Duplex Nickel Plating Market Summary, Size & Emerging Trends

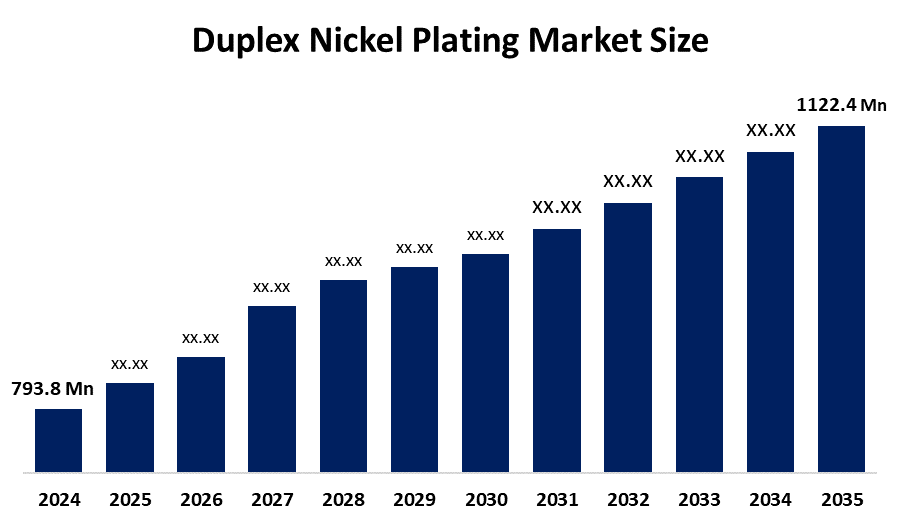

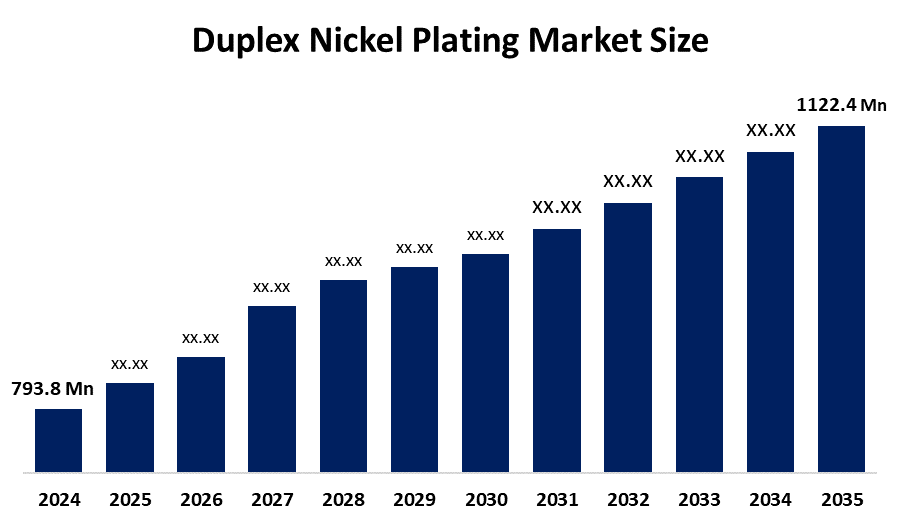

According to Spherical Insights, The Global Duplex Nickel Plating Market Size is expected to Grow from USD 793.8 Million in 2024 to USD 1122.4 Million by 2035, at a CAGR of 3.2% during the forecast period 2025-2035. Rising demand for corrosion-resistant coatings in automotive and industrial machinery applications is a key driving factor for the duplex nickel plating market.

Key Market Insights

- Asia Pacific is expected to account for the largest share in the duplex nickel plating market during the forecast period.

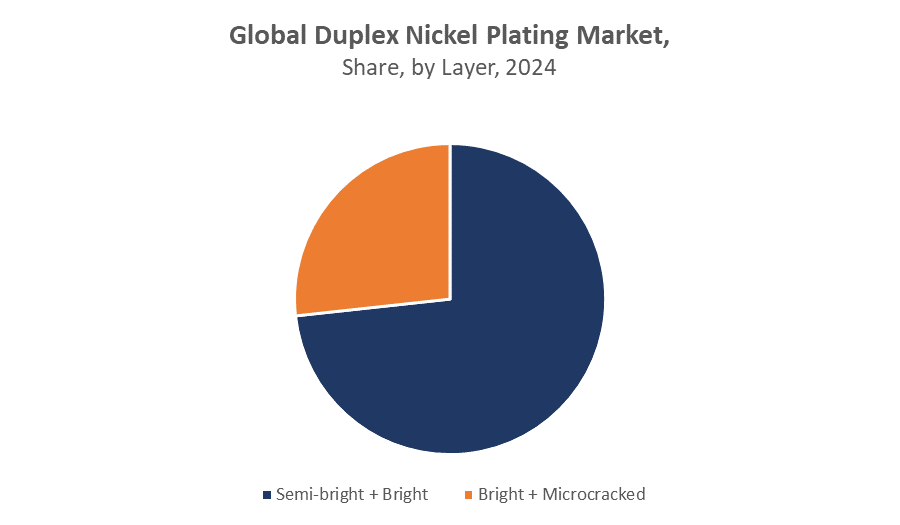

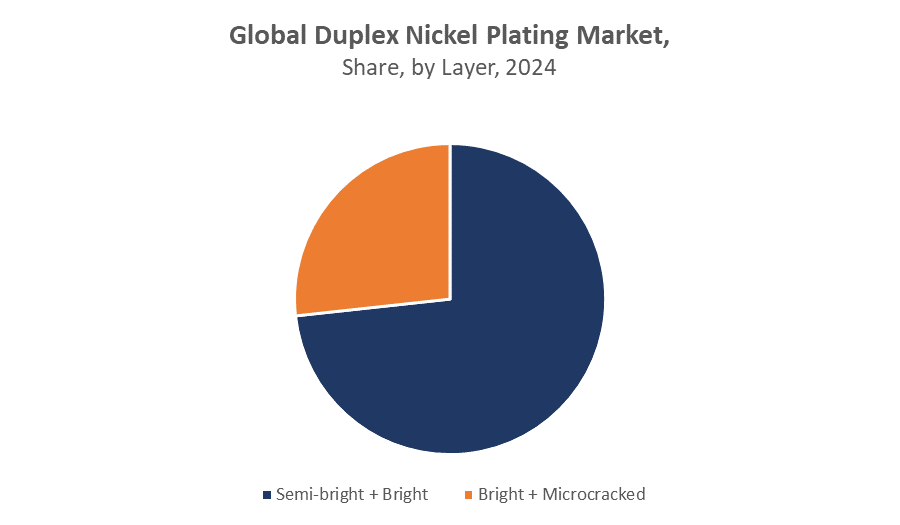

- In terms of layer, the Semi-bright + Bright and Bright + Microcracked layer segment dominated in terms of revenue during the forecast period.

- In terms of application, the automotive segment accounted for the largest revenue share in the global duplex nickel plating market during the forecast period.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 793.8 Million

- 2035 Projected Market Size: USD 1122.4 Million

- CAGR (2025-2035): 3.2%

- Asia Pacific: Largest market in 2024

- North America: Fastest growing market

Duplex Nickel Plating Market

The duplex nickel plating market focuses on the application of a dual-layer nickel coating process that combines semi-bright or bright layers with microcracked layers to enhance corrosion resistance, hardness, and wear protection. This plating technique is widely used in automotive components and industrial machinery, where durability and surface finish quality are critical. Governments and industry bodies globally are promoting advanced coating technologies through subsidies and R&D funding, aiming to enhance production efficiency and environmental sustainability. Demand for duplex nickel plating is driven by the need for longer-lasting components, resistance to harsh environmental conditions, and high-performance standards in automotive and industrial sectors. The market is poised for steady growth as manufacturers increasingly adopt duplex nickel plating to improve product life cycles and reduce maintenance costs.

Duplex Nickel Plating Market Trends

- Growing adoption of environmentally friendly plating solutions to reduce hazardous emissions.

- Advances in coating technology are creating more durable, corrosion-resistant duplex nickel layers.

- Strategic mergers and partnerships are being used to expand geographic presence and product offerings.

Duplex Nickel Plating Market Dynamics

Driving Factors: Rising demand from automotive and industrial machinery sectors

The global duplex nickel plating market is witnessing strong growth driven by the increasing adoption of plated components in automotive and industrial machinery sectors. Automotive manufacturers rely on duplex nickel coatings for critical parts such as gears, fasteners, engine components, and exhaust systems due to their superior corrosion resistance, wear protection, and enhanced surface aesthetics. Similarly, industrial machinery applications benefit from plated surfaces that improve durability, reduce friction, and extend equipment life in harsh operating conditions. Rapid industrialization and large-scale infrastructure projects in emerging economies are further fueling the demand for high-performance coatings that can withstand extreme environments. Additionally, advancements in plating technology, such as optimized duplex layering processes, allow for precise control over layer thickness and microstructure, improving performance and efficiency, which further supports market growth.

Restraint Factors: High production costs and environmental compliance

Despite its advantages, the duplex nickel plating market faces several restraints that can limit its expansion. The production process is often costly due to the high price of nickel and the energy-intensive nature of electroplating operations. Moreover, stringent environmental regulations related to the handling and disposal of chemicals and plating by-products add to operational challenges, especially in regions with strict compliance norms. Limited technical expertise in handling advanced plating techniques and the volatility of raw material prices can also impede adoption among smaller manufacturers. These factors collectively contribute to higher manufacturing costs and slower market penetration in price-sensitive regions.

Opportunity: Expansion into emerging markets and technological innovations

Emerging economies present significant growth opportunities for the duplex nickel plating market due to rapid industrialization, expanding automotive production, and increased investment in infrastructure. Innovations in plating technology, including advanced microcracked layer solutions and semi-bright + bright combinations, have enhanced corrosion resistance, surface finish, and coating efficiency, enabling manufacturers to meet demanding industrial standards. Additionally, the rising global emphasis on sustainability and eco-friendly manufacturing processes encourages the adoption of low-emission, environmentally safe plating solutions. Companies investing in these technologies can differentiate themselves in competitive markets and tap into new applications across automotive, aerospace, and industrial sectors.

Challenges: Supply chain volatility and regulatory constraints

The duplex nickel plating market is also challenged by external factors such as supply chain volatility and regulatory complexities. Nickel prices are subject to fluctuations due to geopolitical tensions, trade restrictions, and mining constraints, which can increase production costs and disrupt supply consistency. Manufacturers must also navigate complex environmental compliance requirements, including limits on heavy metals and hazardous chemicals, which necessitate significant investment in waste management and emission control systems. To remain competitive, companies must innovate not only in plating technologies but also in sourcing strategies and operational efficiency to maintain product quality and pricing stability.

Global Duplex Nickel Plating Market Ecosystem Analysis

The market ecosystem includes nickel raw material suppliers, plating solution manufacturers, and end-users in automotive and industrial machinery sectors. Suppliers, especially from China and Europe, influence cost and availability. Plating companies focus on improving environmental compliance and coating efficiency. Regulatory bodies enforce sustainable manufacturing standards, driving adoption of advanced duplex nickel plating processes.

Global Duplex Nickel Plating Market, By Layer

The semi-bright + bright segment holds a significant share of the global duplex nickel plating market, estimated at approximately 60% of total revenue. This layer combination is highly preferred in automotive and industrial machinery applications because it provides a smooth, visually appealing surface while maintaining strong adhesion to the substrate. The semi-bright layer ensures uniform coating thickness and improved brightness, while the bright layer enhances the aesthetic appeal and surface quality. These properties make it suitable for decorative as well as functional applications, including engine components, fasteners, and precision machinery parts, where both appearance and corrosion protection are critical. Its widespread use across multiple industries has driven its dominance in terms of market revenue.

The bright + microcracked segment accounts for approximately 45% of the global market revenue and is growing steadily due to its superior wear resistance and corrosion protection. Microcracked layers are intentionally engineered to create a network of microscopic cracks, which allow for controlled oil or lubricant retention, enhancing the durability of moving parts and reducing friction in mechanical applications. Combined with a bright nickel layer, this approach ensures both functional performance and surface quality, making it ideal for high-stress components in automotive and industrial machinery. The segment’s growth is supported by increasing demand for high-performance coatings in harsh operational environments and industries prioritizing long-lasting and maintenance-efficient parts.

Global Duplex Nickel Plating Market, By Application

The automotive segment dominates the global duplex nickel plating market, accounting for approximately 65% of total revenue. This strong share is driven by the increasing use of plated components such as gears, engine parts, fasteners, and exhaust systems that require high corrosion resistance, wear protection, and aesthetic appeal. Duplex nickel plating enhances the durability and performance of these parts while reducing maintenance requirements, making it an ideal choice for automotive manufacturers. Rising automotive production in emerging economies, coupled with stringent quality standards in developed regions, further supports the segment’s market leadership.

The industrial machinery segment holds around 40% of the market revenue and continues to grow steadily. Duplex nickel plating is extensively used in machinery components exposed to heavy wear, friction, and harsh operating environments. By providing superior corrosion resistance and enhanced surface hardness, duplex nickel coatings extend the life of equipment, improve operational efficiency, and reduce downtime and maintenance costs. Applications include pumps, valves, gears, and precision tools across industries such as manufacturing, energy, and construction. The demand for high-performance, long-lasting coatings in industrial machinery is a key driver for this segment’s consistent revenue contribution.

Asia Pacific is projected to hold the largest share of the global duplex nickel plating market, accounting for approximately 45% of total revenue. This dominance is primarily driven by the rapid growth of automotive and industrial machinery manufacturing in key countries such as China, India, and Japan. China continues to lead in automotive production and exports, creating substantial demand for corrosion-resistant, high-performance plated components. Japan maintains a strong presence in precision machinery and industrial equipment, while India is emerging as a major growth hub due to increased industrialization, expanding manufacturing infrastructure, and government initiatives promoting advanced manufacturing technologies. Collectively, these factors position Asia Pacific as the most lucrative market for duplex nickel plating during the forecast period.

India is expected to register a robust CAGR of approximately 10% during the forecast period. Growth is fueled by rapid industrial expansion, increasing automotive production, and supportive government policies aimed at promoting advanced manufacturing technologies. The country’s growing focus on modernizing industrial infrastructure and boosting domestic production capabilities enhances the adoption of high-performance coatings like duplex nickel plating in automotive, machinery, and other industrial applications.

North America is anticipated to hold around 20% of the global market revenue and register a significant CAGR during the forecast period. Growth in this region is largely driven by high adoption of duplex nickel plating in automotive manufacturing and industrial machinery sectors, where corrosion resistance, wear protection, and extended component life are critical. The United States, in particular, shows steady growth due to increasing demand for plated components in automotive, aerospace, and heavy machinery industries. Technological advancements in plating processes and stringent quality standards further support the region’s market expansion, making North America an important contributor to global revenue.

WORLDWIDE TOP KEY PLAYERS IN THE DUPLEX NICKEL PLATING MARKET INCLUDE

- Atotech

- Uyemura International Corp.

- MacDermid Enthone

- Coventya

- Enthone Japan

- Tanaka Kikinzoku Kogyo

- Hangzhou Newtown Chemical Co., Ltd.

- Shandong Huarui Metal Materials Co., Ltd.

- Others

Product Launches in Duplex Nickel Plating Market

- In March 2024, Atotech introduced a new eco-friendly duplex nickel plating solution specifically designed for automotive applications. This innovative coating technology enhances the corrosion resistance and wear performance of automotive components such as engine parts, gears, and fasteners, ensuring longer service life and reduced maintenance requirements. A key differentiator of this product is its environmentally conscious formulation, which minimizes hazardous emissions and reduces the environmental impact typically associated with traditional nickel plating processes.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Decision Advisor has segmented the duplex nickel plating market based on the below-mentioned segments:

Global Duplex Nickel Plating Market, By Layer

- Semi-bright + Bright

- Bright + Microcracked

Global Duplex Nickel Plating Market, By Application

- Automotive

- Industrial Machinery

Global Duplex Nickel Plating Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa