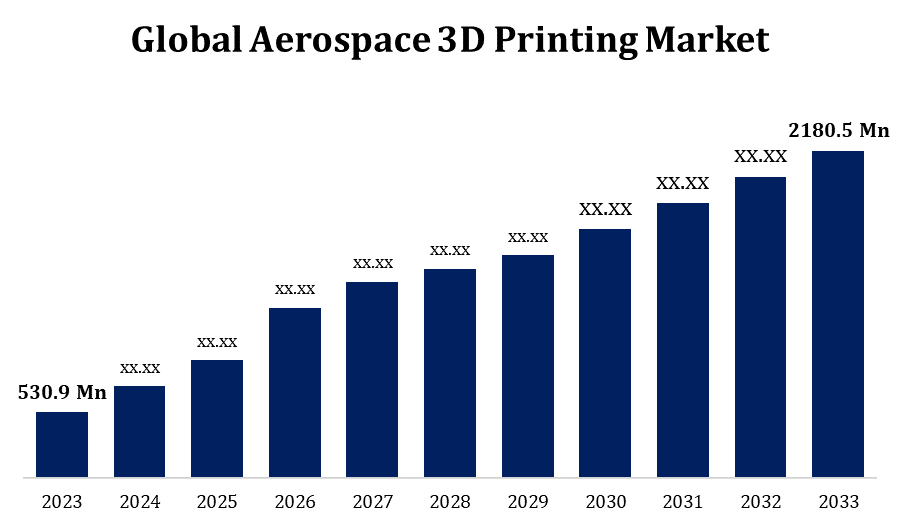

Global Aerospace 3D Printing Market Size To Worth USD 2180.5 Million By 2033 | CAGR of 15.17%

Category: Aerospace & DefenseGlobal Aerospace 3D Printing Market Size To Worth USD 2180.5 Million By 2033

According to a research report published by Spherical Insights & Consulting, the Global Aerospace 3D Printing Market Size to Grow from USD 530.9 Million in 2023 to USD 2180.5 Million by 2033, at a Compound Annual Growth Rate (CAGR) of 15.17% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 110 Market data tables and figures & charts from the report on the "Global Aerospace 3D Printing Market Size By Technology (FDM, SLS, SLA, PBF, Others), By Platform (Commercial Aircraft, Military Aircraft, UAV, Spacecraft, Printers, Materials), By Application (Structural Components, Engine, Spacecraft Components), By Region, And Segment Forecasts, By Geographic Scope And Forecast to 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/aerospace-3d-printing-market

Aerospace manufacturers employ 3D printing to quickly develop and iterate designs. This technology allows for the fabrication of complicated, bespoke components with shorter lead times than with typical production processes. The ability of 3D printing to create lightweight, structurally optimised parts helps reduce the weight of aircraft. This is necessary for reducing running costs and increasing fuel efficiency. Additive manufacturing makes it possible to fabricate intricate geometries that would be challenging or impossible to accomplish with traditional techniques. This capacity improves the efficiency and performance of aerospace components.

Aerospace 3D Printing Market Value Chain Analysis

Suppliers of 3D printing materials play a crucial role in the aerospace 3D printing value chain. These materials may include specialised metals, plastics, and composites developed to meet the exacting requirements and high performance requirements of the aircraft industry. Businesses that specialise in manufacturing 3D printing equipment, such as printers and powder bed fusion machines, are essential to the value chain. These manufacturers supply the hardware required by aircraft companies to initiate additive manufacturing. Software developers create the design and simulation tools that aeronautical engineers need to manufacture parts that are suitable for 3D printing. These consist of CAD (Computer-Aided Design) software, simulation tools, and workflow management systems. Software developers create the design and simulation tools that aeronautical engineers need to manufacture parts that are suitable for 3D printing. Ensuring the quality and certification of 3D-printed aeronautical parts is an essential element. Standards are established, inspections are carried out, and certification bodies, along with regulatory agencies and quality control specialists, certify that 3D-printed products meet safety and performance requirements. After printing, post-processing and finishing are often required to meet specific aerospace standards. Distribution and logistics play a key role in ensuring that 3D-printed parts reach aircraft manufacturers in a timely and efficient manner.

Aerospace 3D Printing Market Opportunity Analysis

The aerospace industry is using additive manufacturing technologies more and more to create complex parts. There is a chance to meet the growing demand for 3D-printed parts in the aviation and aerospace sectors. The demand for lightweight components that increase overall performance and fuel efficiency presents opportunities for 3D printing. Manufacturers have an opportunity because of the need for lightweight, structurally optimised parts in aviation applications. Manufacturers of aerospace products search for solutions to optimise their supply chains through additive manufacturing. Companies can offer goods and services that facilitate reduced inventory, optimised transportation, and production on demand.

Launching lighter satellites requires less fuel because they are lighter. Launch costs are often determined by the weight of the payload. By reducing their satellites' weight, aerospace companies can reduce their launch costs. Lighter satellites enable launch vehicles to carry greater payloads. This allows space agencies and satellite operators to launch multiple satellites on a single mission, maximising the use of the rocket's available space. 3D printing facilitates the use of advanced lightweight materials like composites and high-strength polymers. Manufacturers of aircraft components can use these materials to make structurally optimised pieces that lighten the spacecraft overall.

While 3D printing-compatible materials have come a long way, it is still challenging to develop materials that meet the specific requirements of aviation applications. Materials that are incredibly durable, robust, and resistant to change are needed. Investing in 3D printing machinery can be expensive up front, especially in the case of additive production of metal. This is a challenge for certain aircraft companies, particularly the smaller ones, looking to adopt 3D printing technologies. Lack of established protocols and rules for 3D printing in the aerospace sector may lead to variations in quality and consistency.

Insights by Technpology

The SLS segment accounted for the largest market share over the forecast period 2023 to 2033. SLS is well known for its ability to produce complex, highly accurate, and finely geometrized parts. In the aerospace industry, where complicated designs are common, SLS's precision is beneficial. Support structures are not needed for SLS printing because the object's surrounding unsintered powder acts as a natural support. This makes it possible to create complex, hanging structures and does away with the requirement for additional support material and post-processing steps. In aircraft applications, lightweight components are often prioritised to improve overall performance and fuel efficiency.

Insights by Platform

The commercial aircraft segment accounted for the largest market share over the forecast period 2023 to 2033. 3D printing can be used to create lightweight components with optimum shape. In the commercial aviation sector, lowering component weight is crucial to increasing fuel efficiency, lowering operating costs, and abiding by stringent environmental regulations. The overall fuel efficiency of an airliner is increased when parts are manufactured via 3D printing. The ability to create intricate designs, lightweight structures, and improved aerodynamics all help to reduce emissions and fuel usage. Thanks to 3D printing, intricate and sophisticated designs that would be challenging or impossible to produce using conventional manufacturing techniques can now be produced.

Insights by Application

The engine segment accounted for the largest market share over the forecast period 2023 to 2033. Due to 3D printing, intricate and lightweight structures that would be challenging to manufacture using traditional methods may now be produced. The engine segment's internal component and turbine blade designs must be optimised with these features. Metal additive manufacturing, a kind of 3D printing, is widely used in the engine sector to produce high-performance parts. Superalloys and titanium are used to make components that have the required strength, durability, and heat resistance. Thanks to 3D printing, intricate internal cooling channels may be created for engine parts.

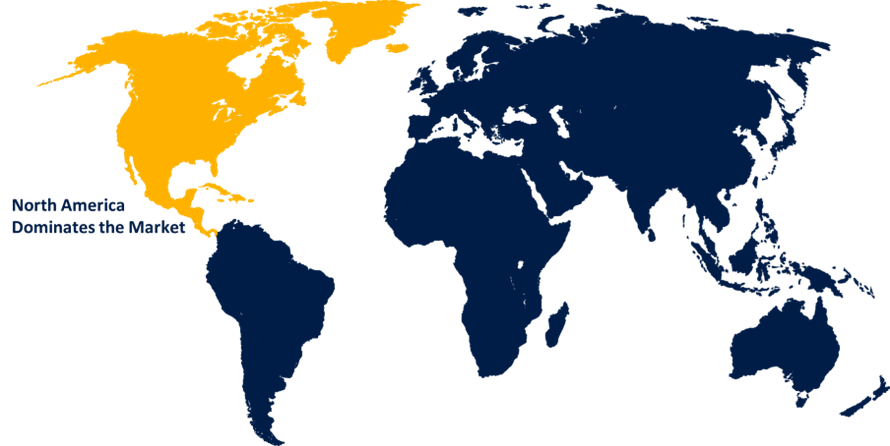

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Aerospace 3D Printing Market from 2023 to 2033. North America is home to several aerospace hubs, such as Seattle, Southern California, and the Space Coast region of Florida. These facilities act as hubs for manufacturing, research, and development operations pertaining to aerospace 3D printing. Commercial aviation companies in North America have started utilising 3D printed parts in their aircraft. This includes producing structural, lightweight, and even essential pieces like engine parts. The defence sector in North America has embraced 3D printing as a way to manufacture parts for military aircraft, unmanned aerial vehicles (UAVs), and space exploration.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. The Asia-Pacific region has seen tremendous growth in the aircraft industry. Several countries, including as China, Japan, and India, have made large expenditures in R&D, aircraft manufacturing, and 3D printing technology adoption. Regional 3D printing businesses with a focus on aerospace applications have emerged in the Asia-Pacific region. These companies provide services and solutions for the production of 3D-printed aircraft parts. The commercial aviation sector in the Asia-Pacific area is growing rapidly, which has raised demand for advanced manufacturing technologies.

Recent Market Developments

- In November 2020, NASA unveiled the first two three-dimensional printed rocket engine parts: a copper alloy combustion chamber and a high-strength alloy nozzle.

Major players in the market

- 3D Systems Corporation

- ARCAM AB

- Aerojet Rocketdyne Holdings Inc

- EnvisionTEC GmbH

- EOS GmbH

- ExOne Co.

- GE Aviation

- Hoganas AB

- Materialise NV

- Moog Inc.

- MTU AERO ENGINE

- Norsk Titanium

- Oerlikon Group

- Renishaw plc

- Stratasys Ltd.

- The Trumpf Group

- Ultimaker BV

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Aerospace 3D Printing Market, Technology Analysis

- FDM

- SLS

- SLA

- PBF

- Others

Aerospace 3D Printing Market, Platform Analysis

- Commercial Aircraft

- Military Aircraft

- UAV

- Spacecraft

- Printers

- Materials

Aerospace 3D Printing Market, Application Analysis

- Structural Components

- Engine

- Spacecraft Components

Aerospace 3D Printing Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?