Top 50 Companies in Carbon Fiber Prepreg 2025 Watchlist: Statistical Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

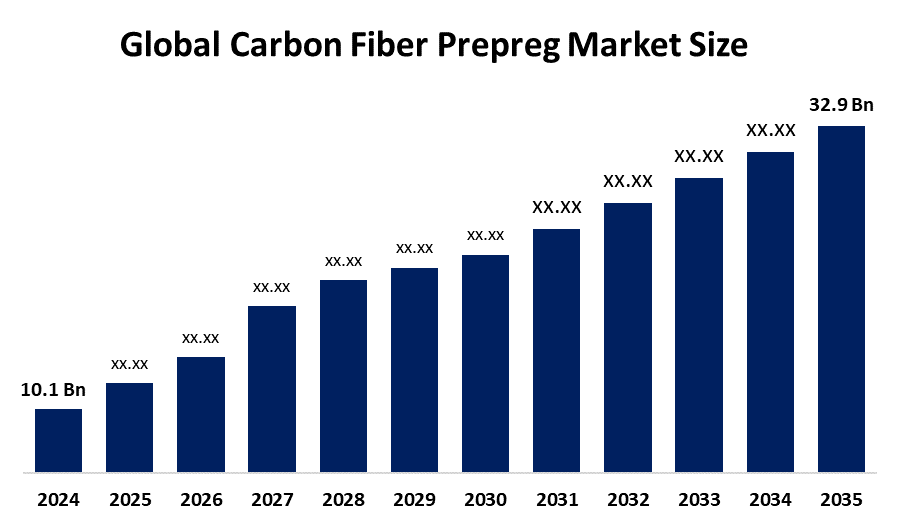

According to a research report published by Spherical Insights & Consulting,The Global Carbon Fiber Prepreg Market Size is projected to Grow from USD 10.1 Billion in 2024 to USD 32.9 Billion by 2035, at a CAGR of 11.33% during the forecast period 2025–2035. The market for carbon fiber prepreg is in greater demand because of its remarkable strength-to-weight ratio; they are particularly important in fields like electric vehicles, aircraft, and defense, where lighter constructions improve performance and efficiency. Another promising growth path is wind energy, which uses prepregs to create longer, more dependable turbine blades that increase energy output.

Introduction

Carbon fibre prepreg is a composite intermediate material made by pre-impregnating reinforcing carbon fibres in forms such as woven textiles or unidirectional tapes using a partially cured ("B-stage") resin matrix, typically thermosetting resins like epoxy. High-strength carbon fibres in the form of textiles or unidirectional tapes are pre-impregnated with a resin system, typically a thermoset resin like epoxy, that is partially cured ("B-stage"). This process creates carbon fibre prepreg, a composite material. After being soaked in resin, this reinforcing material is placed into moulds and heated and compressed to solidify into components that are strong, lightweight, and long-lasting. Compared to wet lay-up techniques, prepregs provide homogeneous mechanical qualities, fewer flaws such as dry spots or voids, and good strength-to-weight ratios since the resin content and fibre orientation are predetermined. Prepreg is perfect for applications in high-performance industries like aerospace, automotive, sports, and defence because of its remarkable fatigue resistance, rigidity, corrosion resistance, and design flexibility.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Carbon Fiber Prepreg Market.

Carbon Fiber Prepreg Market Size & Statistics

- The Market Size for Carbon Fiber Prepreg Was Estimated to be worth USD 10.1 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 11.33% between 2025 and 2035.

- The Global Carbon Fiber Prepreg Market Size is anticipated to reach USD 32.9 Billion by 2035.

- Europe is expected to generate the highest demand during the forecast period in the Carbon Fiber Prepreg Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Carbon Fiber Prepreg Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the carbon fiber prepreg market. The market for carbon fiber prepreg is now growing in the Asia Pacific due to the increasing need for lightweight, high-performance materials is increasing due to rapid industrialisation and the growth of the automotive and aerospace sectors, particularly EVs. Use is further increased by wind energy projects because turbine blades benefit from strength and rigidity. Increasing regional supply chains and local producers aid in more effectively meeting demand. Additionally, the robust market for sporting goods like bikes, golf clubs, and rackets reinforces the region's dominance.

Europe is expected to generate the highest demand during the forecast period in the carbon fiber prepreg market. The carbon fiber prepreg market with the quickest rate of growth throughout the study period is anticipated to be in Europe. Airbus and other firms want lightweight prep regs for fuel-efficient airframes, which are important drivers. The rise in wind energy, particularly offshore turbines, has also increased the demand for carbon prepregs for blades that need to be extremely strong and long-lasting. Regulations in Europe also promote environmental sustainability by encouraging the use of materials that enhance performance and reduce emissions. Despite the rapid growth of regions such as the Asia Pacific and North America, Europe is anticipated to continue to have a dominant position throughout the projected period

Top 10 trends in the Carbon Fiber Prepreg Market

- Lightweighting in EVs and Aerospace

- Wind Energy Sector Expansion

- Epoxy and Advanced Resin Systems

- Out-of-Autoclave and Alternative Curing Processes

- Sustainability & Eco-Friendly Materials

- Automation & Precision Manufacturing

- Customized and Hybrid Composites

- Growth in Sports, Marine, and High-Performance Applications

- Regulatory & Emissions Pressures

- Supply Chain & Cost Challenges

1. Lightweighting in EVs and Aerospace

Carbon fibre prepregs are being used more and more in aerospace and electric vehicle applications to reduce weight significantly and improve performance and energy efficiency. Carbon fibre prepregs' excellent strength-to-weight ratio helps EV components, including battery enclosures and structural elements, which enhances safety and extends driving range. To prevent thermal runaway and meet crash safety regulations, the battery shell of Tesla's Cybertruck, for example, uses multi-layered prepreg composites.

2. Wind Energy Sector Expansion

The need for carbon fibre prepregs is being driven by the growth of the wind energy industry, especially in the production of longer and more efficient turbine blades. Lightweight yet robust materials are essential as wind turbines get bigger to improve energy extraction. Because of their exceptional strength-to-weight ratio, carbon fibre prepregs are perfect for creating blades longer than 100 meters. The capacity for wind energy has been growing quickly worldwide, and forecasts suggest that this growth will continue. In order to guarantee the manufacturing of high-performance turbine blades that can resist the dynamic loads imposed by wind and other climatic conditions, this expansion is increasing the demand for sophisticated composite materials like carbon fibre prepregs.

3. Epoxy and Advanced Resin Systems

The market for carbon fibre prepreg is still dominated by epoxy resins. They are widely used because of their remarkable mechanical qualities, which include high strength-to-weight ratios, outstanding bonding ability, and outstanding resistance to chemicals and moisture. Epoxy-based prepregs are perfect for demanding applications in the wind energy, automotive, and aerospace industries because of these qualities. For example, the aircraft sector is the target market for Solvay's MTM 348FR epoxy prepreg, which offers enhanced performance and fire resistance. Additionally, sustainability is a key emphasis of resin system improvements, as evidenced by the creation of bio-based epoxy resins that preserve mechanical performance while lessening their environmental impact. The composites industry's material development is changing as a result of these advancements, in line with expanding environmental laws and business sustainability objectives.

4. Out-of-Autoclave and Alternative Curing Processes

The production of carbon fibre prepreg is being revolutionised by out-of-autoclave and alternative curing techniques, which lower prices and increased flexibility. OOA techniques cure composites using hoover bags, heat, and pressure inside a closed mould, as opposed to standard autoclave processes, which call for high temperatures and pressures. With this method, costly autoclave equipment is not required, and lower curing temperatures are possible. Fibermax's C242T2pp prepreg, for instance, delivers a glass transition temperature of 120-125C and a gel time of 7-8 minutes at 125C, making it ideal for OOA curing. Graphene nanoplatelet epoxy composites that are electrically conductive allow for curing by Joule heating, which is an advancement in alternative curing techniques. This method creates localised heat during curing by using the electrical conductivity of GNPs to decrease microvoids and improve mechanical characteristics.

4. Sustainability & Eco-Friendly Materials

The market for carbon fibre prepreg is being greatly impacted by the drive towards sustainability and environmentally friendly products. Bio-based epoxy resins made from renewable resources like cashew nut shells and lignin are being used by manufacturers more and more. These bio-based resins lessen the carbon footprint of composite materials while also reducing dependency on petrochemicals. For example, within 18 months of its launch, a European company gained 22% of the maritime application market with a prepreg supplemented with flax fibre that had 40% less embodied carbon. Closed-loop recycling is also becoming possible due to developments in recyclable epoxy systems; tests on automobile composite parts have shown a 92% material recovery efficiency. These developments put eco-friendly materials at the forefront of the changing carbon fibre prepreg sector, satisfying both customer demand for sustainable products and regulatory requirements.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the carbon fiber prepreg market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Carbon Fiber Prepreg Market

- SGL Carbon

- Solvay

- Hexcel Corporation

- Axiom Materials

- Park Electrochemical Corporation

- Teijin Limited

- Airtech Advanced Materials Group

- Toray Industries

- Mitsubishi Rayon Co. Ltd.

- TCR Composites

- Gurit Holding AG

- Park Aerospace Corp

- ZOLTEK Group

- Royal TenCate N.V.

- Weihai Guangwei Composite Materials

- Sichuan Tianyi Composites Co., Ltd.

- Others

1. SGL Carbon

Headquarters: Wiesbaden, Germany

SGL Carbon SE is a major worldwide supplier of carbon-based products and solutions, with its main office located in Wiesbaden, Germany. Its offering includes carbon fibres, composites, and specialty graphite that are suited for industries like industrial production, semiconductors, solar and wind energy, aircraft, and chemical processing. The company's four main business units, Graphite Solutions, Process Technology, Carbon Fibres, and Composite Solutions, cover the whole value chain, from fibre precursors and raw graphite materials to completed composite components. When it comes to friction materials, heat exchangers, carbon-ceramic braking systems, and lightweight structural composites for mobility and renewable energy applications, SGL Carbon works directly with clients to provide customised solutions that require high strength, stiffness, and material expertise.

2. Solvay

Headquarters: Brussels, Belgium

The advanced materials and specialty chemicals company Solvay is well-known for its advancements in prepreg materials, high-performance resin systems, and lightweight composites. For high-demand industries like aerospace, automotive, and renewable energy, its Composite Materials business section provides goods including prepregs, adhesives, surface films, textiles, tools, and hoover bagging consumables. In order to improve cost-performance in major aerospace structures, one of its partnerships with SGL Carbon is to provide composite solutions based on large-tow intermediate modulus carbon fibre combined with Solvay's resin systems. To expand its material offering, Solvay also develops new thermoplastic and bio-based composite materials, including CF, polyamide, and polyphenylene sulphide systems.

3. HEXCEL CORPORATION

Headquarters: Connecticut, United States

Hexcel is a top provider of innovative composites, primarily serving the industrial, defence, and aerospace industries with its structural materials and systems. Its product line consists of moulded composite parts, prepregs, honeycomb core materials, carbon fibres, speciality reinforcements, adhesives, and engineered structures. Fiber-reinforced matrix materials, laminates, and resins are the main focus of its Composite Materials section, while its Engineered Products segment provides finished or semi-finished parts for rotorcraft blades, nacelles, aircraft structures, fairings, and other applications. Serving major aerospace OEMs, Hexcel operates globally through a vast network that spans Europe, Asia-Pacific, and the Americas.

4. Axiom Materials

Headquarters: California, USA

Advanced composites and specialty materials company Axiom Materials offers a wide range of products, such as honeycomb core materials, adhesive film, paste, and tooling adhesives, auxiliary composites, and composite prepregs, carbon, fibreglass, and ceramic matrix composites. With resin systems that include epoxy, phenolic, bismaleimide, polyimide, cyanate ester, and others, their prepregs are designed for demanding applications. The business is quality-certified and operates worldwide in a variety of fields, including the energy, sports, medical, automotive, aerospace, and defence sectors. Oxide-Oxide ceramic matrix composite prepregs that can endure high continuous temperatures and generate both woven fabrics and unidirectional tape format are two of Axiom's most notable products.

5. Park Electrochemical Corporation

Headquarters: New York, United States

Serving the electronics, aerospace, telecommunications, high-speed computer, and defence industries, Park Aerospace is an expert in innovative materials. Its product lines include innovative composite materials, digital and microwave printed circuit materials, and lightweight aerospace and general aviation structures and assemblies. Polymer chemistry, coating technology, and composite design are the company's technological strong points. These areas are appropriate for demanding applications, including high-frequency electronics, radomes, aircraft components, toolings, and assembly. The company has focused on its aerospace product lines, such as prepregs, adhesives, and composite parts for primary and secondary aircraft structures, since changing its name to Park Aerospace.

Are you ready to discover more about the carbon fiber prepreg market?

The report provides an in-depth analysis of the leading companies operating in the global carbon fiber prepreg market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- SGL Carbon

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Solvay

- HEXCEL CORPORATION

- Axiom Materials

- Park Electrochemical Corporation

- JDA Software

- Epicor Software Corporation

- TECSYS

- Made4net

- Others

Conclusion

The carbon fiber prepreg market is accelerating because it is using carbon fiber prepregs more and more to lighten aeroplane parts, which reduces emissions and increases fuel efficiency. Prefabricated materials are used in the automobile industry to reduce weight, increase range, and meet higher pollution rules, particularly in EVs and high-performance cars. Carbon fiber's strength-to-weight ratio and fatigue resistance make wind turbine blades ideal for renewable energy sources because they allow for larger, more effective blades that improve energy extraction. Carbon fibre prepregs are becoming more and more important as these industries' need for strong, lightweight materials increases.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?