Chemical Industry 4.0 Market Summary

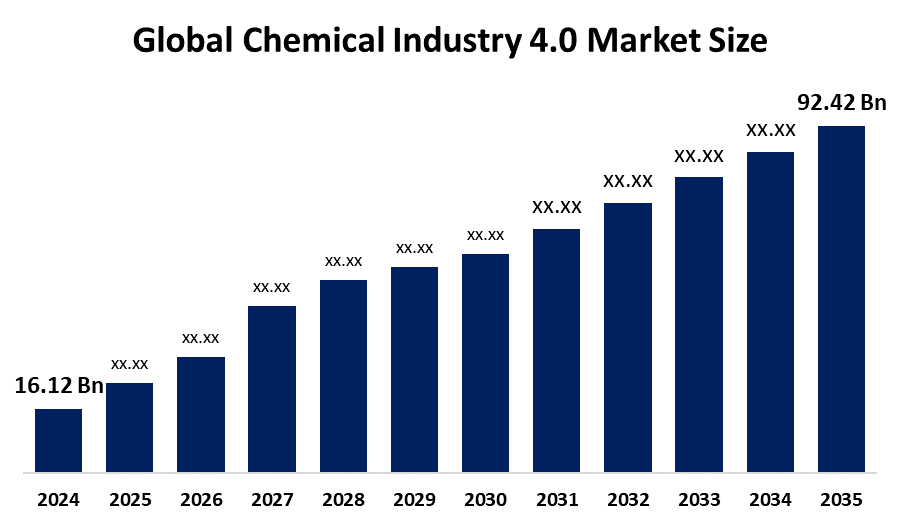

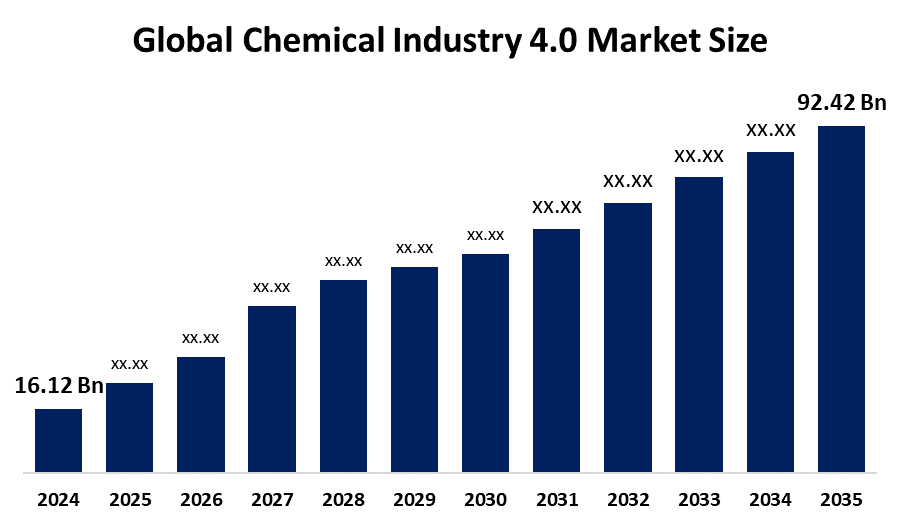

The Global Chemical Industry 4.0 Market Size Was Estimated at USD 16.12 Billion in 2024 and is Projected to Reach USD 92.42 Billion by 2035, Growing at a CAGR of 17.2% from 2025 to 2035. The market for Chemical Industry 4.0 is expanding due to factors such as increased demand for automation, digital transformation, predictive maintenance, IoT integration, data-driven decision-making, sustainability objectives, cost-effectiveness, improved safety, the adoption of smart manufacturing, and growing competition in the global chemical production industry.

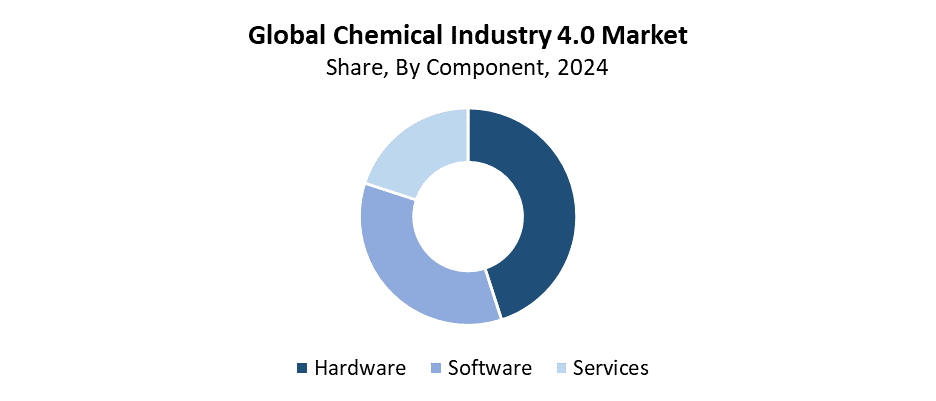

Key Regional and Segment-Wise Insights

- In 2024, the Asia Pacific chemical industry 4.0 market size held the largest revenue share of 43.3% and dominated the global market.

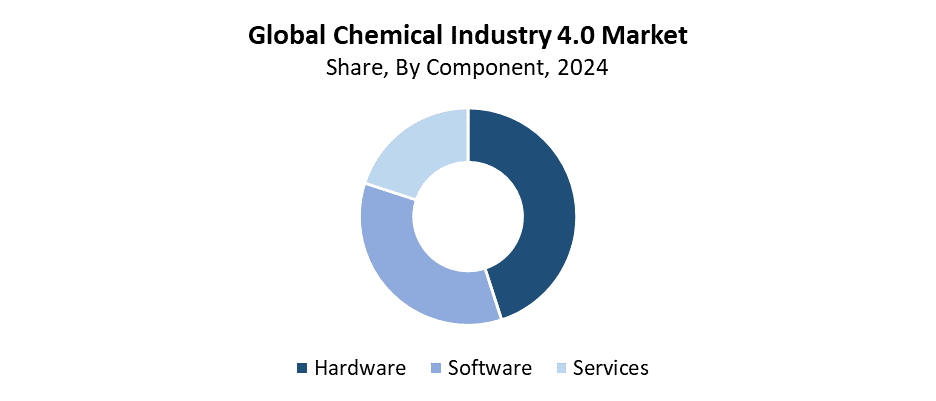

- In 2024, the hardware segment held the highest revenue share of 45.5% and dominated the global market size by component.

- With the biggest revenue share of 29.4% in 2024, the Internet of Things (IoT) segment led the worldwide chemical industry 4.0 market by technology.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 16.12 Billion

- 2035 Projected Market Size: USD 92.42 Billion

- CAGR (2025-2035): 17.2%

- Asia Pacific: Largest market in 2024

The Chemical Industry 4.0 market represents the integration of modern digital technologies, including robotics, cloud computing, big data analytics, artificial intelligence (AI), and the Internet of Things (IoT), for enhancing chemical manufacturing and operational processes. The organisation seeks to lower expenses through this transformation while enhancing production efficiency, product quality, sustainability, and safety standards. The industry experiences rising demand for automation systems because companies want to monitor data in real time and perform predictive maintenance while using resources more efficiently to protect the environment. The market grows because businesses need to keep their operational flexibility and competitive position in an industrial environment that keeps evolving.

The chemical production industry, together with supply chain operations, experiences a transformation because of digital twin technology, smart sensors, and advanced process control systems. Businesses can now predict equipment failures, optimise energy consumption and maintain regulatory standards through these technologies. The worldwide adoption of Industry 4.0 receives support from governments through their financial backing, legislative frameworks, and digital transformation initiatives. The chemical industry across North America, Europe, and Asia-Pacific adopts Industry 4.0 technology through initiatives which support industrial digital transformation. These support smart manufacturing and sustainability goals.

Component Insights

The hardware segment led the worldwide Chemical Industry 4.0 market by holding the largest revenue share of 45.5% in 2024. The extensive use of modern machinery, including sensors, industrial robots, control systems, and Internet of Things devices that enable automation and real-time monitoring in chemical production, leads to this dominance. Smart factories operate through hardware components, which serve as their base foundation to collect data and optimise processes. They enable predictive maintenance. Hardware deployment operates as a driving force because organisations need dependable networked production systems to enhance their operational performance and safety standards. The hardware segment will experience growth in the upcoming years because AI-driven devices will integrate with industrial automation technology developments.

The software segment of the Chemical Industry 4.0 market will experience significant growth during the forecast period because digital platforms, data analytics tools, and chemical manufacturing operations have become more widely used. The combination of digital twin technologies with enterprise resource planning (ERP), factory execution systems (MES), and software solutions enables predictive maintenance and real-time process optimisation, and improved decision-making. The transition to cloud-based AI-powered software platforms in production facilities enables better scalability, integration, and operational agility. The growing interest in supply chain transparency, sustainability, and regulatory compliance requirements has accelerated software adoption. The market will expand over the next years because technological advancement continues. Smart automation and intelligent analytics systems experience rising demand.

Technology Insights

The Internet of Things (IoT) segment leads the global Chemical Industry 4.0 market size with the largest revenue share of 29.4% in 2024. Across chemical production facilities, IoT technology facilitates real-time data gathering, monitoring, and process optimisation by enabling seamless communication among equipment, devices, and systems. The implementation of IoT solutions enables businesses to decrease their production expenses and system interruptions while achieving better control of assets, maintenance prediction, and operational performance. The sector supports IoT implementation because of its growing need for smart sensors, networked devices, and remote monitoring systems. The chemical manufacturing industry undergoes a digital transformation through IoT dominance, which advances because of its integration with AI and cloud computing. Analytics systems enable advanced automation and data-driven decision-making.

The artificial intelligence (AI) segment will experience substantial growth during the forecast period because it now serves critical roles in quality control, predictive maintenance, and chemical production process optimisation. Manufacturers can achieve better production results, waste reduction, and decision-making through AI technology, which enables advanced data analytics and pattern recognition. Process simulation capabilities. The integration of AI with cloud computing, digital twins, and Internet of Things technology accelerates the development of automation and smart manufacturing skills. AI-powered systems operate in real-time to monitor and optimise operations for chemical companies because energy efficiency and sustainable manufacturing have become essential priorities. The market expansion will result from ongoing technical developments and expanding AI applications.

Regional Insights

The Asia Pacific region led the global Chemical Industry 4.0 market size by holding the largest revenue share of 43.3% in 2024. The dominance of these countries stems from their fast industrial growth and strong manufacturing sectors, and major digital transformation funding in China, Japan, South Korea, and India. Chemical production facilities now operate more efficiently and sustainably because they implement automation systems, Internet of Things (IoT) technology, and artificial intelligence (AI) solutions. The market growth receives additional support through government initiatives, which promote Industry 4.0. These initiatives support smart manufacturing and industrial digitalisation. The Asia Pacific region leads the world market because Industry 4.0 technologies are advancing through its major chemical manufacturers, increasing demand for high-performance materials, and rising environmental regulations.

Europe Chemical Industry 4.0 Market Trends

Europe held a significant revenue share of the global Chemical Industry 4.0 market during 2024 because of its dedication to modern production methods, sustainable practices, and innovative development. The established chemical industry of the region drives new production methods and safety standards through its adoption of automation systems, Internet of Things (IoT) technology, artificial intelligence (AI), and digital twin systems. European governments, together with the European Union, back Industry 4.0 development through financial programs, research collaborations, and regulatory frameworks which promote digital transformation. These promote carbon neutrality. The United Kingdom, together with France and Germany, lead the charge in adopting smart manufacturing technologies at the national level. The chemical industry in Europe adopts Industry 4.0 technology at an accelerated rate because of stringent environmental regulations and growing requirements for eco-friendly chemical manufacturing operations.

North America Chemical Industry 4.0 Market Trends

North America held 19.3% revenue share of the global Chemical Industry 4.0 market in 2024 because of its early adoption of digital technologies and its status as home to major chemical manufacturers. The region achieves better safety and process optimisation and operational efficiency through its use of automation, data analytics, and smart manufacturing solutions at all production facilities. The United States and Canada lead the way in using robotics, artificial intelligence, and Internet of Things technology to enhance chemical operations for better productivity and environmental sustainability. The market growth results from government support programs, industrial digitisation funding, and increasing consumer interest in environmentally sustainable manufacturing. North America stands as a leading region for Chemical Industry 4.0 development because its technological infrastructure supports innovation.

Key Chemical Industry 4.0 Companies:

The following are the leading companies in the chemical industry 4.0 market. These companies collectively hold the largest market share and dictate industry trends.

- Siemens

- Mitsubishi Chemical Group Corporation

- GE Vernova

- Honeywell International Inc.

- Rockwell Automation

- Yokogawa Electric Corporation

- Schneider Electric

- ABB

- Aspen Technology

- Emerson Electric Co.

- Others

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Decision Advisors has segmented the chemical industry 4.0 market based on the below-mentioned segments:

Global Chemical Industry 4.0 Market, By Component

- Hardware

- Software

- Services

Global Chemical Industry 4.0 Market, By Technology

- Internet of Things

- Artificial Intelligence

- Digital Twin & Simulation

- Robotics & Process Automation

- Other Technologies

Global Chemical Industry 4.0 Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa