World's Top 40 Companies in Light Curing Acrylic Adhesive Market in 2025 Watch List: Statistics Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

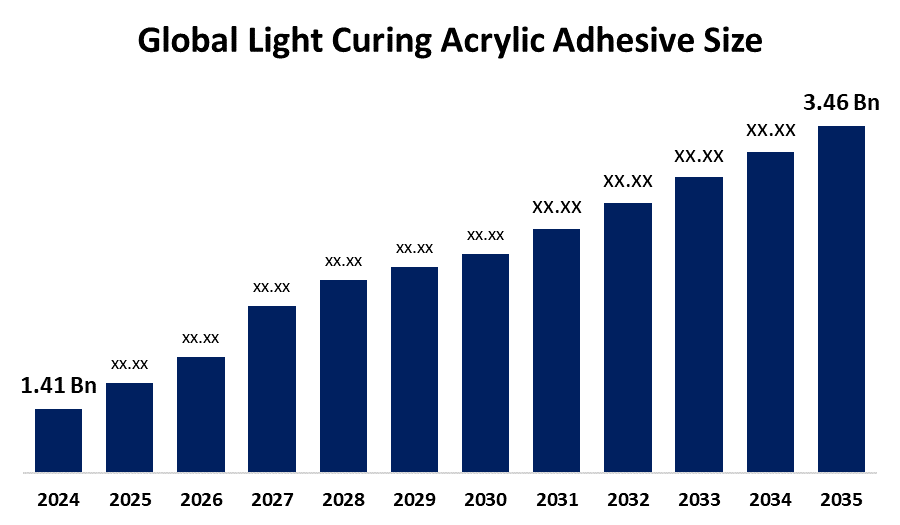

According to a research report published by Spherical Insights & Consulting, The Global Light Curing Acrylic Adhesive Market Size is projected To Grow from USD 1.41 Billion in 2024 to USD 3.46 Billion by 2035, at a CAGR of 8.5 % during the forecast period 2025–2035. The Light Curing Acrylic Adhesive market offers opportunities in electronics, medical devices, automotive, and renewable energy, driven by fast curing, eco-friendly formulations, miniaturization needs, precision bonding, and rising demand for sustainable, high-performance assembly solutions.

Introduction

The Light Curing Acrylic Adhesive Market Size is gaining significant traction as industries demand faster, cleaner, and more reliable bonding solutions. These adhesives cure rapidly when exposed to UV or visible light, offering high strength, durability, and precision in applications requiring minimal heat. They are widely used across electronics, medical devices, automotive, and renewable energy sectors, where miniaturization, sustainability, and performance are critical. Light curing acrylic adhesives enhance productivity by enabling on-demand curing, reducing waste, and supporting automated assembly processes. With growing emphasis on eco-friendly, solvent-free solutions and advanced manufacturing, this market is positioned for robust growth in the coming years.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Light Curing Acrylic Adhesive market.

Light Curing Acrylic Adhesive Market Size & Statistics

- The Market for Light Curing Acrylic Adhesive Market Size Was Estimated to be Worth USD 1.41 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 8.5 % Between 2025 and 2035.

- The Global Light Curing Acrylic Adhesive Market Size is Anticipated to Reach USD 3.46 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Light Curing Acrylic Adhesive Market.

- North America is expected to grow the fastest during the forecast period in the Light Curing Acrylic Adhesive Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Light Curing Acrylic Adhesive market. Growth is fueled by rising adoption in advanced medical devices, electronics, and aerospace applications, where precision and high-performance bonding are critical. The region’s strong focus on R&D, technological innovation, and automated manufacturing accelerates demand for light curing adhesives. Additionally, increasing investments in EV manufacturing, renewable energy, and sustainable production practices drive expansion.

Asia Pacific is expected to generate the highest demand during the forecast period in the Light Curing Acrylic Adhesive market. The region’s strong electronics manufacturing base, booming automotive sector, and rapid growth in medical device production are major demand drivers. Countries like China, Japan, South Korea, and India are leading adopters, supported by expanding renewable energy projects, industrial automation, and infrastructure investments.

Top 5 Trends in Light Curing Acrylic Adhesive Market

1. Rising Demand in Electronics and Miniaturization

The surge in consumer electronics and miniaturized devices is driving the adoption of light curing acrylic adhesives. These adhesives enable precision bonding of tiny components in smartphones, wearables, sensors, and circuit boards. Their rapid curing ability supports high-speed automated production lines, improving efficiency and reducing costs. With electronics manufacturers seeking adhesives that provide durability, electrical insulation, and resistance to environmental stress, light curing acrylics are becoming indispensable. The trend toward smaller, multifunctional devices, coupled with increasing demand for 5G technology and IoT-enabled products, continues to strengthen the role of these adhesives in next-generation electronics manufacturing.

2. Expanding Applications in Medical Devices

Medical device manufacturers are increasingly turning to light curing acrylic adhesives for their biocompatibility, fast curing, and high bond strength. These adhesives are widely used in assembling syringes, catheters, diagnostic devices, and wearable healthcare technologies. They ensure reliable bonding of plastics and glass while meeting stringent regulatory and sterilization requirements. The rise in demand for minimally invasive devices and advanced diagnostics is fueling adoption. Furthermore, their solvent-free and low-VOC properties align with safety and sustainability standards. With growing investments in healthcare innovation and medical device production, light curing acrylic adhesives are emerging as a critical enabler of modern healthcare solutions.

3. Growth in Automotive and Electric Vehicles (EVs)

The automotive industry, particularly EV manufacturing, is embracing light curing acrylic adhesives for lightweight assemblies, sensor bonding, and electronic component integration. These adhesives provide vibration resistance, thermal stability, and high reliability, ensuring safety and performance in demanding environments. Their fast curing speeds support efficient, high-volume production processes, making them ideal for automated automotive assembly lines. The transition toward EVs, with their reliance on battery systems, sensors, and electronic control units, is further amplifying demand. As automakers prioritize energy efficiency and sustainability, the role of advanced adhesive technologies will continue to grow, positioning light curing acrylic adhesives as vital automotive enablers.

4. Shift Toward Eco-Friendly and Sustainable Adhesives

Sustainability is a defining trend in the light curing acrylic adhesive market. Manufacturers are developing solvent-free, low-VOC, and energy-efficient formulations to meet environmental regulations and customer demand for greener solutions. Light curing adhesives inherently align with sustainability goals by reducing waste, enabling precise application, and minimizing energy use during curing. Their ability to improve product longevity also supports circular economy principles. Industries like electronics and medical devices are particularly keen on adopting eco-friendly adhesives that ensure compliance without compromising performance. This trend is reshaping R&D priorities, driving innovation in sustainable bonding technologies that balance performance with environmental responsibility.

5. Integration with Automated Manufacturing and Industry 4.0

Industry 4.0 and smart manufacturing are transforming adhesive application methods, creating opportunities for light curing acrylic adhesives. These adhesives are increasingly integrated with robotic dispensing and automated curing systems, ensuring precision, consistency, and high throughput. Real-time monitoring and process control enhance quality assurance, while rapid curing reduces downtime. Electronics, automotive, and medical device industries benefit significantly from this trend, as automated systems align with their need for scalable and efficient production. The convergence of digital manufacturing, robotics, and advanced adhesive technology underscores a major shift, making automation-friendly adhesives central to next-generation industrial operations.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Light Curing Acrylic Adhesive market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 21 Companies Leading the Light Curing Acrylic Adhesive Market

- 3M Company

- Henkel AG & Co. KGaA

- Dymax Corporation

- H.B. Fuller Company

- Permabond LLC

- Master Bond Inc.

- DELO Industrial Adhesives

- Panacol-Elosol GmbH

- LOCTITE (Henkel)

- ITW Devcon

- Norland Products Inc.

- ResinLab LLC

- Permatex Inc.

- Bostik SA

- Sika AG

- Ashland Inc.

- Adhesives Research Inc.

- Parson Adhesives Inc.

- Cyberbond LLC

- Epoxy Technology Inc.

1. 3M Company

Headquartered in Minnesota, USA, 3M is a global leader in adhesives, tapes, and advanced materials. Its portfolio includes high-performance light curing acrylic adhesives used in electronics, automotive, medical devices, and industrial assembly. 3M focuses on innovation, offering fast-curing, durable, and eco-friendly adhesives that enable precision bonding in miniaturized and complex applications. The company invests heavily in R&D to develop advanced formulations compatible with automated manufacturing and Industry 4.0 processes. With a strong global presence and diversified product portfolio, 3M remains a trusted supplier for industries seeking reliable, high-performance, and sustainable bonding solutions worldwide.

2. Henkel AG & Co. KGaA

Headquartered in Düsseldorf, Germany, Henkel is a global leader in adhesives, sealants, and surface technologies. Its LOCTITE brand is widely recognized for light curing acrylic adhesives, offering rapid, high-strength bonding solutions for electronics, automotive, medical, and industrial applications. Henkel emphasizes sustainability with low-VOC, solvent-free formulations that meet regulatory and environmental standards. The company integrates adhesives with automated dispensing systems for precision manufacturing. With extensive global distribution, strong brand equity, and continuous innovation in light curing technologies, Henkel maintains a dominant position in the market, supporting high-performance applications and emerging sectors like EVs, IoT devices, and medical equipment.

3. Dymax Corporation

Dymax Corporation, headquartered in Torrington, USA, specializes in UV and visible light curing adhesives, coatings, and dispensing equipment. The company offers advanced light curing acrylic adhesives used in electronics, medical devices, automotive, and industrial assembly. Dymax focuses on rapid curing, precision application, and environmentally friendly formulations, including low-odor and low-VOC products. Its adhesives enable high-throughput automated processes while maintaining reliability in complex assemblies. Strong R&D capabilities and a global service network allow Dymax to tailor solutions for emerging applications such as miniaturized electronics, wearable devices, and EV components, positioning it as a key innovator in light curing adhesive technologies.

4. H.B. Fuller Company

Headquartered in Minnesota, USA, H.B. Fuller is a leading global adhesive manufacturer with a focus on industrial, construction, and specialty adhesives. The company produces light curing acrylic adhesives that deliver high-strength, precision bonding for electronics, automotive, medical devices, and industrial sectors. H.B. Fuller emphasizes sustainable, low-VOC, and solvent-free formulations while supporting automated dispensing and rapid curing processes. With extensive R&D investments and strategic partnerships, the company addresses emerging trends such as miniaturization, Industry 4.0 integration, and environmentally responsible manufacturing. Its global presence and tailored adhesive solutions make H.B. Fuller a trusted supplier for critical applications.

5. Permabond LLC

Permabond LLC, headquartered in Connecticut, USA, is a specialty adhesive manufacturer offering light curing acrylic adhesives for electronics, medical devices, automotive, and industrial applications. The company provides rapid-curing, high-strength, and reliable adhesives designed for precision assemblies and automated manufacturing processes. Permabond focuses on innovation, developing low-odor, low-VOC, and eco-friendly formulations that meet stringent regulatory and performance requirements. Its solutions support miniaturized devices, complex assemblies, and high-volume production lines. With a strong emphasis on customer support and global distribution, Permabond has established itself as a key player in the light curing adhesive market, catering to diverse industrial and emerging technology sectors.

Are you ready to discover more about the Light Curing Acrylic Adhesive market?

The report provides an in-depth analysis of the leading companies operating in the global Light Curing Acrylic Adhesive market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- 3M Company.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- Henkel AG & Co. KGaA

- Dymax Corporation

- H.B. Fuller Company

- Permabond LLC

- Master Bond Inc.

- DELO Industrial Adhesives

- Panacol-Elosol GmbH

- LOCTITE (Henkel)

- ITW Devcon

Conclusion

The Global Light Curing Acrylic Adhesive Market Size is poised for robust growth, driven by demand from electronics, medical devices, automotive, and renewable energy sectors. Rapid curing, precision bonding, miniaturization, and eco-friendly formulations are transforming industrial assembly processes, while automation and Industry 4.0 integration further enhance efficiency. Asia Pacific is set to generate the highest demand, while North America is expected to grow the fastest, fueled by technological innovation and advanced manufacturing adoption. Leading companies such as 3M, Henkel, Dymax, H.B. Fuller, and Permabond are driving innovation and sustainability, positioning the market for long-term expansion and strategic opportunities worldwide.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?