Top 25 Global Companies in PTFE-Based Dry Film Lubricants Market (2025–2035): Spherical Insights Analysis

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

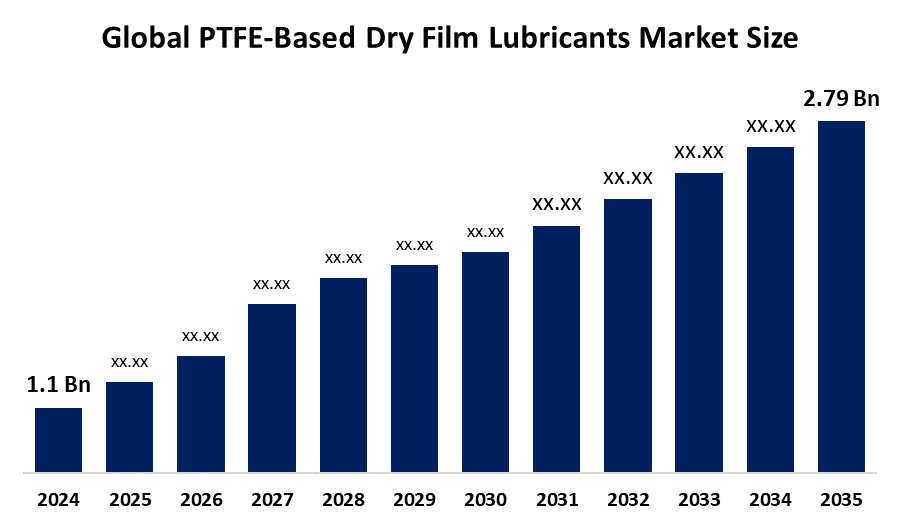

According to a research report published by Spherical Insights & Consulting, The Global PTFE-Based Dry Film Lubricants Market Size is projected to Grow from USD 1.1 Billion in 2024 to USD 2.79 Billion by 2035, at a CAGR of 8.83% during the forecast period 2025–2035. The market for PTFE-based dry film lubricants is in greater demand due to rising demand for high-performance lubricants, growth in the automotive industry, and technological advancements.

Introduction

The PTFE-Based Dry Film Lubricants Market Size is a specialized sector of the lubrication industry that uses polytetrafluoroethylene (PTFE), a high-performance fluoropolymer, as a major component in the formulation of advanced dry film lubricants. PTFE is recognized for its low friction coefficient, superior chemical resistance, and high temperature stability, making it an excellent option for demanding industrial applications where traditional lubricants frequently fail. Unlike typical liquid lubricants, PTFE-based dry films produce a thin, resilient coating that lowers friction and wear, offering long-term protection for machinery and equipment. This industry has developed rapidly due to its increasing application in the automotive, aerospace, manufacturing, and renewable energy industries. Automotive engines, drivetrains, and EV components benefit from improved performance and longevity, while aerospace and industrial machines rely on PTFE lubricants to operate reliably at severe pressures and temperatures. The rising emphasis on sustainability and environmentally friendly formulations fuels innovation as sectors meet with regulatory criteria such as the EU's REACH legislation. Furthermore, the increasing use of automation, robots, and renewable energy technologies brings new opportunities, emphasizing the critical role of PTFE-based dry film lubricants in enabling efficiency, cost savings, and environmental responsibility.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the PTFE-Based Dry Film Lubricants Market.

PTFE-Based Dry Film Lubricants Market Size & Statistics

- The Market Size for PTFE-Based Dry Film Lubricants Was Estimated to be worth USD 1.1 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 8.83% between 2025 and 2035.

- The Global PTFE-Based Dry Film Lubricants Market Size is anticipated to reach USD 2.79 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the PTFE-Based Dry Film Lubricants Market

- Asia Pacific is expected to grow the fastest during the forecast period in the PTFE-Based Dry Film Lubricants Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the PTFE-Based Dry Film Lubricants market. Asia Pacific is expected to grow the fastest in the PTFE-based dry film lubricants market due to rapid industrialization, expanding automotive and aerospace sectors, and rising investments in manufacturing and renewable energy. Growing demand for cost-efficient, high-performance lubrication solutions further accelerates adoption.

North America is expected to generate the highest demand during the forecast period in the PTFE-Based Dry Film Lubricants market. North America is expected to generate the highest demand in the PTFE-based dry film lubricants market, driven by advanced automotive, aerospace, and defense industries, stringent environmental regulations, and strong adoption of high-performance, sustainable lubrication solutions to reduce machinery downtime and enhance operational efficiency.

Top 10 Trends in the PTFE-Based Dry Film Lubricants Market

- Eco-Friendly Formulations

- Nanotechnology Integration

- Specialized Lubricants

- Smart Lubricants

- Customization and Personalization

- Digital Transformation

- Investment in R&D

- Consolidation through M&A

- Focus on High-Performance Characteristics

- Growth in Emerging Economies

1. Eco-Friendly Formulations

Increasing regulatory pressure and an industry focus on sustainability are propelling the development of PTFE-based lubricants with a lower environmental footprint. Manufacturers are developing solvent-free or low-VOC formulations to fulfill global safety standards and reduce environmental impact.

2. Nanotechnology Integration

Incorporating nanoparticles into PTFE lubricants improves their heat stability, wear resistance, and friction-reducing qualities. Nanotechnology allows greater performance under harsh conditions, opening the way for revolutionary applications in aerospace, automotive, and high-precision manufacturing.

3. Specialized Lubricants

Industries require specialized PTFE dry film lubricants for specific applications, such as high-load automobile drivetrains, corrosion-prone aquatic conditions, and temperature-sensitive aerospace components. This specialization boosts dependability and increases end-user acceptance.

4. Smart Lubricants

Emerging smart formulations incorporate sensing or self-healing characteristics, allowing PTFE-based lubricants to adjust to changing operating circumstances. These improvements enhance machine monitoring, predictive maintenance, and long-term performance.

5. Customization and Personalization

End-users are increasingly seeking customized options based on their specific equipment requirements. Manufacturers are focused on flexible formulas and application-specific solutions to provide lubricants that combine performance, cost, and environmental compliance.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the PTFE-based dry film lubricants market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the PTFE-Based Dry Film Lubricants Market

- Chemours Company

- DuPont de Nemours, Inc.

- Henkel AG & Co. KGaA

- 3M Company

- Dow Corning Corporation

- Whitford Corporation

- Asbury Carbons, Inc.

- Klüber Lubrication München SE & Co. KG

- Miller-Stephenson Chemical Company, Inc.

- E/M Corporation

- Molytech Corporation

- CRC Industries, Inc.

- Fuchs Lubricants Co.

- B'laster Corporation

- IKO International, Inc.

- Electrolube Limited

- Setral Chemie GmbH

- OKS Spezialschmierstoffe GmbH

- ROCOL (a division of ITW Ltd.)

- Zeller Gmelin GmbH & Co. KG

- Shamrock Technologies, Inc.

- Michem (Michelman, Inc.)

- Acheson Colloids Company

- Sunnex Group

- Metal Coatings Corp.

- Others

1. Chemours Company

Headquarters: Wilmington, Delaware, USA

Chemours, based in Wilmington, Delaware, USA, operates in over 120 countries and is considered a global leader in fluoroproducts. The company's Teflon™ trademark offers PTFE resins and lubricants with exceptional temperature resistance, chemical stability, and low friction performance. Chemours is a key player in the PTFE-based dry film lubricant industry, delivering novel formulations to address the demands of demanding industries like as automotive, aerospace, electronics, and industrial equipment. Its products improve equipment endurance, minimize maintenance requirements, and increase operational efficiency, bolstering its global reputation as a reliable provider.

2. DuPont de Nemours, Inc.

Headquarters: Wilmington, Delaware, USA

DuPont, headquartered in Wilmington, Delaware, USA, has operations in over 70 countries worldwide. The firm has a long history in materials research and continues to develop PTFE-based technology. DuPont uses its expertise in the dry film lubricants industry to provide high-performance PTFE coatings and additives that improve durability, decrease friction, and provide dependable performance in severe situations. Its solutions are widely used in the automotive, aerospace, electronics, and energy industries. DuPont's commitment to innovation, sustainability, and advanced material science allows it to respond to changing market demands, positioning the business as a leading worldwide contributor to lubricating technology.

3. HENKEL AG & CO. KGAA

Headquarters: Düsseldorf, Germany

Henkel is headquartered in Düsseldorf, Germany, and operates in more than 120 countries. Henkel is well-known for its adhesives, sealants, and functional coatings, but it also operates in the PTFE-based dry film lubricant business. The firm provides sophisticated surface treatment and lubrication solutions for automotive, aerospace, and industrial applications where dependability and efficiency are key. Henkel's formulas include PTFE, which reduces wear, resists harsh conditions, and improves overall equipment performance. Henkel's strong R&D skills and global reach make it a trusted partner for sectors seeking innovative, sustainable, and high-quality lubricating solutions that meet current performance criteria.

4. 3M Company

Headquarters: St. Paul, Minnesota, USA

3M is headquartered in St. Paul, Minnesota, and operates in over 90 countries, serving customers in practically every sector. In the PTFE-based dry film lubricants industry, 3M uses its materials science knowledge to create new solutions that minimize friction, increase wear resistance, and extend equipment life. Its PTFE-based compositions find widespread application in automobiles, industrial machinery, medical devices, and electronics. 3M focuses on producing advanced coatings and specialized lubricants that achieve sustainability objectives while retaining performance excellence. With a strong innovation pipeline, 3M continues to expand its position as a significant global supplier of PTFE-based lubrication technology.

5. Dow Corning Corporation

Headquarters: Midland, Michigan, USA

Dow, headquartered in Midland, Michigan, USA, has operations in over 160 countries and is a significant global provider of silicone and fluoropolymer-based products. Dow leverages Dow Corning's expertise in the PTFE-based dry film lubricant industry to produce enhanced PTFE formulations with long-lasting lubrication, chemical resistance, and thermal stability. These solutions are commonly employed in high-performance applications such as automobile drivetrains, aircraft systems, and industrial production equipment. Dow's dedication to innovation and sustainability solutions allows it to fulfill the expanding global need for efficient lubrication technologies, delivering maximum performance and dependability in vital and demanding operating conditions.

Are you ready to discover more about the PTFE-based dry film lubricants market?

The report provides an in-depth analysis of the leading companies operating in the global PTFE-based dry film lubricants market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Chemours Company

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- DuPont de Nemours, Inc.

- HENKEL AG & CO. KGAA

- 3M Company

- Dow Corning Corporation

- Whitford Corporation

- Asbury Carbons, Inc.

- Klüber Lubrication München SE & Co. KG

- Miller-Stephenson Chemical Company, Inc.

- Others

Conclusion

The PTFE-Based Dry Film Lubricants Market Size is projected to witness steady expansion, supported by rising demand across automotive, aerospace, industrial, and electronics sectors, where superior friction reduction and durability are essential. PTFE’s unique characteristics—chemical resistance, thermal stability, and long-lasting performance—make it a preferred choice for critical applications operating under extreme conditions. The market is further shaped by the growing emphasis on sustainable and eco-friendly formulations, along with advancements in nanotechnology and tailored lubrication solutions. Additionally, emerging applications in renewable energy systems and electric vehicles are expected to accelerate adoption, positioning PTFE-based dry film lubricants as a cornerstone of industrial innovation and efficiency.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?