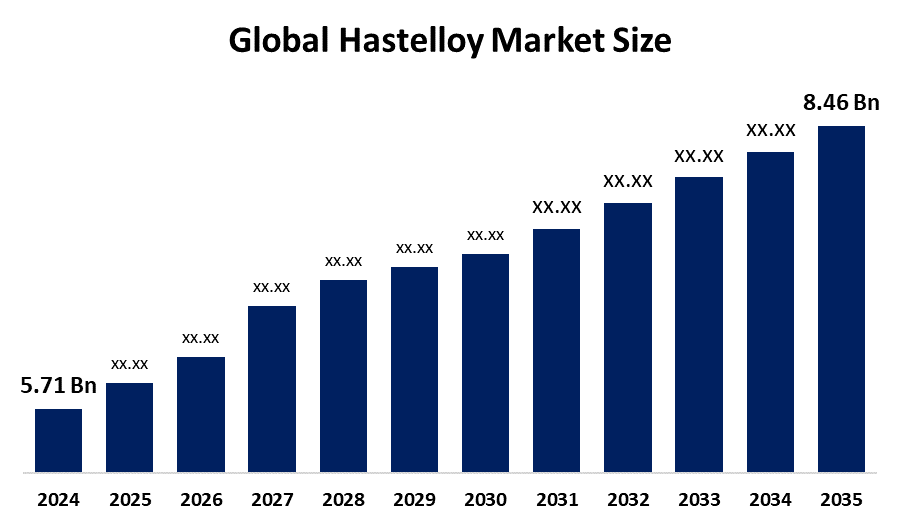

- The Global Hastelloy Market Size Was Estimated at USD 5.71 Billion in 2024

- The Market Size is Expected to Grow at a CAGR of around 3.64% from 2025 to 2035

- The Worldwide Hastelloy Market Size is Expected to Reach USD 8.46 Billion by 2035

- Asia Pacific is expected to grow the fastest during the forecast period.

Get more details on this report -

According to a Research Report Published by Spherical Insights and Consulting, The Global Hastelloy Market Size was worth around USD 5.71 Billion in 2024 and is predicted to Grow to around USD 8.46 Billion by 2035 with a compound annual growth rate (CAGR) of 3.64% from 2025 to 2035. The hastelloy market is expanding as there is a rising demand for corrosion-resistant commodities in the chemical processing, aerospace, and marine industries. Its higher strength, durability, and resistance to harsh environments make it suitable for tough applications, which is fueling broad industrial use across the world.

Market Overview

The global hastelloy market refers to the industry of manufacturing and using hastelloy, a chemical-resistant metal alloy with a major ingredient of nickel and different proportions of molybdenum, iron, cobalt, and chromium. It has excellent resistance to aggressive chemicals, high temperatures, and oxidizing agents. Hastelloy finds broad application in chemical processing, aerospace, naval, pharmaceutical, and power generation industries. Their prime applications are heat exchangers, pressure vessels, reactors, and piping systems, where they get exposed to aggressive chemicals. Growth in the demand for high-strength and corrosion-resistant materials applied in hostile environments, especially in the chemical and petrochemical industries, drives growth in the market. Additionally, advancements in clean energy technologies, such as nuclear power and geothermal, and demand for high-strength materials further drive demand. Advancements in alloy composition and novel fabrication techniques, such as additive manufacturing, are enhancing Hastelloy's properties and broadening its applications.

Tremendous growth opportunities exist in the emerging markets of the Asia Pacific and Latin American regions, driven by the fast pace of industrialization and growing infrastructure spending. Major industry players such as Haynes International, Allegheny Technologies Incorporated (ATI), Carpenter Technology Corporation, and VDM Metals are focusing on product development and strategic partnerships to enhance their global reach. Additionally, a greater focus on sustainable and long-term materials in process industries is creating new business opportunities. On 27 Jan 2025, in New Delhi, Pre-budget, Jindal Stainless urged the government to lift import levies on key raw materials such as molybdenum ore and impose zero levies on pure nickel, ferro-nickel, and steel scrap. The Budget will be tabled by Finance Minister Nirmala Sitharaman in Parliament on 1 February. The firm also requested increased customs duty on inexpensive imports and highlighted infrastructure development to aid the stainless-steel sector.

Report Coverage

This research report categorizes the hastelloy market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the hastelloy market. Recent market developments and competitive strategies, such as expansion, type launch, development, partnership, merger, and acquisition, have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the hastelloy market.

Global Hastelloy Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 5.71 Billion |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | 3.64% |

| 2035 Value Projection: | USD 8.46 Billion |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 169 |

| Tables, Charts & Figures: | 129 |

| Segments covered: | By Form, By Grade and COVID-19 Impact Analysis |

| Companies covered:: | Haynes International, SABIC, Carpenter Technology, Hitachi Metals, Sandvik Coromant, QuesTek Innovations, Allegheny Technologies (ATI) Alloys, Nippon Yakin Kogyo, Alcoa Howmet Castings, ThyssenKrupp Materials, KME Germany, Daronmont Technologies, Alloy Wire International, and Others |

| Pitfalls & Challenges: | COVID-19 Impact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The hastelloy market worldwide is fueled by growing needs for corrosion-resistant alloys in severe industrial conditions such as chemical processing, marine, aerospace, and power generation. Growth in infrastructure, clean energy, and pharmaceutical manufacturing investments also fuels market growth. The increased resistance of the alloy to harsh chemicals and extreme temperatures makes it suitable for reactors, heat exchangers, and pressure vessels. Further, increasing green regulations and a demand for longer-lasting, low-maintenance materials promote the use of high-performance materials such as hastelloy. Advances in technological capabilities for alloy manufacturing and growth in industrial operations in emerging economies are also key drivers of the market's upward direction.

Restraining Factors

The hastelloy market is constrained by its expensive production and material costs, restraining adoption in cost-sensitive applications. Scarce raw materials such as nickel and molybdenum, as well as volatile prices, also affect the stability of the market. Market growth may be affected by competition from other alloys and composites.

Market Segmentation

The hastelloy market share is classified into form, grade, and application.

- The sheets segment dominated the market in 2024, approximately 35% and is projected to grow at a substantial CAGR during the forecast period.

Based on the form, the hastelloy market is divided into sheets, bars, wires, pipes, and fittings. Among these, the sheets segment dominated the market in 2024 and is projected to grow at a substantial CAGR during the forecast period. The sheets segment led the hastelloy market is attributed to rising demand in chemical processing, aerospace, and marine sectors, where corrosion resistance and high strength are necessary. Hastelloy sheets find extensive applications in fabricating reactors, tanks, and structural parts, making them indispensable in harsh conditions and enhancing their use across a range of high-performance applications.

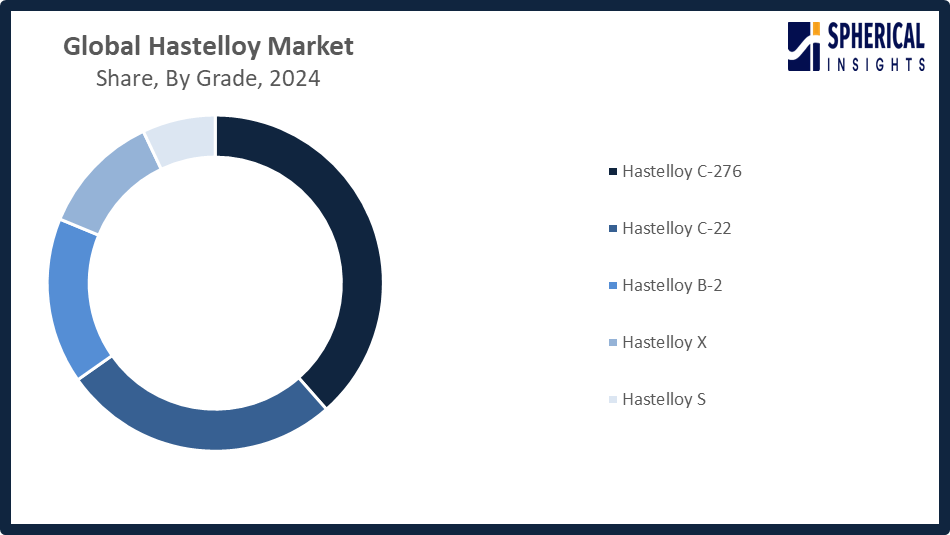

- The hastelloy C-276 segment accounted for the largest share in 2024, approximately 38% and is anticipated to grow at a significant CAGR during the forecast period.

Based on the grade, the hastelloy market is divided into hastelloy C-276, hastelloy C-22, hastelloy B-2, hastelloy X, and hastelloy S. Among these, the hastelloy C-276 segment accounted for the largest share in 2024 and is anticipated to grow at a significant CAGR during the forecast period. This segment is leading due to its high corrosion resistance, particularly against strong oxidizers and reducing chemicals, in applications such as chemical processing, aerospace, and in marine environments, fueling its expansion. Its adaptability and strength in tough conditions continue to increase demand in many industries.

Get more details on this report -

- The aerospace segment accounted for the highest market revenue in 2024, approximately 45% and is anticipated to grow at a significant CAGR during the forecast period.

Based on the application, the hastelloy market is divided into aerospace, oil and gas, chemical processing, marine, and power generation. Among these, the aerospace segment accounted for the highest market revenue in 2024 and is anticipated to grow at a significant CAGR during the forecast period. The aerospace industry is growing due to the rising use of lightweight, corrosion-resistant alloys that support high temperatures and stresses. The superior performance of hastelloy in jet engines, turbines, and aerospace parts drives its increasing use in the market.

Regional Segment Analysis of the Hastelloy Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA

North America is anticipated to hold the largest share of the hastelloy market over the predicted timeframe.

Get more details on this report -

North America is anticipated to hold the largest share of the hastelloy market over the predicted timeframe. North America is expected to hold about 35% market share of hastelloy in the forecast period due to the United States, Canada, and Mexico. The region's growth is supported by sophisticated aerospace and defense sectors requiring corrosion-resistant high-performance alloys such as Hastelloy. Harsh environmental regulations and safety standards encourage the application of hard materials in the chemical process and power generation industries. Also, heavy investments in research and development, technological improvements in infrastructure, and the establishment of major industry players support steady demand and technological development, making North America the top market in the hastelloy market.

Asia Pacific is expected to grow at a rapid CAGR in the hastelloy market during the forecast period. Asia Pacific is rapidly growing in the Hastelloy market over the forecast period, approximately 28% of market share, with China, India, Japan, and South Korea being the drivers. This expansion is fueled by high-speed industrialization, growing chemical processing, power generation, and aerospace industries. Rising investments in infrastructure and the growing need for corrosion-resistant products in hostile environments drive market growth. Supportive government policies, increased manufacturing efficiencies, and a clean energy and advanced technology focus further drive the use of hastelloy alloys throughout the region, and the Asia Pacific emerges as a prime growth center.

The growth of Europe's Hastelloy market is fueled by robust demand from Germany, France, and the UK, especially in the aerospace, marine, and chemical industries. EU environmental regulations and sustainability of industrial practices enhance demand for corrosion-proof materials such as hastelloy. Advanced manufacturing and engineering lead in Germany, while aerospace and energy dominate in France and the UK, driving overall regional market growth collectively.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the hastelloy market, along with a comparative evaluation primarily based on their type of offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes type development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Haynes International

- SABIC

- Carpenter Technology

- Hitachi Metals

- Sandvik Coromant

- QuesTek Innovations

- Allegheny Technologies (ATI) Alloys

- Nippon Yakin Kogyo

- Alcoa Howmet Castings

- ThyssenKrupp Materials

- KME Germany

- Daronmont Technologies

- Alloy Wire International

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In September 2025, QuesTek Innovations announced a collaboration with a global niobium producer to develop a high-temperature alloy tailored for additive manufacturing. The project targets next-generation aerospace and energy applications, emphasizing performance, scalability, and a resilient supply chain through advanced computational materials engineering.

- In August 2025, Haynes International, an Acerinox company, announced the launch of HASTELLOY WR-66, a new high-performance alloy for the wear and corrosion market. Honoring founder Elwood Haynes’ legacy, the innovation continues over a century of expertise in developing advanced, wear-resistant cobalt-based alloys.

- In February 2025, Navin Molecular announced a $35 million investment to expand its Dewas GMP plant in Madhya Pradesh. The new 9,000-square-meter facility will nearly double capacity, adding 200 cubic meters with advanced vessels such as Hastelloy and Inconel, enabling complex chemistries and enhancing safety through a distributed control system.

- In July 2024, QuesTek Innovations partnered with CBMM, the leading Niobium producer, to advance materials engineering. The collaboration aims to develop high-strength, heat-resistant alloys for additive manufacturing using QuesTek’s ICMD platform, exploring new Niobium-based compositions and optimizing existing alloys for enhanced performance across various applications.

- In April 2024, ATI Inc. celebrated the completion of its Vandergrift Operations expansion, now one of the most advanced materials finishing facilities. This milestone supports ATI’s transformation of its Specialty Rolled Products business, strengthening its leadership in high-quality titanium and nickel-based alloys.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the hastelloy market based on the below-mentioned segments:

Global Hastelloy Market, By Form

- Sheets

- Bars

- Wires

- Pipes

- Fittings

Global Hastelloy Market, By Grade

- Hastelloy C-276

- Hastelloy C-22

- Hastelloy B-2

- Hastelloy X

- Hastelloy S

Global Hastelloy Market, By Application

- Aerospace

- Oil and Gas

- Chemical Processing

- Marine

- Power Generation

Global Hastelloy Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the hastelloy market over the forecast period?The global hastelloy market is projected to expand at a CAGR of 3.64% during the forecast period.

-

2. What is the market size of the hastelloy market?The global hastelloy market size is expected to grow from USD 5.71 billion in 2024 to USD 8.46 billion by 2035, at a CAGR of 3.64% during the forecast period 2025-2035.

-

3. What is the hastelloy market?The hastelloy market is a global industry focused on the production and sale of high-performance nickel-based alloys used in demanding applications due to their superior resistance to corrosion and high temperatures.

-

4. Which region holds the largest share of the hastelloy market?North America is anticipated to hold the largest share of the hastelloy market over the predicted timeframe.

-

5. Who are the top 10 companies operating in the global hastelloy market?The major players operating in the hastelloy market are Haynes International, SABIC, Carpenter Technology, Hitachi Metals, Sandvik Coromant, QuesTek Innovations, Allegheny Technologies (ATI) Alloys, Nippon Yakin Kogyo, Alcoa Howmet Castings, ThyssenKrupp Materials, KME Germany, Daronmont Technologies, Alloy Wire International, and Others.

-

6. What factors are driving the growth of the hastelloy market?The growth of the hastelloy market is primarily driven by increasing demand from high-performance industrial sectors that require materials resistant to corrosion and high temperatures. Technological innovation, stringent environmental regulations, and investments in infrastructure are also key factors fueling market expansion.

-

7. What are the market trends in the hastelloy market?Key trends in the hastelloy market include rising demand in aerospace and chemical industries, increased use in additive manufacturing, and innovations in high-performance alloy development.

-

8. What are the main challenges restricting wider adoption of the hastelloy market?The main challenges restricting wider adoption of the hastelloy market are its extremely high cost, complex and difficult fabrication and machining, and limited supply.

Need help to buy this report?