Laser Processing Market Summary

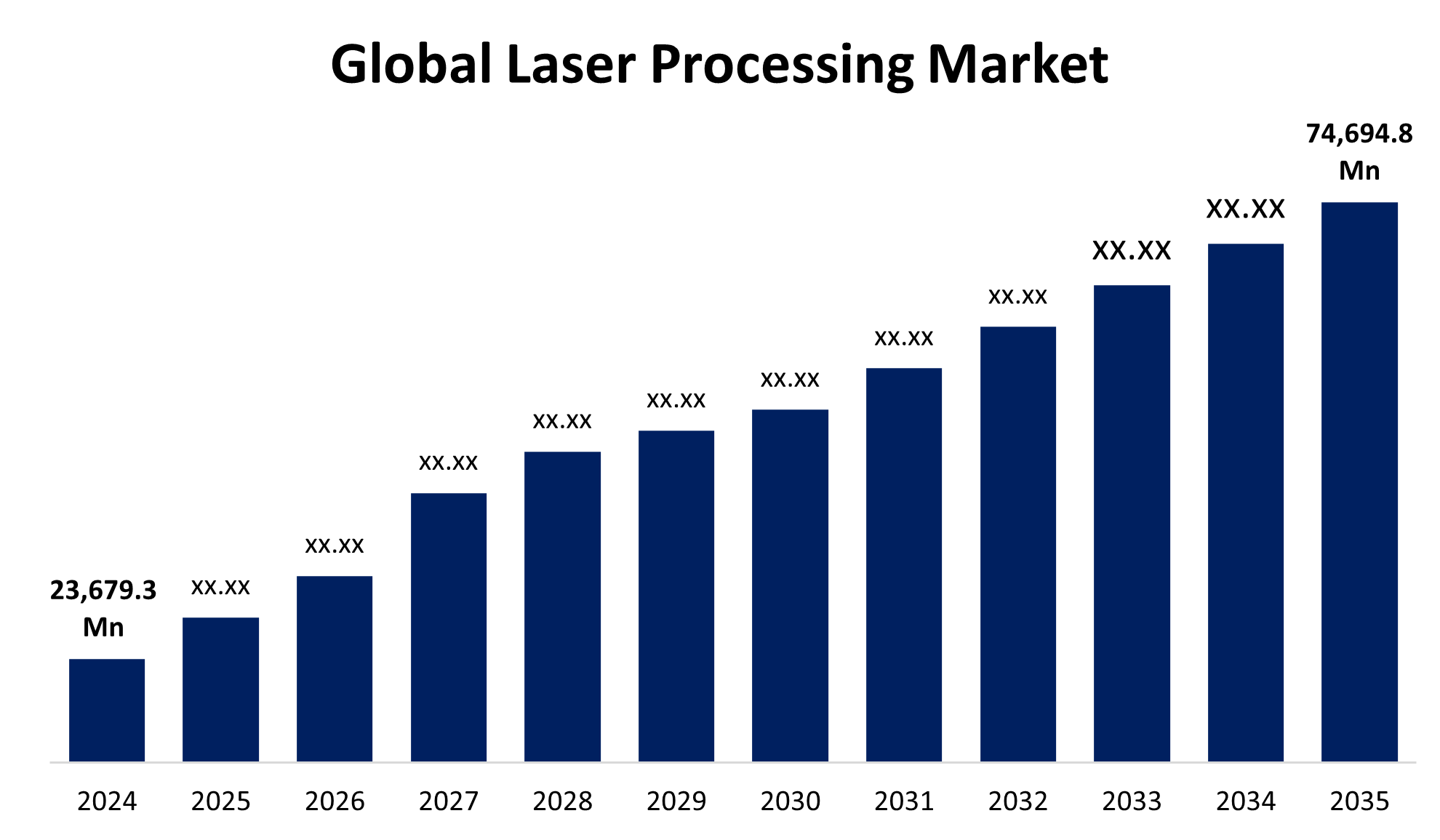

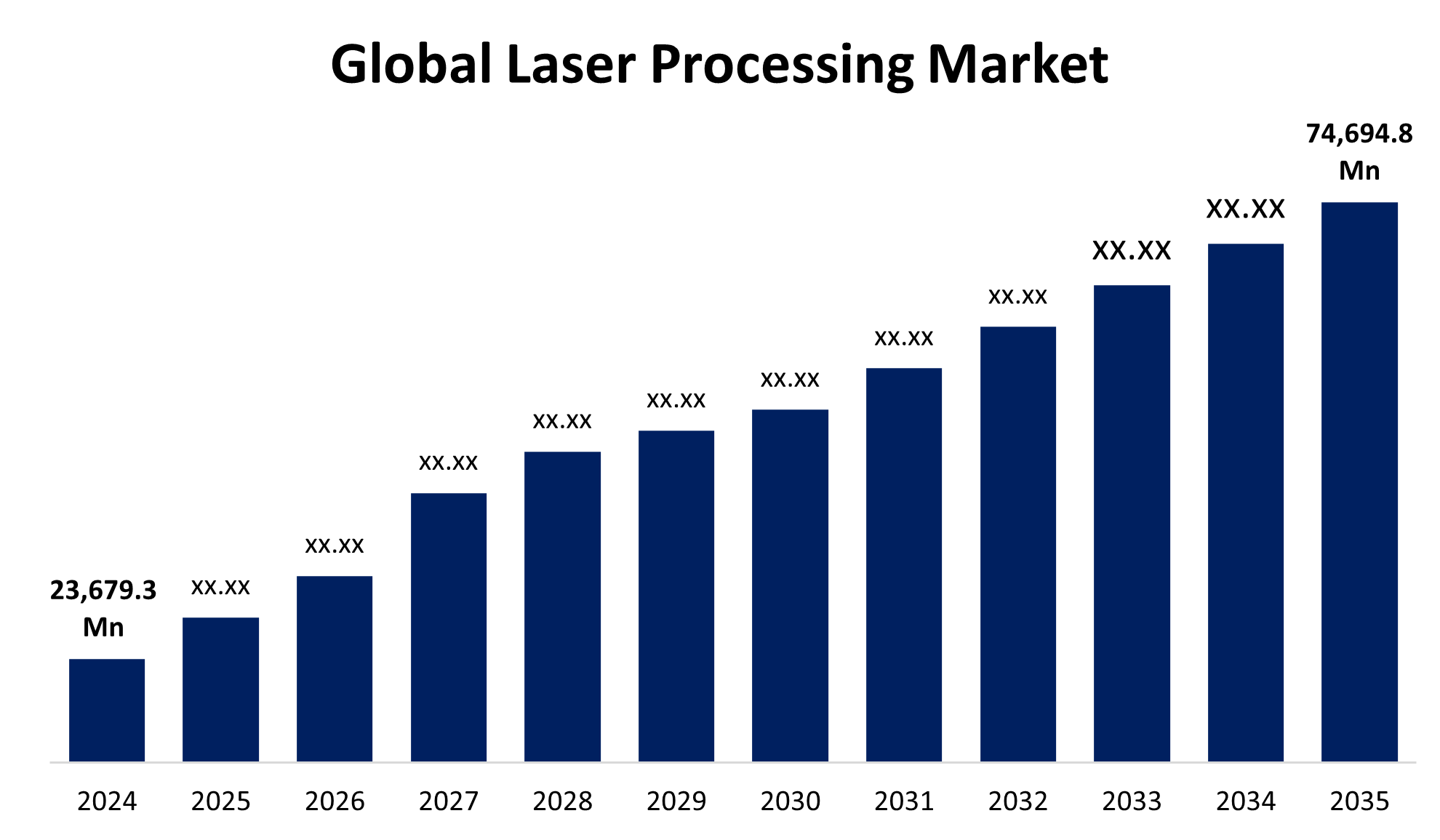

The Global Laser Processing Market Size Was Estimated at USD 23,679.3 Million in 2024 and is projected to reach USD 74,694.8 Million by 2035, Growing at a CAGR of 11.01% from 2025 to 2035. The benefits that laser technology provides over conventional techniques across a range of industries are the main drivers of the market's notable expansion in laser processing. The market is also growing as a result of improvements in laser technology, the integration of AI and automation, and the rising need for high-quality final products.

Key Regional and Segment-Wise Insights

- The market that generated the largest revenue in 2024 was Asia Pacific by region.

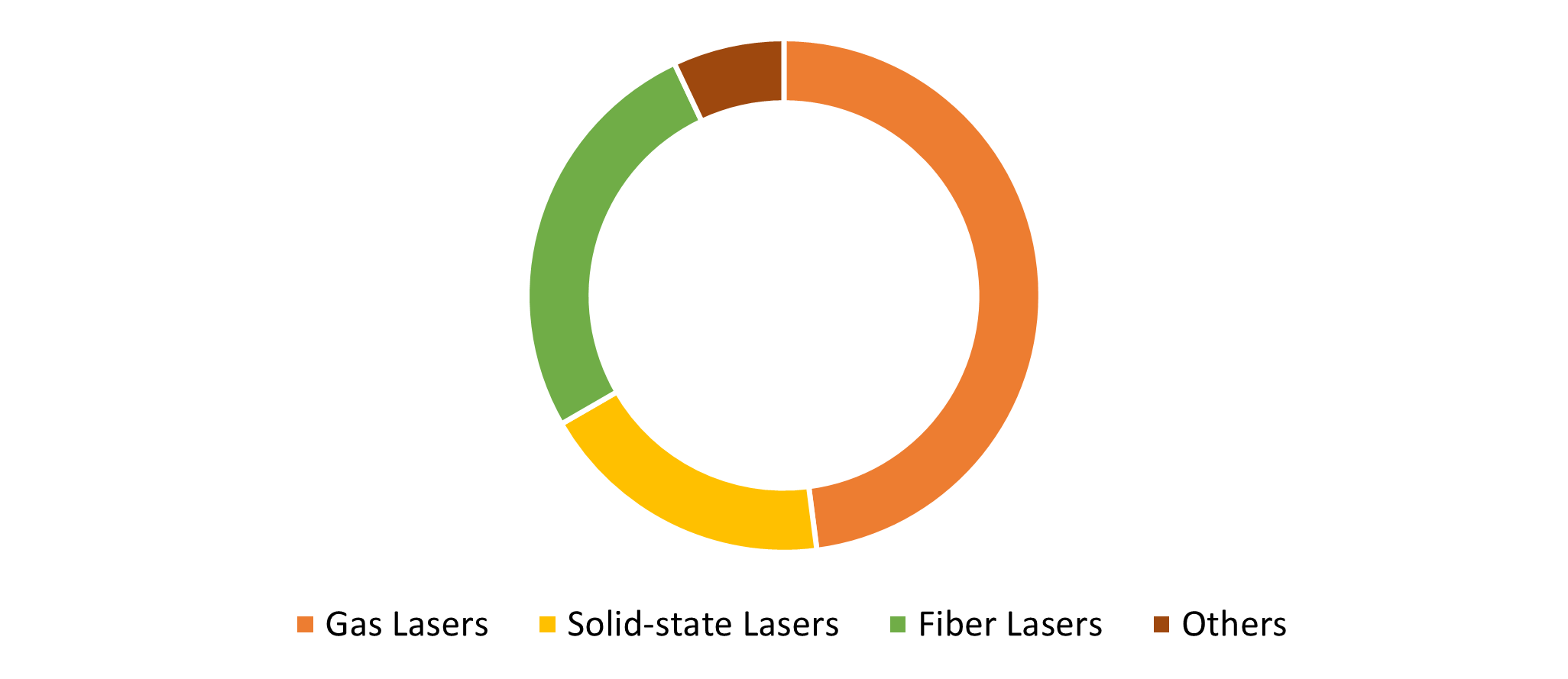

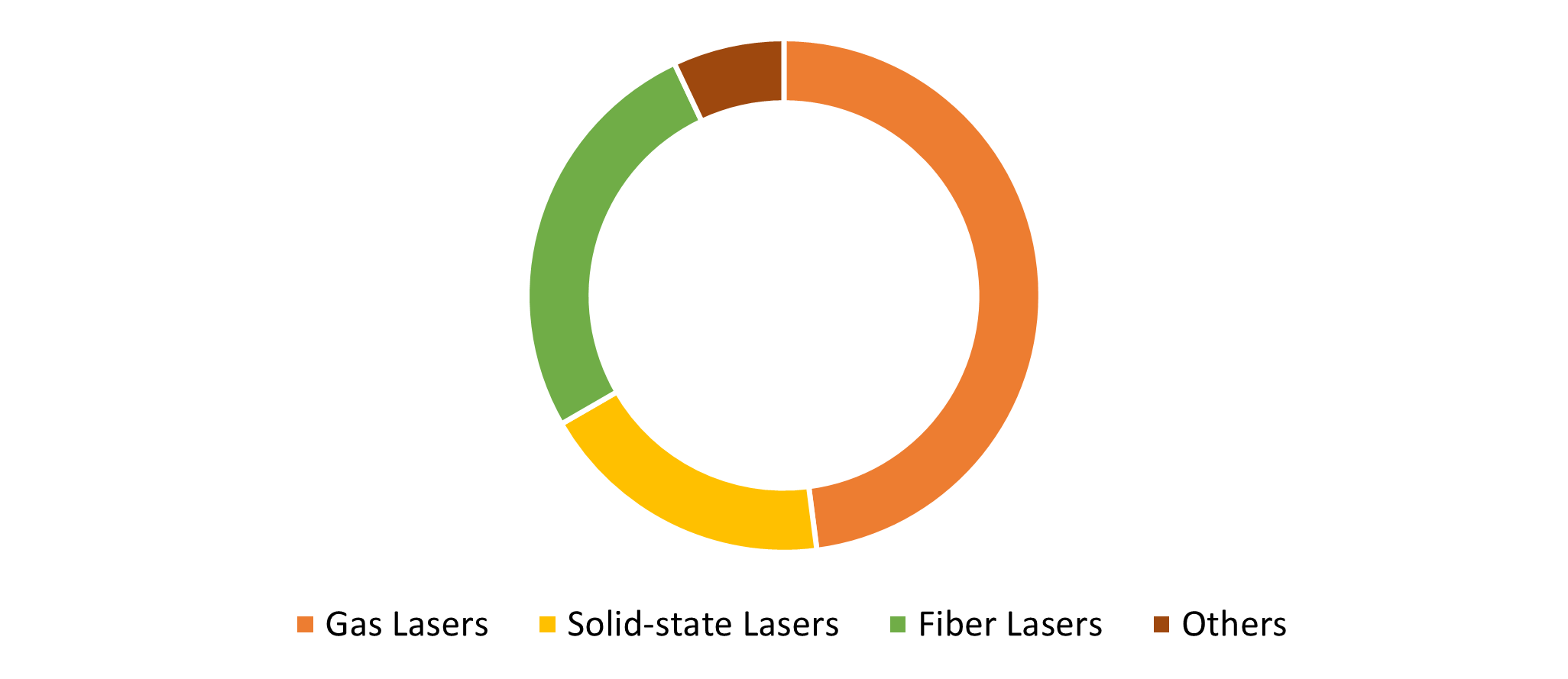

- According to the product segment, gas lasers lead the market by holding a revenue share of 63% in 2024.

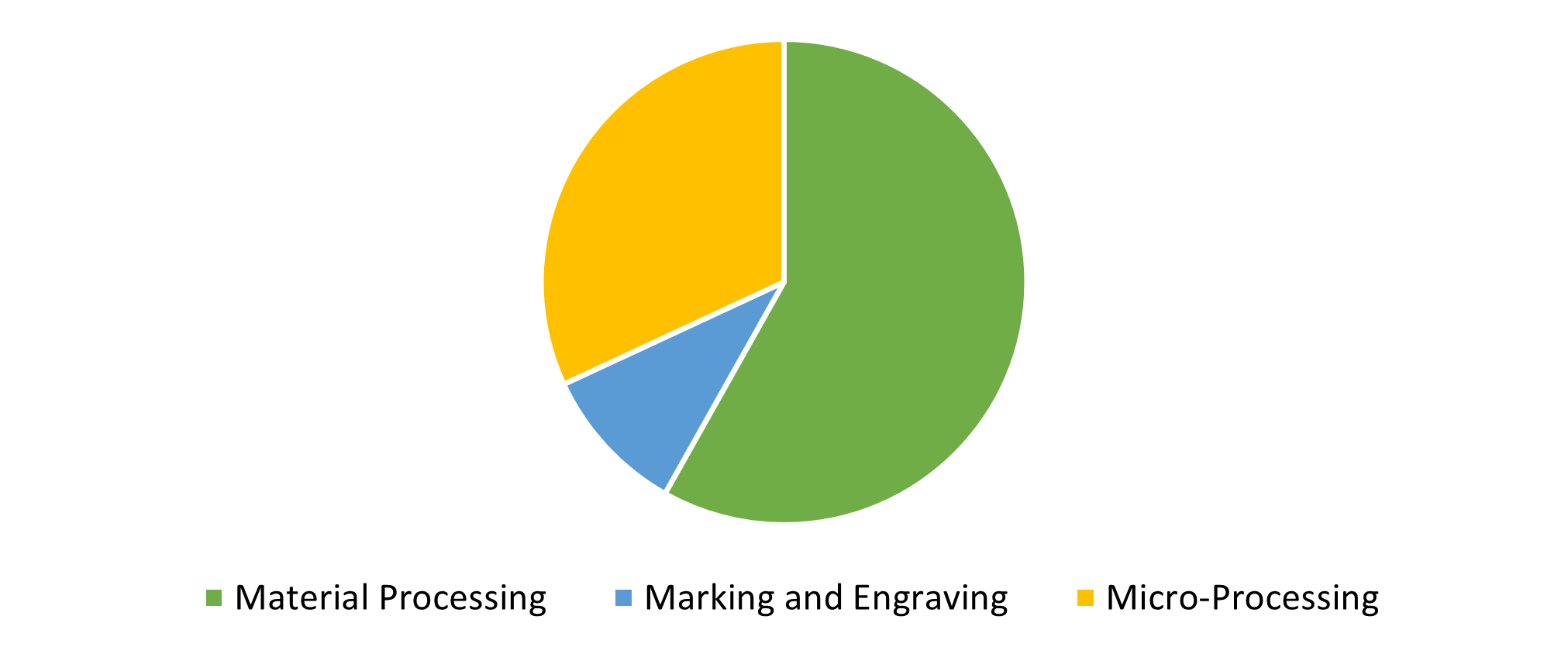

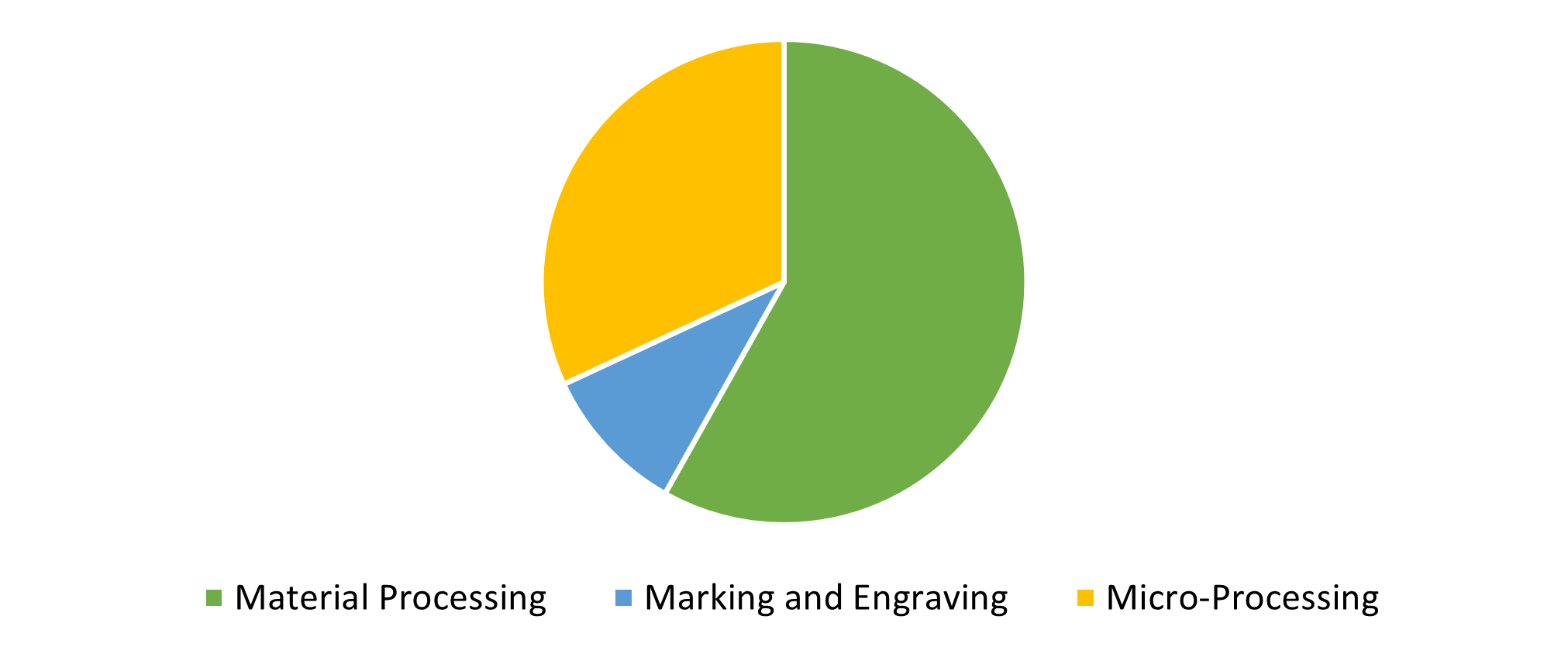

- In the process category material processing sector captured the largest market revenue in 2024.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 23,679.3 Million

- 2035 Projected Market Size: USD 74,694.8 Million

- CAGR (2025-2035): 11.01%

- Asia Pacific: Largest market in 2024

The laser processing market is the sector that includes the use of lasers to alter materials and perform manufacturing processes. It includes all of the microprocessing technologies that have been used in the automotive, electronics, and healthcare industries, such as laser cutting, welding, labelling, engraving, etc. The demand for lasers is driven by the accuracy, speed, and efficiency that an ordinary laser processing method can provide as a replacement for traditional methods. The worldwide laser processing market is expected to grow from a relatively small size compared to other new technologies because of the numerous benefits of laser processing as a material processing technology. Laser processing is a permanent, faster, more precise method of branding and engraving, and provides great efficiency, excellent beam quality, and dependability. The market is also being examined because product shrinking, such as microelectronic devices, has become a sales trend.

The electronics sector is a major driver of the market, especially in applications working with precision cutting, engraving, and marking. The precision and ability to incorporate complexity with laser technology align with the increased demand for smaller electrical components. This is especially relevant in microchips, wearable technology, and smartphones, where laser processes enhance the reliability and efficiency of the product. It is anticipated that the use of laser processing in the electronics industry would increase as producers aim to create more intricate and small items. Laser processing technology is being applied in the manufacture of surgical tools, implantable devices, and pacemakers, to name a few medical devices, as well. Moreover, advancements in technology have enhanced laser processing's edge cut quality and cut speed. The market is also expected to grow due to increased use of precise laser drilling processes in the exploration and extraction of oil and gas, which reduces the costs of drilling and increases the potential viability of nonviable oil resources around the world.

Product Insights

The gas lasers segment accounted for over 63% of the global sales share in 2024, making it the dominant segment of the laser market. The gas segment has several advantages, including great coherence, a consistent central wavelength, excellent spectral purity, and strong alignment and beam quality. Gas lasers are easily accessible and cost-effective. Helium-neon (HeNe) lasers are expected to gain in popularity throughout the forecast period for their reliability with a variety of applications. The popularity of laser cutting is spreading widely for the processing of metals and alloys since laser cutting allows for quick, precise cuts with minimal waste. Growth in industries such as automotive, aerospace, and construction, which need precision cutting of metals for efficiency and structural integrity, is supporting an increase in the use of stretching laser cutting.

In the forecasted period, the fiber lasers sector will be growing faster. Fiber lasers are also gaining traction in additive manufacturing, an area where they are vital to processes such as laser sintering and selective laser melting (SLM). Fiber lasers can melt powdered metals or polymers due to their high energy density, allowing layer-by-layer precision needed for 3D printing. As a result, they are well-suited to building custom parts for aerospace, automotive, and health care applications due to their ability to accurately build complex parts stable process. As 3D printing increases in popularity, fiber lasers will be even more important to additive manufacturing. This trend will help industries to innovate with lightweight and complex structures while maintaining structural integrity.

Process Insights

In 2024, the material processing sector captured the largest market revenue. Material processing includes surface modification, machining, micro-drilling, the research and application of laser beam welding, and hybrid processes. The market is expected to grow due to its use for direct manufacturing, such as micro deposition, and competitors removing bulk material, such as coating. Lasers provide a clean, non-contact process that preserves the integrity of the material as industries expand and prepare for lightweight metals such as aluminum and titanium to increase fuel efficiency. Lasers are used within aerospace to build very complicated structures of high strength, while in automobiles, they are used to weld and cut key parts, such as frame and engine components. The speed of laser processing provides the control and consistency needed for all these applications.

The microprocessing industry is anticipated to grow at a high rate in the forecasted period. A microprocessor is a single integrated circuit (IC), made up of millions of interdependent small components (resistors, diodes, transistors). This chip is responsible for performing multiple tasks, including timing, data storage, and communication with the peripherals (devices). For the manufacture of microchips, wafers, and circuit boards, the semiconductor industry relies on laser microprocessing, where precision is essential. The semiconductor community will invest more in laser microprocessing technologies in response to the growing demand for faster, smaller, and better processors, especially for AI, 5G, and IoT applications. In addition, the increased demand for smartphones and tablets will drive market growth during the projection period.

Regional Insights

In 2024, the North American laser processing market accounted for a significant revenue share of 28.3%. Laser processing is growing quite rapidly in North America, primarily driven by the automotive and aerospace sectors. The demand for laser-based automation systems is further fueled by the region's emphasis on innovation and smart manufacturing adoption. This region is adopting or utilizing advanced manufacturing technologies more frequently, and laser processing is helping to precisely cut, weld, and engrave high-performance items.

U.S. Laser Processing Market Trends

The U.S. laser processing market is expected to grow at a significant CAGR from 2025-2035. The market in the United States is being driven by the high demand from manufacturers of medical devices, automotive, and aerospace. Innovation in laser processing technologies, such as fiber and diode lasers, is encouraged by the highly established R&D ecosystem in the United States. Due to recent investments in the production of electric vehicles, there is a growing need for laser-based welding and battery component processing in the United States.

Europe Laser Processing Market Trends

During the forecast period, the laser processing market in Europe is expected to grow significantly. The market for laser processing is growing due to the automotive and industrial sectors, where Germany and the UK dominate the industry. Growth in the market can be related to the increased use of lasers in medical devices and procedures. Furthermore, the rapid advancement of nanofabrication is also expected to enable market growth. Lasers are increasingly used for welding and cutting applications with lightweight materials due to the trend of lightweighting in vehicles to address environmental concerns. Additionally, the European Union is encouraging the use of advanced laser technologies in manufacturing in the context of a low-carbon economy.

Asia Pacific Laser Processing Market Trends

In 2024, the laser processing market in the Asia Pacific region is growing at the highest rate. Demand from the semiconductor, automotive, and electronics industries, especially in China, Japan, and South Korea, is facilitating the rapid growth of laser processing in the Asia Pacific. The precision and performance properties of laser technology, which are important for the mass production of micro-components, are beneficial for the production of electronics components in the fast-growing electronics manufacturing industry in the region. There is also growth in laser processing as a result of government initiatives to modernize factories and adopt Industry 4.0 technology. Furthermore, the increasing deployment of laser systems in the region across a range of application areas is anticipated to boost market development. In addition, it is expected that government regulations on permanent and clear markings for consumer goods in selected countries will further drive the uptake of laser processing technologies.

Key Laser Processing Companies:

The following are the leading companies in the laser processing market. These companies collectively hold the largest market share and dictate industry trends.

- Altec GmbH

- Alpha Nov laser

- Bystronic Laser AG

- Eurolaser GmbH

- Amada Co., Ltd.

- Coherent Inc.

- IPG Photonics Corporation

- Newport Corporation (MKS Instruments, Inc.)

- Epilog Laser, Inc.

- Han's Laser Technology Industry Group Co., Ltd.

- LaserStar Technologies Corporation

- Newport Corporation

- Trumpf GmbH + Co. KG

- Universal Laser Systems, Inc.

- Xenetech Global Inc.

- Others

Recent Developments

- In April 2025, AkzoNobel and IPG Photonics formed a partnership to use laser technology to cure powder coatings. The company's Interpon powder coatings are formulated with IPG's laser curing technologies in mind for optimal performance with this new process. This will be a faster and more economical alternative to traditional curing methods. An agreement between the two companies states they will only work with clients in the EMEA (Europe, Middle East, and Africa). The powder coating is selectively heated after being deposited, in a "cold oven" with lasers.

- In January 2024, Coherent Corp., a leader in lasers and thermoelectrics for scientific and life science research, has announced the OBIS 640 XT diode-pumped solid-state (DPSS) laser module, involving super-resolution microscopy (SRM), with an output of up to 1000 mW at 640 nm. New advances being made in SRM that can resolve macromolecular structures and provide critical new insights into cell biology are made possible by advances in visible and ultraviolet lasers. Coherent introduced the OBIS 640 XT red laser module to augment the blue and green laser modules they currently have, which now provides high output power, low noise, good beam quality, and compactness, allowing for high-performance SRM systems.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the laser processing market based on the below-mentioned segments:

Global Laser Processing Market, By Product

- Gas Lasers

- Solid-state Lasers

- Fiber Lasers

- Others

Global Laser Processing Market, By Process

- Material Processing

- Marking and Engraving

- Micro-Processing

Global Laser Processing Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa