Top 50 Companies in Smart Factory Market: Statistics Report Till 2035

RELEASE DATE: Aug 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

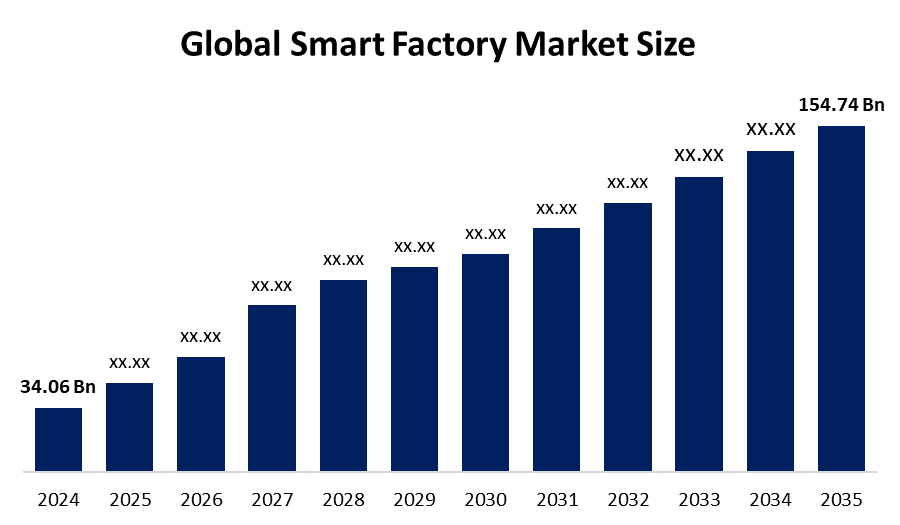

According to a research report published by Spherical Insights & Consulting, The Global Smart Factory Market Size is projected to Grow from USD 34.06 Billion in 2024 to USD 154.74 Billion by 2035, at a CAGR of 14.75% during the forecast period 2025–2035. The market for smart factory market is being driven by various factors, including increased adoption by industry, rising demand for real-time data analytics, and rising need to reduce operational costs.

Introduction

The global smart factory market encompasses the use of sophisticated manufacturing technologies such as the Internet of Things (IoT), artificial intelligence (AI), robots, and big data analytics to build highly automated, efficient, and networked manufacturing environments. Smart factories connect machines, sensors, and systems to provide real-time monitoring, predictive maintenance, and seamless communication throughout the manufacturing process, resulting in increased productivity, lower downtime, and higher product quality. The market is being driven by an increasing demand for operational efficiency, cost reduction, and agility in manufacturing processes, as industries use automation and data-driven insights to optimize production, improve supply chain management, and meet rising demand for customized products. The integration of AI and IoT technology enables manufacturers to monitor equipment performance, forecast maintenance requirements, and minimize energy usage, hence increasing adoption. Furthermore, government efforts supporting Industry 4.0, digitization, and smart manufacturing infrastructure help to drive market growth. South Korea's smart factory industry is quickly increasing as a result of strong government backing for digital transformation and extensive use of innovative technologies in the electronics, automotive, and semiconductor sectors. As businesses strive to increase competitiveness, operational resilience, and creativity, smart factories are emerging as a vital component of contemporary manufacturing, changing the future of production globally.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Smart Factory Market.

Smart Factory Market Size & Statistics

- The Market Size for Smart Factory Was Estimated to be worth USD 34.06 Billion in 2024.

- The Market is Going to Expand at a CAGR of 14.75% between 2025 and 2035.

- The Global Smart Factory Market Size is anticipated to reach USD 154.74 Billion by 2035.

- The South Korea Smart Factory Market Size is Growing at a CAGR of 7.6% from 2023 to 2033.

- North America is expected to generate the highest demand during the forecast period in the Smart Factory Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Smart Factory Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the Smart Factory market. The North American smart factory industry is quickly expanding as firms in the United States and Canada use IoT, AI, and robots to boost efficiency and competitiveness. Automotive and electronics industries are pushing substantial industrial automation throughout the area, aided by government efforts, modern infrastructure, technological knowledge, and favorable legislation.

North America is expected to generate the highest demand during the forecast period in the Smart Factory market. China, Japan, and South Korea are driving the rapid growth of the Asia Pacific smart factory market. Government initiatives such as China's "Made in China 2025" and Japan's "Society 5.0" promote advanced manufacturing technologies, increasing productivity, lowering costs, and encouraging innovation, while technological advancement and robust manufacturing infrastructure drive widespread adoption across industries.

Top 10 trends in the Smart Factory Market

- Artificial Intelligence (AI) and Machine Learning (ML)

- Industrial Internet of Things (IIoT)

- Advanced Robotics and Cobots

- Digital Twins

- 5G Integration

- Cloud and Edge Computing

- Sustainability

- Cybersecurity

- Supply Chain Optimization

- Workforce Evolution and Extended Reality (AR/VR)

1. Artificial Intelligence (AI) and Machine Learning (ML)

Artificial intelligence and machine learning are shaping smart factories by allowing predictive maintenance, process optimization, and real-time decision-making. These systems analyze massive amounts of production data to find inefficiencies, predict equipment breakdowns, and improve operations. AI and machine learning improve productivity, quality, and operational efficiency in industrial environments by minimizing downtime and optimizing resource use.

2. Industrial Internet of Things (IIoT)

IIoT links machines, sensors, and devices throughout the manufacturing floor, enabling real-time monitoring, data collection, and communication. IIoT promotes predictive maintenance, saves waste, and improves efficiency by delivering actionable insights into equipment performance, energy use, and production indicators. This integrated approach facilitates smarter decision-making and the seamless integration of production processes across businesses.

3. Advanced Robotics and Cobots

Advanced robotics and collaborative robots (cobots) are rapidly being employed in smart industries to automate repetitive activities, increase accuracy, and improve worker safety. Cobots operate with human operators to handle complicated procedures while maintaining production flexibility. The incorporation of robotics saves labor costs, enhances production speed, and allows for uniform quality, allowing efficient and scalable manufacturing processes.

4. Digital Twins

Digital twins are virtual counterparts of actual assets, processes, or systems that can be simulated, monitored, and optimized in real time. In smart factories, digital twins enable producers to test scenarios, forecast equipment problems, and improve workflows without affecting actual operations. This technology improves decision-making, lowers downtime, and promotes continual improvement and innovation in manufacturing.

5. 5G Integration

5G technology allows ultra-fast, low-latency communication throughout smart industrial systems, allowing for real-time data flow between machines, sensors, and control systems. Its high bandwidth enables sophisticated applications like as remote monitoring, augmented reality, and autonomous robots. 5G integration enhances communication and operational responsiveness, improving production efficiency, scalability, and total digital transformation in manufacturing contexts.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the smart factory market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the Smart Factory Market

- Siemens

- General Electric Company

- ABB

- Rockwell Automation

- Schneider Electric

- Honeywell International Inc.

- FANUC Corporation

- Mitsubishi Electric Corporation

- Emerson Electric Co.

- Yokogawa Electric Corporation

- Bosch Limited

- Stratasys

- TE Connectivity

- Texas Instruments Incorporated

- KUKA AG

- ABB SE

- HP Development Company, L.P.

- OMRON Corporation

- Dassault Systèmes SE

- Danfoss

- Bosch Rexroth

- Parker Hannifin

- Johnson Controls

- Bock GmbH

- Critical Manufacturing

- Others

1. Siemens

Headquarters: Munich, Germany

Siemens, a company that operates in over 200 countries, is a global leader in smart factory solutions, including sophisticated industrial automation, digital twin, and IIoT technologies. Its solutions enable firms to monitor production in real time, improve processes, and decrease downtime, hence increasing overall operational efficiency. Siemens helps businesses execute Industry 4.0 goals by combining smart manufacturing technologies across many sectors. These technologies enable data-driven decision-making, boost productivity, and increase production flexibility. Siemens positions itself as a significant participant in the worldwide smart factory industry by continuously innovating to assist manufacturers in achieving improved efficiency, cost savings, and competitiveness.

2. General Electric Company

Headquarters: Boston, Massachusetts, USA

General Electric (GE), it operates in over 180 countries, is a prominent developer of smart industrial solutions that combine IoT, AI, and predictive maintenance technology. Its platforms are intended to improve manufacturing processes by monitoring equipment performance, increasing energy efficiency, and minimizing downtime. GE's technologies provide real-time insights into production processes, enabling manufacturers to make data-driven choices, increase efficiency, and reduce costs. GE's smart factory products, widely embraced in industries such as energy, aviation, and electronics, support digital transformation projects by assisting organizations in achieving operational excellence, higher productivity, and sustainable, technology-driven manufacturing processes.

3. ABB

Headquarters: Zurich, Switzerland

ABB, based in Zurich, Switzerland, operates in more than 100 countries and is a major provider of smart manufacturing solutions. The firm focuses on robotics, automation, and Industrial Internet of Things (IIoT) technologies, which allow manufacturers to monitor operations in real time, perform predictive maintenance, and improve production processes. ABB's platforms improve productivity, flexibility, and operational efficiency by combining intelligent robots and modern control systems. ABB supports Industry 4.0 adoption by assisting manufacturers in streamlining processes, reducing downtime, and making data-driven choices, therefore generating overall performance gains and promoting the global digital transformation of industrial operations.

4. Rockwell Automation

Headquarters: Milwaukee, Wisconsin, USA

Rockwell Automation, operates in over 80 countries, is a global leader in industrial automation and IIoT-enabled smart factory solutions. Its platforms include advanced control systems, analytics tools, and linked devices that simplify manufacturing processes, improve product quality, and reduce operational downtime. Rockwell integrates these technologies, allowing manufacturers to acquire real-time information, enhance operations, and increase overall productivity. The company is instrumental in assisting organizations in implementing Industry 4.0 strategies, facilitating digital transformation, and creating intelligent, interconnected factory environments that drive productivity, operational resilience, and competitive advantage in today's rapidly changing manufacturing landscape.

5. Schneider Electric

Headquarters: Rueil-Malmaison, France

Schneider Electric, operates in more than 100 countries, is a global leader in energy management, industrial automation, and smart manufacturing solutions. Its platforms use modern technologies including the Internet of Things (IoT), digital twins, and automation systems, to optimize production processes, increase energy efficiency, and improve operational performance. Schneider Electric's real-time monitoring, predictive analytics, and intelligent control enable manufacturers to execute data-driven strategies that simplify production, decrease costs, and boost productivity. Its solutions promote sustainable and efficient manufacturing processes, allowing firms to adopt Industry 4.0 concepts while remaining competitive and promoting innovation across a wide range of industrial sectors.

Are you ready to discover more about the Smart Factory market?

The report provides an in-depth analysis of the leading companies operating in the global Smart Factory market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Siemens

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- General Electric Company

- ABB

- Rockwell Automation

- Schneider Electric

- Honeywell International Inc.

- FANUC Corporation

- Mitsubishi Electric Corporation

- Emerson Electric Co.

- Others.

Conclusion

The Global Smart Factory Market is quickly growing as businesses use new technologies like IoT, AI, robots, digital twins, and 5G to improve automation, efficiency, and production. Siemens, General Electric, ABB, Rockwell Automation, Schneider Electric, Honeywell, FANUC, and Mitsubishi Electric are among the leading providers of complete solutions for real-time monitoring, predictive maintenance, and data-driven decision-making. Governments throughout the world, notably in North America and the Asia Pacific, are supporting digital transformation projects, which will increase adoption. Smart factories are becoming increasingly important for Industry 4.0, fostering innovation and sustainable, competitive production on a global scale.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?