Top 30 Glassy Carbon Coating Graphite Companies in Globe 2025: Statistics View by Spherical Insights and Consulting

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

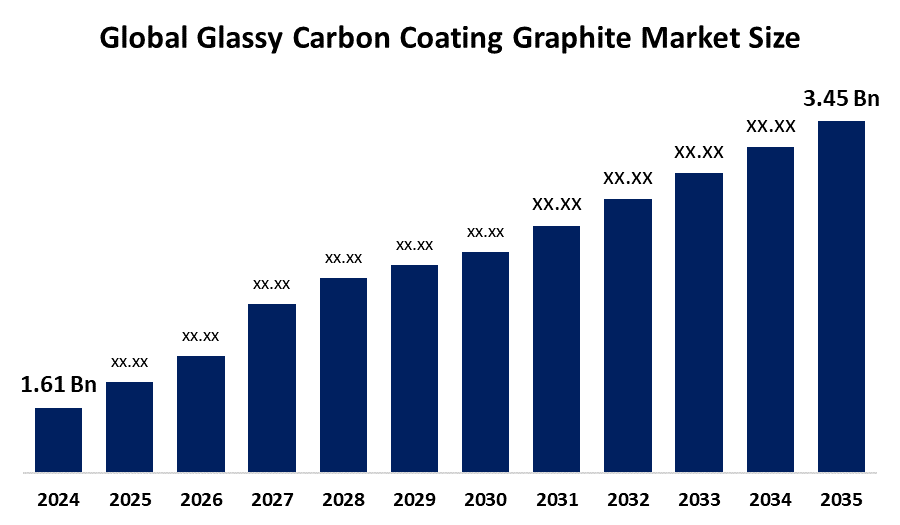

According to a research report published by Spherical Insights & Consulting, The Global Glassy Carbon Coating Graphite Market Size is projected to Grow from USD 1.61 Billion in 2024 to USD 3.45 Billion by 2035, at a CAGR of 7.17 % during the forecast period 2025–2035. Opportunities include expanded use in battery bipolar plates, corrosion-resistant coatings for chemical equipment, high-temperature aerospace components, electrochemical sensors, fuel cells, wear-resistant tooling, additive manufacturing integration, and sustainable electrode development applications.

Introduction

The Glassy Carbon Coating Graphite Market Size is gaining momentum due to its exceptional chemical inertness, thermal stability, electrical conductivity, and corrosion resistance. Glassy carbon coatings enhance the durability and performance of graphite components used in batteries, fuel cells, semiconductor manufacturing, and high-temperature industrial processes. Increasing demand for advanced materials in energy storage, aerospace, and electronics sectors is driving market growth. Moreover, advancements in coating technologies, such as chemical vapor deposition (CVD) and plasma coating, are improving coating uniformity and adhesion. As industries move toward sustainable and high-performance materials, glassy carbon-coated graphite is emerging as a critical solution for modern applications.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Glassy Carbon Coating Graphite market.

Glassy Carbon Coating Graphite Market Size & Statistics

- The Market Size for Glassy Carbon Coating Graphite Was Estimated to be Worth USD 1.61 Billion in 2024.

- The Market Size is going to Expand at a CAGR of 7.17 % Between 2025 and 2035.

- The Global Glassy Carbon Coating Graphite Market Size is Anticipated to Reach USD 3.45 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Glassy Carbon Coating Graphite market.

- North America is expected to grow the fastest during the forecast period in the Glassy Carbon Coating Graphite market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Glassy Carbon Coating Graphite market. North America is expected to grow the fastest due to advanced semiconductor manufacturing, strong R&D investments, adoption of high-precision coating technologies, rising demand for energy storage and electronic devices, and stringent quality standards driving glassy carbon-coated graphite usage.

Asia Pacific is expected to generate the highest demand during the forecast period in the Glassy Carbon Coating Graphite market. This growth is primarily driven by the rapid expansion of the semiconductor industry in countries like China, Japan, and South Korea. These nations are major players in electronics manufacturing, where glassy carbon-coated graphite is utilized in semiconductor processes such as chemical vapor deposition (CVD) and plasma etching.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Glassy Carbon Coating Graphite market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 5 Trends in Glassy Carbon Coating Graphite Market

1. Rising Adoption in Energy Storage Applications

Glassy carbon-coated graphite is increasingly used in lithium-ion and next-generation batteries due to its high conductivity, chemical stability, and corrosion resistance. Battery manufacturers are leveraging GCCG to enhance electrode performance, extend cycle life, and improve energy density. The growth in electric vehicles, renewable energy storage, and consumer electronics is driving demand. Additionally, GCCG helps prevent degradation in high-temperature and high-voltage applications, ensuring safer and more efficient energy storage solutions. The trend emphasizes the role of advanced carbon materials in meeting global energy transition and electrification goals.

2. Expansion in Semiconductor and Electronics Industries

GCCG is finding growing use in semiconductor manufacturing and electronic components due to its precision, durability, and chemical inertness. The material serves in electrodes, crucibles, and high-performance coatings where thermal and electrical stability is critical. Rising demand for miniaturized devices, high-performance chips, and advanced electronics drives the adoption of glassy carbon coatings. The trend is further accelerated by the ongoing global electronics boom, requiring materials that can withstand high temperatures and corrosive processes. Manufacturers are innovating coating techniques to ensure uniformity, reliability, and long-term performance in semiconductor and electronic applications.

3. Technological Advancements in Coating Processes

Innovations in deposition and coating technologies are improving the performance and scalability of glassy carbon coatings. Techniques such as chemical vapor deposition (CVD), pyrolytic carbonization, and advanced surface treatments enhance adhesion, uniformity, and corrosion resistance. These advancements allow manufacturers to produce high-quality GCCG for precision applications in energy storage, electronics, and industrial sectors. Improved process control reduces defects, increases yield, and lowers production costs. Continuous R&D in material engineering and coating technologies is expanding GCCG applications, enabling tailored properties for specific industrial, chemical, and high-temperature environments.

4. Focus on Sustainability and Environmental Compliance

The GCCG market is aligning with global sustainability initiatives, as glassy carbon coatings extend the lifespan of graphite products and reduce material waste. Manufacturers are optimizing processes to minimize energy consumption and chemical emissions during production. Recyclable and long-lasting coated materials contribute to circular economy practices in electronics, energy, and industrial applications. Regulatory pressures on environmental compliance and carbon footprint reduction are motivating the adoption of eco-friendly and efficient glassy carbon solutions. The trend demonstrates the increasing importance of sustainable material engineering in high-performance applications while maintaining industrial and technological competitiveness.

5. Growth in Industrial and Chemical Applications

GCCG is increasingly used in harsh chemical, high-temperature, and corrosive environments across various industrial sectors, including metallurgy, chemical reactors, and crucibles. Its stability, thermal conductivity, and inertness make it ideal for applications requiring resistance to oxidation, acids, and extreme temperatures. Industries are investing in coated graphite solutions to improve process efficiency, reduce maintenance, and ensure operational safety. The trend highlights the rising importance of advanced carbon materials in industrial innovation, enabling reliable performance in demanding environments while supporting enhanced productivity, reduced downtime, and cost-effective operations across global industrial applications.

Top 20 Companies Leading the Glassy Carbon Coating Graphite Market

- Tokai Carbon Co., Ltd.

- Mersen Group

- SGL Carbon SE

- Schunk Carbon Technology

- Nippon Carbon Co., Ltd.

- GrafTech International Ltd.

- Morgan Advanced Materials

- Ibiden Co., Ltd.

- Toyotanso Co., Ltd.

- HEG Limited

- SEC Carbon, Ltd.

- Graphite India Limited

- Orion Engineered Carbons

- Asbury Carbons

- Cova Carbon & Graphite

- Carbone Lorraine

- Toyo Tanso Co., Ltd.

- Entegris, Inc.

- Poco Graphite, Inc.

- Bay Carbon, Inc.

1. Tokai Carbon Co., Ltd.

Headquarters: Tokyo, Japan

Tokai Carbon Co., Ltd. is a leading manufacturer of advanced carbon materials, including graphite, carbon fibers, and glassy carbon coatings. The company specializes in high-performance coated graphite products for semiconductor, energy storage, and industrial applications. Tokai Carbon emphasizes technological innovation, sustainability, and quality, offering durable solutions for harsh chemical and high-temperature environments. Its global presence and R&D capabilities enable tailored material solutions, ensuring reliable performance in batteries, electronics, and industrial equipment. With a focus on precision and advanced carbon engineering, Tokai Carbon continues to support the growing demand for energy-efficient and durable coated graphite materials.

2. Mersen Group

Headquarters: La Défense, France

Mersen Group is a global expert in electrical power and advanced materials, providing high-performance graphite, carbon, and glassy carbon-coated solutions. The company serves energy storage, semiconductor, electronics, and chemical processing industries. Mersen focuses on innovation, quality, and sustainability, offering products that enhance conductivity, thermal stability, and chemical resistance. Its engineering expertise enables customized coated graphite solutions for demanding industrial and high-temperature applications. Through global operations and strategic partnerships, Mersen ensures reliable supply, technical support, and innovation-driven products, positioning itself as a key player in the advancement of energy storage, electronics, and industrial carbon materials.

3. SGL Carbon SE

Headquarters: Wiesbaden, Germany

SGL Carbon SE is a leading provider of carbon-based solutions, including graphite, carbon fibers, and glassy carbon coatings. The company caters to industries such as energy, chemical, automotive, and electronics, providing high-performance, durable, and corrosion-resistant coated graphite. SGL Carbon emphasizes technological innovation, R&D, and sustainability in developing advanced carbon materials for harsh and high-temperature environments. Its global production network and engineering capabilities allow for tailored solutions that improve performance, reliability, and efficiency. By combining material science expertise with process innovation, SGL Carbon supports the growing demand for advanced coated graphite in energy storage, semiconductors, and industrial applications.

4. Schunk Carbon Technology

Headquarters: Heuchelheim, Germany

Schunk Carbon Technology is a global leader in carbon and graphite solutions, specializing in glassy carbon-coated graphite products for industrial, electronics, and energy applications. The company offers materials with excellent thermal conductivity, chemical resistance, and mechanical strength. Schunk focuses on innovation, precision manufacturing, and sustainable practices to deliver high-quality products for demanding environments, including battery electrodes, semiconductors, and high-temperature industrial processes. Its global presence ensures reliable supply and technical expertise, enabling customized solutions that enhance performance and operational efficiency. Schunk Carbon Technology continues to lead in developing durable, high-performance carbon materials for advanced industrial and energy applications.

5. Nippon Carbon Co., Ltd.

Headquarters: Tokyo, Japan

Nippon Carbon Co., Ltd. is a prominent Japanese company specializing in carbon, graphite, and glassy carbon-coated materials. It serves semiconductor, electronics, battery, and industrial sectors with high-performance, chemically resistant, and thermally stable coated graphite solutions. The company invests in research, advanced production techniques, and sustainable practices to meet the growing demand for durable, energy-efficient, and precision-engineered materials. Nippon Carbon’s global operations and technical expertise enable tailored solutions that enhance industrial, electronic, and energy applications. The company’s focus on innovation and quality ensures long-lasting, high-performance materials that support technological advancement and the evolving needs of modern industries.

Are you ready to discover more about the Glassy Carbon Coating Graphite market?

The report provides an in-depth analysis of the leading companies operating in the global Glassy Carbon Coating Graphite market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Tokai Carbon Co., Ltd.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- Mersen Group

- SGL Carbon SE

- Schunk Carbon Technology

- Nippon Carbon Co., Ltd.

- GrafTech International Ltd.

- Morgan Advanced Materials

- Ibiden Co., Ltd.

- Toyotanso Co., Ltd.

- HEG Limited

Conclusion

The Glassy Carbon Coating Graphite (GCCG) Market Size is poised for significant growth, driven by its exceptional chemical resistance, thermal stability, and electrical conductivity. Rising demand from energy storage, semiconductor, electronics, and industrial sectors is fueling adoption, while technological advancements in coating processes enhance performance, uniformity, and durability. Sustainability and environmental compliance are becoming central, with longer-lasting coated materials reducing waste and supporting circular economy practices. Key players are leveraging innovation, R&D, and global operations to meet evolving industry needs. As applications expand across batteries, fuel cells, high-temperature processes, and advanced electronics, GCCG remains a critical material for modern, high-performance, and sustainable industrial solutions.

Browse Related Reports

Global Interdental Cleaning Products Market Size To Exceed USD 2.15 Billion By 2033: Industry Report

Global Vehicle Subscription Market Size To Exceed USD 78.43 Billion By 2033: Industry Analysis Report

Global Nickel Pig Iron Market Size To Exceed USD 27.28 Billion by 2033: Industry Report

Global Dual and Multi Energy Computed Tomography Market Size To Exceed USD 1776.3 Million by 2033: Industry Analysis Report

Global Marine Alternators Motor Market Size To Exceed USD 1270 Million by 2033: Market Growth Report

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?