Top 50 Global Alcohol Drying Molecular Sieve Companies 2025: Market Intelligence & Investment Trends (2024–2035)

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

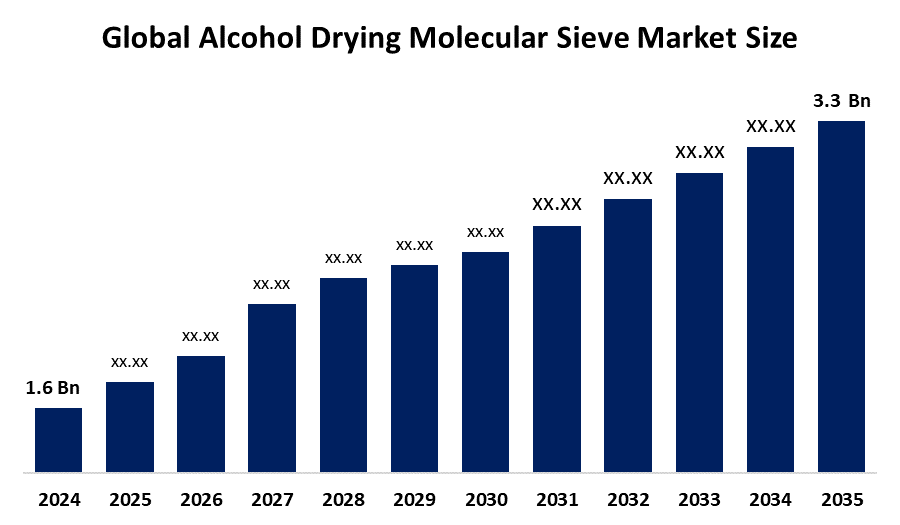

According to a research report published by Spherical Insights & Consulting, The Global Alcohol Drying Molecular Sieve Market Size is projected to grow from USD 1.6 Billion in 2024 to USD 3.3 Billion by 2035, at a CAGR of 6.8% during the forecast period 2025–2035. The growing need for high-purity alcohols in a variety of industrial applications and growing knowledge of the advantages of molecular sieves over conventional drying techniques are driving this market's expansion.

Introduction

The Molecular Sieve Market Size for Alcohol Drying Worldwide is based on the materials employed to eliminate water from alcohols during production and/or purification. Molecular sieves are characterized by high adsorption capacity, thermal stability, and selectivity, contributing to their significance in chemical, pharmaceutical, and fuel processes. Furthermore, developments in nanotechnology may lead to improvements in molecular sieve efficiency. According to research, nanoscale materials can improve the adsorption capacity of conventional molecular sieves, resulting in higher rates of moisture removal. The market's growth prospects are further highlighted by the potential to create new applications in industries like biofuels and renewable energy.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Alcohol Drying Molecular Sieve Market.

Alcohol Drying Molecular Sieve Market Size & Statistics

- The Market Size for Alcohol Drying Molecular Sieve Was Estimated to be Worth USD 1.6 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 6.8% Between 2025 and 2035.

- The Global Alcohol Drying Molecular Sieve Market Size is Anticipated to Reach USD 3.3 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Alcohol Drying Molecular Sieve Market.

- Asia Pacific is expected to grow the fastest during the forecast period in the Alcohol Drying Molecular Sieve Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the alcohol drying molecular sieve market. This is due to the quickening pace of industrialization and the expanding need for high-purity alcohols across a range of industries. The growing food and beverage, pharmaceutical, and chemical industries in the area are major drivers of market expansion. Leading the way in the adoption of cutting-edge drying technologies are nations like China, India, and Japan, aided by government programs that support industrial growth and quality standards.

North America is expected to generate the highest demand during the forecast period in the alcohol drying molecular sieve market. The use of molecular sieves is growing as a result of strict regulatory requirements and the emphasis on efficiency and quality in production processes. With their strong infrastructure and prominent market players, the US and Canada are two of the biggest contributors to the North American market.

Top 10 Alcohol Drying Molecular Sieve Trends

1. Advanced Methods of Regeneration

2. Transition to Eco-Friendly Manufacturing

3. Integration with Systems for Continuous Processing

4. Personalization for Particular Types of Alcohol

5. Improved Mechanical and Thermal Stability

6. Integration of Smart Control and Digital Monitoring

7. Growth in Applications of Biofuel

8. Adsorbent Systems That Are Hybrid

9. Local Centers for Manufacturing

10. Pay attention to safety and regulatory compliance

1. Advanced Methods of Regeneration

Molecular sieves used in alcohol drying are becoming more effective and long-lasting thanks to advancements in regeneration techniques. In order to support cost-effective operations, methods such as vacuum regeneration and thermal swing are being optimized to lower energy consumption and preserve adsorption capacity over several cycles.

2. Transition to Eco-Friendly Manufacturing

To meet sustainability targets, producers are switching to low-emission processing and more environmentally friendly synthesis methods for molecular sieves. When producing drying agents for bioethanol and industrial alcohols, this entails utilizing renewable feedstocks, reducing waste, and incorporating the concepts of the circular economy.

3. Integration with Systems for Continuous Processing

In the production of alcohol, molecular sieves are increasingly being made to work with continuous flow systems. Particularly in large-scale chemical and fuel manufacturing facilities, this trend encourages increased throughput, constant purity levels, and decreased downtime.

4. Personalization for Particular Types of Alcohol

To maximize drying performance for various alcohols, including ethanol, methanol, and isopropanol, customized molecular sieve formulations are being developed. These specially made grades improve adsorption kinetics and selectivity, increasing process dependability in a variety of industrial applications.

5. Improved Mechanical and Thermal Stability

Improved resilience to mechanical stress and heat degradation is being provided by novel molecular sieve compositions. This prolongs service life and lowers the need for replacement by guaranteeing steady performance in harsh operating environments and high temperatures.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the alcohol drying molecular sieve market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Alcohol Drying Molecular Sieve Market

1.Arkema Group

2.Honeywell International Inc.

3.BASF SE

4.Zeochem AG

5.W. R. Grace & Co.

6.Tosoh Corporation

7.KNT Group

8.Sorbead India

9.Zeolyst International

10.Clariant AG

11.Ningbo Jiahe New Materials Technology Co., Ltd.

12.Shijiazhuang Jianda High-Tech Chemical Co., Ltd.

13.Shanghai Hengye Molecular Sieve Co., Ltd.

14.Zhongbao Molecular Sieve Co., Ltd.

15.Luoyang Jianlong Chemical Industrial Co., Ltd.

16.Pingxiang Xintao Chemical Packing Co., Ltd.

1.Arkema Group

Headquarters - Colombes, France.

A multinational manufacturer of specialty materials chemicals is Arkema SA (Arkema). The company's product line consists of coating resins and additives for coating solutions, specialty polymers and performance additives for advanced materials, and high-performance adhesives for industrial assembly and construction. Agriculture, automotive, construction, consumer goods, electrical, oil, chemicals, packaging, plastics, pulp, rubber, health, and water treatment are just a few of the industries that use Arkema's products.

2.Honeywell International Inc.

Headquarters - Charlotte, North Carolina, the US.

Serving a variety of industries worldwide, Honeywell International Inc. (Honeywell) is an integrated operating company. Through its various business divisions, the company focuses on offering solutions that improve comfort, safety, and productivity. Aerospace technologies, building automation systems, industrial automation solutions, and energy and sustainability solutions are some of Honeywell's main offerings. Customers in sectors like aviation, refining, life sciences, utilities, and building management are served by the company's goods and services. To reach its customers, Honeywell uses a network of distribution networks and channel partners.

3.BASF SE

Headquarters - Ludwigshafen, Germany.

BASF SE (BASF) is a chemical corporation. It produces, markets, and sells plastics, chemicals, crop protection products, and performance products. Solvents, adhesives, surfactants, fuel additives, electronic chemicals, pigments, paints, food additives, fungicides, and herbicides are all part of its product line. Construction, furniture and wood, agriculture, electronics and electrical, paints and coatings, automobiles, home care, nutrition, and chemicals are just a few of the industries that the company serves. BASF conducts research and development in collaboration with scientists, partners, and customers worldwide.

4.Zeochem AG

Headquarters - Rüti, Zurich, Switzerland

Zeochem AG serves the pharmaceutical, petrochemical, and environmental technology industries worldwide by providing premium molecular sieves, chromatography gels, and deuterated compounds. The business is renowned for its precisely designed adsorbents, which are employed in solvent recovery, gas purification, and alcohol drying procedures. Zeochem provides customized solutions that adhere to strict performance and regulatory requirements, with a strong emphasis on innovation and quality control.

5.W. R. Grace & Co.

Headquarters - Columbia, Maryland, the US.

The chemical company W. R. Grace & Co. (Grace) creates, manufactures, and markets engineered materials and specialty catalysts. FCC additives, FCC catalysts, polyolefin catalysts, chiral intermediates, boronic acids, ethanol and biodiesel adsorbents, matting agents, refractory additives, inkjet absorbents, beer clarifiers, and rubber and tire additives are among its product offerings. Products from the company are used in the life sciences, pharmaceutical, packaging, and commercial and residential construction sectors.

Are you ready to discover more about the alcohol drying molecular sieve market?

The report provides an in-depth analysis of the leading companies operating in the global alcohol drying molecular sieve market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

1.Arkema Group

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

2.Honeywell International Inc.

3.BASF SE

4.Zeochem AG

5.W. R. Grace & Co.

6.Tosoh Corporation

7.KNT Group

8.Sorbead India

9.Zeolyst International

10.Clariant AG

11.Ningbo Jiahe New Materials Technology Co., Ltd.

12.Shijiazhuang Jianda High-Tech Chemical Co., Ltd.

13.Shanghai Hengye Molecular Sieve Co., Ltd.

14.Zhongbao Molecular Sieve Co., Ltd.

15.Luoyang Jianlong Chemical Industrial Co., Ltd.

16.Pingxiang Xintao Chemical Packing Co., Ltd.

Conclusion

The Global Alcohol Drying Molecular Sieve Market is experiencing steady growth due to the rise in the demand for high-purity alcohols along with increased advantages of the molecular sieves over other drying methods. Along these lines, technological developments towards nanoscale materials and smart monitoring systems are benefitting efficiencies and expanding the possibility for applications. Regional dynamics draw attention to Asia Pacific’s fast-moving industrialization, and North America’s adoption from a regulatory consideration. Companies are determined to invest in environmentally-friendly manufacturing and customized solutions to meet the changing needs of the industry. Capturing future opportunities in this growing market will require strategic planning and a focus on innovation.

Browse Related Reports:

Global Intimate Lingerie Market Size to Exceed USD 36.72 Billion by 2033: Forecast Analysis Report

Global Innerwear Market Size To Exceed USD 403.72 Billion by 2033: Market Insight Report

Global Product Engineering Services Market Size To Exceed USD 2213.24 Billion By 2033: Market Statistics Report

Global Odor Control System Market Size To Exceed USD 9.12 Billion By 2033: Forecast Analysis Report

Global Rhamnolipids Market Size To Exceed USD 85 Million By 2033: Market Insight Report

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?