Top 50 Companies in Single use Assemblies Market in the World in 2025: Market Research Report (2024–2035)

RELEASE DATE: Aug 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

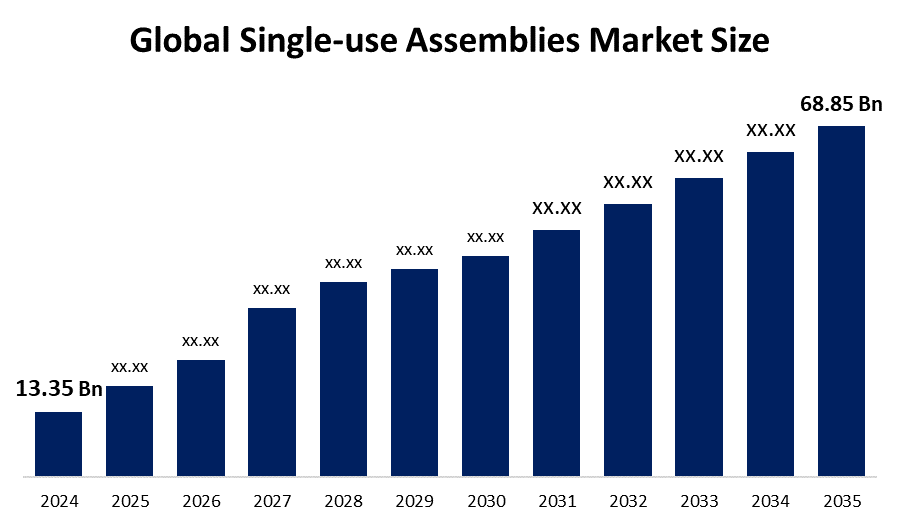

According to a research report published by Spherical Insights & Consulting, The Global Single use Assemblies Market Size is projected to Grow from USD 13.35 Billion in 2024 to USD 68.85 Billion by 2035, at a CAGR of 16.08 % during the forecast period 2025–2035. The Single use assemblies market offers future opportunities in biopharmaceutical manufacturing, personalized medicine, continuous processing, flexible production systems, and rising demand for contamination-free, cost-effective solutions in vaccine, cell therapy, and biologics production.

Introduction

The Single use assemblies market refers to the industry focused on preassembled, sterilized, and ready-to-use fluid management components used in biopharmaceutical and biotechnology manufacturing. These assemblies typically include tubing, connectors, filters, and sensors that are designed for one-time use, ensuring sterility and minimizing contamination risk. Key factors driving market growth include the rising adoption of biopharmaceuticals, increased demand for flexible and scalable manufacturing solutions, reduced cleaning validation costs, and faster production turnaround times. Additionally, the expansion of vaccine and cell therapy production, along with a growing focus on GMP compliance and reducing cross-contamination, is accelerating the shift toward Single use technologies.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights—Download the Brochure now and dive deeper into the future of the Single use assemblies market.

Single use Assemblies Market Size & Statistics

- The Market Size for Single use Assemblies was Estimated to be Worth USD 13.35 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 16.08 % between 2025 and 2035.

- The Global Single use Assemblies Market Size is Anticipated to Reach USD 68.85 Billion by 2035.

- North America is Expected to generate the highest demand during the forecast period in the Single use assemblies market.

- Asia Pacific is Expected to Grow the fastest during the forecast period in the Single use Assemblies market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the Single use assemblies market. The biopharma infrastructure within China's Single use assembly market is rapidly advancing in the Asia-Pacific region, driven by government support, the rise of local production, and the influx of international expertise. The demand for Single use assemblies is fueled by the shift from generics to biologics, the emphasis on biopharma independence, and the expansion of local CDMOs. Nevertheless, the uniformity of regulations and the sensitivity to pricing remain significant considerations.

North America is expected to generate the highest demand during the forecast period in the Single use assemblies market. Factors contributing to the North American region include the growth of the pharmaceutical and biotechnology industries, advancements in products, increasing incidences of diseases such as cancer, and funding for drug discovery research. Thanks to its 400,000-square-foot facilities valued at USD 105 million, the company can meet the increasing demand for bioprocessing materials essential for developing innovative treatments and vaccines for cancer and other diseases.

Top Key Drivers & Single use Assemblies Trends

- Rising Demand for Biopharmaceuticals and Personalized Medicine

The growing demand for biologics, vaccines, and personalized therapies is a major driver of the Single use assemblies market. Biopharmaceutical production often requires sterile, adaptable, and contamination-free environments—conditions ideally met by Single use systems. These assemblies allow faster production changes and reduce downtime between batches, which is crucial for short-run, high-value therapies. Personalized medicine also demands smaller, flexible batches, aligning perfectly with the Single use model. As more companies shift toward biologics and precision therapies, the need for cost-effective, disposable solutions that ensure process integrity and regulatory compliance continues to grow, significantly boosting adoption across bioprocessing facilities.

- Operational Efficiency and Cost Reduction

Single use assemblies enable significant cost savings by eliminating the need for cleaning, sterilization, and validation associated with traditional stainless-steel systems. This reduction in labor, water, and energy use translates into faster turnaround and lower overhead, particularly valuable for contract manufacturing organizations (CMOs) and emerging biotech firms. The modularity and ease of integration also allow for rapid process setup and scalability, enhancing flexibility across clinical and commercial production stages. As biomanufacturers aim for leaner operations and faster time-to-market, the drive for operational efficiency continues to fuel the adoption of Single use assemblies in both upstream and downstream processing.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Single use assemblies market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 5 Single use Technology Startups Impacting the Pharma Industry

1. New Horizon Biotech – Fermentors

Single use technologies have multiple benefits in pharmaceutical production, including reductions in time and costs, increases in productivity, as well as easy disposal. Single use fermentors replace the traditional steel vessels with polymer bags. These bags are customizable for each test and optimized for high oxygen mass transfer. The US-based startup New Horizon Biotech develops a patented fermentor system for flexible and cost-effective biopharmaceutical production. SUHF, short for Single use horizontal fermentor, is a pressurizable, low volume, modular, and scalable fermentor. It features a bag retention vessel, as well as agitation impellers and aerators. The fermentor is also mobile and has a flexible capacity, ranging from 50 liters to 300 liters, for production.

2. OmniBRx – Single use Assembling

With conventional bioreactors, the turnaround time between batches is high since they require cleaning and sterilization after every run. Single use assembling speeds up the process by offering sterile, ready-to-use systems, allowing biopharma startups to develop products faster. Moreover, it saves costs on chemicals by eliminating the need for cleaning and sterilization. Indian startup OmniBRx offers Single use assembling and other bioprocessing solutions. The startup provides disposable bioreactors that are run within minutes by a single worker. This allows for operational flexibility which, in turn, leads to a reduction in time-to-market and an increase in profit margins.

3. Yposkesi – Bioprocess Development

Single use fermentors and bioreactors also find applications in low-volume manufacturing. This includes pilot tests of biopharmaceuticals or the production of small batches of personalized drugs. For autologous cell therapy, where a patient’s own cells are used to treat diseases, Single use technologies offer a rapid solution for bioprocess development. Yposkesi is a French contract developer and manufacturer of gene therapies. It performs process evaluation and optimization in bioreactors with capacities of 2 liters to 10 liters. For scale-up experiments up to 200 liters, the startup uses a Single use bioreactor. The startup’s platforms further accelerate the production of adeno-associated virus (AAV) and lentiviral therapies.

4. CMAB Biopharma – Fill & Finish

In addition to production, pharma startups also use Single use technologies in other operations where sterility is absolutely vital. This includes aseptic fill & finish procedures which take a lot of time to ensure complete product sterility. Single use systems automate the fill & finish process to speed it up while reducing the variability associated with manual processing. Chinese startup CMAB BioPharma provides solutions for filling and lyophilization, as well as process development and good manufacturing practice (GMP) manufacturing. It engineers the filling equipment’s contact surfaces to be Single use. The filling process occurs in an open restricted access barrier system (oRABS) to further minimize exposure.

5. Fuelium – Paper Batteries

Startups are also exploring the use of Single use technologies for solutions in diagnostics, particularly point-of-care tests. These accelerate the development of rapid testing kits with high specificity and sensitivity. Solutions include paper batteries that facilitate the flexible production of diagnostic kits for a range of applications in pharmaceutical production and healthcare. Fuelium is a Spanish startup developing an eco-friendly power source for Single use applications. The paper-based batteries are composed of lateral flow materials and are also activated by any liquid sample. This makes them a sustainable solution for diagnostic applications for drugs, infectious disease, women’s health, and veterinary services.

Top 15 Companies Leading the Single use Assemblies Market

- Thermo Fisher Scientific, Inc.

- Intellitech, Inc.

- Merck KGaA

- Corning Incorporated

- Antylia Scientific

- KUHNER AG

- Sartorius AG

- Danaher Corporation

- Cobetter

- Entegris

- Avantor

- Lonza

- Nupore Filtration Systems

- Saint-Gobain

- Others

1. Thermo Fisher Scientific, Inc.

Headquarters: Waltham, Massachusetts, USA

Thermo Fisher Scientific is a leading global provider of life science tools, analytical instrument, specialty diagnostics, laboratory consumables, and pharmaceutical services. formed in 2006 through the merge of Thermo Electro and Thermo Fisher Scientific, The company support customers in research, clinical diagnostics, and biopharma manufacturing. Its vrands Thermo Fisher Scientific, Applied Biosystems, Invitrogen, Fisher Scientific, Unity Lab Services, Patheon, and PPD span diagnostics, genomics, drug development, and CDMO services in over 65 global locations.

2. Ingtellitec, Inc.

Headquarters: Saint Petersburg, Florida, USA

Intellitech,Inc. Specializes in precision dispensing Pump and Single use Fluid path systems for the biotech and pharmaceutical industries. Its flagship i- FILL and i-FILL Micro pumps deliver unmatched repeatability and fill accuracy for volumes from 100 mL, ideal for sensitive applications such as live cell transfer. Founded in 1995 and operating in clean room environment , Intellitech also designs and assembles custom single use system , supporting validation and testing in compliance with quality standard in bioprocessing.

3. Merck KGaA

Headquarters: Darmstadt, Germany

Merck KGaA, established in 1668, is a leading science and technology company organized as a Kommanditgesellschaft auf Aktien (KGaA). Operating through three main sectors—Healthcare, Life Science, and Electronics—the company is recognized globally for its brands, including MilliporeSigma (North America) and EMD Serono. Merck specializes in pharmaceutical innovation, diagnostics, laboratory consumables, and materials science. With a global workforce of approximately 62,000 employees, the company maintains operations in more than 65 countries.

4. Corning Incorporated

Headquarters: Corning, New York, USA

Founded in 1851, Corning Incorporated is a technology-driven manufacturer renowned for its expertise in glass, ceramics, and optical physics. The company operates across several key areas, including optical communications, display technologies, environmental solutions, specialty materials, and life sciences. Notable innovations such as Gorilla Glass, precision optical fiber, emission-control substrates, and scientific vessels have positioned Corning as a vital player across the electronics, biotechnology, automotive, and telecommunications sectors. The company employs over 56,000 people globally.

5. Antylia Scientific

Headquarters: Vernon Hills, Illinois, USA

Antylia Scientific, formerly known as Cole-Parmer, is a prominent provider of specialized laboratory and fluid-handling solutions catering to the life sciences and biopharmaceutical sectors. Established in 1955, the company supports critical applications in therapeutics, vaccine development, diagnostics, and environmental sciences. With a strong operational footprint across North America, Europe, Asia, and India, Antylia delivers precision instruments and consumables that are fundamental to global scientific and bioprocessing advancements.

Are you ready to discover more about the single-use assemblies market?

The report provides an in-depth analysis of the leading companies operating in the global single-use assemblies market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Thermo Fisher Scientific, Inc.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Intellitech, Inc.

- Merck KGaA

- Corning Incorporated

- Antylia Scientific

- KUHNER AG

- Sartorius AG

- Danaher Corporation

- Cobetter

- Entegris

- Avantor

- Lonza

- Nupore Filtration Systems

- Saint-Gobain

- Others

Conclusion

The single-use assemblies market is rapidly transforming biopharmaceutical manufacturing by offering flexible, scalable, and contamination-free solutions. With increasing adoption across biologics, vaccines, and cell therapies, these assemblies are driving operational efficiency and accelerating time-to-market. Emerging trends such as personalized medicine, continuous processing, and regulatory focus on GMP compliance are further reinforcing the shift toward disposable systems. Backed by innovation from both established leaders and agile startups, the market is positioned for sustained global growth. Companies investing in single-use technologies are poised to gain a competitive edge by meeting the evolving demands of modern bioprocessing with speed, safety, and efficiency.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?