Fluoropolymer Coating Market Summary

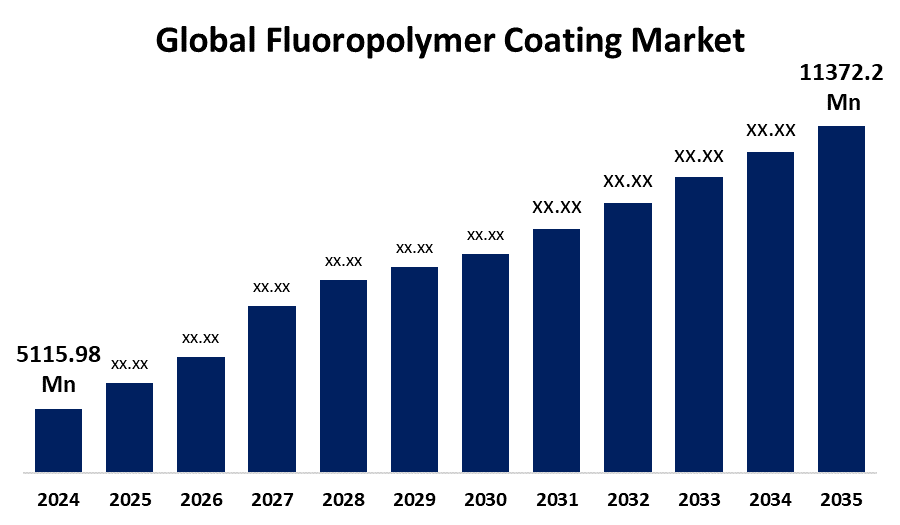

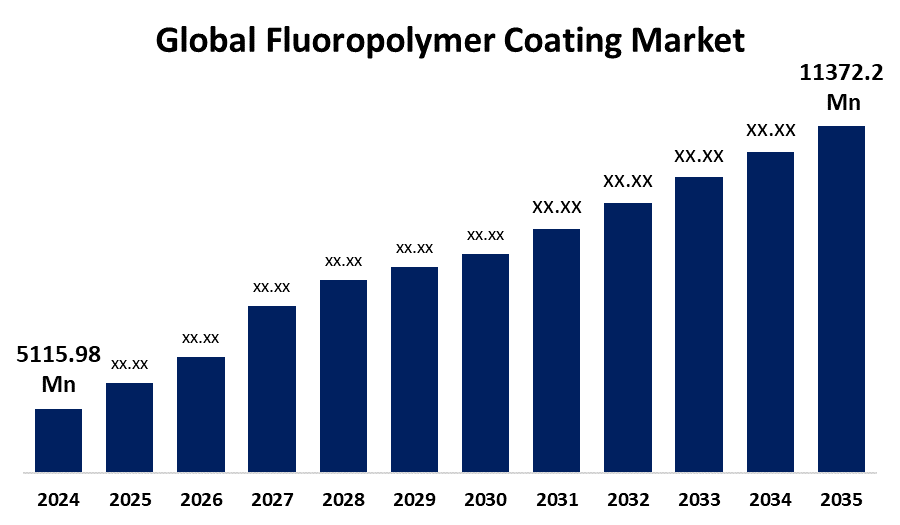

The Global Fluoropolymer Coating Market Size Was Estimated at USD 5115.98 Million in 2024 and is Projected to Reach USD 11372.2 Million by 2035, Growing at a CAGR of 7.53% from 2025 to 2035. The market for fluoropolymer coatings is expanding as a result of rising demand for fluoropolymers' special qualities in a number of industries, such as automotive, aerospace, electronics, and healthcare.

Key Regional and Segment-Wise Insights

- In 2024, Asia Pacific held the largest revenue share of over 36.2% and dominated the market globally.

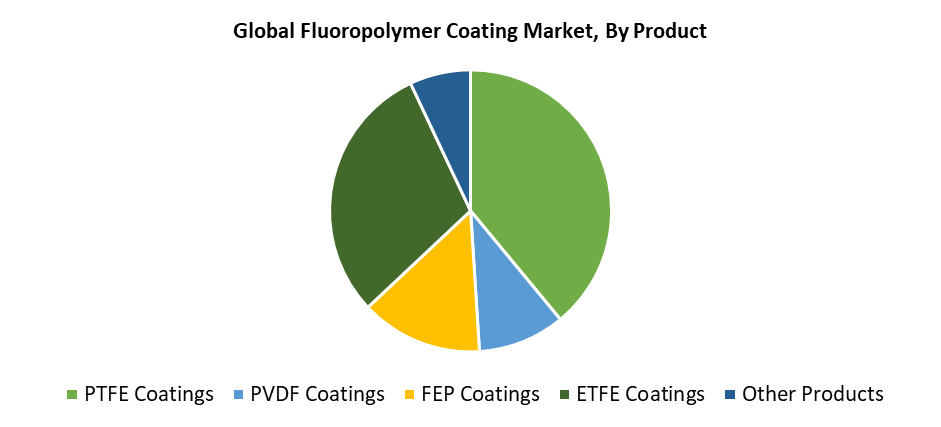

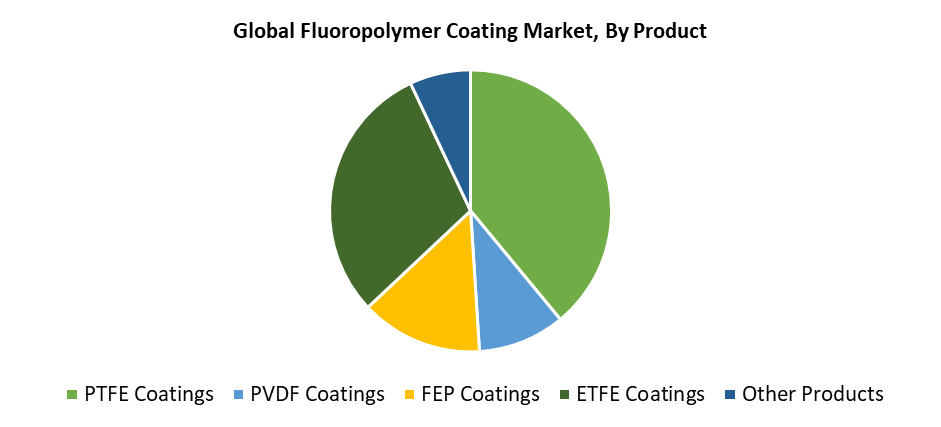

- In 2024, the Polytetrafluoroethylene (PTFE) coatings segment had the highest market share by product, accounting for 39.7%.

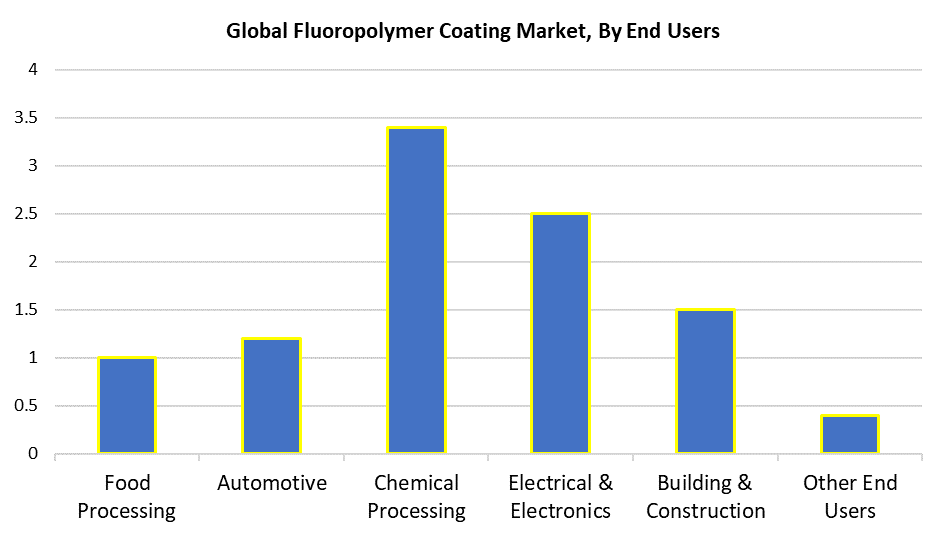

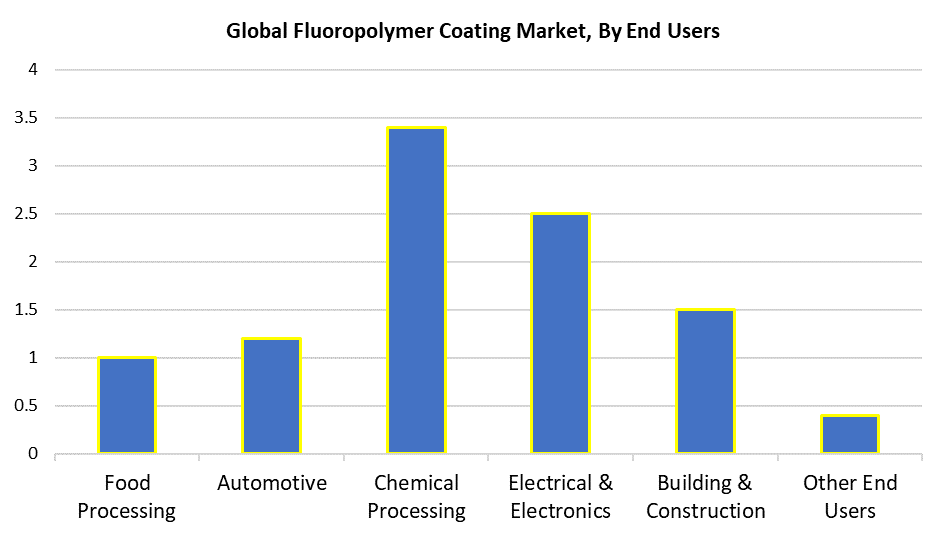

- In 2024, the chemical processing segment had the biggest market share by end-users, accounting for 34.7%.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 5115.98 Million

- 2035 Projected Market Size: USD 11372.2 Million

- CAGR (2025-2035): 7.53%

- Asia Pacific: Largest market in 2024

The manufacture and application of fluoropolymer-based coatings, with their distribution network, form the fluoropolymer coating market. The market for fluoropolymer coatings is expanding slowly since industries seek advanced materials with minimal friction properties alongside high thermal resistance and chemical durability. These coatings serve essential industries such as electronics and automotive, oil and gas, and industrial equipment to protect equipment from harmful conditions, particularly in corrosive and high-temperature environments. Offshore wind energy projects, together with chemical processing activities, have driven a faster adoption of these coatings. The number of applications using fluoropolymers like PVDF, ETFE, and FEP continues to expand. The list of applications includes lithium-ion battery facilities alongside LNG storage tanks, electric vehicle powertrain components, and pipeline systems that resist corrosion. The rising investment in infrastructure development across emerging regions, particularly in Asia Pacific and Latin America, is driving up the necessity for durable and persistent coatings.

Environmental regulations represent a key factor that propels the expanding fluoropolymer coating industry. The rising environmental standards regarding VOC emissions in North America, Europe, and California are creating strong demand for aqueous and powder fluoropolymer formulations. The transition toward green energy creates novel chances for industries that need modern high-performance coatings, including offshore wind turbines, as well as hydrogen infrastructure and electric vehicle battery production. The increasing customer preference for efficient ecological materials motivates ongoing advancements in this field. Research continues to develop affordable alternatives for PFAS while designers explore ways to restructure products to meet compliance standards, thus opening new market potential. The market receives additional long-term support through the rising production of automobiles and electronics across the Asia Pacific region.

Product Insights

The Polytetrafluoroethylene (PTFE) coatings sector dominated the market with a 39.7% revenue share in 2024 because of its outstanding thermal stability, chemical inertness, and low friction properties. The ability of PTFE to endure extreme temperatures and chemically aggressive environments makes it vital for electrical insulation, automotive, aerospace, and chemical processing industries. The material demonstrates temperature resistance in both high and cryogenic conditions, so it serves perfectly for gaskets, seals, bearings, and sliding components. Filled versions of PTFE have become increasingly popular for applications in hostile environments because technological advancements have enhanced their wear resistance. The low dissipation factor, together with the strong dielectric strength of PTFE, makes it an ideal choice for plug wire and cable insulation applications. The outstanding qualities of PTFE coatings lead the industry because they fulfill demanding performance standards across numerous industrial applications.

The ethylene tetrafluoroethylene (ETFE) coatings market will experience a 6.4% CAGR from 2025 to 2035. The main factors behind this growth are ETFE's outstanding corrosion resistance properties, together with its impact toughness and its ability to resist harsh environmental conditions. ETFE coatings continue to gain popularity in aerospace applications and semiconductor fabrication processes as well as industrial processing operations, especially in the Asia Pacific region, because its electronics and chemical manufacturing industries are rapidly expanding. The commercial applications of ETFE grow because it can be used for various architectural films and liner applications. The high growth protective coatings market segment of ETFE coatings exists because multiple industries need lightweight UV stable high performance coating solutions.

End Users Insights

The chemical processing segment led the fluoropolymer coatings market by accounting for 34.7% of total revenue in 2024. The leading position of this industry stems from its requirements for machinery that can handle both aggressive chemicals and elevated temperatures. The protection of product integrity, together with operational reliability and safety standards in chemical and pharmaceutical plants, depends on PTFE-lined pipes, vessels, and gaskets. The worldwide drive for high and low maintenance systems, together with rapid industrialization in the Asia Pacific, Middle East, and Africa regions, creates increasing demand. The segment secures its market position through these elements, which drive continuous growth while pushing the adoption of advanced fluoropolymer coatings made to meet stringent chemical processing requirements.

The electrical and electronics industry is expected to experience a CAGR of 7.5% during the period 2025 through 2035. High dielectric protection requirements, together with superior performance insulation needs and thermal stability demands from consumer electronics, telecommunications, and automotive electronics segments, are fueling this market expansion. PTFE and ETFE coatings find extensive application in printed circuit boards, connection assemblies, and wire insulation because they enhance safety and performance when operating at high frequencies and temperatures. The market growth receives additional momentum from both smart device proliferation and electric vehicle production since these technologies require advanced coating solutions to ensure prolonged operational performance. The segment experiences growth because of technological advancements, together with worldwide electronics manufacturing expansion.

Regional Insights

The Asia Pacific region dominated the global fluoropolymers market in 2024 with 36.2% revenue share because of its substantial infrastructure development and rapid industrial growth. The growing requirement of urban planning, along with electronics manufacturing and power plant development, stems from strong demand across Southeast Asia, China, and India. Environmental regulations promoting low VOC aqueous fluoropolymer coatings help the market expand its reach. The rising importance of durable and non stick coatings emerges from increasing wind farm installations and electric vehicle powertrain manufacturing. The aviation and aerospace sectors generate growing demand by using fluoropolymers because of their durable nature, combined with lightweight characteristics and chemical resistance. The APAC region's leading position in China demonstrates its essential function for solar module development, together with lithium ion battery production, water filtration systems, electrical insulation, and automobile fuel systems.

North America Fluoropolymer Coating Market Trends

The North American market for fluoropolymer coatings accounted for 28.4% market share in 2024 because of advanced industrial facilities and environmental protection regulations. The region leads in adopting aqueous fluoropolymer and low VOC systems across food equipment and chemical processing, as well as the aerospace industries. The expanding lithiumion battery gigafactories, together with offshore wind farms and electric vehicle production, drive the need for advanced coatings. The development of PFAS replacements promotes environmentally responsible usage of fluoropolymers. The defense, along with civil aviation sectors, extensively utilize fluoropolymers to enhance operational performance, together with safety measures and product longevity in fundamental applications, including fuel cells along with engine components, and aircraft parts. The thriving North American electronics sector drives market growth because thermal stability and chemical resistance properties of materials enhance their use in printed circuit board connections and insulating materials.

Europe Fluoropolymer Coating Market Trends

The European market for fluoropolymer coatings is expected to grow at a 5.9% CAGR throughout the forecast period because of low VOC regulations and renewable energy infrastructure investments. Offshore wind energy projects and hydrogen pipeline development require durable fluoropolymer coatings because they protect against corrosion and embrittlement. The automotive and aerospace industries drive growth through their adoption of fluoropolymers to meet energy efficiency standards and sustainability objectives. The market continues to expand because of rising environmental technology focus and regulatory adherence requirements. Europe serves as a key market for fluoropolymer coatings because of the combined market factors that will drive consistent growth throughout the forecast period.

Key Fluoropolymer Coating Companies:

The following are the leading companies in the fluoropolymer coating market. These companies collectively hold the largest market share and dictate industry trends.

- Akzo Nobel N.V.

- HaloPolymer, OJSC

- The Sherwin-Williams Company

- Solvay

- Arkema

- The Chemours Company

- Coating Systems, Inc. (Whitford Corporation)

- Axalta Coating Systems, LLC

- ENDURA COATINGS

- PPG Industries, Inc.

- DAIKIN INDUSTRIES, Ltd.

- Orion Industries

- Others

Recent Development

• In May 2025, PPG Industries, Inc. unveiled ENVIROLUXE Plus powder coating, withh are made of recycled plastic and without PIFE fluoropolymer. In line with PPG sustainability principles, The lunch aims to cut carbon emission while preserving performance. With ramification for the industrial and architectural worlds, this invention offers a fluoropolymer free alternative for long lasting powder coatings.

- In May 2023, PPG declared a 44 million investment to modernize five powder coating manufacturing facilities across the United States and Latin America. These projects form part of PPG's strategic approach to expand its powder coating portfolio and increase global manufacturing output to meet growing consumer demand for sustainable product benefits.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the fluoropolymer coating market based on the below-mentioned segments:

Global Fluoropolymer Coating Market, By Product

- PTFE Coatings

- PVDF Coatings

- FEP Coatings

- ETFE Coatings

- Other Products

Global Fluoropolymer Coating Market, By End Users

- Food Processing

- Automotive

- Chemical Processing

- Electrical & Electronics

- Building & Construction

- Other End Users

Global Fluoropolymer Coating Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa