Global Flexible Epoxy Resin Market Size, Share, and COVID-19 Impact Analysis, By Product Type (Urethane Modified, Rubber Modified, Dimmer Acid Modified), By Application (Composites, Adhesives & Sealants, Electrical & Electronics, Paints and Coatings), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Industry: Chemicals & MaterialsGlobal Flexible Epoxy Resin Market Insights Forecasts To 2035

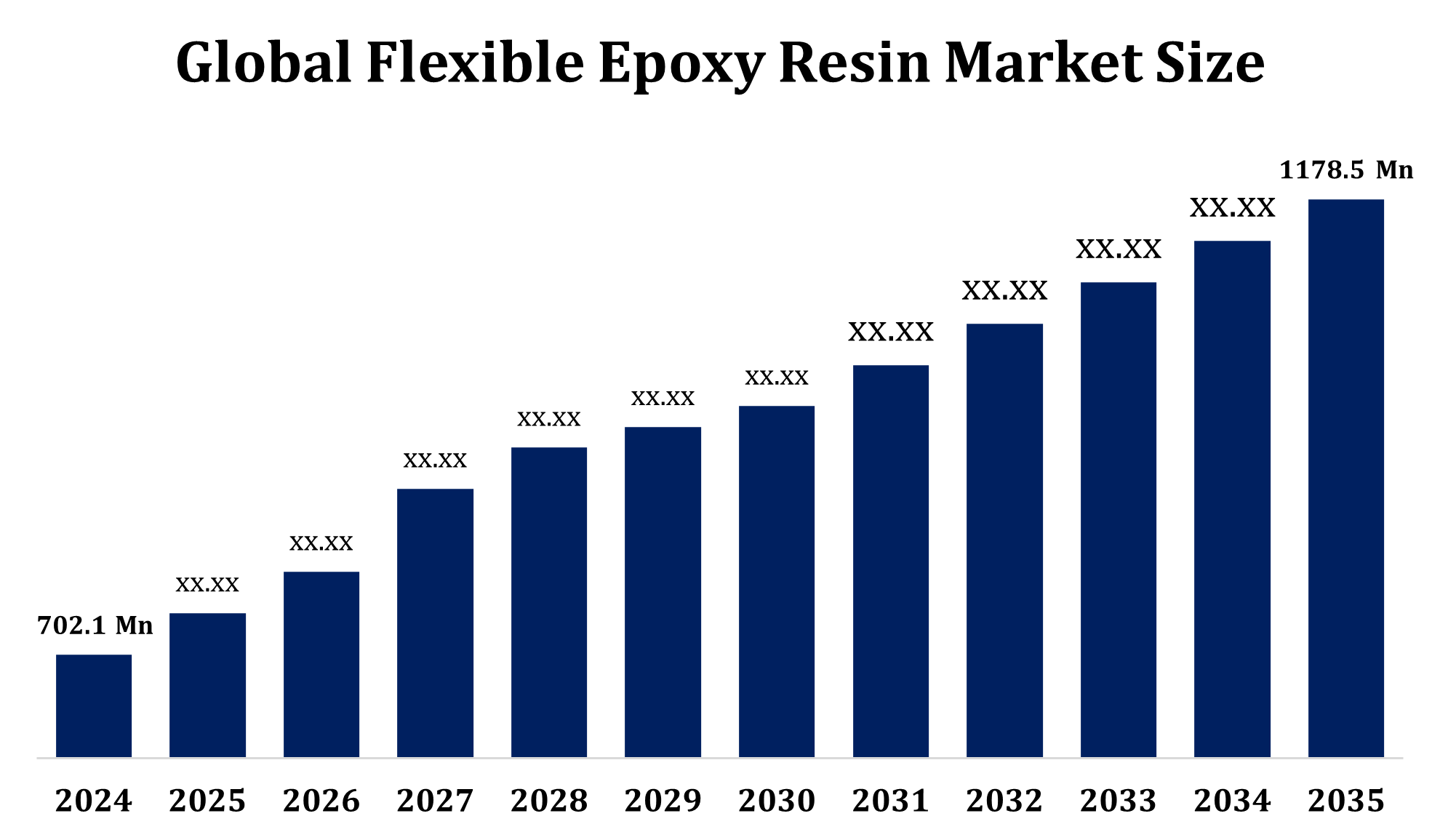

- The Flexible Epoxy Resin Market Size was Valued at USD 702.1 Million in 2024.

- The Market is Growing at a CAGR of 5.32% from 2025 to 2035.

- The Global Flexible Epoxy Resin Market Size is Expected To Reach USD 1178.5 Million by 2035.

- Asia Pacific is Expected To Grow Fastest During the Forecast Period.

Get more details on this report -

The Flexible Epoxy Resin Market Size is witnessing steady growth, driven by Rising demand across construction, automotive, electronics, and aerospace industries. Flexible epoxy resins offer superior adhesion, impact resistance, thermal stability, and flexibility compared to conventional epoxy systems, making them ideal for coatings, adhesives, composites, and encapsulants. In construction, they enhance flooring, sealants, and waterproofing applications, while in electronics, they provide protection for delicate components against mechanical stress and thermal cycling. The automotive and aerospace sectors are adopting these resins for lightweight, durable components that improve fuel efficiency and safety. Growing emphasis on renewable energy and wind turbine manufacturing further boosts demand. However, high production costs and raw material price volatility remain challenges. Technological advancements in resin formulations are creating new growth opportunities.

Flexible Epoxy Resin Market Size Value Chain Analysis

The flexible epoxy resin market value chain begins with raw material suppliers providing epichlorohydrin, bisphenol A, and other additives essential for resin synthesis. Resin manufacturers then process these inputs to produce flexible epoxy resins with tailored properties such as elasticity, toughness, and thermal resistance. Distributors and chemical suppliers play a key role in channelling products to end-use industries. Downstream, formulators and compounders blend resins with curing agents, fillers, or modifiers to create application-specific solutions. These are utilised by industries such as construction, automotive, aerospace, electronics, and energy for coatings, adhesives, composites, and encapsulants. End-users benefit from enhanced durability and performance in finished products. Continuous R&D, regulatory compliance, and sustainability initiatives influence each stage of the value chain, driving innovation and competitiveness.

Flexible Epoxy Resin Market Opportunity Analysis

The flexible epoxy resin market presents significant opportunities driven by expanding applications in high-growth sectors such as construction, automotive, aerospace, electronics, and renewable energy. Increasing demand for lightweight, durable, and impact-resistant materials is boosting adoption in automotive and aerospace for fuel-efficient and safer components. In construction, opportunities arise from rising infrastructure development and demand for advanced flooring, coatings, and waterproofing solutions. The electronics sector offers growth potential as flexible epoxy resins are increasingly used for encapsulation, insulation, and protection of sensitive components against mechanical stress and thermal fluctuations. Rapid expansion of wind energy, where resins are used in turbine blades and protective coatings, adds further prospects. Additionally, advancements in bio-based formulations and sustainable chemistries open new avenues for eco-friendly product development.

Global Flexible Epoxy Resin Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024 : | USD 702.1 Million |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | 5.32% |

| 2035 Value Projection: | USD 1178.5 Million |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | Product Type Analysis, Application Analysis, Regional Analysis |

| Companies covered:: | Conren Limited, DIC Corporation, Dow, Easy Composites, EPOXONIC, Hexion, INTERTRONICS, KUKDO Chemical (Kunshan) Co., Ltd., LymTal International, Inc., Mereco Technologies, Nan Ya Plastic Corporation, Olin Corporation, Resintech Limited, Sicomin Epoxy Systems |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics

Flexible Epoxy Resin Market Dynamics

The growing need for flexible epoxy in the construction sector to propel the market growth

The construction sector is emerging as a major growth driver for the flexible epoxy resin market due to the rising demand for durable, versatile, and high-performance materials. Flexible epoxy resins are increasingly used in flooring, sealants, coatings, adhesives, and waterproofing systems, offering superior adhesion, impact resistance, and flexibility compared to conventional solutions. With rapid urbanization, infrastructure upgrades, and commercial and residential development worldwide, builders are seeking materials that can withstand heavy loads, chemical exposure, and thermal fluctuations. Flexible epoxies provide long-lasting protection for concrete structures, bridges, and industrial facilities, reducing maintenance costs and enhancing safety. Additionally, the growing emphasis on sustainable and energy-efficient construction is fostering innovation in eco-friendly resin formulations, creating new opportunities for wider adoption in the global construction industry.

Restraints & Challenges

One of the primary concerns is the high cost of production, as raw materials such as bisphenol A and epichlorohydrin are subject to price fluctuations, directly impacting overall profitability. Additionally, stringent environmental regulations regarding VOC emissions and the use of petroleum-based feedstocks pose compliance challenges for manufacturers. Limited availability of sustainable and bio-based alternatives further restricts eco-friendly product development. Technical limitations, such as achieving the right balance between flexibility and mechanical strength, can also affect performance in demanding applications. Intense competition from substitute materials like polyurethane and silicone resins adds further pressure.

Regional Forecasts

North America Market Statistics

North America is anticipated to dominate the Flexible Epoxy Resin Market from 2025 to 2035. The North American flexible epoxy resin market is experiencing steady growth, supported by strong demand from construction, automotive, aerospace, electronics, and renewable energy sectors. The U.S. leads the region with significant adoption in infrastructure projects, advanced flooring, adhesives, and protective coatings due to rising urbanization and industrial activity. The aerospace and automotive industries further drive demand for lightweight, durable, and impact-resistant materials that enhance fuel efficiency and safety. In electronics, flexible epoxies are widely used for encapsulation and insulation of sensitive components. The region’s growing focus on wind energy and sustainable building materials also supports market expansion.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2025 to 2035. China, India, Japan, and South Korea are the key contributors, supported by booming construction, automotive, aerospace, and electronics industries. In construction, flexible epoxy resins are widely used in flooring, coatings, sealants, and adhesives to improve durability and safety of large-scale infrastructure and residential projects. The region’s strong electronics manufacturing base further fuels demand for encapsulants and protective materials. Expanding automotive and aerospace sectors are also adopting lightweight, high-performance materials for improved efficiency and reliability. Additionally, government initiatives promoting renewable energy, particularly wind power, are creating new opportunities.

Segmentation Analysis

Insights by Product Type

The Urethane Modified segment accounted for the largest market share over the forecast period 2025 to 2035. The growth is owing to its superior performance characteristics compared to conventional epoxy systems. These resins combine the toughness, flexibility, and chemical resistance of urethanes with the strong adhesion and thermal stability of epoxies, making them highly versatile across industries. In construction, they are widely used in flooring, sealants, and waterproofing applications requiring durability under heavy loads and harsh conditions. The automotive and aerospace sectors favor urethane modified epoxies for lightweight components that enhance fuel efficiency and impact resistance. Electronics applications also benefit from their excellent encapsulation and protective properties. Growing demand for advanced materials that balance strength and flexibility, along with ongoing R&D in resin technology, is driving this segment’s expansion.

Insights by Application

The paints and coatings segment accounted for the largest market share over the forecast period 2025 to 2035. The growth is driven by rising demand for durable, protective, and high-performance finishes across industries. Flexible epoxy-based coatings offer excellent adhesion, chemical resistance, impact strength, and flexibility, making them ideal for protecting surfaces in construction, automotive, aerospace, marine, and industrial applications. In construction, they are used for flooring, waterproofing, and corrosion-resistant coatings to enhance the longevity of infrastructure. Automotive and aerospace sectors adopt these coatings for lightweight structures that resist wear, abrasion, and thermal fluctuations. Growing industrial activity and urbanization in emerging economies further fuel demand. Additionally, increasing focus on eco-friendly and low-VOC formulations is encouraging innovation, creating new opportunities for flexible epoxy resins in the paints and coatings segment.

Recent Market Developments

- In April 2024, Westlake Corporation introduced a range of innovative low-yellowing epoxy products at the American Coatings Show 2024 in Indianapolis, Indiana.

Competitive Landscape

Major players in the market

- Conren Limited

- DIC Corporation

- Dow

- Easy Composites

- EPOXONIC

- Hexion

- INTERTRONICS

- KUKDO Chemical (Kunshan) Co., Ltd.

- LymTal International, Inc.

- Mereco Technologies

- Nan Ya Plastic Corporation

- Olin Corporation

- Resintech Limited

- Sicomin Epoxy Systems

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2025 to 2035.

Flexible Epoxy Resin Market, Product Type Analysis

- Urethane Modified

- Rubber Modified

- Dimmer Acid Modified

Flexible Epoxy Resin Market, Application Analysis

- Composites

- Adhesives & Sealants

- Electrical & Electronics

- Paints and Coatings

Flexible Epoxy Resin Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Flexible Epoxy Resin Market?The global Flexible Epoxy Resin Market is expected to grow from USD 702.1 million in 2024 to USD 1178.5 million by 2035, at a CAGR of 5.32% during the forecast period 2025-2035.

-

1. What is the market size of the Flexible Epoxy Resin Market?The global Flexible Epoxy Resin Market is expected to grow from USD 702.1 million in 2024 to USD 1178.5 million by 2035, at a CAGR of 5.32% during the forecast period 2025-2035.

-

2. Who are the key market players of the Flexible Epoxy Resin Market?Some of the key market players of the market are Conren Limited; DIC Corporation; Dow; Easy Composites; EPOXONIC; Hexion; INTERTRONICS; KUKDO Chemical (Kunshan) Co., Ltd.; LymTal International, Inc.; Mereco Technologies; Nan Ya Plastic Corporation; Olin Corporation; Resintech Limited; Sicomin Epoxy Systems.

-

3. Which segment holds the largest market share?The paints and coatings segment holds the largest market share and is going to continue its dominance.

Need help to buy this report?