3D Printing Gases Market Summary

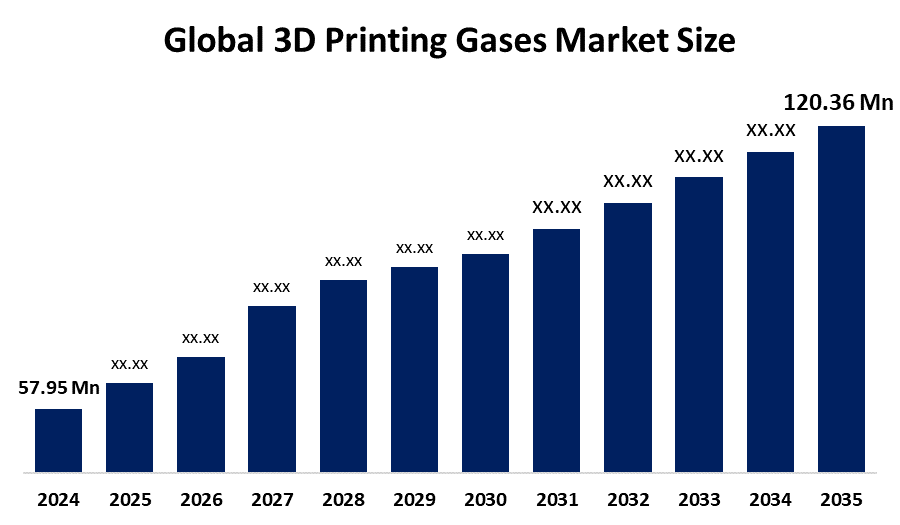

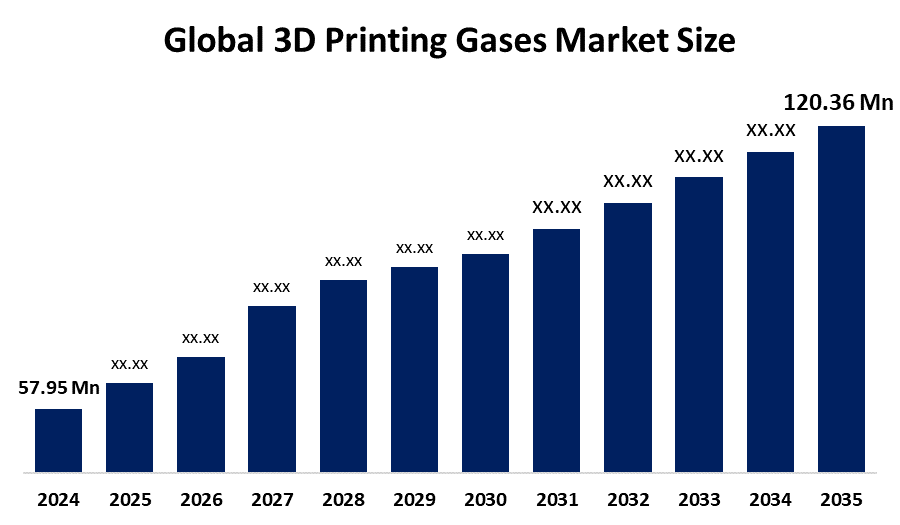

The Global 3D Printing Gases Market Size Was Estimated at USD 57.95 Million in 2024 and is Projected to Reach USD 120.36 Million by 2035, Growing at a CAGR of 6.87% from 2025 to 2035. The growing use of 3D printing in a variety of industries, such as aerospace, automotive, and healthcare, the growing need for high-quality, customized products, and developments in gas mixtures and specialty gases are all contributing to the growth of the 3D printing gases market.

Regional and Segment-Wise Insights

- In 2024, Asia Pacific held the largest revenue share of over 54.37% and dominated the market globally.

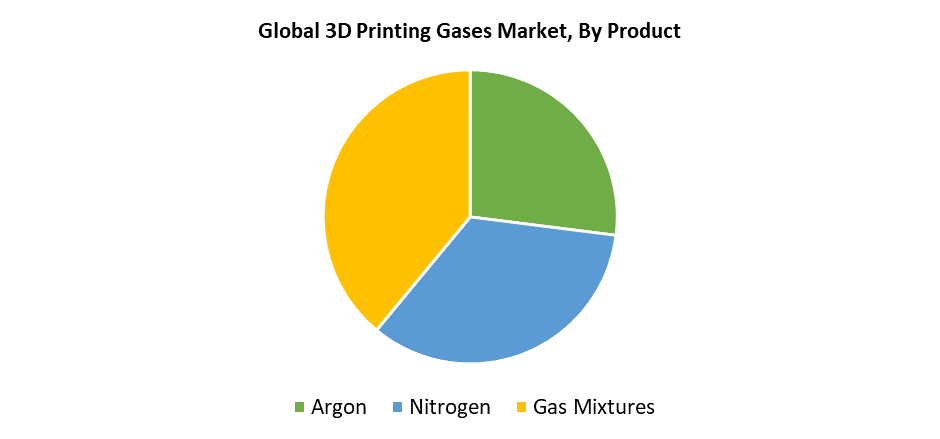

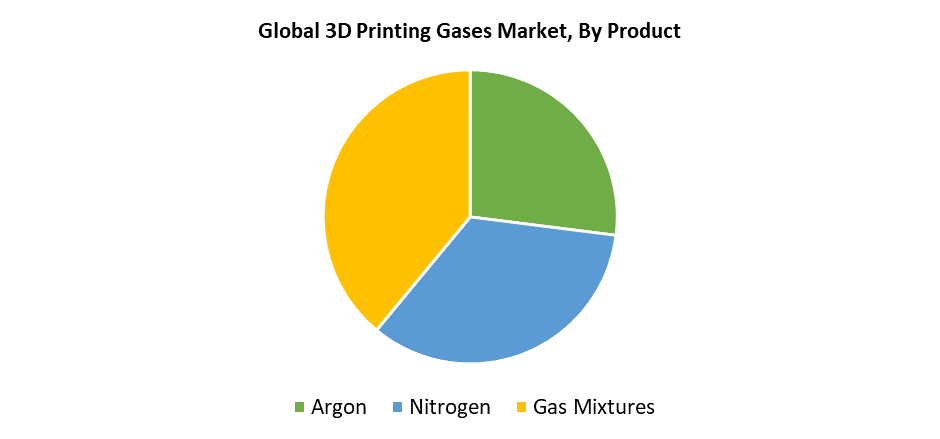

- In 2024, the gas mixtures segment had the highest market share by product, accounting for 39.5%.

- In 2024, the design and manufacturing segment had the biggest market share by end use, accounting for 36.4%.

Global Market Forecast and Revenue Outlook

- 2024 Market Size: USD 57.95 Million

- 2035 Projected Market Size: USD 120.36 Million

- CAGR (2025-2035): 6.87%

- Asia Pacific: Largest market in 2024

The 3D Printing Gases Market Size represents a specialized industrial gas sector that delivers controlled environments for enhancing printed component quality and stability during additive manufacturing operations. 3D printing gases consist primarily of nitrogen, hydrogen, and argon, which help maintain temperature control and stop oxidation while improving material properties. The expanding utilization of 3D printing across electronic, healthcare, automotive, and aerospace applications drives substantial market development. The demand for pure gases increases because numerous companies adopt additive manufacturing for creating intricate items and testing prototypes. The trend toward customized and lightweight components alongside reduced material waste promotes 3D printing growth, which creates increased demand for stable and reliable gas supply systems.

Technological progress in gas supply systems combined with 3D printing equipment leads to major improvements in additive manufacturing performance and efficiency. Integrated gas management systems, together with automated gas flow control and real-time gas monitoring, enhance print quality and reduce operating costs. R&D expenditures are driving the development of application-specific gas blends, which will expand market opportunities. Governments around the world support 3D printing through incentives and infrastructural investments, and supportive regulations to promote local manufacturing and innovation. The global demand for 3D printing gases increases because of industry 4.0 roadmaps and smart manufacturing programs, which drive the growth of additive manufacturing.

Product Insights

The gas mixtures segment held 39.5% revenue share and led the 3D printing gases market in 2024. The superior performance of gas mixtures in maintaining perfect atmospheric conditions during additive manufacturing processes stands as their main reason for widespread adoption. Specialized gas mixtures, which contain argon, nitrogen, and hydrogen along with other inert gases, exist to fulfill specific material requirements, improve layer adhesion and thermal stability, and reduce oxidation. The aerospace, automotive, and healthcare industries employ gas mixtures to print high-performance metals and alloys because they need precise and consistent results. The growth of metal 3D printing, along with rising demands for specialized gas solutions to support complex printing processes, has propelled gas mixtures to lead the product sector within the market.

The nitrogen segment within the 3D printing gases market will experience substantial development throughout the forecast period because of its low cost and multiple applications in additive manufacturing processes. 3D printing processes that utilize materials that have low oxygen reactivity such as specific polymers, together with low-alloy metals commonly implement nitrogen as a shielding gas to build inert printing environments. The industrial world selects this option since it prevents oxidation and delivers better print surface quality, together with stable mechanical properties. The rising market share of nitrogen depends on its anticipated significant compound annual growth rate (CAGR) because polymer and metal 3D printing adoption grows within electronics, automotive, and consumer product sectors.

Application Insights

The design and manufacturing category dominated the 3D printing gases market by securing 36.4% revenue share in 2024, as 3D printing maintains its widespread application for rapid prototyping and complex custom part creation. The market benefits from 3D printing because the technology shortens product development cycles and decreases material waste while reducing production expenses. The establishment of controlled environments that deliver perfect prints with specific mechanical properties depends on argon and nitrogen and specialized gas mixtures. The rising adoption of 3D printing in design and manufacturing operations drives continuous demand from aerospace and automotive sectors, along with industrial equipment manufacturers for high-purity gases to maintain production reliability.

The healthcare segment of the 3D printing gases market is expected to experience substantial CAGR throughout the forecast period due to rising medical applications of additive manufacturing for implants, prosthetics, dental equipment, and surgical instruments. The production of biocompatible materials requires high-purity argon and nitrogen gases to maintain sterile, oxidation-free environments, while 3D printing provides the customization needed for patient-specific solutions. The growth results from advancements in tissue engineering combined with bioprinting capabilities, together with rising demand for precise medical devices. The market growth for this category is propelled by supportive regulatory frameworks, together with increasing research and development expenditures in medical 3D printing technologies.

Regional Insights

The North American 3D printing gas market experiences rapid growth because of the fast implementation of additive manufacturing across the defense, aerospace, automotive, and healthcare industries. The area benefits from three main factors, including substantial R&D investment alongside strong technological infrastructure and major 3D printing and industrial gas companies. Argon, along with nitrogen and specialty mixtures, serves as a highly desired gas for achieving the best print quality, material integrity, and maximum process efficiency. The US maintains market dominance because of government support for manufacturing innovation and Industry 4.0 technology integration. Throughout the entire region, the demand for 3D printing gases continues to grow because manufacturers require lightweight components with customization options at affordable prices.

Asia Pacific 3D Printing Gases Market Trends

The Asia Pacific 3D printing gases market held the highest revenue share of 54.37% in 2024 because of rising production capacities, together with fast industrial development and increased adoption of additive manufacturing in developing economies. The automotive industry, along with electronics, healthcare, and aerospace sectors, receives major 3D printing investments from China, along with Japan, South Korea, and India. The production of high-performance products requires exact manufacturing processes, thus driving up the demand for argon, nitrogen, and gas mixes throughout the region. The industry growth received additional support from research facilities alongside highly qualified workers and government programs that encourage innovative manufacturing. The Asia Pacific region's cost-efficient conditions, along with advancing technology, serve to attract major players from the global industry, thus driving market growth.

Europe 3D Printing Gases Market Trends

The European 3D printing gases market continues its expansion because of the rising application of additive manufacturing within the electronics, automotive, aerospace, and healthcare industries. The printing process depends on nitrogen and argon, as well as oxygen and carbon dioxide, to maintain optimal conditions while ensuring product quality. The market sees expansion because of improved 3D printing technology and growing consumer requirements for detailed and lightweight parts. The regional market leadership belongs to Germany, France, and the UK because these countries maintain strong industrial ecosystems and innovative research centers. The market faces challenges from supply chain restrictions, together with the expensive nature of specialized gases. The European 3D printing gases market will discover new growth opportunities because of continuous R&D investments and the increasing adoption of eco-friendly manufacturing practices.

Key 3D Printing Gases Companies:

The following are the leading companies in the 3D printing gases market. These companies collectively hold the largest market share and dictate industry trends.

- Air Liquide

- Praxair Inc.

- Airgas Inc.

- BASF SE

- Messer Group

- Air Products and Chemicals, INC.

- Iwatani Corporation

- Matheson Tri-Gas Inc.

- Nippon Sanso Holdings Corporation

- SOL Group

- The Linde Group

- Iceblick Ltd.

- Universal Industrial Gases

- Linde PLC

- Others

Recent Developments

- In March 2024, Linde plc unveiled a brand-new range of high-purity gas solutions designed especially for metal 3D printing applications.

- In February 2024, Air Products and Chemicals, Inc. expanded its 3D printing gas manufacturing facility in Texas, intending to satisfy the expanding demands of the healthcare and aerospace industries.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the 3D printing gases market based on the below-mentioned segments:

Global 3D Printing Gases Market, By Product

- Argon

- Nitrogen

- Gas Mixtures

Global 3D Printing Gases Market, By Application

- Design and Manufacturing

- Healthcare

- Consumer Products

- Others

Global 3D Printing Gases Market, By Regional Analysis

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa