Top 40 Global Companies in PTFE Membrane Structure Design Market 2025: Strategic Overview and Future Trends (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

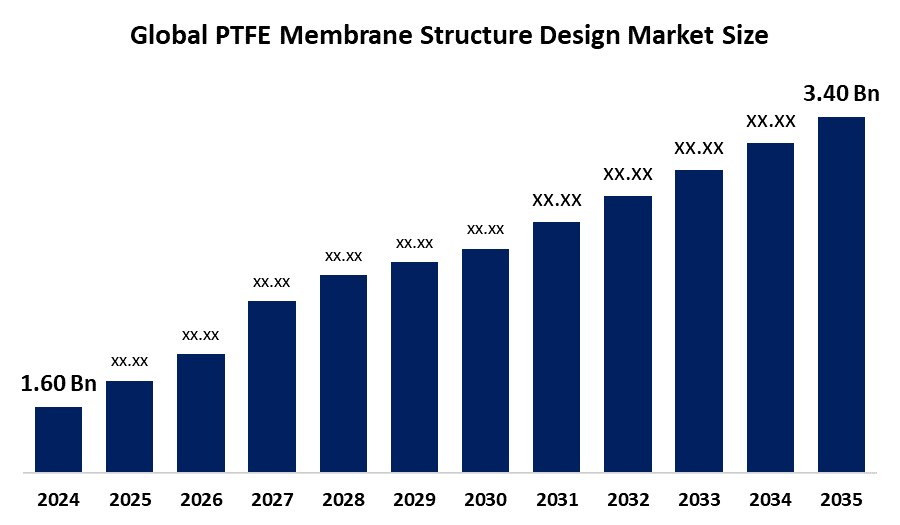

According to a research report published by Spherical Insights & Consulting, The Global PTFE Membrane Structure Design Market Size is projected To Grow from USD 1.60 Billion in 2024 to USD 3.40 Billion by 2035, at a CAGR of 7.09% during the forecast period 2025–2035. This expansion is driven by increasing demand across various sectors, including healthcare, water and wastewater management, and electronics. A key factor driving growth in the PTFE membrane structure design market is the increasing need for effective and dependable filtration systems. Industries worldwide are placing greater emphasis on maintaining high levels of purity and cleanliness, particularly in sectors such as pharmaceuticals, food and beverage, and water treatment.

Introduction

The Worldwide PTFE Membrane Structure Design Market Size pertains to the specialized area engaged in the creation, production, and utilization of polytetrafluoroethylene (PTFE) membranes primarily employed in architectural and industrial frameworks. PTFE membranes are advanced polymer materials valued for their strength, resistance to chemicals, UV stability, thermal endurance, lightweight design, and self-cleaning abilities. These traits render PTFE membranes perfect for constructing tensile structures like roofs, facades, canopies, stadiums, airports, exhibition areas, and various large public and commercial buildings. The industry includes the design and engineering of membrane structures, which are appreciated for their capacity to create expansive, unobstructed areas without columns, along with aesthetic charm and practical advantages such as energy efficiency, sustainability, lower maintenance expenses, and adherence to environmental and fire safety standards. Increasing urbanization, eco-friendly construction efforts, and the need for cutting-edge infrastructure are primary factors broadening the use of PTFE membrane systems.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the PTFE Membrane Structure Design Market.

PTFE Membrane Structure Design Market Size & Statistics

- The Market Size for PTFE Membrane Structure Design Was Estimated to be worth USD 1.60 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 7.09% between 2025 and 2035.

- The Global PTFE Membrane Structure Design Market Size is anticipated to reach USD 3.40 Billion by 2035.

- Asia Pacific is anticipated to generate the highest demand over the forecast period in The PTFE Membrane Structure Design Market.

- North America is projected to grow at the fastest CAGR during the forecast period in The PTFE Membrane Structure Design Market.

Regional growth and demand

North America is predicated to grow the fastest during the forecast period in the PTFE membrane structure design market.

Primary factors consist of growing environmental sustainability regulations, fire safety guidelines, governmental incentives for green construction, and technological progress enhancing membrane efficiency and affordability, which propelled the regional market expansion. Further, primary uses include tensile constructions like roofs and façades, stadiums, airports, industrial buildings, and various large-scale infrastructure initiatives. Moreover, domestic demand in metropolitan regions and coastal states, particularly in California, Texas, and New York, is notable due to substantial infrastructural investments, shaping the market's characteristics. Further, top companies focus on research and development, forming partnerships, and adhering to changing regulations to preserve their competitive edge.

Asia Pacific is estimated to generate the highest share during the forecast period in the PTFE membrane structure design market.

The Asia Pacific market is set for significant expansion, fueled by swift industrialization, urban growth, and rising investments in infrastructure. Countries like China, India, and Japan are experiencing substantial progress in their manufacturing and healthcare industries, which are major users of PTFE membranes. Moreover, the growing awareness of environmental protection and strict regulations on waste management in these nations are anticipated to drive the demand for PTFE membrane technologies.

Top 10 Trends in the PTFE Membrane Structure Design Market

- Sustainability and Energy Efficiency

- High-Performance and Multi-functional Coatings

- Expansion into Diverse Application

- Customization and Complex Geometries

- Integration with Smart Technologies

- Hybrid Structures

- Global Infrastructure Development

- Focus on Durability and Longevity

- Increased Cost-Effectiveness

- Stringent Safety Regulations and Fire Resistance

1. Sustainability and Energy Efficiency

This is a significant factor. PTFE membrane systems are very sustainable because of their extended lifespan (over 25 years), low maintenance requirements, and capacity to decrease a building's energy usage. Their elevated solar reflectivity and transparency facilitate considerable natural light passage, decreasing the reliance on artificial lighting and lowering the cooling expenses of a building.

2. High-Performance and Multi-functional Coatings

Producers are creating cutting-edge coatings that improve the function of the membranes. This encompasses photocatalytic coatings that utilize sunlight to decompose pollutants such as nitrogen oxides (NOx) and sulfur dioxide (SOx), along with self-cleaning features that ensure the material remains bright white without frequent upkeep.

3. Expansion into Diverse Application

PTFE membranes are recognized for their utilization in sports arenas and airport terminals, but their use is broadening into additional sectors. This encompasses building facades, parking structure canopies, industrial rooftops, and atrium coverings in retail malls and business centers. The durability and visual attractiveness of the material render it a flexble option for various projects.

4. Customization and Complex Geometries

Improvements in computer modeling and manufacturing methods enable architects and engineers to create intricate, three-dimensional, free-form designs that were once unachievable with conventional construction materials. The tensile strength and flexibility of PTFE fabric offer a significant level of design versatility and personalization.

5. Stringent Safety Regulations and Fire Resistance

The market is influenced by rigorous safety and construction regulations. Fiberglass fabrics coated with PTFE are naturally non-flammable and possess a high melting temperature, rendering them among the safest materials for application in expansive public areas. This feature is a crucial selling advantage in a market that prioritizes fire safety.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the PTFE membrane structure design market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the PTFE Membrane Structure Design Market

- Saint-Gobain Performance Plastics Corporation

- W. L. Gore & Associates, Inc.

- Donaldson Company, Inc.

- Merck Millipore

- General Electric Company

- Pall Corporation

- Sartorius AG

- Layne Christensen Company

- Markel Corporation

- Zeus Industrial Products, Inc.

- Hyundai Micro Co., Ltd.

- Chukoh Chemical Industries, Ltd.

- Nitto Denko Corporation

- Sumitomo Electric Fine Polymer, Inc.

- Porex Corporation

- Membrane Solutions LLC

- Cobetter Filtration Equipment Co., Ltd.

- Hangzhou Anow Microfiltration Co., Ltd.

- Lydall, Inc.

- Filtration Group Corporation

1. Saint-Gobain Performance Plastics Corporation

Headquarters: Ohio, United States

Saint-Gobain Performance Plastics is a significant and direct participant in the PTFE membrane structure design industry, mainly via its Sheerfill Architectural Membrane brand. In contrast to firms that create and build the finished constructions, Saint-Gobain functions as a specialized supplier and manufacturer of materials. It supplies the essential fabric material utilized by architects, engineers, and fabricators for constructing large-scale tensile membrane structures. A major value proposition of Sheerfill is its established, long-lasting durability. It is built to endure for 25 years or longer without requiring re-tensioning or replacement, greatly lowering maintenance expenses in comparison to alternative roofing materials.

2. W. L. Gore & Associates, Inc.

Headquarters: Newark, USA

W. L. Gore & Associates, Inc. is an international materials science firm focused on fluoropolymers, particularly Polytetrafluoroethylene (PTFE). The firm is most recognized for its GORE TEX materials. Gore plays a significant and indirect role in the design market for PTFE membrane structures. Its business strategy in this field involves producing and providing the high-performance ePTFE (expanded PTFE) membrane material utilized by architects and builders to construct physical structures. Gore collaborates with its clients to supply materials possessing particular characteristics, like a durable thread crafted from GORE TENARA Architectural Fabric.

3. Donaldson Company, Inc.

Headquarters: Bloomington, United States

Donaldson Company, Inc. is a significant and direct participant in the PTFE membrane market, yet its involvement is primarily centered on the filtration and industrial sectors, rather than architectural structure design. The firm produces and provides advanced PTFE membranes for a range of industrial uses. Donaldson is a premier worldwide producer of Tetratex, its line of expanded microporous PTFE (ePTFE) membranes, films, and laminates. These substances are designed for high flow rates, remarkable chemical resistance, and the capability to filter fine particles and microorganisms.

4. Merck Millipore

Headquarters: Burlington, United States

Merck Millipore, currently a brand under Merck KGaA, is a significant and direct participant in the PTFE membrane industry, but it is important to specify its involvement: the firm's focus is on filtration and life science applications, rather than on large-scale architectural design. This is the main market of the company, with the Fluoropore and Omnipore brands of PTFE membranes are utilized in laboratory environments for diverse applications. Additionally, the company's PTFE membranes are employed in multiple industrial filtration processes that demand outstanding chemical resistance and high temperature durability.

5. Pall Corporation

Headquarters: Port Washington, New York, USA

Pall's proficiency in PTFE membrane technology focuses on its capability to regulate pore size and material characteristics for essential filtration requirements. The Emflon Series and Tetrafluor Membranes represent the two product lines. This is a recognized group of Pall's PTFE filter membranes. These items are employed for sterile filtration of gases and liquids in sectors like pharmaceuticals, food and drink, and microelectronics.

Are you ready to discover more about the PTFE membrane structure design market?

The report provides an in-depth analysis of the leading companies operating in the global PTFE membrane structure design market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Saint-Gobain Performance Plastics Corporation

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- W. L. Gore & Associates, Inc.

- Donaldson Company, Inc.

- Merck Millipore

- General Electric Company

- Pall Corporation

- Sartorius AG

- Layne Christensen Company

- Markel Corporation

- Zeus Industrial Products, Inc.

- Hyundai Micro Co., Ltd.

- Chukoh Chemical Industries, Ltd.

- Nitto Denko Corporation

- Sumitomo Electric Fine Polymer, Inc.

- Porex Corporation

- Membrane Solutions LLC

- Cobetter Filtration Equipment Co., Ltd.

- Hangzhou Anow Microfiltration Co., Ltd.

- Lydall, Inc.

- Filtration Group Corporation

- Others

Conclusion

The Global PTFE Membrane Structure Design Market Size is set for significant expansion, growing from USD 1.60 Billion in 2024 to an anticipated USD 3.40 Billion by 2035, with a CAGR of 7.09%. This expansion is supported by increasing demand in various industries like healthcare, water management, and electronics, where strict standards for purity and filtration efficacy propel the use of PTFE membranes. The markets growth is additionally fueled by rising urbanization, eco-friendly construction projects, and technological progress that facilitates the creation of sustainable, long-lasting, and visually attractive large-scale buildings. Major trends influencing the market encompass sustainability and energy efficiency multifunctional coatings, and integration with intelligent technologies. In terms of demand, the Asia Pacific region is at the forefront, propelled by industrial growth and infrastructure spending, whereas North America experiences the quickest growth, supported by regulations and ongoing infrastructure initiatives. Top companies such as Saint-Gobain Performance Plastics, W.L. Gore & Associates, and Donaldson Company concentrate heavily on R&D, product innovation, and more.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?