Top 50 Companies in Selective Laser Sintering Market: Expert View By Spherical Insights

RELEASE DATE: Aug 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

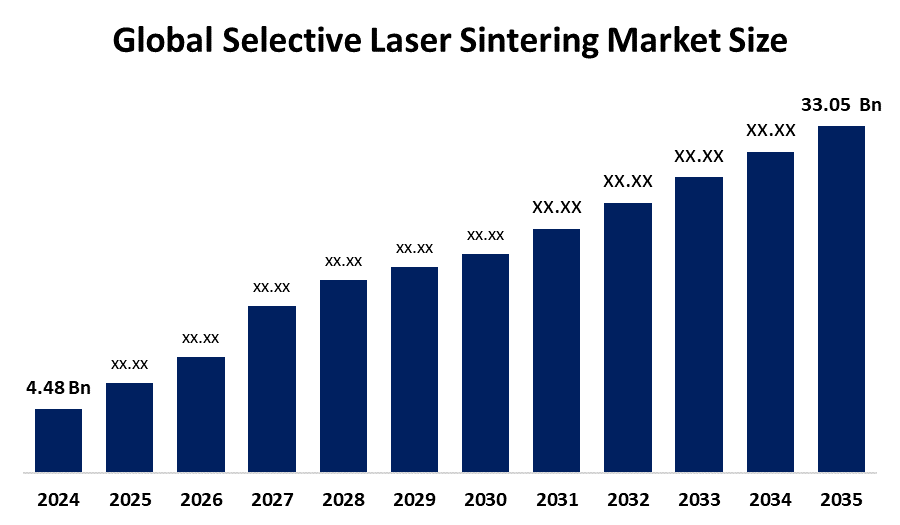

According to a research report published by Spherical Insights & Consulting, the Global Selective laser sintering Market Size is projected To Grow from USD 4.48 Billion in 2024 to USD 33.05 Billion by 2035, at a CAGR of 19.92% during the forecast period 2025–2035. One of the main factors propelling the selective laser sintering market's expansion is the growing need for SLS from the aerospace and defense industries. Selective laser sintering (SLS) makes it possible to fabricate parts with intricate geometry, and aerospace producers deal with robust, lightweight assemblies subject to stringent safety rules.

Introduction

Selective laser sintering (SLS) is an additive manufacturing (3D printing) technique where a high-powered laser fuses powdered material, typically nylon, polyamide, or metal powders, layer by layer to form solid objects based on a digital 3D model. The market for selective laser sintering is expanding as a result of various sectors' growing demand for quick prototyping and customization. When it comes to creating extremely intricate and functional pieces, this technique offers significant advantages. Selective laser sintering (SLS) is an additive manufacturing process that creates complete 3D geometries by fusing powdered materials in successive thin strands using a powerful laser. Additionally, it is appropriate for the consumer electronics, automotive, medical, and aerospace industries due to its capacity to create parts with exceptional mechanical qualities.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download The Brochure now and dive deeper into the future of the Selective Laser Sintering Market.

Selective Laser Sintering Market Size & Statistics

- The Market Size for Selective Laser Sintering Was Estimated to be worth USD 4.48 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 19.92% between 2025 and 2035.

- The Global Selective Laser Sintering Market Size is anticipated to reach USD 33.05 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Selective Laser Sintering Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Selective Laser Sintering Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the selective laser sintering market. The primary cause of this is the manufacturing sector's explosive growth. SLS and other forms of additive manufacturing are becoming more and more popular in manufacturing companies. Regional market growth is anticipated to be supported by the automotive industry's rapid expansion and rising vehicle production. Smart manufacturing and industrial automation are heavily emphasized, which creates new opportunities for SLS. The increased infrastructural investment in additive manufacturing by China, Japan, and South Korea has made it possible for SLS to be used more widely.

North America is expected to generate the highest demand during the forecast period in the selective laser sintering market. The presence of significant market competitors and the strong demand for additive manufacturing are the primary causes of this. SLS and other forms of additive manufacturing were pioneered in the area. The U.S. Department of Energy (DOE) highlighted in 2024 how North America is leading the way in the use of additive manufacturing technology, especially in the automotive, aerospace, and healthcare industries. The aerospace and automotive industries are thriving in the area. These industries have a strong requirement for lightweight components and rapid prototyping, which increases the need for SLS.

Top 10 trends in the Selective Laser Sintering Market

- Advanced multi-laser systems

- Integration of artificial intelligence (AI) and machine learning (ML) for process optimization

- Growth in use of high-performance, sustainable, and bio-based powders

- Expansion of SLS applications in aerospace, automotive, healthcare, and consumer goods

- Adoption of Industry 4.0 and smart manufacturing capabilities, such as real-time monitoring and automation.

- Shift toward zero-waste and sustainable manufacturing practices

- Development of multi-material and gradient material printing

- Increased demand for rapid prototyping and lightweight complex parts

- AI-driven predictive maintenance and automated quality control

- Emergence of decentralized and on-demand manufacturing hubs

1. Advanced multi-laser systems

The adoption of multiple lasers working in parallel dramatically speeds up the printing process while maintaining high precision. These systems enable larger build volumes, faster production, and optimized scanning strategies, which is critical for meeting industrial-scale demands in sectors such as aerospace and automotive.

2. Integration of artificial intelligence (AI) and machine learning (ML) for process optimization

AI and ML are transforming SLS by enabling real-time print parameter adjustments to improve part quality, reduce errors, and optimize material usage. These technologies offer predictive maintenance to minimize downtime and automated defect detection to ensure consistent product standards.

3. Growth in the use of high-performance, sustainable, and bio-based powders

There is a rising emphasis on eco-friendly manufacturing, leading to increased use of recyclable, bio-based, and sustainable polymer powders. These materials help reduce waste and align with environmental regulations while maintaining or enhancing part performance.

4. Expansion of SLS applications in aerospace, automotive, healthcare, and consumer goods

SLS technology is increasingly utilized for producing complex, lightweight, and high-strength parts across diverse industries. Customized implants, lightweight automotive components, and intricate aerospace parts highlight the versatility and growing industrial adoption of SLS.

5. Adoption of Industry 4.0 and smart manufacturing capabilities, such as real-time monitoring and automation

SLS systems are integrating digital solutions that enable real-time process monitoring, predictive analytics, autonomous operation, and seamless factory integration. This supports higher efficiency, traceability, and scalability, propelling SLS into mainstream production environments.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the selective laser sintering market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the Selective Laser Sintering Market

- 3D Systems Inc.

- EOS GmbH

- Farsoon Technologies

- Formlabs Inc.

- Prodways Group

- Sisma

- KEEN Group

- Sinterit

- XYZprinting

- SLM Solutions

- HP Inc. (3D Printing division)

- Stratasys Ltd.

- Renishaw plc

- 3Yourmind

- Trumpf

- Materialise

- Voxeljet

- ExOne Company

- Aurora Labs

- EnvisionTEC

- HP Multi Jet Fusion

- Ultimaker

- Mimaki Engineering

- Sandvik Additive Manufacturing

- Autodesk

1. 3D Systems Inc. — Headquarters: Rock Hill, South Carolina, USA

3D Systems is a pioneering leader in Selective laser sintering technology, offering industry-leading high-speed SLS printers known for multi-material compatibility and precision. Founded in 1986, the company is at the forefront of additive manufacturing innovation, serving aerospace, automotive, healthcare, and industrial sectors. Their SLS systems enable rapid prototyping, complex part production, and high-strength functional components, aligning with the growing demand for lightweight and customized solutions. 3D Systems emphasizes digital workflow integration, cloud-based software, and sustainability through efficient material use and recycling capabilities. With a global footprint and commitment to R&D, 3D Systems continues shaping the future of Selective laser sintering and drive industrial adoption worldwide.

2. EOS GmbH — Headquarters: Krailling, Bavaria, Germany

EOS GmbH is a global leader specializing in high-precision Selective laser sintering systems designed for demanding industrial applications. Founded in 1989, EOS provides advanced SLS printers widely used in aerospace, medical, automotive, and tooling industries. The company focuses on delivering scalable, reliable, and high-performance SLS solutions that support cost-effective production of lightweight, complex parts with superior mechanical properties. EOS integrates sustainable manufacturing principles with digital process controls and extensive material portfolios, including polymers and metals. Its strong European base and worldwide presence underpin its reputation for innovation, quality, and compliance, making EOS a key driver in advancing Selective laser sintering technology globally.

3. Farsoon Technologies — Headquarters: Changsha, Hunan, China

Farsoon Technologies is a leading provider of open-platform Selective laser sintering solutions focused on industrial customization and flexible manufacturing. Established in 2009, Farsoon is recognized for its innovative high-performance SLS machines that enable manufacturers to tailor materials, parameters, and workflows for automotive, aerospace, education, and healthcare applications. The company champions accessibility and adaptability by offering open architecture platforms, fostering rapid technology adoption and integration. Farsoon’s emphasis on automation, digital connectivity, and sustainable practices reflects evolving market demands. Its growing global footprint positions Farsoon as a prominent player driving Selective laser sintering advancements, particularly in Asia-Pacific.

4. Formlabs Inc. — Headquarters: Somerville, Massachusetts, USA

Formlabs is an innovative manufacturer known for democratizing Selective laser sintering technology through compact, cost-effective SLS printers like the Fuse series. Founded in 2011, Formlabs serves diverse sectors including engineering, manufacturing, and healthcare by providing user-friendly, high-quality additive manufacturing solutions that balance performance with accessibility. Their SLS systems emphasize precision, reliability, and material versatility, targeting small to medium enterprises and research institutions. Formlabs integrates advanced software, cloud connectivity, and sustainability initiatives focused on material reuse and waste reduction. With robust venture backing and continuous innovation, Formlabs stands as a key disruptor enabling wider adoption of Selective laser sintering technology globally.

5. Prodways Group — Headquarters: Paris, France

Prodways Group is a leading European manufacturer specializing in large-format, high-resolution Selective laser sintering printers designed for automotive, medical, and industrial applications. Founded in 2015, Prodways emphasizes integration of high-performance hardware with advanced software and materials to deliver efficient, scalable additive manufacturing solutions. Their portfolio supports production-grade part manufacturing with enhanced accuracy and speed, meeting complex geometric and mechanical demands. Prodways is committed to sustainability, leveraging energy-efficient designs and recyclable materials in its SLS systems. With a strong presence in Europe and expanding global operations, Prodways drives market growth through innovation and customer-focused solutions in Selective laser sintering technology.

Are you ready to discover more about the selective laser sintering market?

The report provides an in-depth analysis of the leading companies operating in the global selective laser sintering market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- 3D Systems Inc.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- EOS GmbH

- Farsoon Technologies

- Formlabs Inc.

- Prodways Group

- Sisma

- KEEN Group

- Sinterit

- XYZprinting

- Others.

Conclusion

The selective laser sintering (SLS) market is witnessing robust growth, driven by expanding industrial adoption across aerospace, automotive, healthcare, and consumer goods sectors. Increasing demand for complex, lightweight, and high-strength components, along with advancements such as multi-laser systems, Industry 4.0 integrations, and AI-driven process optimization, are transforming production capabilities. Sustainability is becoming a key focus through the use of recyclable, bio-based powders and energy-efficient manufacturing. While North America and Europe remain strong innovation hubs, Asia-Pacific is rapidly emerging as a major growth region due to expanding manufacturing capacity and technology adoption.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?