Global Downstream Processing Market Size, By Product (Chromatography Systems, Filters, Evaporators, Centrifuges, Dryers, Others), By Technique (Cell Disruption, Solid-liquid separation, Concentration, Purification, Formulation), By Application (Antibiotic Production, Hormone Production, Antibodies Production, Enzyme Production, Vaccine Production), By Geographic Scope and Forecast, 2022 – 2032

Industry: HealthcareGlobal Downstream Processing Market Size Insights Forecasts to 2032

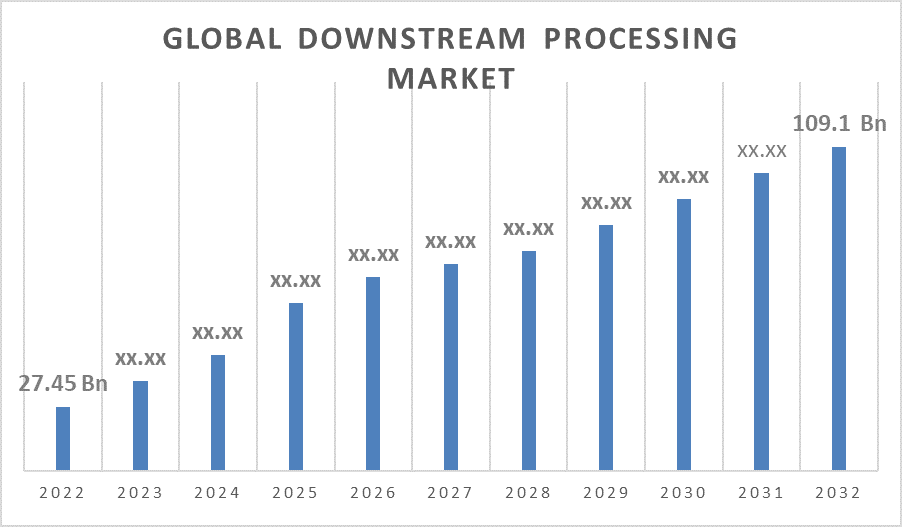

- The Downstream Processing Market Size was valued at USD 27.45 Billion in 2022.

- The Market is Growing at a CAGR of 14.8% from 2022 to 2032

- The worldwide Downstream Processing Market Size is expected to reach USD 109.1 Billion by 2032

- Asia Pacific is expected to grow the fastest during the forecast period

Get more details on this report -

The Global Downstream Processing Market Size is expected to reach USD 109.1 Billion by 2032, at a CAGR of 14.8% during the forecast period 2022 to 2032.

Downstream processing is the recuperation and purification of biosynthetic products, especially pharmaceuticals, from biological sources such as animal or plant tissue or fermentation, as well as the regeneration of viable components and efficient waste treatment and disposal. Downstream processing is critical in the biopharmaceutical business, as it is required for the purification and separation of biologically generated products such as biopharmaceuticals, enzymes, vaccines, and monoclonal antibodies. Following the first fermentation or cell culture stages, this process focuses on the recovery and purification of the target products from the complex mixtures created. It is critical in assuring the safety, quality, and efficacy of these products for clinical and commercial usage. It also intends to produce a highly pure and physiologically active product while minimizing contaminants and preserving product integrity. To manufacture biopharmaceuticals that fulfill quality and safety criteria, downstream processing necessitates precision, efficiency, and adherence to stringent regulatory standards. Downstream processing is an important component of the biopharmaceutical sector, influencing product quality, time-to-market, and cost-effectiveness. The downstream processing market is projected to grow primarily because of a number of factors, such as the substantial advancements in healthcare infrastructure, particularly in emerging countries, and the increasing expenditure on research and development (R&D) in the field of biochemical engineering.

Market Outlook

Downstream Processing Market Price Analysis

The downstream processing market is critical to the biopharmaceutical industry since it encompasses the purification and separation of biologically derived products such as biopharmaceuticals, enzymes, and vaccines. A variety of factors determine pricing analysis in this field, notably the complex nature of purifying procedures, regulatory constraints, and market demand. Raw material costs, labor, equipment, and adherence to demanding quality and safety standards are all cost issues. Pricing is also influenced by market dynamics and competition. As the biopharmaceutical sector grows, new downstream processing technologies emerge, influencing pricing strategies. The balance of quality, efficiency, and cost-effectiveness is an important part of downstream processing price.

Downstream Processing Market Distribution Analysis

The distribution analysis in the downstream processing market emphasizes the efficient and compliant conveyance of biopharmaceutical materials from producers to end-users, who are primarily biopharmaceutical businesses, clinical research organizations, and research institutes. Because of the complexity of these items, specific distribution networks and temperature-controlled logistics are required. To maintain product integrity and patient safety, regulatory compliance, including good distribution practices (GDP), is extremely important. Storage, warehousing, and inventory management, as well as last-mile delivery, are all part of distribution. Effective distribution strategies are crucial in delivering biopharmaceuticals to patients while ensuring product quality and regulatory compliance.

Global Downstream Processing Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 27.45 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 14.8% |

| 2032 Value Projection: | USD 109.1 Billion |

| Historical Data for: | 2019-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 120 |

| Segments covered: | Global Downstream Processing Market Size, By Product, By Technique, By Application, By Geographic Scope |

| Companies covered:: | 3M Company, Thermo Fisher Scientific Inc., GE Healthcare, Sartorius Stedim Biotech S.A., Merck KGaA, Danaher Corporation Inc., Lonza Group Ltd., Dover Corporation, Ashai Kasei, Ferner PLC, Eppendorf AG, Corning Corporation, Boehringer Ingelheim International GmbH, and other key vendors |

| Growth Drivers: | Biopharmaceutical advancements and innovation |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Market Dynamics

Downstream Processing Market Dynamics

Biopharmaceutical advancements and innovation

The biopharmaceutical sector is expanding rapidly, fueled by technical advancements and the development of innovative therapeutic agents such as monoclonal antibodies, gene treatments, and vaccines. Purification and isolation of these complex biopharmaceuticals frequently necessitate sophisticated downstream processing procedures. The constant advancement of biopharmaceuticals increases the requirement for downstream processing solutions. Furthermore, companies are investing in cutting-edge technologies and procedures to fulfill the industry's changing needs, which is driving downstream processing market growth.

Rising demand for personalized medicine

The increased need for personalized medicine is a major driver in the downstream processing market. It promotes the development of versatile and flexible downstream processing technologies capable of handling novel and patient-specific medicines. As personalized medicine develops in popularity, the market for downstream processing is projected to grow even more.

Restraints & Challenges

High Initial Capital Investment

The establishment of downstream processing facilities, which necessitate complex equipment and technologies, necessitates a significant initial capital expenditure. Biopharmaceutical businesses must invest significantly in order to build and maintain these facilities. Additionally, for smaller biopharmaceutical companies, the large capital requirements might be a significant impediment to entrance. It may also stymie the growth of established businesses, which must constantly invest in updating and scaling their downstream processing capabilities. This cost burden has the potential to hamper market expansion and innovation.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the downstream processing market from 2023 to 2032. The downstream processing market in North America is well-established and expanding its operations, particularly in the biopharmaceutical sector. The region is home to a slew of major pharmaceutical and biotech firms, making it a bioprocessing and downstream purification hotspot. In addition, the region has witnessed significant collaboration activity with healthcare behemoths that are heavily investing in biopharmaceutical and vaccine R&D. Furthermore, leading players in the downstream processing industry are growing their presence in this region. Moreover, due to sophisticated research and development activities, a solid regulatory framework, and a competent workforce, the United States, in particular, maintains the majority of this industry. The downstream processing market in North America is distinguished by cutting-edge technologies and a concentration on biologics production.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2032. The Asia Pacific region is rapidly establishing itself as a key player in the downstream processing market, particularly in the biopharmaceutical and biotechnology sectors. China, Japan, India, and South Korea are also boosting their bioprocessing capabilities. The region has a nurtured and cost-effective workforce, making it a compelling option for outsourcing biomanufacturing. The downstream processing market in the Asia Pacific is distinguished by a focus on cost-effective production and the development of biosimilars.

Segmentation Analysis

Insights by Product

The chromatography system segment accounted for the largest market share over the forecast period 2023 to 2032. This is because of their critical role in biopharmaceutical purification and ongoing R&D to improve the effectiveness and rapidity of chromatography systems. Chromatography is a popular technique for isolating and purifying biopharmaceutical products such as proteins and monoclonal antibodies. It entails the use of columns packed with resins that bind to the target molecules selectively. In bioprocessing, various techniques such as affinity chromatography, ion exchange chromatography, and size-exclusion chromatography are used. Chromatography systems are critical for achieving high product purity, which is critical for biologics and medicines.

Insights by Technique

The purification segment accounted for the largest market share over the forecast period 2023 to 2032. Purification is a crucial phase in downstream processing that involves the use of several chromatography techniques and other techniques to separate and purify the target molecule. It entails selective binding and separation of the product from other impurities and pollutants, resulting in a high-purity product. Purification is a time-consuming and resource-intensive procedure that frequently necessitates many chromatography processes and other approaches to attain the desired product purity and yield. Purification has been a significant emphasis in the biopharmaceutical sector due to the increased demand for purified biopharmaceuticals, particularly monoclonal antibodies, and other complicated compounds.

Insights by Application

The antibodies production segment accounted for the largest market share over the forecast period 2023 to 2032. Antibody manufacturing is an important element in downstream processing, notably for monoclonal antibody (mAb) isolation and purification. Monoclonal antibodies (mAbs) are a type of biopharmaceutical that is widely used in a variety of therapeutic fields. mAbs are employed in a variety of therapeutic applications, including cancer treatment and the treatment of autoimmune illnesses. The need for mAbs continues to rise, making antibody purification and isolation a key emphasis in downstream processing.

Competitive Landscape

Major players in the market

- 3M Company

- Thermo Fisher Scientific Inc.

- GE Healthcare

- Sartorius Stedim Biotech S.A.

- Merck KGaA

- Danaher Corporation Inc.

- Lonza Group Ltd.

- Dover Corporation

- Ashai Kasei

- Ferner PLC

- Eppendorf AG

- Corning Corporation

- Boehringer Ingelheim International GmbH

Recent Market Developments

- On October 2023, WuXi Biologics, a CDMO, has announced WuXiUI, a bioprocessing platform that claims to save 60-80% on COGS when compared to standard fed-batch procedures in single-use bioreactors. The ultra-intensified intermittent-perfusion fed-batch (UI-IPFB) technique, according to WuXi Biologics, enhances the productivity and quality of various CHO or other mammalian cell lines for monoclonal antibodies (mAbs), bispecifics, and recombinant proteins. The platform is capable of producing such cost-of-goods-sold savings through a three-to-six-fold boost in productivity.

- On October 2023, SCHOTT has launched the ViewCell flow cell, a novel component for biopharmaceutical process analysis. The flow cell is intended to provide safe, continuous process control directly in the manufacturing line. The flow cell allows in-situ measurements of biological and physical parameters in downstream processing via a sterile-safe optical window. It can be employed during purification, filtering, and subsequent formulation. As a result, physical sampling is decreased, as is the necessity for storage containers.

- On January 2023, Sartorius has renewed a strategic cooperation agreement with RoosterBio Inc. (RoosterBio) to address purification problems and build scalable downstream manufacturing processes for exosome-based medicines. Sartorius and RoosterBio will collaborate to provide best-in-class solutions and expertise for a human mesenchymal stem/stromal cell (hMSC)-based exosome production platform with industry-leading yield, purity, and potency.

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2032.

Downstream Processing Market, Product Analysis

- Chromatography Systems

- Filters

- Evaporators

- Centrifuges

- Dryers

- Others

Downstream Processing Market, Technique Analysis

- Cell Disruption

- Solid-liquid separation

- Concentration

- Purification

- Formulation

Downstream Processing Market, Application Analysis

- Antibiotic Production

- Hormone Production

- Antibodies Production

- Enzyme Production

- Vaccine Production

Downstream Processing Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the downstream processing market?The global downstream processing market is expected to grow from USD 27.45 Billion in 2023 to USD 109.1 Billion by 2032, at a CAGR of 14.8% during the forecast period 2023-2032.

-

2. Who are the key market players of the downstream processing market?3M Company, Thermo Fisher Scientific Inc., GE Healthcare, Sartorius Stedim Biotech S.A., Merck KGaA, Danaher Corporation Inc., Lonza Group Ltd., Dover Corporation, Ashai Kasei, Ferner PLC, Eppendorf AG, Corning Corporation, Boehringer Ingelheim International GmbH

-

3. Which segment holds the largest market share?Chromatography system segment holds the largest market share and is going to continue its dominance.

-

4. Which region is dominating the downstream processing market?North America is dominating the downstream processing market with the highest market share.

Need help to buy this report?