Top 50 Companies in Granular Molding Compound (GMC) (2025–2035): Competitive Analysis and Forecast

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

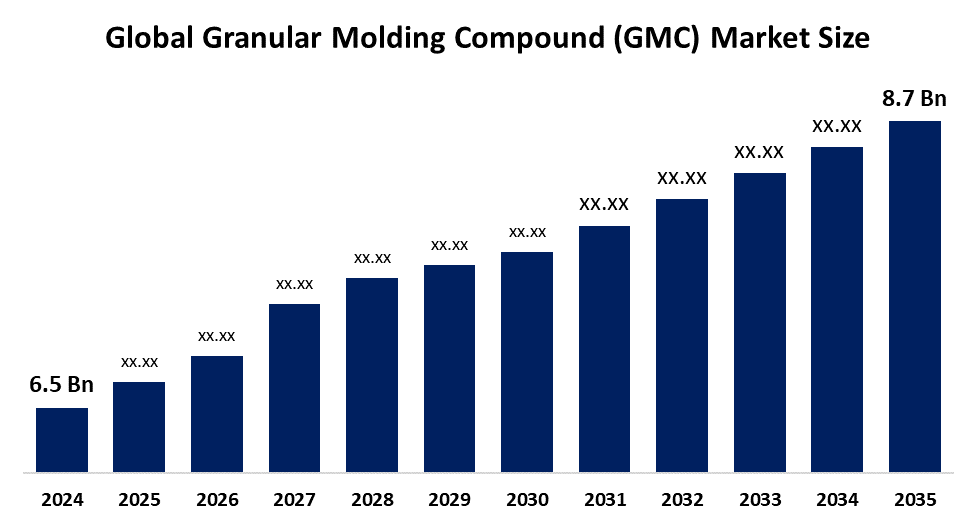

According to a research report published by Spherical Insights & Consulting, The Global Granular Molding Compound (GMC) Market Size is projected to Grow from USD 6.5 Billion in 2024 to USD 8.7 Billion by 2035, at a CAGR of 2.61% during the forecast period 2025–2035. The market for granular molding compound ((GMC)) is in greater demand as the need for electric and fuel-efficient automobiles is a major factor in the automotive industry's move towards lightweight and high-performance materials. Because of their exceptional mechanical qualities and thermal stability, (GMC)s are perfect for use in automotive applications. Furthermore, as smart technologies and Internet of Things devices proliferate, the electrical and electronics sector is expanding quickly, which is driving up demand for dependable and long-lasting parts built from (GMC)s.

Introduction

Granular molding compound ((GMC)) is a thermosetting resin-based substance that is usually made up of fillers and glass fibres as well as epoxy or phenolic resins. In order to improve energy efficiency and reduce weight, (GMC)s are being used more and more in the automotive industry for lightweight, strong, and long-lasting components, especially in electric vehicles. Because electronic equipment must be reliable and small, the electrical and electronics sector is boosting demand for (GMC)s in the production of parts like circuit breakers, connectors, and insulators. In order to meet performance and safety regulations, the aerospace sector is also implementing (GMC)s for both external and interior aircraft components. Due to factors like expanding vehicle production, fast industrialisation, and large expenditures in the electrical and electronics sector in nations like China, Japan, and India, the North America region is expected to dominate the (GMC) market on a regional level.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Granular Molding Compound (GMC) Market.

Granular Molding Compound (GMC) Market Size & Statistics

- The Market Size for Granular Molding Compound (GMC) Was Estimated to be worth USD 6.5 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 2.61% between 2025 and 2035.

- The Global Granular Molding Compound (GMC) Market Size is anticipated to reach USD 8.7 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Granular Molding Compound (GMC) Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Granular Molding Compound (GMC) Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the granular molding compound (GMC) market. The market for granular molding compound (GMC) is now growing in the Asia Pacific due to notable developments in the electrical and electronics sectors, and the growing aerospace sector is the main driver of this expansion. With significant investments in technology and infrastructure, nations like China, Japan, and India are leading the way. The adoption of (GMC)s is further accelerated by the growing requirement for strong, lightweight materials in electric vehicles as well as high-performance parts for electronics and aerospace applications. Together, these elements establish Asia Pacific as a major player in the (GMC industry.

North America is expected to generate the highest demand during the forecast period in the granular molding compound (GMC) market. The granular molding compound (GMC) market with the quickest rate of growth throughout the study period is anticipated to be in North America, due to improved vehicle performance and economy, the region's thriving automotive industry, which is represented by firms like General Motors, is progressively implementing cutting-edge materials like GMCs. Further driving the need for (GMC)s is the aerospace industry's requirement for lightweight, high-strength components. The broad use of these materials in a variety of industries is supported by technological developments and a robust North American manufacturing base. The increased desire for (GMC)s in manufacturing processes might also be attributed to the emphasis on sustainability and energy efficiency.

Top 10 trends in the Granular Molding Compound (GMC) Market

- Sustainability Focus

- Advanced Molding Technologies

- Lightweight Materials Demand

- Miniaturization in Electronics

- Regional Market Expansion

- Aerospace Applications

- Automotive Industry Growth

- Technological Collaborations

- Cost Efficiency

- Regulatory Compliance

1. Sustainability Focus

In the granular molding compound market, the emphasis on sustainability is growing as businesses look for environmentally suitable substitutes for conventional materials. Recycled materials and bio-based resins are being used by manufacturers more and more to lessen their impact on the environment. For example, to improve component performance and reduce its environmental impact, the automotive industry is integrating recyclable materials and bioplastics into GMC. This change reflects global efforts to advance the circular economy, which emphasises material reuse and recycling. Manufacturers may recycle materials without sacrificing quality by putting modern recycling methods into practice, which helps to reduce waste and conserve resources. These ecologically friendly methods are not only satisfying legal obligations but also satisfying the rising demand from customers for goods that respect the environment.

2. Advanced Molding Technologies

Granular Moulding Compound is undergoing a revolution due to advanced moulding processes that improve component precision and manufacturing efficiency. With tolerances of 10 to 100 microns and shot weights as low as 0.1 grammes, complex items can be produced using techniques like micro-injection moulding. Furthermore, conformal cooling channels, which are made to fit the mold's contours, enable consistent cooling, cutting down on cycle times and minimizing flaws. When deep reinforcement learning is included in process optimisation, it enables real-time modifications that balance profitability and product quality in a variety of scenarios. These developments not only enhance the production process but also aid in the creation of high-performance parts that are necessary for sectors like electronics, automotive, and aerospace.

3. Lightweight Materials Demand

The necessity for better fuel efficiency and performance in the automotive and aerospace industries is driving a notable trend in the granular molding compound market an increase in demand for lightweight materials. Vehicle weight is being decreased by the use of lightweight materials like composites, magnesium, and aluminium, which improves fuel economy and lowers pollutants. Lightweight materials are being used in the aerospace sector to save operational costs and increase fuel efficiency. This tendency is in line with international campaigns that support the circular economy's tenets, which place an emphasis on material reuse and recycling. Manufacturers can reduce waste and conserve resources by reusing materials without sacrificing quality through the use of sophisticated recycling processes. In addition to satisfying legal obligations, these sustainable practices are satisfying the rising demand from consumers for goods that respect the environment.

4. Miniaturization in Electronics

The market for granular molding compound is greatly impacted by the trend of electronics becoming smaller. The need for materials that can deliver great performance in smaller forms is increasing as electronic devices get smaller. (GMC)s are perfect for making a variety of electronic components, including connections, housings, and encapsulations, because of their superior electrical insulation, thermal stability, and chemical resistance. This development is especially noticeable in the semiconductor packaging industry, where the use of sophisticated moulding compounds is being driven by the need for smaller and more effective components. For example, the demand for micro-sized connectors and housings has increased due to the development of 5G infrastructure and the proliferation of smart devices. Thermoplastic micro moulding is an efficient method of producing these components.

5. Regional Market Expansion

The granular molding compound market is expanding significantly on a regional level due to a variety of variables in different regions. Strong electronics and auto manufacturing, quick industrialisation, and helpful government regulations are all credited with this dominance. Next is North America, where the automotive, aerospace, and electronics industries are showing significant demand in the United States and Canada. Europe is still somewhat present, especially in Germany and the United Kingdom, where it focuses on the automotive and manufacturing sectors. The (GMC) market is expanding as a result of investments made in the automotive and electronics sectors by nations like Brazil and Mexico, which are making Latin America the fastest-growing area. The demand for innovative materials in a variety of industries around the world is shown by this regional diversity.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the granular molding compound (GMC) market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the Granular Molding Compound (GMC) Market

- Sumitomo Bakelite Co., Ltd.

- Hitachi Chemical Co., Ltd.

- Hexion Inc.

- Huntsman Corporation

- BASF SE

- Evonik Industries AG

- Mitsubishi Chemical Corporation

- Kolon Industries Inc.

- KCC Corporation

- Chang Chun Plastics Co., Ltd.

- Plenco (Plastic Engineering Company)

- IDI Composites International

- Showa Denko K.K.

- Kyocera Chemical Corporation

- Panasonic Corporation

- Tencate Advanced Composites

- SABIC (Saudi Basic Industries Corporation)

- Toray Industries, Inc.

- Daicel Corporation

- A. Schulman, Inc.

- Others

1. Sumitomo Bakelite Co., Ltd.

Headquarters: Shinagawa, Tokyo

The headquarters of the Japanese chemical producer Sumitomo Bakelite Co., Ltd., are located in Shinagawa, Tokyo. Medical devices, semiconductor materials, and high-performance polymers are the company's areas of expertise. With an emphasis on a range of applications, such as automotive, electronics, and healthcare, it runs research labs in Kobe, Amagasaki, Kanuma, Fujieda, Utsunomiya, and Nogata. Listed on the Tokyo Stock Exchange, Sumitomo Bakelite upholds the Sumitomo Business Spirit, which places a strong emphasis on innovation and sustainability. The business is dedicated to maximising plastics' potential to create a more enjoyable society.

2. Hitachi Chemical Co., Ltd.

Headquarters: Tokyo, Japan

The Japanese chemical business Hitachi Chemical Co., Ltd., which is now Showa Denko Materials Co., Ltd., had its headquarters in Tokyo. It served sectors like automotive, electronics, and healthcare by specialising in the production of sophisticated components and functional materials. Lithium-ion battery components, semiconductor materials, display-related materials, and automotive items were among the company's varied product offerings. Enhancing the merged entity's capabilities in high-performance materials and expanding its global market presence were the goals of this strategic move. Showa Denko Materials is still focused on material science innovation and sustainability after the acquisition.

3. Hexion Inc.

Headquarters: Columbus, Ohio

The headquarters of Hexion Inc., a well-known manufacturer of specialty chemicals worldwide, is located in Columbus, Ohio. Adhesives, coatings, composites, and engineered wood materials are among the company's many products, with a focus on thermoset resins and associated technologies. Hexion offers solutions that improve sustainability and performance to a range of industries, including construction, automotive, energy, and agriculture. The two primary divisions of Hexion, the Epoxy, Phenolic, and Coating Resins Division and the Forest Products Division, are dedicated to innovation. With clients in about 60 countries, the business is present all over the world. Hexion's processes and product line demonstrate its commitment to responsible chemistry.

4. Huntsman Corporation

Headquarters: Woodlands, Texas

The headquarters of Huntsman Corporation, a multinational maker of specialty chemicals, is located in The Woodlands, Texas. In around 25 countries, the business runs more than 60 production, R&D, and operations sites. With items including polyurethanes, performance goods, and sophisticated materials, Huntsman caters to a wide range of industries, including textiles, automotive, aerospace, construction, and energy. The business is dedicated to sustainability and innovation, concentrating on creating solutions that tackle global issues, including resource efficiency and climate change. Under the ticker sign HUN, Huntsman is listed for public trading on the New York Stock Exchange.

5. BASF SE

Headquarters: Ludwigshafen, Germany

The headquarters of the well-known international chemical corporation BASF SE are located in Ludwigshafen, Germany. The largest chemical manufacturer in the world, BASF, has operations in more than 90 nations and provides a wide range of goods and services for a number of sectors, including healthcare, energy, electronics, automotive, and agriculture. Chemicals, polymers, performance goods, coatings, catalysts, and crop protection products are all part of the company's product line. BASF is dedicated to sustainability and innovation, making large R&D investments to tackle global issues including food security, resource efficiency, and climate change. BASF continues to be a key player in determining the direction of the chemical industry, with a focus on operational excellence and customer-centric solutions.

Are you ready to discover more about the granular molding compound (GMC) market?

The report provides an in-depth analysis of the leading companies operating in the global granular molding compound (GMC) market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Sumitomo Bakelite Co., Ltd.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Hitachi Chemical Co., Ltd.

- HEXION INC.

- Huntsman Corporation

- BASF SE

- Evonik Industries AG

- Mitsubishi Chemical Corporation

- Kolon Industries Inc.

- KCC Corporation

- Chang Chun Plastics Co., Ltd.

- Plenco (Plastic Engineering Company)

- IDI Composites International

- Showa Denko K.K.

- Kyocera Chemical Corporation

- Panasonic Corporation

- Tencate Advanced Composites

- SABIC (Saudi Basic Industries Corporation)

- Toray Industries, Inc.

- Daicel Corporation

- A. Schulman, Inc.

- Others

Conclusion

The Granular Molding Compound (GMC) Market Size is accelerating due to the growing need for lightweight, high-performance materials in the automotive and aerospace industries, particularly with the transition to electric automobiles and fuel-efficient aeroplanes. This presents substantial development prospects for the granular molding compound market. Furthermore, the requirement for dependable, compact components is growing as the electrical and electronics sector expands due to smart technologies and Internet of Things devices. By spending money on R&D to enhance (GMC) features and uses, market participants can take advantage of these trends.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?