Orbital Forging Press Market Summary, Size & Emerging Trends

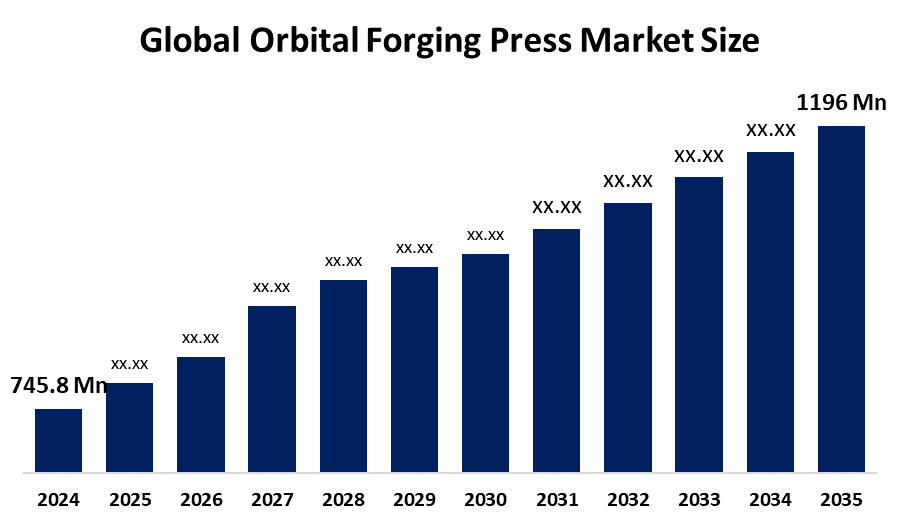

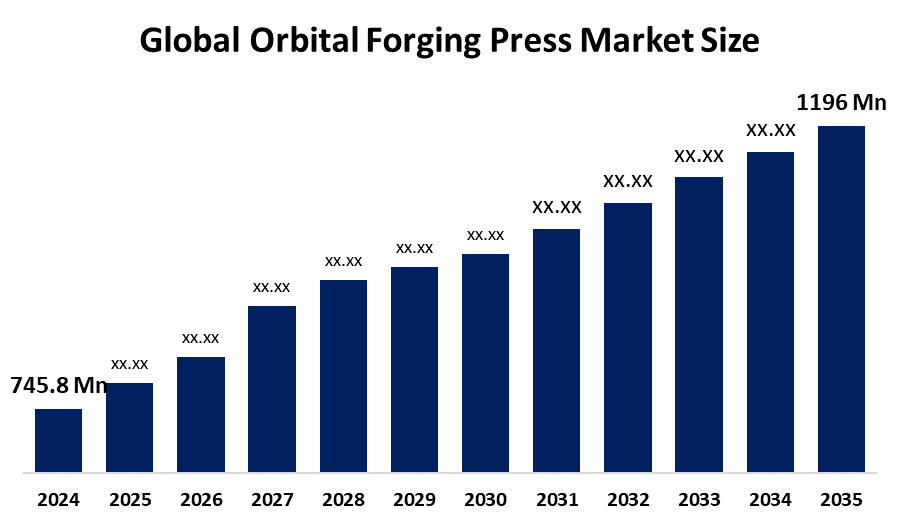

According to Decision Advisor, The Global Orbital Forging Press Market Size is Expected To Grow from USD 745.8 Million in 2024 to USD 1196 Million by 2035, at a CAGR of 4.39% during the forecast period 2025-2035. The increasing demand for precision metal forming in automotive, aerospace, and industrial applications is a key driving factor for the orbital forging press market.

Key Market Insights

- Asia Pacific is expected to account for the largest share in the orbital forging press market size during the forecast period.

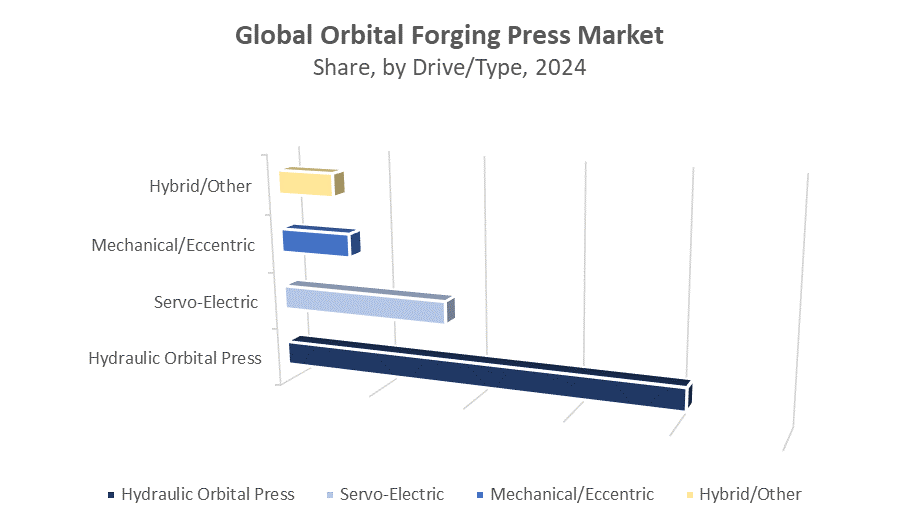

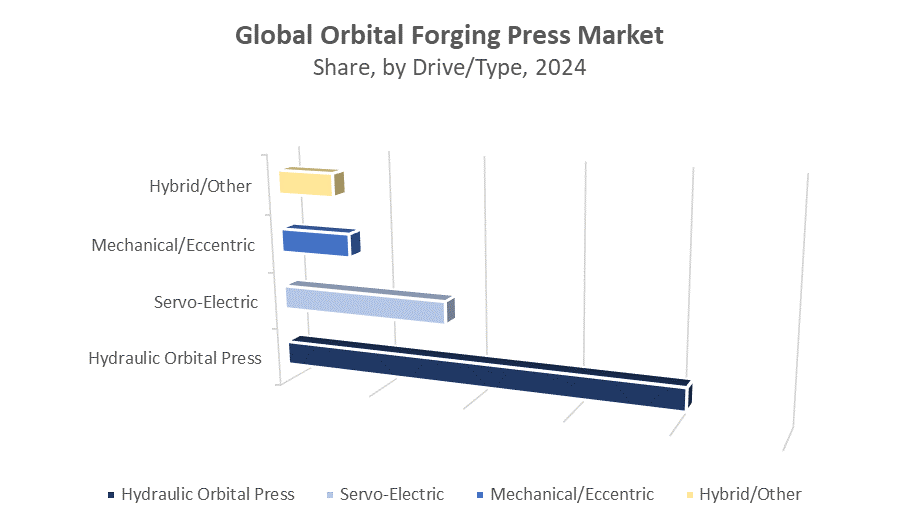

- In terms of drive/type, the hydraulic orbital press segment dominated in terms of revenue during the forecast period.

- In terms of workpiece, the bearings/races segment accounted for the largest revenue share in the global orbital forging press market during the forecast period.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 745.8 Million

- 2035 Projected Market Size: USD 1196 Million

- CAGR (2025-2035): 4.39%

- Asia Pacific: Largest market in 2024

- North America: Fastest growing market

Orbital Forging Press Market

The Orbital Forging Press Market Size centers on high-precision metal forming presses essential in automotive, aerospace, and industrial manufacturing. These presses enable uniform material flow, reduce defects, and improve the strength and durability of forged components. Hydraulic and servo-electric systems dominate due to their precision and energy efficiency, while mechanical/eccentric and hybrid presses serve specialized industrial applications. Governments globally support the market through initiatives promoting advanced manufacturing technologies, offering subsidies, and funding research to enhance production efficiency and sustainability. Ongoing demand for precision-engineered components fuels market growth, positioning orbital forging presses as a critical tool in modern manufacturing and engineering sectors.

Orbital Forging Press Market Trends

- Growing adoption of automation and smart manufacturing for improved precision and efficiency.

- Advances in press technology enhancing durability, control, and energy efficiency.

- Companies are merging and partnering to expand their product range and strengthen their global presence.

Orbital Forging Press Market Dynamics

Driving Factors: Rising demand from automotive, aerospace, and industrial machinery sectors

The Global Orbital Forging Press Market Size is primarily driven by the increasing demand for precision-engineered components across several high-growth industries. The automotive sector, for instance, requires robust and highly precise metal components such as gears, bearings, and transmission parts, which can only be reliably produced using advanced orbital forging presses. Similarly, the aerospace industry relies on these presses for producing high-strength, lightweight components like aero rings and flanges, where precision and material integrity are critical. In addition to these industries, industrial machinery manufacturers are adopting orbital forging presses to enhance productivity, improve component durability, and meet stringent quality standards. Government initiatives that support the modernization of manufacturing technologies, including subsidies for advanced machinery and research grants, further accelerate market growth. Moreover, continuous technological advancements in press design, automation, and process control improve efficiency and product quality, making orbital forging presses more attractive to industrial applications globally.

Restrain Factors: High capital investment and skilled labor requirements may limit growth

Despite strong demand, the orbital forging press market size faces significant restraints, primarily due to the high capital investment required to acquire state-of-the-art equipment. High-end hydraulic, servo-electric, or hybrid presses can cost millions of dollars, making it challenging for small and medium-sized enterprises to invest. Additionally, operating these presses requires a skilled workforce proficient in both mechanical operations and advanced automation systems, creating a bottleneck in regions where specialized labor is limited. Competition from alternative metal-forming methods, such as forging hammers or conventional mechanical presses, also restrains market expansion, particularly in cost-sensitive segments.

Opportunity: Technological innovations enable more efficient and precise forging methods

The Orbital Forging Press Market Size offers numerous growth opportunities, largely fueled by technological innovations and emerging market expansion. Advances in automation, servo-electric control systems, and smart manufacturing integration allow presses to operate with higher precision, lower energy consumption, and improved material utilization. These technological enhancements make orbital forging presses suitable for advanced applications in aerospace, automotive, and industrial machinery, particularly in high-value components where accuracy and repeatability are critical. Emerging economies, with their growing industrialization and focus on modern manufacturing, present lucrative opportunities for manufacturers to expand their footprint. Additionally, strategic partnerships, joint ventures, and collaborations enable companies to diversify their product offerings, enter new regional markets, and strengthen their competitive position.

Challenges: Supply chain disruptions and regulatory pressures

The Market Size faces several challenges that could impact growth despite favorable demand trends. Fluctuations in raw material availability, such as high-grade steel or alloy components, can disrupt production schedules and increase costs. Geopolitical tensions and trade restrictions further exacerbate supply chain vulnerabilities, particularly for manufacturers relying on imported materials or parts. Additionally, stringent environmental regulations across developed regions impose compliance costs for energy-intensive operations, waste management, and emissions control.

Global Orbital Forging Press Market Ecosystem Analysis

The global orbital forging press market ecosystem includes key players such as raw material suppliers, press manufacturers, and end-users in automotive, aerospace, and industrial machinery sectors. Suppliers, especially in Asia, influence availability and costs. Manufacturers focus on developing energy-efficient and precise presses. Regulatory bodies enforce safety and environmental rules encouraging sustainable practices. This ecosystem’s growth depends on balancing supply, technological innovation, and compliance with regulations, driving advancements and market expansion worldwide.

Global Orbital Forging Press Market, By Drive/Type

The hydraulic orbital press segment dominated the global market in terms of revenue during the forecast period. This dominance is attributed to its superior force control, precision, and versatility in handling a wide range of materials and component sizes. Hydraulic presses are particularly favored in industries such as automotive, aerospace, and heavy machinery, where high-strength components and consistent dimensional accuracy are critical. Their ability to maintain uniform pressure throughout the forging process ensures enhanced product quality and reduced material wastage.

The servo-electric segment is experiencing rapid growth due to increasing demand for energy-efficient, environmentally friendly, and highly precise forging solutions. These presses leverage electric servo drives to offer precise control over stroke, speed, and force, making them ideal for applications requiring intricate component geometry and tight tolerances. The lower energy consumption and reduced maintenance costs compared to traditional hydraulic presses further enhance their appeal. By 2024, the servo-electric orbital press segment held a market share of roughly 30%, driven by adoption in advanced manufacturing environments such as aerospace component production, automotive lightweight parts, and precision industrial machinery.

Global Orbital Forging Press Market, By Workpiece

The bearings and races segment held the largest revenue share in the global orbital forging press market during the forecast period. This is primarily driven by strong demand from the automotive and industrial machinery sectors, where high-precision bearings are critical for smooth operation and durability. Orbital forging presses provide the necessary accuracy and consistent material density to produce high-quality bearings and races, ensuring long service life and reliability under high-stress conditions. In 2024, this segment accounted for approximately 40% of the total market revenue, reflecting its widespread adoption in manufacturing powertrain components, heavy machinery, and precision industrial equipment. The continued expansion of the automotive and industrial sectors globally is expected to sustain growth in this segment.

The gears and transmission segment represents another key application area for orbital forging presses, driven by the growing demand for drivetrain components in automotive, aerospace, and industrial machinery industries. These presses enable precise forging of gears, ensuring optimal hardness, uniformity, and dimensional accuracy, which are essential for efficient power transmission and long-term performance. By 2024, the gears and transmission segment accounted for around 25% of the global market revenue, reflecting steady demand from both OEMs and aftermarket suppliers. Increasing vehicle production, advancements in drivetrain technology, and the adoption of automated manufacturing processes are expected to further support growth in this segment over the forecast period.

Asia Pacific holds the largest share of the global orbital forging press market, primarily driven by rapid industrial growth in countries like China and India. The region’s booming automotive and aerospace sectors are significant contributors, with manufacturers increasingly investing in high-precision forging equipment to meet growing domestic and export demands. Additionally, infrastructure development, expanding heavy machinery production, and government initiatives supporting advanced manufacturing technologies are fueling market growth. In 2024, Asia Pacific accounted for approximately 45% of the global market revenue, reflecting its dominance in both production capacity and consumption. The availability of skilled labor, cost-effective manufacturing, and the presence of key regional players further reinforce the region’s leadership in the orbital forging press market.

North America is the fastest-growing market for orbital forging presses, driven by increasing demand from the automotive, aerospace, and industrial machinery sectors. The adoption of advanced manufacturing technologies, automation, and energy-efficient presses is accelerating growth in this region. Additionally, the resurgence of domestic manufacturing, reshoring of critical components, and investments in electric vehicle production are contributing to strong market expansion. By 2024, North America accounted for around 20% of the global market revenue, and its growth trajectory is expected to remain robust due to continued technological advancements and supportive government policies.

Europe represents an established orbital forging press market, characterized by advanced manufacturing adoption and a focus on precision engineering. The region’s mature automotive, aerospace, and industrial machinery industries demand high-quality, reliable forged components, supporting steady market revenue. Countries like Germany, France, and Italy are leading in terms of technological integration, including automated presses and energy-efficient systems. In 2024, Europe accounted for approximately 25% of the global market revenue, reflecting a stable and mature market where innovation, compliance with environmental regulations, and adoption of Industry 4.0 practices are key growth enablers.

WORLDWIDE TOP KEY PLAYERS IN THE ORBITAL FORGING PRESS MARKET INCLUDE

- Schuler Group

- SMS Group GmbH

- Aida Engineering, Ltd.

- Fagor Arrasate S. Coop.

- Nidec Minster

- JIER Heavy Industry Co., Ltd.

- Henschel GmbH

- Others

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Decision Advisor has segmented the orbital forging press market based on the below-mentioned segments:

Global Orbital Forging Press Market, By Drive/Type

- Hydraulic Orbital Press

- Servo-Electric

- Mechanical/Eccentric

- Hybrid/Other

Global Orbital Forging Press Market, By Workpiece

- Bearings/Races

- Gears/Transmission

- Aero Rings/Flanges

- Pipes/Fittings & Other

Global Orbital Forging Press Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

FAQs

Q: Which industries are the major end-users of orbital forging presses?

A: The main end-use industries include automotive, aerospace, and industrial machinery manufacturing, where high precision and durability of components are critical.

Q: Which segment is expected to grow the fastest over the next 10 years?

A: The servo-electric segment is expected to register the fastest growth due to increasing demand for energy-efficient and environmentally friendly forging solutions.

Q: What are the major trends shaping the orbital forging press market?

A: Key trends include automation and smart manufacturing integration, technological advances for higher precision, and strategic mergers and partnerships to expand global reach.

Q: How do Asia–Pacific and North America compare in terms of market growth?

A: Asia–Pacific currently holds the largest market share, while North America shows the highest growth rate due to technological upgrades and investments in electric vehicle and aerospace manufacturing.

Q: What regulations or standards impact the orbital forging press market?

A: Regional and international standards related to safety, emissions, and energy efficiency in manufacturing—particularly those in Europe and North America—impact production and equipment design.

Q: What are the top investment opportunities in the Global Orbital Forging Press Market?

A: Investments in servo-electric and hybrid press technologies, automation systems, and smart manufacturing solutions represent attractive growth opportunities.

Q: What is the long-term outlook (2025–2035) for the orbital forging press market?

A: The market is expected to maintain steady growth, driven by ongoing industrial expansion, modernization of manufacturing processes, and sustained demand for precision-forged components worldwide.