World’s Top 30 Companies in Automated Optical Inspection 2025 Watchlist: Statistical Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

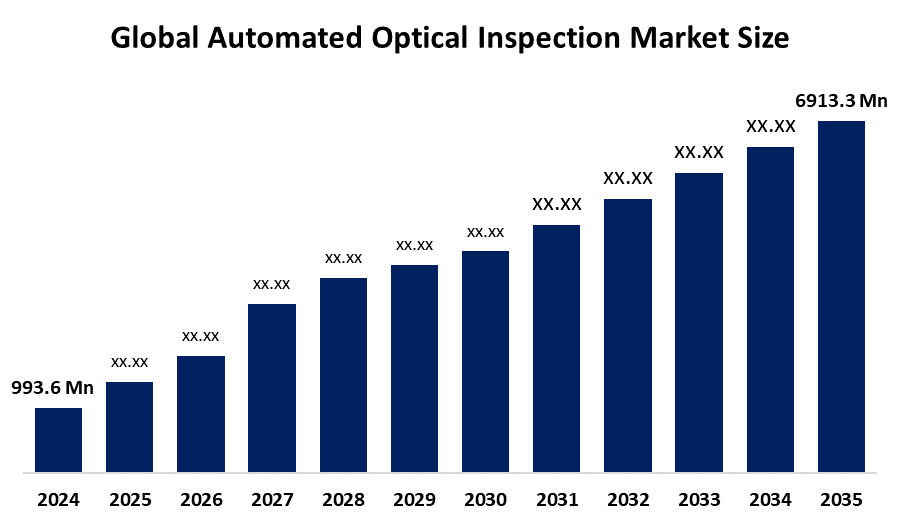

According to a research report published by Spherical Insights & Consulting, The Global Automated Optical Inspection Market Size is projected to Grow from USD 993.6 Million in 2024 to USD 6913.3 Million by 2035, at a CAGR of 19.29% during the forecast period 2025–2035.The main drivers of growth in this industry are the complexity of electronics manufacturing, the rising demand for high-quality electronic products, and developments in AOI technology.

Introduction

The Global Market Size for Automated Optical Inspection (AOI) includes sophisticated visual inspection systems made to find flaws and guarantee the quality of manufactured parts, especially in precision engineering and electronics. To find anomalies like soldering errors, misalignments, and missing parts during production, AOI systems make use of high-resolution cameras, lighting configurations, and sophisticated image processing algorithms. These systems facilitate adherence to strict quality standards, increase operational efficiency, and lower human error. AOI solutions are becoming essential for preserving product dependability and optimizing manufacturing processes as industries embrace automation and smaller technologies. Additionally, in the production of electronics, the advent of nanotechnology has led to the miniaturization and application of high-density PCBs. However, a lot of issues are emerging as a result of these developments. A variety of PCB defects arise as a result of the ball grid array (BGA) gap decreasing in tandem with the PCB's shrinking size. Solder paste flaws, material mismatch, substrate corrosion, and EMI interference susceptibility are a few of these flaws. Manual inspection cannot accurately detect these flaws. The application of AOI systems in the identification of IC substrate defects is therefore becoming more and more popular.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Automated Optical Inspection Market.

Automated Optical Inspection Market Size & Statistics

- The Market Size for Automated Optical Inspection Was Estimated to be Worth USD 993.6 Million in 2024.

- The Market Size is Going to Expand at a CAGR of 19.29% Between 2025 and 2035.

- The Global Automated Optical Inspection Market Size is Anticipated to Reach USD 6913.3 Million by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Automated Optical Inspection Market.

- North America is expected to grow the fastest during the forecast period in the Automated Optical Inspection Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the automated optical inspection market. The main drivers of the region's growth are its high per capita consumption, strong emphasis on innovation and technological advancements, and rising demand for electrical components. AOI systems are being adopted as a result of the development of smart technologies for accurate inspection and defect detection brought about by the growth of the automotive and consumer electronics industries.

Asia Pacific is expected to generate the highest demand during the forecast period in the automated optical inspection market. The growing demand for consumer electronics and the abundance of PCB manufacturers are the main factors propelling this market. The rapid growth of consumer electronics and automobiles in nations like China and India, coupled with rising disposable income, has prompted the adoption of AOI systems. Additionally, the area is one of the biggest automakers, which increases demand for premium electronic parts. To meet the increasing demand, different governments and businesses are also working together.

Top 10 Automated Optical Inspection Trends

1.Convert 2D to 3D AOI systems

2.AI-Assisted Defect Identification

3.Edge Computing with Inline AOI

4.High-Resolution Imaging and Miniaturization

5.ISO Compliance & Automotive Electrification

6.Integration of Smart Factories

7.Scalable and Modular AOI Platforms

8.Economical Adoption of 3D AOI

9.Workflows for Multi-Stage Inspection

10.Workforce Enablement & Training

1.Convert 2D to 3D AOI systems

A major development in quality control for the production of electronics is the switch from 2D to 3D Automated Optical Inspection (AOI) systems. By capturing volumetric data, 3D AOI technologies enable accurate measurement of component height, solder joint shape, and spatial alignment, in contrast to traditional 2D systems that only use surface imaging. This ability is particularly important for inspecting printed circuit boards (PCBs) with a high density of components, where micro-scale features and overlapping components necessitate improved depth perception.

2.AI-Assisted Defect Identification

Automated optical inspection (AOI) is being revolutionized by AI-powered defect detection, which allows systems to learn from large datasets and gradually increase inspection accuracy. By separating acceptable variations from actual defects using machine learning algorithms, AOI platforms can drastically cut down on false positives and manual rechecks. Additionally, these intelligent systems facilitate predictive analytics, which enables manufacturers to foresee process deviations and take corrective action prior to defects occurring.

3.Edge Computing with Inline AOI

Edge computing-enabled inline automated optical inspection (AOI) systems are transforming real-time quality control in high-throughput manufacturing settings. Instead of depending on cloud or centralized servers, these systems process inspection data locally at the edge, allowing for quick feedback and remedial actions within the production line. Through dynamic parameter adjustments based on real-time data, this closed-loop process control reduces downtime, improves the accuracy of defect detection, and facilitates adaptive manufacturing.

4.High-Resolution Imaging and Miniaturization

The demand for high-resolution imaging in Automated Optical Inspection (AOI) systems is being driven by the increasing complexity and miniaturization of electronic components, particularly in chiplet packaging and sophisticated PCB designs. Manufacturers are incorporating ultra-high-resolution cameras, sophisticated lighting systems, and precision optics that can quickly capture minute details in order to precisely detect features and micro-defects that are smaller than -10 µm. Since even minute irregularities can impair performance in next-generation electronics, this change is essential to maintaining quality.

5.ISO Compliance & Automotive Electrification

Automatic Optical Inspection (AOI) systems are being modified to satisfy the strict quality and safety requirements of battery-management PCBs and other crucial electronic components as automotive electrification picks up speed. Because even small flaws can impair a vehicle's performance and safety, adherence to ISO 26262 functional safety standards is crucial in this field. AOI technologies are developing to ensure dependability and regulatory compliance by offering high-precision inspection of solder joints, connectors, and micro-scale circuitry in electric vehicle systems.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the automated optical inspection market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Automated Optical Inspection Market

1.Koh Young Technology Inc.

2.Test Research, Inc. (TRI)

3.Omron Corporation

4.Camtek Ltd.

5.Viscom AG

6.Saki Corporation

7.Nordson YESTECH

8.KLA Corporation

9.CyberOptics Corporation

10.Goepel Electronic GmbH

11.Mirtec Co., Ltd.

12.ASC International

13.ViTrox Corporation

14.Machine Vision Products, Inc. (MVP)

15.AOI Systems Ltd.

16.ZhenHuaXing Technology

17.Ohers

1.Koh Young Technology Inc.

Headquarters - South Korea

Koh Young Technology Inc. is a world leader in 3D measurement-based inspection solutions, with a focus on semiconductor inspection systems, automated optical inspection (AOI), and solder paste inspection (SPI). The company supports Industry 4.0 transformation and smart factory initiatives by utilizing cutting-edge optomechatronics and machine vision technologies. Its range of products includes process optimization software, medical robotics, and electronics manufacturing, providing intelligent, real-time quality control for a variety of industrial applications.

2.Test Research, Inc. (TRI)

Headquarters – Taiwan

Automated Optical Inspection (AOI), Solder Paste Inspection (SPI), Automated X-ray Inspection (AXI), and In-Circuit Test (ICT) systems are all part of Test Research, Inc.'s (TRI) extensive portfolio of automated test and inspection solutions for the electronics manufacturing sector. The company's platforms are designed to seamlessly integrate with production lines, allowing for reduced operator workload, process optimization, and real-time defect detection.

3.Omron Corporation

Headquarters - Shimogyo-ku, Kyoto, Japan

Omron Corp. (Omron) produces and sells healthcare equipment, social systems, electronic components, and automation components. The company's product line includes motion and drive components, automation systems, sensors, relays, safety components, power supplies, motion and drive components, robotics, switches, relays, and connectors. Additionally, it provides road and traffic management systems, mems sensors, amusement equipment components, face recognition software, and railway station services systems.

4.Camtek Ltd.

Headquarters - Migdal HaEmek, Israel

Camtek Ltd. (Camtek) is a manufacturer and developer that specializes in high-end metrology and inspection tools for the semiconductor sector. Throughout the semiconductor manufacturing process, the company's primary focus is on wafer inspection and measurement. Complete wafer inspection and metrology systems, as well as software for measurement analysis and defect classification, are among Camtek's main offerings. Among its products are Golden Eagle, Eagle-AP, Eagle-AP Plus, Hawk, Eagle G5, 360°Scan, Eagle-I, and Eagle-i Plus for Full Wafer Inspection & Metrology. Leading multinational foundries, outsourced semiconductor assembly and testing firms (OSATs), and integrated device manufacturers (IDMs) use the company's systems.

5.Viscom AG

Headquarters - Hanover, Lower Saxony, Germany

Viscom AG is a prominent supplier of high-precision inspection technologies, with a focus on computed tomography systems for electronics manufacturing, automated optical inspection (AOI), and X-ray inspection. The company provides solutions that guarantee product quality, dependability, and adherence to international standards to sectors like automotive, aerospace, telecommunications, and industrial electronics. The systems from Viscom are made to be integrated into contemporary production settings, facilitating smart factory initiatives, process optimization, and real-time defect detection.

Are you ready to discover more about the automated optical inspection market?

The report provides an in-depth analysis of the leading companies operating in the global automated optical inspection market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

1.Koh Young Technology Inc.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

2.Test Research, Inc. (TRI)

3.Omron Corporation

4.Camtek Ltd.

5.Viscom AG

6.Saki Corporation

7.Nordson YESTECH

8.KLA Corporation

9.CyberOptics Corporation

10.Goepel Electronic GmbH

11.Mirtec Co., Ltd.

12.ASC International

13.ViTrox Corporation

14.Machine Vision Products, Inc. (MVP)

15.AOI Systems Ltd.

16.ZhenHuaXing Technology

17.Others

Conclusion

The market for automated optical inspection is changing quickly due to the need for precise quality control and the complexity of electronics manufacturing. Innovations in technology like edge computing, 3D imaging, and AI-powered defect detection are improving inspection capabilities and operational efficiency. North America's innovation momentum and Asia Pacific's manufacturing dominance drive regional growth. AOI systems are becoming essential in many industries as miniaturization and automotive electrification increase. Leading companies are investing in scalable, intelligent solutions to meet evolving demands and regulatory standards.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?