Global Decanter Centrifuge Market Size By Design Type (Horizontal, Vertical), By Application (Waste Water Treatment, Oil/Gas Exploration and Petrochemical Industry, Food and Beverages, Mining and Metal Processing, Chemical, Pharmaceutical and Biotechnology, Pulp and Paper, Polymer Industry, Water Purification and Others), By Region, And Segment Forecasts, By Geographic Scope And Forecast 2022 - 2032

Industry: Machinery & EquipmentGlobal Decanter Centrifuge Market Size Insights Forecasts to 2032

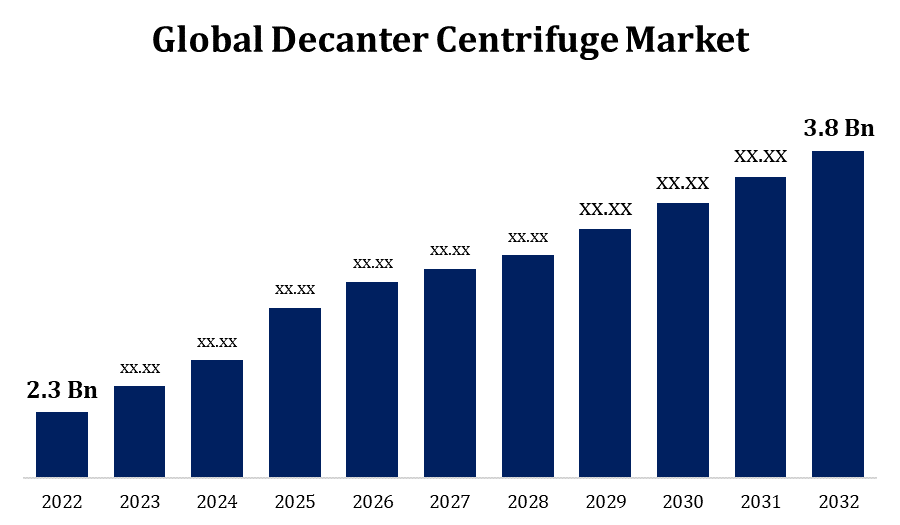

- The Decanter Centrifuge Market Size was valued at USD 2.3 Billion in 2022.

- The Market Size is Growing at a CAGR of 5.6% from 2022 to 2032

- The Global Decanter Centrifuge Market Size is expected to reach USD 3.8 Billion by 2032

- Asia Pacific is expected to grow the fastest during the forecast period

Get more details on this report -

The Global Decanter Centrifuge Market Size is expected to reach USD 3.8 Billion by 2032, at a CAGR of 2.3% during the forecast period 2022 to 2032.

In recent years, the decanter centrifuge market has grown at a rapid pace. A primary driver has been the demand for efficient and cost-effective separation technologies across sectors. Industries are investing in technologies such as decanter centrifuges for wastewater treatment and sludge dewatering as environmental laws become more rigorous. Decanter centrifuges are critical in the oil and gas industry for the separation of solids from drilling mud and wastewater, contributing to the market's overall growth. These devices are also used in the food processing industry to separate solids from liquids in procedures such as juice extraction and oil clarifying.

Decanter Centrifuge Market Value Chain Analysis

Suppliers of raw materials such metals, polymers, and other components needed in the production of decanter centrifuges. Companies that develop and manufacture decanter centrifuges. This includes designing, building, and testing the machines. Distributors or sales channels that link manufacturers and end customers. Wholesalers, retailers, and direct sales to industries are examples of this. Industries that use decanter centrifuges for a variety of purposes, including wastewater treatment, oil and gas processing, food and beverage production, pharmaceuticals, and so on. Companies that provide decanter centrifuge maintenance, repair, and support services to ensure optimal performance throughout their lives. In sectors such as wastewater treatment, the waste generated during the separation process may be further treated or recycled.

Decanter Centrifuge Market Opportunity Analysis

Investigate potential in emerging economies where industrialization is accelerating. These areas may see an increase in demand for decanter centrifuges in a variety of sectors. Investigate potential in emerging economies where industrialization is accelerating. These areas may see an increase in demand for decanter centrifuges in a variety of sectors. Collaborate with other businesses or research organisations to take use of complementary technology. Partnerships can result in the creation of integrated solutions and the expansion of market reach. Develop extensive after-sales services and maintenance contracts to foster long-term customer connections. Continuous help can boost client satisfaction and loyalty. Digital technologies and data analytics should be integrated into decanter centrifuge systems. This information can be used to improve predictive maintenance, performance, and overall efficiency.

Global Decanter Centrifuge Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 2.3 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 2.3% |

| 2032 Value Projection: | USD 3.8 Billion |

| Historical Data for: | 2018-2021 |

| No. of Pages: | 183 |

| Tables, Charts & Figures: | 115 |

| Segments covered: | By Design Type, By Application, By Region And Segment Forecast, By Geographic Scope And Forecast |

| Companies covered:: | GEA (Germany), Flottweg SE (Germany), Pieralisi (Italy), Alfa Laval (Sweden), ANDRITZ (Austria), SLB (US), IHI ROTATING MACHINERY ENGINEERING CO LTD (Japan), Mitsubishi Kakoki Kaisha, Ltd (Japan), Tomoe Engineering Co Ltd (Japan), Fismidth (Denmark), and other key companies. |

| Pitfalls & Challenges: | Covid-19 Empact,Challenges,Growth, Analysis. |

Get more details on this report -

Market Dynamics

Decanter Centrifuge Market Dynamics

Rise in demand for decanter centrifuges in process industries

Decanter centrifuges are extremely effective at separating solid particles from liquid, making them extremely beneficial in process sectors where such separation is critical. The efficient removal of particles from liquids benefits industries such as medicines, chemicals, and food & beverage. With the global expansion of process industries, there is a rising demand for technology that can improve production efficiency. Decanter centrifuges provide a scalable and versatile solution for a wide range of industrial applications, meeting the demands of rising industrialization. Decanter centrifuges are used in the oil and gas industry to separate solids from drilling mud and wastewater. As exploration and extraction activities continue, there is a considerable need for decanter centrifuges in this area. Decanter centrifuges are used for a variety of purposes in food and beverage production.

Restraints & Challenges

The initial investment in purchasing and installing decanter centrifuges might be significant. This initial investment may be difficult for smaller enterprises or industries with limited resources. Although decanter centrifuges are efficient, they must be serviced on a regular basis to ensure peak performance. Maintenance expenditures can add up over time, and businesses must account for them in their operating budgets. Decanter centrifuge operation can be complicated, requiring specialised staff for setup, monitoring, and maintenance. Some sectors may struggle to train and retain trained operators. Decanter centrifuges can consume a lot of energy, especially when processing huge amounts of material. As energy costs rise and environmental concerns develop, more energy-efficient centrifuge designs are required. It might be difficult to achieve optimal performance across a large range of materials.

Regional Forecasts

North America Market Statistics

Get more details on this report -

North America is anticipated to dominate the Decanter Centrifuge Market from 2023 to 2032. Decanter centrifuges are used in the oil and gas industry in North America for a variety of applications, including the separation of solids from drilling mud and effluent. The region's ongoing oil and gas exploration and production activities contribute to the demand for decanter centrifuges. Decanter centrifuges are used in the food and beverage sector in North America for operations like as clarifying liquids, extracting oils, and separating particles from various food processing streams. The emphasis on quality and efficiency in the industry pushes the implementation of improved separation technologies. Decanter centrifuges are used in operations such as the separation of chemical compounds, the purification of pharmaceutical products, and the recovery of precious materials in the pharmaceutical and chemical industries in North America. These industries' strict quality standards stimulate demand.

Asia Pacific Market Statistics

Asia Pacific is witnessing the fastest market growth between 2023 to 2032. Demand for effective separation technologies is being driven by rising industrialization and infrastructural development in countries such as China and India. Decanter centrifuges are used in a variety of industries, including wastewater treatment, mining, food and beverage, and others. As urbanisation accelerates, so does the demand for wastewater treatment solutions. Decanter centrifuges serve a critical role in the effective separation of solids from wastewater, fulfilling the growing demand for environmentally sustainable and efficient water management strategies. Decanter centrifuges are used in the Asia-Pacific mining industry to dewater and separate mining slurries. With continuous mining operations in Australia, Indonesia, and other nations, the demand for solid-liquid separation technology remains high.

Segmentation Analysis

Insights by Design Type

The horizontal type segment accounted for the largest market share over the forecast period 2023 to 2032. Horizontal decanter centrifuges are well-known for their adaptability to a wide variety of materials and applications. In industries like as wastewater treatment, food and beverage, chemicals, and oil and gas, they can efficiently separate solids from liquids. Horizontal decanter centrifuges are built to run continuously, ensuring a steady and uninterrupted separation process. In industries where continuous manufacturing is critical for efficiency, this trait is highly valued. Because of the horizontal design, great throughput and processing capacity are possible. Horizontal decanter centrifuges are so well suited for applications requiring huge amounts of material to be treated efficiently. The horizontal form is frequently preferred for situations requiring effective solids discharge. The design allows for effective separation of separated solids, which contributes to overall efficiency.

Insights by Application

The chemical segment accounted for the largest market share over the forecast period 2023 to 2032. Handling mixes containing solid particles suspended in liquid is common in chemical processes. Decanter centrifuges are critical in separating these components efficiently and guaranteeing the appropriate purity and quality of the chemical output. Decanter centrifuges aid in the intensification of chemical production processes. They provide continuous and effective phase separation, minimising the need for additional processing steps and improving overall production efficiency. Decanter centrifuges are used in operations such as the separation of APIs (Active Pharmaceutical Ingredients), the purification of chemical compounds, and the manufacturing of high-purity substances in the chemical industry. Decanter centrifuges are used in the polymer processing industry to separate polymer solids from liquid monomers or solvents.

Recent Market Developments

- In March 2022, Flottweg SE introduced juice extraction decanters. The important characteristic of this product was its low cost juice extraction while maintaining good product quality. This will enable the company to expand its food and beverage solution offering.

Competitive Landscape

Major players in the market

- GEA (Germany)

- Flottweg SE (Germany)

- Pieralisi (Italy)

- Alfa Laval (Sweden)

- ANDRITZ (Austria)

- SLB (US)

- IHI ROTATING MACHINERY ENGINEERING CO LTD (Japan)

- Mitsubishi Kakoki Kaisha, Ltd (Japan)

- Tomoe Engineering Co Ltd (Japan)

- Fismidth (Denmark)

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2032.

Decanter Centrifuge Market, Design Type Analysis

- Horizontal

- Vertical

Decanter Centrifuge Market, Application Analysis

- Waste Water Treatment

- Oil/Gas Exploration and Petrochemical Industry

- Food and Beverages

- Mining and Metal Processing

- Chemical

- Pharmaceutical and Biotechnology

- Pulp and Paper

- Polymer Industry

- Water Purification

- Others

Decanter Centrifuge Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of the Decanter Centrifuge Market?The global Decanter Centrifuge Market is expected to grow from USD 2.3 Billion in 2023 to USD 3.8 Billion by 2032, at a CAGR of 5.6% during the forecast period 2023-2032.

-

2. Who are the key market players of the Decanter Centrifuge Market?Some of the key market players of market are GEA (Germany), Flottweg SE (Germany), Pieralisi (Italy), Alfa Laval (Sweden), ANDRITZ (Austria), SLB (US), IHI ROTATING MACHINERY ENGINEERING CO LTD (Japan), Mitsubishi Kakoki Kaisha, Ltd (Japan), Tomoe Engineering Co Ltd (Japan), Fismidth (Denmark).

-

3. Which segment holds the largest market share?The horizontal segment holds the largest market share and is going to continue its dominance.

-

4. Which region is dominating the Decanter Centrifuge Market?North America is dominating the Decanter Centrifuge Market with the highest market share.

Need help to buy this report?