Global Carbon Fiber Prepreg Market Size, Share, and COVID-19 Impact By Resin Type(Epoxy, Phenolic, Thermoplastic, Bismaleimide (BMI)), By End-use Industry(Aerospace & Defense, Wind Energy Sports & Recreation), by Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 – 2032)

Industry: Chemicals & MaterialsGlobal Carbon Fiber Prepreg Market Insights Forecasts to 2032

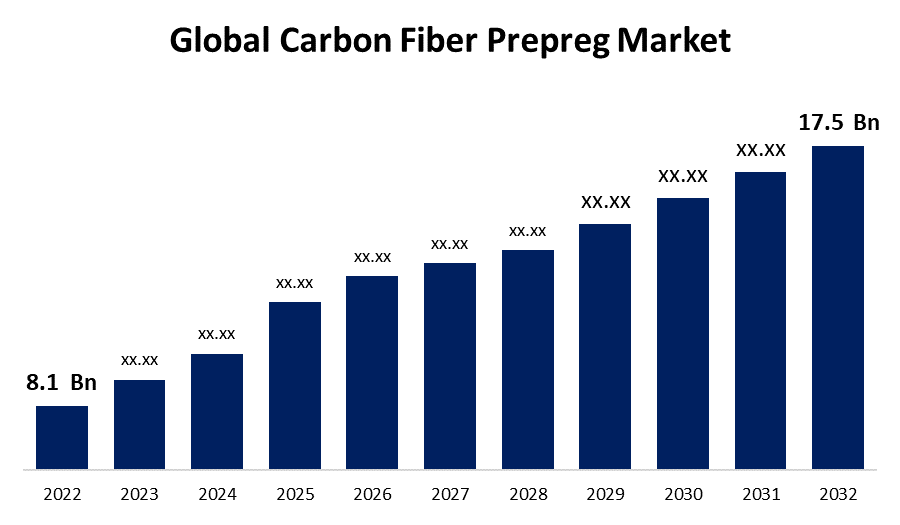

- The Global Carbon Fiber Prepreg Market Size was valued at USD 8.1 Billion in 2022.

- The Market Size is growing at a CAGR of 11.2% from 2022 to 2032

- The Worldwide Carbon Fiber Prepreg Market Size is expected to reach USD 17.5 Billion by 2032

- Asia is expected to grow the fastest during the forecast period

Get more details on this report -

The Global Carbon Fiber Prepreg Market Size is expected to reach USD 17.5 Billion by 2032, at a CAGR of 11.2% during the forecast period 2022 to 2032.

Carbon fibre reinforcements impregnated with a pre-cured polymer resin system make up the composite material known as carbon fibre prepreg. The word "prepreg" is short for "pre-impregnated," which refers to the fibres being soaked with resin before further processing. Due to its excellent strength-to-weight ratio, rigidity, and durability, this material is widely employed in a variety of industries, including aerospace, automotive, sports equipment, and more. High strength, rigidity, and fatigue resistance are just a few of the mechanical qualities that carbon fibre prepreg offers. Additionally, it offers outstanding resistance to corrosion and may be customised to meet particular needs by changing the fibre orientation and resin composition.

Impact of COVID 19 On Global Carbon Fibre Prepreg Market

The pandemic disrupted global supply chains, which had an impact on the supply of the raw ingredients and parts needed to make carbon fibre prepregs. There was a chance that production and delivery would have been delayed due to travel restrictions, lockdowns, and plant closures in various regions of the world. Due to economic uncertainty and lockdown measures, industries like aircraft, automotive, and athletic goods saw a decline in demand for their goods throughout the epidemic. Carbon fibre prepreg material demand may have cascaded as a result of this decreased demand. The epidemic caused numerous manufacturing and construction projects to be postponed or delayed. The orders for carbon fibre prepregs used in these projects would have been influenced by this. Due to decreased air travel and the grounding of aircraft, the aerospace industry—a large consumer of carbon fibre materials—was badly impacted by the epidemic. This might have resulted in fewer orders being placed for the carbon fibre prepregs used in aviation parts.

Global Carbon Fiber Prepreg Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 8.1 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 11.2% |

| 2032 Value Projection: | USD 17.5 Billion |

| Historical Data for: | 2019-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 120 |

| Segments covered: | COVID-19 Impact By Resin Type, By End-use Industry, By Region |

| Companies covered:: | SGL Carbon, Solvay, Hexcel Corporation, Axiom Materials, Park Electrochemical Corporation, Teijin Limited, Airtech Advanced Materials Group, Toray Industries, Mitsubishi Rayon Co. Ltd., and TCR Composites and Other key venders |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Key Market Drivers

Due to its excellent strength-to-weight ratio and longevity, carbon fibre prepregs are an important supplier to the aerospace sector. The usage of carbon fibre composites, particularly prepregs, in aeroplane components is anticipated to rise as demand for lighter, more fuel-efficient aircraft rises. Carbon fibre prepregs are being used more frequently in the automobile sector to lighten vehicles and increase fuel economy. Lightweight materials like carbon fibre are becoming more significant as electric vehicles (EVs) gain popularity and automakers work to increase their range. Because of its strength and endurance, carbon fibre prepregs are utilised in wind turbine blades and other components. The market for carbon fibre materials in this industry is predicted to develop as renewable energy sources like wind power are used more frequently.

Key Market Challenges

Prepregs and other carbon fibre composites are typically more expensive than conventional materials like metals and plastics. The price of production methods, specialised machinery, and raw ingredients all go into making carbon fibre prepregs, which is why their cost is so high. This may prevent widespread use, especially in sectors where cost-effectiveness is a key consideration. Complex manufacturing procedures, such as resin impregnation and controlled curing, are used to produce carbon fibre prepregs. For enterprises wishing to expand production or enter the market, these processes necessitate specialised tools and knowledge, which can present difficulties. The potential advantages of carbon fibre materials may not be as well known in some industries. It might be difficult to get designers, engineers, and decision-makers to understand the benefits and appropriate application of carbon fibre prepregs.

Market Segmentation

Resin Type Insights

Epoxy Resin type segment is dominating the market over the forecast period

On the basis of resin type, the global carbon fiber prepreg market is segmented into Epoxy, Phenolic, Thermoplastic, Bismaleimide (BMI), Polyimide, and Others. Among these, epoxy resin type segment is dominating the market over the forecast period. High strength, rigidity, and fatigue resistance are just a few of the remarkable mechanical qualities that make epoxy resin the material of choice. Epoxy-based carbon fibre prepregs are used to create composite materials with high overall performance when reinforced with carbon fibre. To harden the resin and attain the appropriate mechanical properties, epoxy-based carbon fibre prepregs often go through a curing procedure. This procedure, which uses pressure and heat, is essential for ensuring that the composite is properly consolidated.

End Use Insights

Aerospace and defence segment holds the highest market share over the forecast period

Based on the end use, the global carbon fiber prepreg market is segmented into Aerospace & Defense, Wind Energy Sports & Recreation, Automotive, and Others. Among these, aerospace and defence segment holds the highest market share over the forecast period. In order to increase fuel efficiency and overall performance, the aerospace industry places a high priority on weight reduction for aircraft. Carbon fibre prepregs are perfect for building lightweight components that reduce fuel consumption because of their high strength-to-weight ratio. In order to efficiently build complicated aerospace components with consistent quality, advanced production processes including automated layup and resin infusion are being used. The demand for lightweight materials that can handle payload, endurance, and mission requirements has grown as the number of unmanned aerial vehicles (UAVs) and drones for surveillance and military purposes has increased.

Regional Insights

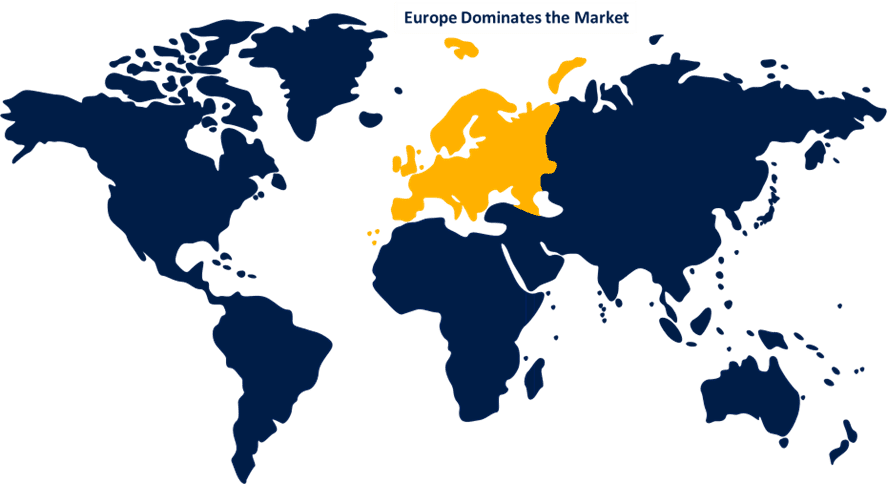

Europe is dominating the market over the forecast period

Get more details on this report -

Europe is dominating the market with the largest market share over the forecast period. The aerospace and automobile industries, which both use a significant amount of carbon fibre prepregs, are both heavily populated in Europe. These materials are used in the aerospace sector by businesses like Airbus to produce lighter, more fuel-efficient aeroplane components. In a similar vein, the automotive sector uses carbon fibre prepregs to create lightweight parts for electric vehicles (EVs) and high-performance cars. The demand for carbon fibre composites in the production of wind turbine blades is driven by Europe's concentration on renewable energy sources, such as wind power. The strength and durability of these components are increased by carbon fibre prepregs. In terms of the development of carbon fibre prepreg applications, other regions, such as North America and Asia, compete with Europe.

Asia Pacific is witnessing the fastest market growth over the forecast period. The Asia Pacific region has experienced significant industrialization and economic expansion, particularly in nations like China, Japan, South Korea, and Taiwan. Due to this expansion, there is now a greater demand across a range of industries for lightweight, high-performance materials like carbon fibre prepregs. China and India, for example, are developing their aerospace industries, which is helping to meet the rising need for carbon fibre prepregs in the aviation industry. The market has grown thanks to the emergence of regional suppliers and manufacturers of aircraft. Bicycles, golf clubs, tennis rackets, and other athletic products have a sizable market in the Asia Pacific region. High-performance sports equipment is frequently produced in the area using carbon fibre prepregs.

Recent Market Developments

- In September 2022, for the industrial, aerospace, automotive, and race car applications, Solvay introduced LTM 350, a carbon fibre epoxy prepreg tooling material that is intended to give considerable time and cost benefits.

List of Key Companies

- SGL Carbon

- Solvay

- Hexcel Corporation

- Axiom Materials

- Park Electrochemical Corporation

- Teijin Limited

- Airtech Advanced Materials Group

- Toray Industries

- Mitsubishi Rayon Co. Ltd.

- TCR Composites

Market Segment

This study forecasts revenue at global, regional, and country levels from 2019 to 2032. Spherical Insights has segmented the global Carbon Fiber Prepreg Market based on the below-mentioned segments:

Carbon Fiber Prepreg Market, Resin Type Analysis

- Epoxy

- Phenolic

- Thermoplastic

- Bismaleimide (BMI)

- Polyimide

- Others

Carbon Fiber Prepreg Market, End Use Analysis

- Aerospace & Defense

- Wind Energy Sports & Recreation

- Automotive

- Others

Carbon Fiber Prepreg Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

Frequently Asked Questions (FAQ)

-

1. What is the market size of Carbon Fiber Prepreg Market?The global Carbon Fiber Prepreg Market is expected to grow from USD 8.1 Billion in 2022 to USD 17.5 Billion by 2032, at a CAGR of 11.2% during the forecast period 2022-2032.

-

2. Who are the key market players of Carbon Fiber Prepreg Market?Some of the key market players of SGL Carbon, Solvay, Hexcel Corporation, Axiom Materials, Park Electrochemical Corporation, Teijin Limited, Airtech Advanced Materials Group, Toray Industries, Mitsubishi Rayon Co. Ltd., TCR Composites.

-

3. Which segment hold the largest market share?Epoxy resin segment holds the largest market share is going to continue its dominance.

-

4. Which region is dominating the Carbon Fiber Prepreg Market?Europe is dominating the Carbon Fiber Prepreg Market with the highest market share.

Need help to buy this report?