Global Digital Twin Cement Kiln Market Size, Share, and COVID-19 Impact Analysis, Russia-Ukraine War Impact, Tariff Analysis, By Component (Software, Hardware, and Services), By Application (Process Optimization, Predictive Maintenance, Energy Management, Asset Management, and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2025 - 2035

Industry: Construction & ManufacturingDigital Twin Cement Kiln Market Summary, Size & Emerging Trends

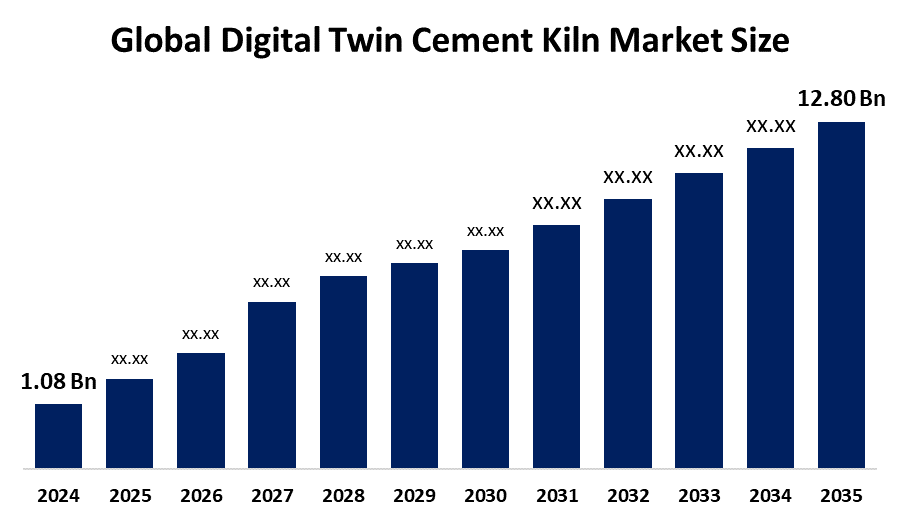

According to Spherical Insights, the Global Digital Twin Cement Kiln Market Size is Expected to Grow from USD 1.08 Billion in 2024 to USD 12.80 Billion by 2035, at a CAGR of 25.2 % during the forecast period 2025-2035. The market for digital twin cement kiln provides opportunities for improved operational effectiveness, data-driven decision-making, cost optimization, a decrease in emissions, predictive maintenance, and continuous tracking in the construction materials manufacturing sector.

Get more details on this report -

Key Market Insights

- Asia Pacific is expected to account for the largest share in the digital twin cement kiln market during the forecast period.

- In terms of component, the software segment is projected to lead the digital twin cement kiln market in terms of equipment throughout the forecast period

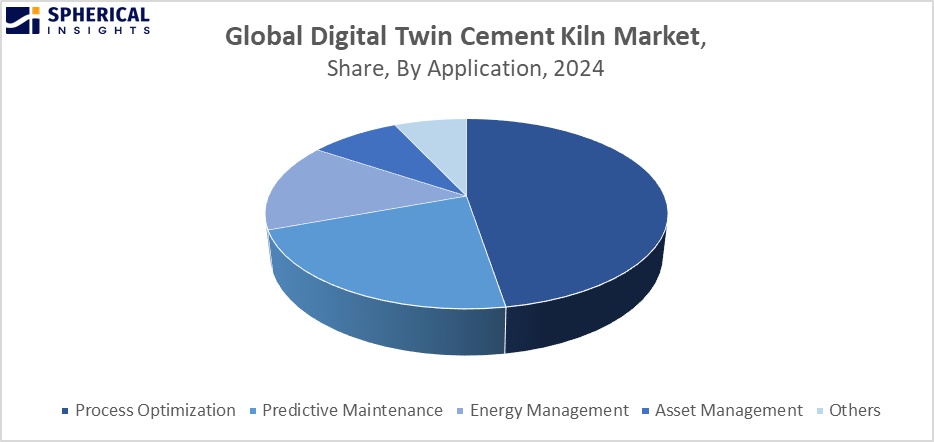

- In terms of application, the process optimization segment captured the largest portion of the market

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 1.08 Billion

- 2035 Projected Market Size: USD 12.80 Billion

- CAGR (2025-2035): 25.2 %

- Asia Pacific: Largest market in 2024

- North America: Fastest growing market

Digital Twin Cement Kiln Market

The industrial and manufacturing technology sector's segment dedicated to the creation, application, and marketing of digital twin solutions especially made for cement kiln operations is known as the "digital twin cement kiln market." A digital twin is a virtual system that mimics the behavior, performance, and circumstances of its real-world counterpart by combining real-time data, simulation models, and sophisticated analytics. Digital twin simulates kiln operations under various conditions, allowing for continuous monitoring, predictive maintenance, process optimization, and performance improvement in the context of cement kilns. The digital twin cement kiln market consists of hardware integrators, software developers, and service providers working together to provide end-to-end digital twin solutions that are customized to meet the unique requirements of the cement production sector. The growing focus on energy efficiency and process optimization is one of the main drivers of the market for digital twin cement kilns. The cement industry's focus on cost reduction, operational efficiency, and adhering to strict environmental requirements is the main driver of this significant development. The increasing demand for asset management and predictive maintenance in cement plants is another important factor.

Digital Twin Cement Kiln Market Trends

- Application of AI and Machine Learning: To improve predictive capacities and process optimization in digital twin systems for cement kilns, artificial intelligence and machine learning algorithms are increasingly being adopted.

- Prioritizing sustainability and lowering emissions: growing need for digital twin solutions that enhance energy efficiency and lower greenhouse gas emissions in cement manufacturing, therefore supporting decarbonization plans.

- Cloud-Based and Edge Computing Solutions: Scalable, real-time data processing and remote cement kiln operations monitoring is made possible by the expanding use of cloud and edge computing technologies.

- Strategic Alliances and Partnerships: Increasing cooperation among technology suppliers, cement producers, and academic institutions to hasten the development and application of cutting-edge digital twin technologies.

Digital Twin Cement Kiln Market Dynamics

Global Digital Twin Cement Kiln Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 1.08 Billion |

| Forecast Period: | 2024-2035 |

| Forecast Period CAGR 2024-2035 : | 25.2 % |

| 2035 Value Projection: | USD 12.80 Billion |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 240 |

| Tables, Charts & Figures: | 150 |

| Segments covered: | By Component, By Application. |

| Companies covered:: | Siemens AG, IBM Corporation, AVEVA Group plc, FLSmidth & Co. A/S, Emerson Electric Co., Aspen Technology, Inc., Schneider Electric SE, Rockwell Automation, Inc., General Electric Company, Yokogawa Electric Corporation, Honeywell International Inc., Mitsubishi Electric Corporation, Bentley Systems, Incorporated, Tata Consultancy Services Limited (TCS) and Others. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors: IoT, AI, and regulations drive market growth.

Improvements in industrial IoT, AI-powered analytics, and mounting regulatory pressure to reduce energy and carbon emissions all contribute to the digital twin cement kiln market's growth. The growing focus on predictive maintenance and operational efficiency is one of the key drivers of the digital twin cement kiln market's expansion. Digital twin technologies efficiently meet the pressing demand for process optimization, cost reduction, and sustainability improvements in the cement sector, which is driving this robust expansion. The nexus of cloud computing, IIoT, and artificial intelligence is anticipated to propel the next wave of innovation in digital twin applications as digital transformation projects build up steam in the cement sector.

Restrain Factors: High costs, expertise gaps, data, and cybersecurity hinder growth.

The presence of high implementation costs, limited technical expertise, integration of data from different sources, and cybersecurity risks restricts the growth of the digital twin cement kiln market. High start-up costs and complexity are among the main restraints. The added complexity of modifying existing infrastructure with digital twin technologies presents insurmountable obstacles, particularly for small and mid-sized cement producers with limited budgets.

Opportunity: Digital twin kilns offer sustainability, efficiency, and innovation.

The market for digital twin cement kilns provides the global cement industry with a variety of opportunities for sustainability, efficiency, and innovation. One of the most exciting opportunities is the convergence of machine learning and artificial intelligence with digital twin systems. The increased adoption of cloud-based deployment avenues and the proliferation of Industrial Internet of Things (IIoT) devices offer additional growth opportunities for the Digital Twin Cement Kiln market. The heightened interest in environmental stewardship and sustainability issues in the cement sector is another great opportunity.

Challenges: Limited expertise and costs limit deployment growth.

Limited technical competence and high initial installation costs prevent widespread deployment, especially among small and medium-sized businesses. The technological challenges of integrating various data sources from older systems that are currently in place are substantial. Interoperability and smooth integration are made more difficult by the lack of standardized frameworks and protocols. The scalability and effectiveness of digital twin technologies in the cement manufacturing industry are hampered by these concerns taken together.

Global Digital Twin Cement Kiln Market Ecosystem Analysis

The ecosystem of the global market for digital twin cement kilns includes important players such as regulators, system integrators, cement producers, and technology suppliers. Technology companies provide cutting-edge gear and software for digital twins, and cement producers use these advancements to boost productivity. System integrators make it easier to integrate data and apply ancient and contemporary infrastructure. Regulatory bodies encourage sustainable behaviors by influencing market dynamics through safety and environmental requirements. Improved performance, predictive maintenance, and lower emissions in the worldwide cement manufacturing sector are made possible by cooperative collaborations and ongoing innovation within this ecosystem, which propels market expansion.

Global Digital Twin Cement Kiln Market, By Component

The software segment led the digital twin cement kiln market, generating the largest revenue share. The foundation of digital twin technology is the software sector, which includes analytics engines, visualization tools, and simulation platforms that allow for real-time kiln operation monitoring and optimization. Vendors are investing in R&D as a result of the increasing need for scalable and customized software solutions, creating a highly competitive market with frequent product advancements.

The services segment in the digital twin cement kiln market is expected to grow at the fastest CAGR over the forecast period. The consultation, implementation, integration, and support services that are necessary for the effective deployment and upkeep of digital twin systems are included in the services section. Cement makers need assistance from service providers to navigate the digital transformation process, from initial evaluation and solution design to system integration and continuing support.

Global Digital Twin Cement Kiln Market, By Application

The process optimization segment held the largest market share in the digital twin cement kiln market. One major application area is process optimization, which uses digital twin models to improve product quality, optimize process parameters, and mimic kiln behavior. Digital twins give producers real-time insight into kiln operations, allowing them to spot inefficiencies, lower variability, and produce consistent results.

Get more details on this report -

The predictive maintenance segment in the digital twin cement kiln market is projected to register the fastest CAGR. Predictive maintenance is another crucial application that aims to maximize asset availability and reduce unscheduled downtime. It is anticipated that the use of digital twin platforms with sophisticated diagnostic and prognostic capabilities could rise as cement makers come to understand the need for predictive maintenance.

Asia Pacific is expected to account for the largest share of the digital twin cement kiln market during the forecast period.

Get more details on this report -

The Asia Pacific region is characterized by significant cement producers in China, India, and Southeast Asia, as well as growing urbanization and infrastructural development. Government programs that assist sustainability and smart manufacturing are available in the region. The growing pool of highly qualified workers, strong IT infrastructure, and advantageous regulatory framework in Asia Pacific are all contributing factors to the region's rapid adoption of digital twin technology.

China is experiencing steady growth in the digital twin cement kiln market. China's large cement manufacturing industry, rising investments in Industry 4.0 technologies, and robust government programs encouraging environmentally friendly business practices are all factors in this development. The adoption of digital twin solutions is also fueled by China's emphasis on improving operational effectiveness and minimizing environmental impact in cement manufacturing, which strengthens its position as a major regional market.

North America is expected to grow at the fastest CAGR in the digital twin cement kiln market during the forecast period.

North America is distinguished by its high emphasis on innovation and early adoption of digital twin solutions. Numerous top research institutes and technology providers are based in the area, which promotes cooperation and knowledge exchange. Investments in Industry 4.0, sustainability, and operational excellence have placed the US and Canada at the forefront of the cement industry's digital transformation.

The United States is the largest market for digital twin cement kiln.

The demand for digital twin technologies to improve operational efficiency and sustainability within the cement manufacturing sector is driven by the United States' sophisticated industrial infrastructure, broad adoption of Industry 4.0 technologies, and strict environmental regulations.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the digital twin cement kiln market, along with a comparative evaluation primarily based on their type of offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborate analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

WORLDWIDE TOP KEY PLAYERS IN THE DIGITAL TWIN CEMENT KILN MARKET INCLUDE

- Siemens AG

- IBM Corporation

- AVEVA Group plc

- FLSmidth & Co. A/S

- Emerson Electric Co.

- Aspen Technology, Inc.

- Schneider Electric SE

- Rockwell Automation, Inc.

- General Electric Company

- Yokogawa Electric Corporation

- Honeywell International Inc.

- Mitsubishi Electric Corporation

- Bentley Systems, Incorporated

- Tata Consultancy Services Limited (TCS)

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Product Launches in Digital Twin Cement Kiln

- In March 2023, Holcim launched the world’s first cement plant digital twin, a groundbreaking 3D virtual replica of its Swiss facility. Integrating enterprise software and performance prediction algorithms, the digital twin enables real-time monitoring, enhancing operational efficiency, reliability, and cost-effectiveness, marking a major step forward in cement industry digitalization.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the digital twin cement kiln market based on the below-mentioned segments:

Global Digital Twin Cement Kiln Market, By Component

- Software

- Hardware

- Services

Global Digital Twin Cement Kiln Market, By Application

- Process Optimization

- Predictive Maintenance

- Energy Management

- Asset Management

- Others

Global Digital Twin Cement Kiln Market, By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the CAGR of the Digital Twin Cement Kiln market over the forecast period?The global Digital Twin Cement Kiln market is projected to expand at a CAGR of 25.2 % during the forecast period.

-

2. What is the market size of the Digital Twin Cement Kiln market?The global Digital Twin Cement Kiln market Size is expected to grow from USD 1.08 billion in 2024 to USD 12.80 billion by 2035, at a CAGR of 25.2 % during the forecast period 2025-2035.

-

3. Which region holds the largest share of the Digital Twin Cement Kiln market?Asia Pacific is anticipated to hold the largest share of the Digital Twin Cement Kiln market over the predicted timeframe.

-

4. Who are the top 10 companies operating in the global Digital Twin Cement Kiln market?Key players include Siemens AG, IBM Corporation, AVEVA Group plc, FLSmidth & Co. A/S, Emerson Electric Co., Aspen Technology, Inc., Schneider Electric SE, Rockwell Automation, Inc., General Electric Company, Yokogawa Electric Corporation, Honeywell International Inc., Mitsubishi Electric Corporation, Bentley Systems, Incorporated, Tata Consultancy Services Limited (TCS), and Others.

-

5. What factors are driving the growth of the Digital Twin Cement Kiln market?The growth of the Digital Twin Cement Kiln market is driven by advancements in IIoT and AI, rising demand for energy efficiency, regulatory pressure to reduce emissions, and increasing digitalization.

-

6. What are the main challenges restricting wider adoption of the Digital Twin Cement Kiln market?The primary challenges preventing the Digital Twin Cement Kiln market from being widely adopted include high installation costs, a lack of standardized frameworks, a lack of technical experience, integration issues with existing systems, and data security concerns.

Need help to buy this report?