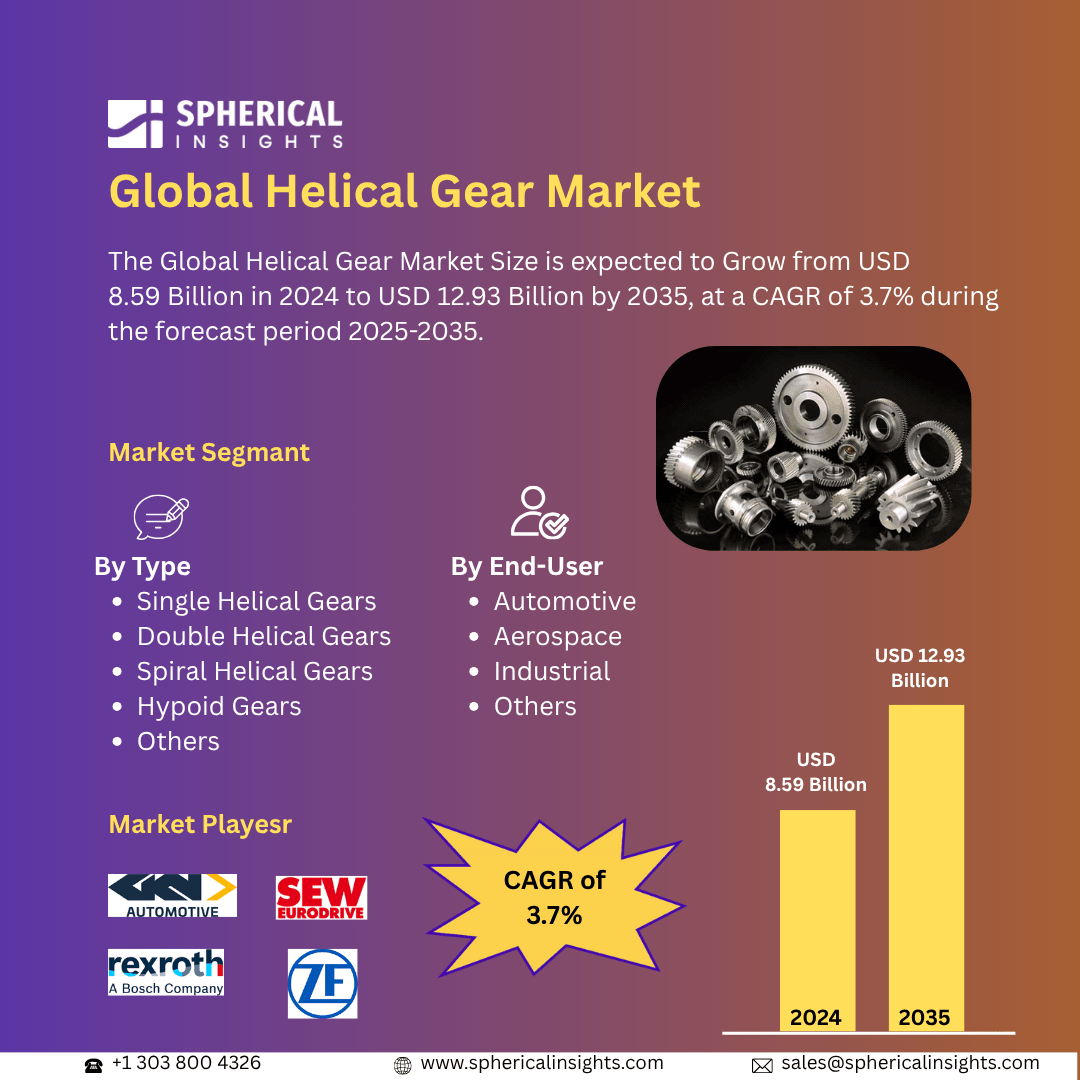

Helical Gear Market Summary, Size & Emerging Trends

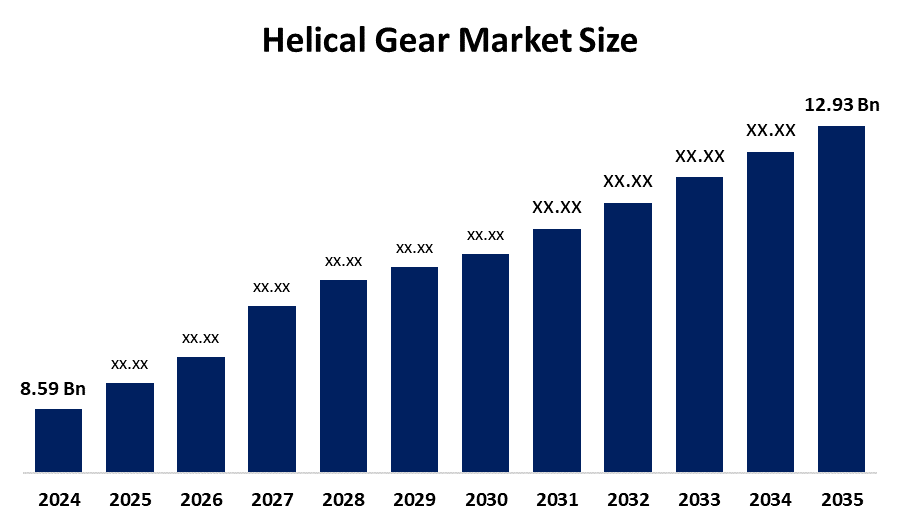

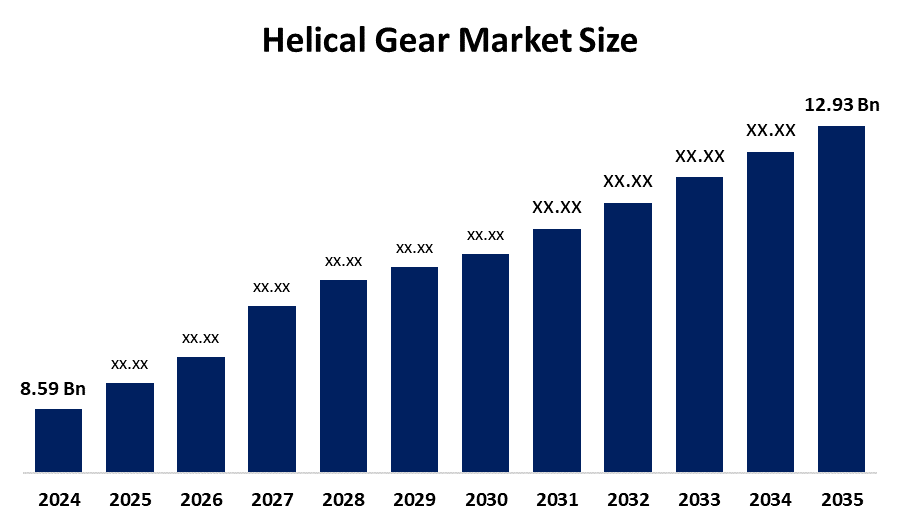

According to Spherical Insights, The Global Helical Gear Market Size is expected to Grow from USD 8.59 Billion in 2024 to USD 12.93 Billion by 2035, at a CAGR of 3.7% during the forecast period 2025-2035. Rising demand for high-efficiency power transmission systems, expanded application in automotive and industrial machines, and a growing desire for quieter, longer-lasting gear solutions.

Key Market Insights

- Asia Pacific is expected to account for the largest share in the helical gear market during the forecast period.

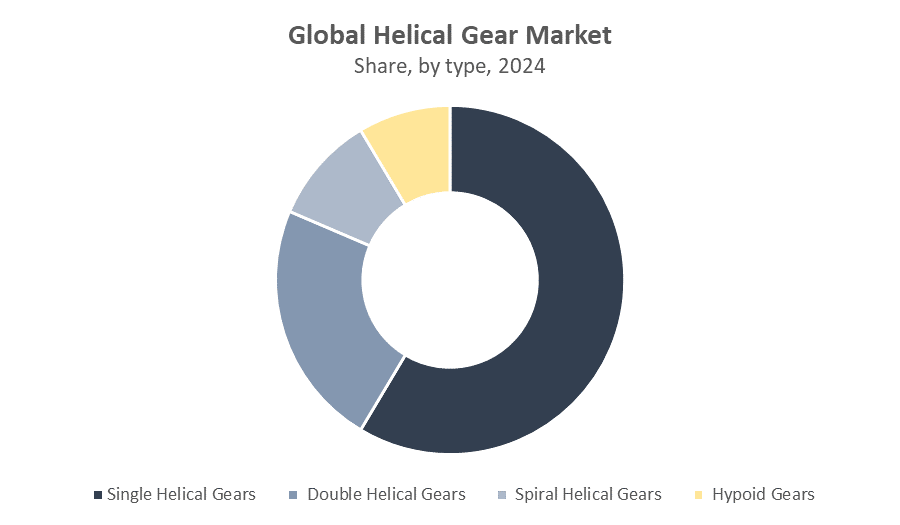

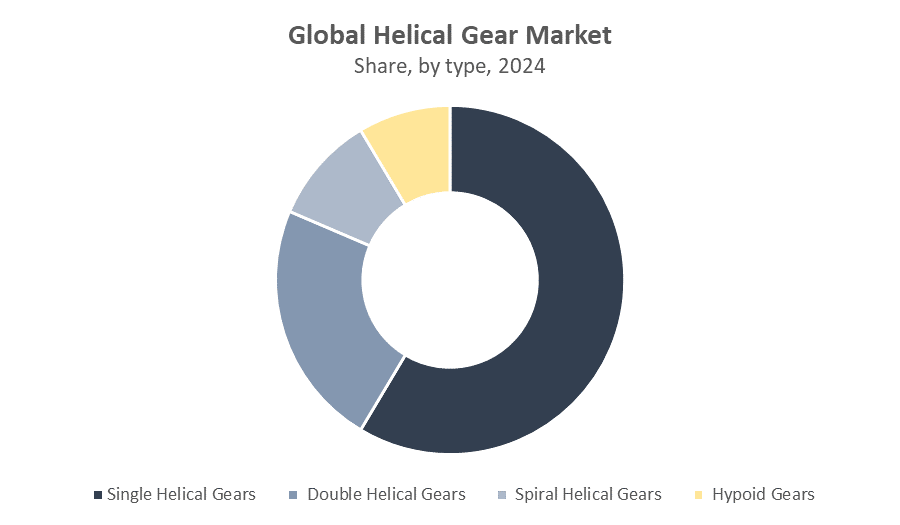

- In terms of type, the single helical gears size segment dominated in terms of revenue during the forecast period

- In terms of end-user, the automotive segment accounted for the largest revenue share in the global helical gear market during the forecast period

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 8.59 Billion

- 2035 Projected Market Size: USD 12.93 Billion

- CAGR (2025-2035): 3.7%

- Asia Pacific: Largest market in 2024

- North America: Fastest growing market

Helical Gear Market

The global helical gear market is experiencing steady growth, fueled by increasing demand for efficient and reliable power transmission systems across automotive, industrial machinery, aerospace, and energy sectors. Helical gears are preferred for their high load-carrying capacity, smooth operation, and ability to handle heavy torque at variable speeds, making them ideal for precision applications. The expansion of manufacturing industries, rising automation, and advancements in gear design and materials are further enhancing market prospects. Additionally, the growing adoption of electric vehicles and renewable energy equipment is creating new opportunities for helical gear manufacturers. With ongoing innovations in production technology and a focus on performance optimization, the market is poised to maintain robust momentum in the coming years.

Helical Gear Market Trends

- Rising adoption of electric and hybrid vehicles is increasing demand for helical gears due to their quiet, efficient, and durable performance.

- Advancements in manufacturing technologies like 3D printing and CNC machining are improving gear precision and efficiency.

- Expanding industrial automation is driving the need for smooth and reliable helical gears in robotics and machinery.

Helical Gear Market Dynamics

Driving Factors: Rising demand for efficient power transmission systems across key industries

The key driving factors for the helical gear market include the rising demand for efficient and high-performance power transmission systems across automotive, industrial, and energy sectors. The growing adoption of electric vehicles and automation technologies is fueling the need for gears that offer smooth operation and high torque capacity. Advancements in materials, precision engineering, and manufacturing methods such as CNC machining are enhancing gear durability and efficiency. Additionally, rapid industrial growth, increased renewable energy projects, and expanding aerospace applications are further contributing to the market’s steady expansion and technological development worldwide.

Restrain Factors: High production costs and design complexity limiting market growth

The helical gear market faces restraints such as high initial manufacturing costs due to precision engineering and advanced materials required for production. The complexity of design and maintenance also increases overall operational expenses for manufacturers and end users. Additionally, the availability of alternative gear types, such as spur and bevel gears for specific applications, can limit widespread adoption in certain industries. Fluctuations in raw material prices and the need for skilled labor to ensure high-quality gear production further challenge market growth, though continuous innovation and automation are gradually helping to overcome these limitations.

Opportunity: Expanding applications and technological advancements creating new growth avenues

The helical gear market presents significant growth opportunities driven by advancements in smart manufacturing and the increasing integration of automation across industries. The expanding adoption of electric vehicles and renewable energy systems creates strong demand for efficient and low-noise gear solutions. Emerging economies are investing heavily in industrial infrastructure and robotics, opening new avenues for high-precision gear applications. Furthermore, innovations in lightweight materials, surface treatments, and digital monitoring technologies are enhancing gear performance and lifespan. The growing focus on energy efficiency and sustainable production processes also encourages manufacturers to develop eco-friendly and high-performance helical gear systems, positioning the market for continued expansion in the coming years.

Challenges: High precision requirements and competitive pressure challenging market growth

The helical gear market faces challenges related to high production precision requirements and the need for advanced machinery to maintain tight tolerances. The complexity of gear alignment and noise control during high-speed operations demands skilled expertise and constant quality monitoring. Additionally, fluctuations in raw material costs and long manufacturing cycles can affect overall profitability. Intense competition among manufacturers to deliver cost-effective yet high-performance products also adds pressure, making continuous innovation and operational efficiency crucial for sustaining market competitiveness.

Global Helical Gear Market Ecosystem Analysis

The global helical gear market ecosystem comprises raw material suppliers, gear manufacturers, component distributors, and end-use industries such as automotive, aerospace, energy, and industrial machinery. Collaboration among these stakeholders ensures efficient production, quality control, and innovation in gear design and materials. Advancements in digital manufacturing, automation, and material science are strengthening the ecosystem by improving supply chain efficiency, enhancing performance standards, and supporting the growing global demand for high-precision helical gear solutions.

Global Helical Gear Market, By Type

The single helical gear segment accounted for the largest revenue share in the global helical gear market during the forecast period. This dominance is attributed to its widespread use in automotive transmissions, industrial machinery, and power generation equipment due to its high efficiency, smooth operation, and ability to handle significant load capacity. Single helical gears offer excellent power transmission with reduced vibration and noise, making them ideal for high-speed and high-torque applications. Their simpler design, lower production cost, and ease of maintenance further enhance their commercial viability across multiple industries.

The double helical gear segment accounted for the highest revenue share in the global helical gear market during the forecast period. This segment’s dominance is driven by its superior load-carrying capacity, balanced thrust forces, and smooth power transmission, making it ideal for heavy-duty applications in marine, aerospace, and industrial machinery sectors. Double helical gears minimize axial thrust and ensure efficient operation even under high torque and continuous load conditions. Their enhanced durability, precision alignment, and reduced vibration contribute to improved performance and longer service life, supporting their widespread adoption across critical industrial applications.

Global Helical Gear Market, By end-user

The automotive segment accounted for the highest revenue share in the global helical gear market during the forecast period. This dominance is primarily driven by the extensive use of helical gears in vehicle transmissions, steering systems, and powertrains, where smooth, quiet, and efficient torque transmission is essential. The increasing production of electric and hybrid vehicles has further boosted demand for high-performance gears that enhance energy efficiency and driving comfort. Additionally, ongoing advancements in automotive engineering and precision manufacturing continue to strengthen the segment’s leading position in the market.

The industrial segment accounted for significant revenue in the global helical gear market during the forecast period. This is attributed to the growing use of helical gears in heavy machinery, conveyors, compressors, and manufacturing equipment, where high torque transmission and durability are essential. The expansion of automation, robotics, and smart manufacturing systems has further increased demand for precision-engineered gears that ensure smooth and efficient operation. Continuous industrial growth across emerging economies and modernization of production facilities are also contributing to the segment’s strong revenue performance worldwide.

Asia Pacific is expected to account for the largest share of the global helical gear market during the forecast period, holding nearly 45% of total market revenue. This dominance is driven by rapid industrialization, expanding automotive production, and the strong presence of manufacturing hubs in countries such as China, India, Japan, and South Korea. The region’s growing investments in automation, renewable energy, and heavy machinery are further propelling demand for high-efficiency helical gears. Additionally, government initiatives promoting industrial modernization and technological advancements in gear design are supporting Asia Pacific’s leading position in the global market.

India is witnessing remarkable growth in the helical gear market, projected to record a CAGR of around 10–11% during the forecast period. This growth is fueled by the rapid expansion of the automotive and industrial sectors, increasing adoption of automation technologies, and rising infrastructure development. Regions such as Tamil Nadu and Maharashtra are emerging as key manufacturing centers, supported by strong government initiatives and foreign investments aimed at strengthening the country’s engineering and machinery production capabilities.

North America is anticipated to register a significant CAGR in the global helical gear market during the forecast period, accounting for approximately 20% of total market revenue. This growth is primarily driven by rising demand from the automotive, aerospace, and industrial machinery sectors, where helical gears are valued for their high efficiency, load-bearing capacity, and smooth operation. The region’s strong focus on technological innovation, precision manufacturing, and automation in production processes is further propelling market expansion. Supportive government initiatives promoting advanced manufacturing and industrial modernization also contribute to the region’s robust growth outlook.

The United States is witnessing steady and substantial growth in the helical gear market, driven by the increasing adoption of advanced transmission systems across automotive, defense, and energy industries. The country hosts several major manufacturers specializing in precision gear engineering and automation technologies, catering to both domestic and international demand. Additionally, the rapid expansion of the electric vehicle (EV) sector, coupled with the ongoing shift toward energy-efficient and low-noise gear systems, is further strengthening the U.S. market’s position in the global landscape.

WORLDWIDE TOP KEY PLAYERS IN THE HELICAL GEAR MARKET INCLUDE

- Sumitomo Drive

- SEW-Eurodrive

- ZF Friedrichshafen

- Kawasaki Heavy

- Bosch Rexroth

- GKN

- Timken

- Gleason

- Nabtesco

- Bonfiglioli

- Others

Product Launches in Helical Gear Market

- In August 2022, Dana Incorporated has launched the Brevini EvoMax family of helical and bevel-helical gearboxes for marine and offshore applications. This line includes five new sizes and 14 revised gearboxes for increased torque, extended service life, and efficiency.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the helical gear market based on the below-mentioned segments:

Global Helical Gear Market, By Type

- Single Helical Gears

- Double Helical Gears

- Spiral Helical Gears

- Hypoid Gears

- Others

Global Helical Gear Market, By End-User

- Automotive

- Aerospace

- Industrial

- Others

Global Helical Gear Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa