Global Engineering Machinery Counterweight Iron Market Size, Share, and COVID-19 Impact Analysis, By Product Type (Ordinary Sand Mold Counterweight Iron and Extra Heavy Iron), By Application (Forklift, Excavator, Crane, Loader, Road Roller, Tower Crane, and Other), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Industry: Chemicals & MaterialsGlobal Engineering Machinery Counterweight Iron Market Insights Forecasts to 2035

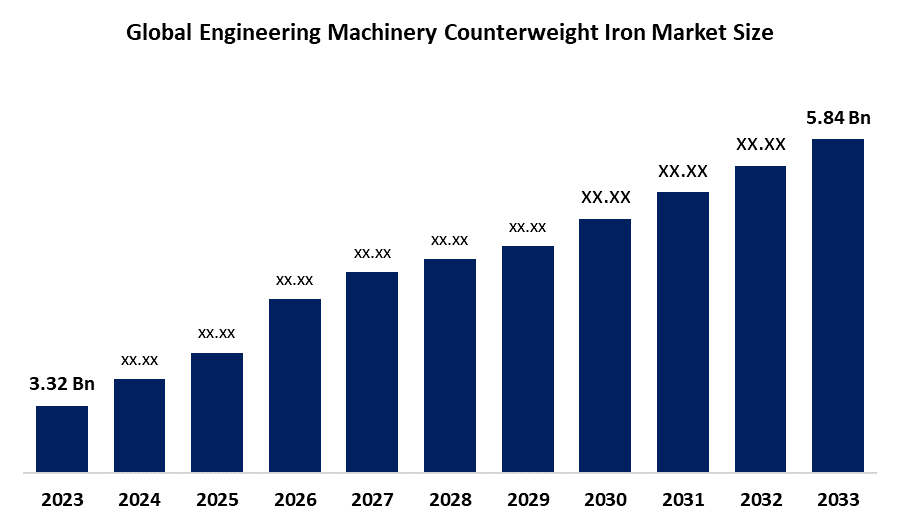

- The Global Engineering Machinery Counterweight Iron Market Size Was Estimated at USD 3.32 Billion in 2024

- The Market Size is Expected to Grow at a CAGR of around 5.27% from 2025 to 2035

- The Worldwide Engineering Machinery Counterweight Iron Market Size is Expected to Reach USD 5.84 Billion by 2035

- North America is expected to grow the fastest during the forecast period.

Get more details on this report -

According to a research report published by Spherical Insights and Consulting, the global engineering machinery counterweight iron market size was worth around USD 3.32 billion in 2024 and is predicted to grow to around USD 5.84 billion by 2035 with a compound annual growth rate (CAGR) of 5.27% from 2025 to 2035. The engineering machinery counterweight iron market is primarily growing due to the expansion of the construction industry and increasing demand for material handling equipment. These sectors require counterweights to ensure stability, safety, and efficient operation of heavy machinery such as cranes and excavators.

Market Overview

The worldwide engineering machinery counterweight iron market refers to the manufacturing of cast-iron parts critical to maintaining stability, balance, and safety in devices such as cranes, excavators, forklifts, elevators, and farm machinery. These counterweights help balance loads. Decrease mechanical stress, enabling machines to operate effectively and safely. The market expansion is propelled by construction and infrastructure growth, particularly in the Asia Pacific region, alongside increasing demand for material handling machinery spurred by the growth of e-commerce and logistics. Government safety regulations and the cost-effectiveness and high density of cast iron further strengthen market demand.

In April 2024, the U.S. Department of Energy, through ARPA-E’s ROSIE initiative, designated $28 million to fund 13 projects in nine states aimed at progressing zero-emission ironmaking and ultra-low-emission steel manufacturing. Targeting emissions and cost competitiveness, this effort encourages eco-iron, for counterweights, lowers steel imports and backs the Biden-Harris Administration’s climate and clean-energy objectives. Opportunities are emerging through advanced manufacturing methods such as precision casting for customized components, the incorporation of IoT sensors enabling predictive maintenance in smart machinery, and increasing needs in the renewable energy sector, particularly for wind turbine installation equipment. Leading market players include FMGC, Farinia Group, Sic Lazaro, Crescent Foundry, and Gallizo, all emphasising innovation, reliability, and high-quality production.

Report Coverage

This research report categorizes the engineering machinery counterweight iron market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the engineering machinery counterweight iron market. Recent market developments and competitive strategies, such as expansion, type launch, development, partnership, merger, and acquisition, have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the engineering machinery counterweight iron market.

Global Engineering Machinery Counterweight Iron Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 3.32 Billion |

| Forecast Period: | 2024 – 2035 |

| Forecast Period CAGR 2024 – 2035 : | CAGR of 5.27% |

| 024 – 2035 Value Projection: | USD 5.84 Billion |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 244 |

| Tables, Charts & Figures: | 100 |

| Segments covered: | By Product Type, By Application |

| Companies covered:: | Max Iron GmbH, Gallizo, Mars Metal, FMGC (Farinia), SIC Lazaro, Crescent Foundry, Blackwood Engineering, Ultraray Metals, Innotec, Vietnam Cast Iron, Swebor, AMAC Alloys, Ondo Metal, Agescan International, International Steel & Counterweights, And Others Players |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The worldwide market for engineering machinery counterweight iron is mainly propelled by the growth of construction and infrastructure projects. A key element is the rising need for machinery such as excavators, cranes and forklifts, which are used to manage heavy loads in construction, mining and logistics sectors. Swift urban. Industrial expansion, particularly in developing economies within the Asia-Pacific area. The critical requirement for counterweights is to guarantee the stability, safety and effectiveness of heavy equipment functioning. The material's superior properties, as cast iron, offer high density, durability, and cost-effectiveness compared to many alternatives. India’s “Make in India” initiative and $1.4 trillion National Infrastructure Pipeline through 2025 are boosting steel demand for housing, roads, and railways, with policies encouraging local content and the use of sustainable materials.

Restraining Factors

The engineering machinery counterweight iron market is primarily restrained by fluctuating raw material prices (iron ore, steel) and stringent environmental regulations. These factors lead to significant margin pressures, higher operating costs, and supply chain volatility, impacting overall market expansion.

Market Segmentation

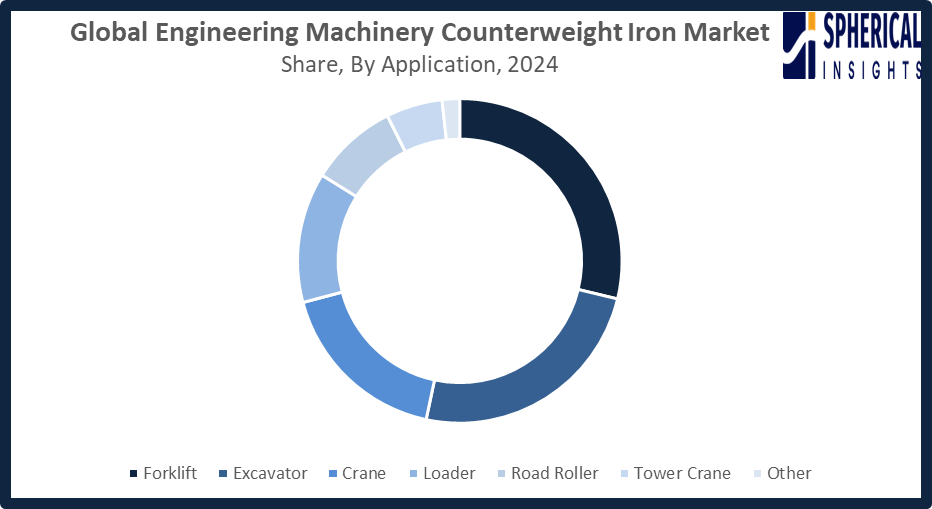

The engineering machinery counterweight iron market share is classified into product type and application.

- The ordinary sand mold counterweight iron segment dominated the market in 2024, approximately 32% and is projected to grow at a substantial CAGR during the forecast period.

Based on the product type, the engineering machinery counterweight iron market is divided into ordinary sand mold counterweight iron and extra heavy iron. Among these, the ordinary sand mold counterweight iron segment dominated the market in 2024 and is projected to grow at a substantial CAGR during the forecast period. The dominance of sand mold castings arises from their economic advantage, adaptable design and suitability with diverse equipment. They enable contouring and efficient weight distribution, making them perfect for forklifts, loaders and small cranes. supported by foundries, uniform procedures and faster manufacturing processes, these counterweights deliver sufficient density and durability for steady, dependable machine functionality.

- The forklift segment accounted for the highest market revenue in 2024, approximately 29% and is anticipated to grow at a significant CAGR during the forecast period.

Based on the application, the engineering machinery counterweight iron market is divided into forklift, excavator, crane, loader, road roller, tower crane, and other. Among these, the forklift segment accounted for the highest market revenue in 2024 and is anticipated to grow at a significant CAGR during the forecast period. The prevalence of counterweight iron in forklifts is driven by its role in maintaining balance and load stability during lifting. Rising industrial warehousing and e-commerce demand boost usage, while high-density iron reduces counterweight volume without compromising strength. Sand casting and modular fabrication suit diverse forklift models, and growth in electric and compact forklifts further increases demand for optimized, safe counterweight designs.

Get more details on this report -

Regional Segment Analysis of the Engineering Machinery Counterweight Iron Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

Asia Pacific is anticipated to hold the largest share of the engineering machinery counterweight iron market over the predicted timeframe.

Asia Pacific is anticipated to hold the largest share of the engineering machinery counterweight iron market over the predicted timeframe. The Asia Pacific area is expected to lead the engineering machinery counterweight iron market, with an approximate 43% market share, propelled by urban growth, expanding industries and significant infrastructure developments. Demand is primarily led by China, India and Japan, fueled by increased construction, mining and manufacturing operations. China emphasizes infrastructure and material-handling equipment, whereas India’s National Infrastructure Pipeline and "Make in India" initiatives boost local equipment demand. Japan progresses in embracing machinery technology. In September 2025, India unveiled a RS16,000-crore incentive plan aimed at increasing the manufacturing of construction machinery, cutting down on imports, strengthening infrastructure capabilities, saving as much as USD3 billion and speeding up the development across the country.

North America is expected to grow at a rapid CAGR in the engineering machinery counterweight iron market during the forecast period. The engineering machinery counterweight iron market in North America is anticipated to expand, with an approximate 25% market share, fueled by infrastructure improvements, modernization of industrial fleets and investments in mining and construction machinery. The U.S. remains at the forefront, backed by the Infrastructure Investment and Jobs Act, increasing needs for forklifts, loaders and cranes alongside initiatives encouraging eco-equipment. Canada plays a role via mining activities and urban growth projects. Growth is additionally propelled by manufacturing, the electrification of equipment and ongoing replacement cycles. In January 2025, the American Iron and Steel Institute called for changes in regulations. Simultaneously, U.S. Steel and Nippon Steel revealed a USD14 billion investment within the country expected to generate over 100,000 jobs by 2028.

Europe’s engineering machinery counterweight iron market is growing steadily due to stringent safety regulations, industrial automation, and infrastructure modernization. Germany, France, and the UK lead demand, driven by construction, mining, and manufacturing sectors investing in advanced machinery. Emphasis on energy-efficient and low-emission equipment, along with the replacement of ageing fleets, supports market growth. Germany, with its strong industrial base and precision engineering focus, remains the key contributor in the region.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the engineering machinery counterweight iron market, along with a comparative evaluation primarily based on their type of offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes type development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Max Iron GmbH

- Gallizo

- Mars Metal

- FMGC (Farinia)

- SIC Lazaro

- Crescent Foundry

- Blackwood Engineering

- Ultraray Metals

- Innotec

- Vietnam Cast Iron

- Swebor

- AMAC Alloys

- Ondo Metal

- Agescan International

- International Steel & Counterweights

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Development

- In April 2025, Caterpillar launched the Next Generation M323, an upgraded M323F road-to-rail excavator for railway applications. Enhancements include improved operator comfort, safety, and maintenance, featuring a redesigned cab, better visibility, simplified service points, and a lowered counterweight to optimize balance and operational efficiency.

- In December 2021, Crescent offered a wide range of custom cast iron counterweights for cranes, forklifts, AWPs, tractors, loaders, and marine ballasts. Designed for optimal performance, they enhance load handling, rotational balance, and vibration reduction, ensuring faster, safer, and more efficient operation across various industrial and heavy machinery applications.

- In August 2021, Blackwood Engineering, established in 1946, supplied castings and counterweights for access equipment and telehandlers. From a UK general foundry, it diversified in the 1970s to focus on counterweights, later expanding in the 1990s to ductile iron, steel, and complex engineered castings, growing substantially over the decades.

- In September 2020, Swebor Counterweights, produced in Lulea, Sweden, since the early 2000s, emphasized precision manufacturing. CNC operator Sandra, joining in 2012, plays a key role in flame-cutting and machining. Counterweights are crucial for balancing heavy machinery like cranes, forklifts, excavators, and reach stackers, ensuring operational safety.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the engineering machinery counterweight iron market based on the below-mentioned segments:

Global Engineering Machinery Counterweight Iron Market, By Product Type

- Ordinary Sand Mold Counterweight Iron

- Extra Heavy Iron

Global Engineering Machinery Counterweight Iron Market, By Application

- Forklift

- Excavator

- Crane

- Loader

- Road Roller

- Tower Crane

- Other

Global Engineering Machinery Counterweight Iron Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the engineering machinery counterweight iron market over the forecast period?The global engineering machinery counterweight iron market is projected to expand at a CAGR of 5.27% during the forecast period.

-

2. What is the engineering machinery counterweight iron market?The engineering machinery counterweight iron market is a global sector for the design, manufacturing, and sale of cast iron and steel components used to balance heavy equipment like cranes and excavators.

-

3. What is the market size of the engineering machinery counterweight iron market?The global engineering machinery counterweight iron market size is expected to grow from USD 3.32 billion in 2024 to USD 5.84 billion by 2035, at a CAGR of 5.27% during the forecast period 2025-2035.

-

4. Which region holds the largest share of the engineering machinery counterweight iron market?Asia Pacific is anticipated to hold the largest share of the engineering machinery counterweight iron market over the predicted timeframe.

-

5. Who are the top 10 companies operating in the global engineering machinery counterweight iron market?Max Iron GmbH, Gallizo, Mars Metal, FMGC (Farinia), SIC Lazaro, Crescent Foundry, Blackwood Engineering, Ultraray Metals, Innotec, Vietnam Cast Iron, Swebor, and Others.

-

6. What factors are driving the growth of the engineering machinery counterweight iron market?The growth of the engineering machinery counterweight iron market is driven by several key factors, primarily the expansion of the construction industry and large-scale infrastructure projects, the increasing demand for material handling equipment, and the inherent material properties of cast iron that make it ideal for counterweights.

-

7. What are the market trends in the engineering machinery counterweight iron market?Market trends in engineering machinery counterweight iron include significant growth driven by the construction and industrial sectors, a continued preference for cast iron due to its density and cost-effectiveness, and emerging interest in sustainable and modular solutions.

-

8. What are the main challenges restricting wider adoption of the engineering machinery counterweight iron market?The main challenges restricting the wider adoption of engineering machinery counterweight iron market include volatile raw material prices, stringent environmental regulations, significant logistical constraints, and competition from alternative materials.

Need help to buy this report?